Automatic component inserter for PCB

An automatic plug-in machine and PCB board technology, which is applied in the direction of electrical components, electrical components, electrical components to assemble printed circuits, etc., can solve the problems of reduced production efficiency, affecting normal production, and product quality cannot be guaranteed, so as to ensure product quality , the effect of improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

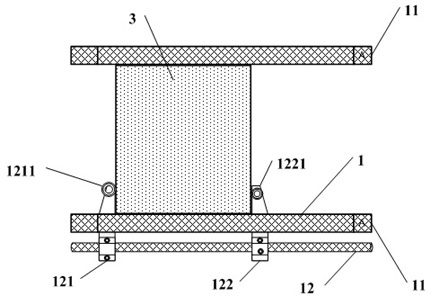

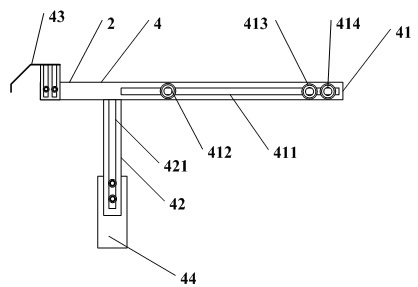

[0027] See figure 1 with figure 2 , The PCB board automatic plug-in machine of the present invention includes a coordinate positioning mechanism 1 for positioning the PCB board for plug-in operation and a board feeding mechanism 2 for feeding the board to the coordinate positioning mechanism. Wherein, the coordinate positioning mechanism 1 includes coordinate system rails 11 located at both ends of the PCB 3 and positioning pin shafts 12 for positioning the PCB 3 . A main positioning pin 121 and a secondary positioning pin 122 are arranged on the positioning pin rotating shaft. The board feeding mechanism 2 includes a board feeding device 4, and the board feeding device 4 includes a push-pull rod 41 and a connecting rod 42 connected with the push-pull rod. It is connected to the left side of the push-pull rod near the front push plate stopper, and the other end is connected with a mobile device handle 44.

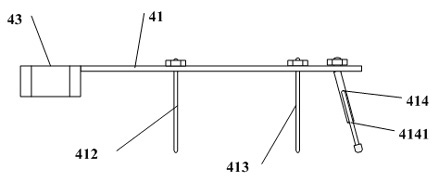

[0028] Please also refer to image 3 with Figure 4 . The push...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com