Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

76results about How to "Does not affect heat transfer" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Nickel-base protection coating of boiler heat exchange pipe, and preparation method thereof

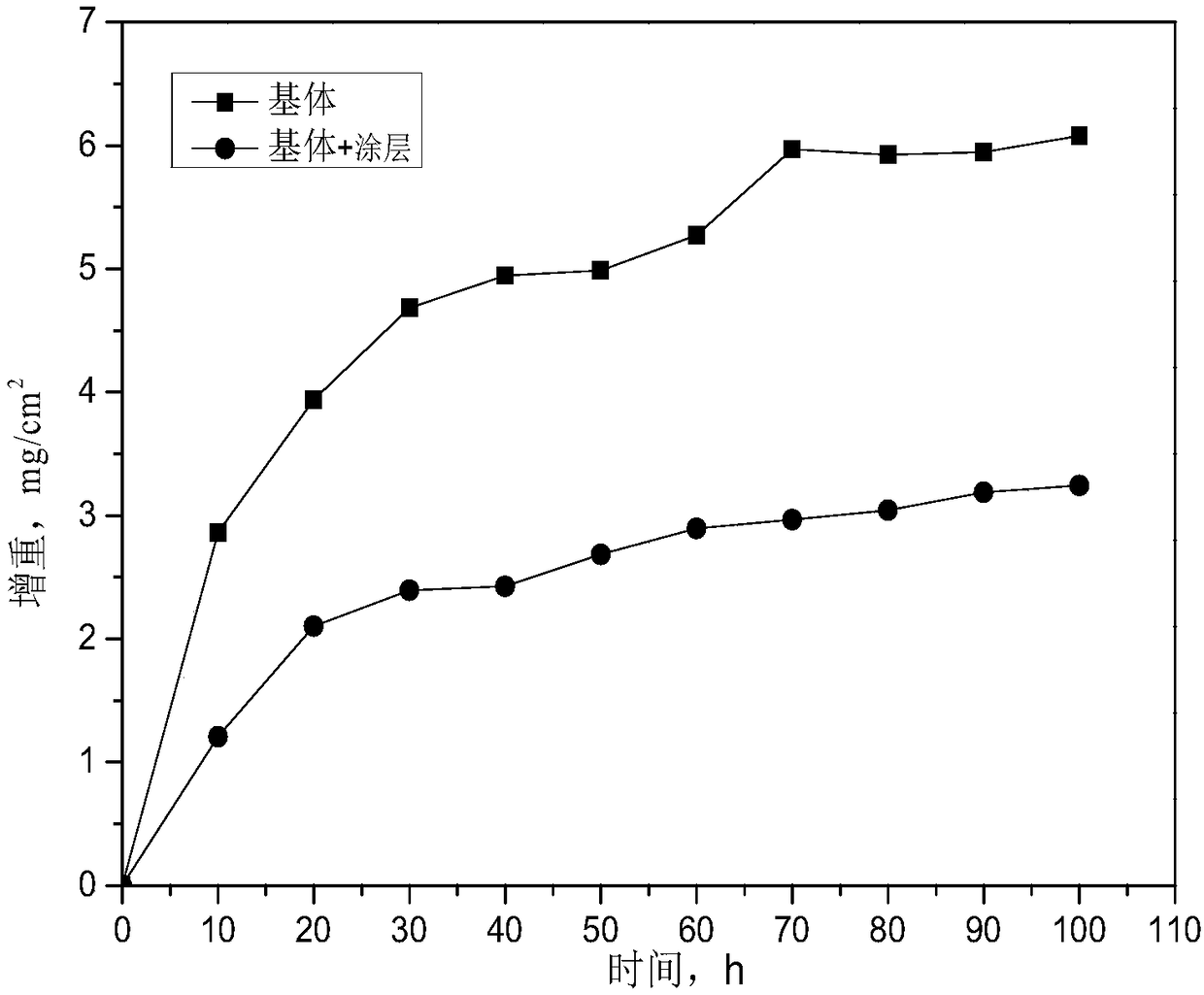

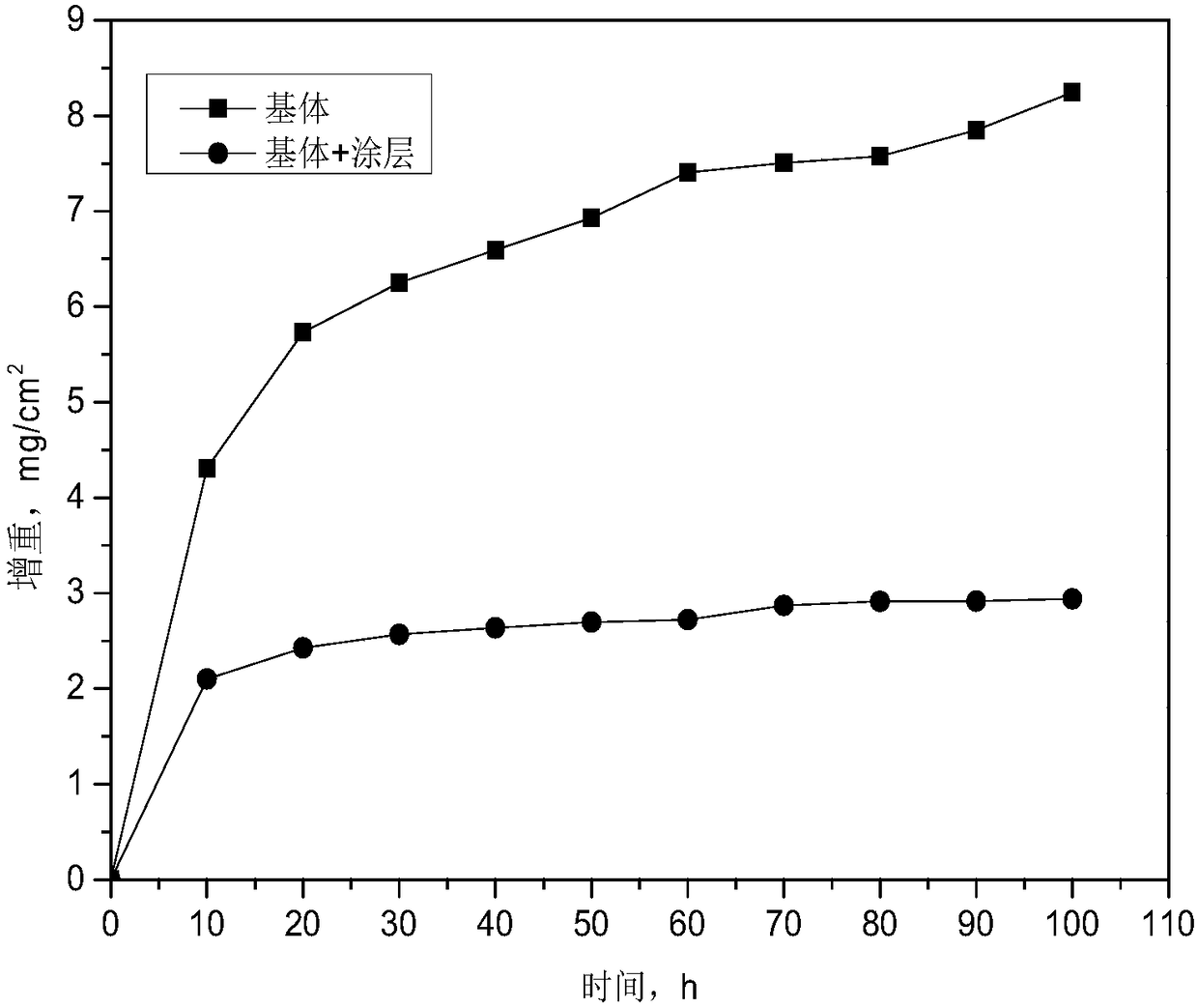

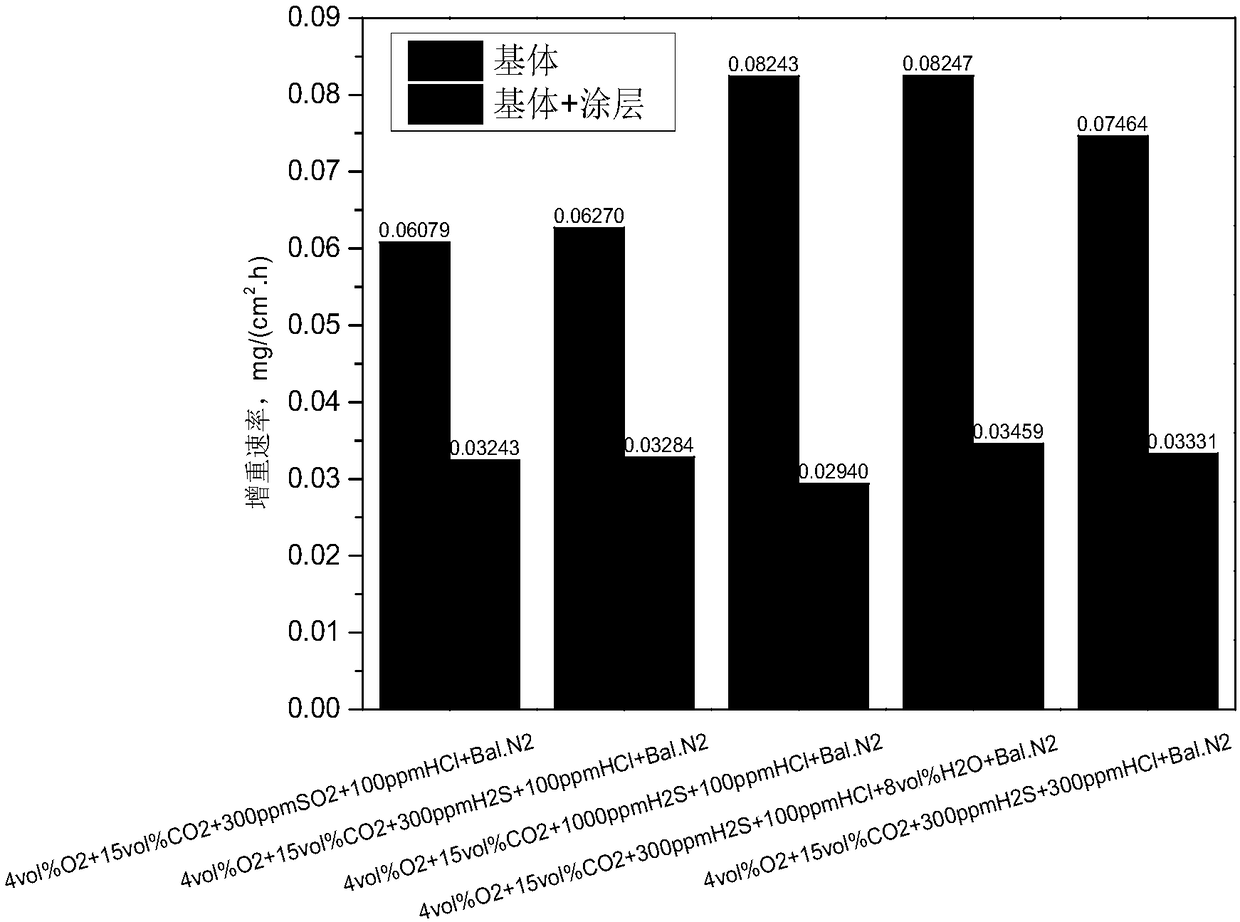

InactiveCN108467974AHigh bonding strengthExtended service lifeMolten spray coatingUltimate tensile strengthBonding strength

The invention relates to a nickel-base protection coating of a boiler heat exchange pipe, and a preparation method thereof which belong to the technical field of corrosion prevention of heat exchangepipes. The nickel-base protection coating of the boiler heat exchange pipe is prepared from the following components in percentage by mass: 50 percent to 58 percent of Ni, 19 percent to 24 percent ofCr, 2 percent to 6 percent of Mo, 3 percent to 6 percent of Fe, 1 percent to 4 percent of Nb, 0.3 percent to 0.7 percent of Mn, 0.8 percent to 1.2 percent of Ti, 0.9 percent to 1.2 percent of Co, 0.7percent to 1.1 percent of B, 0.8 percent to 1.2 percent of Si, 2 percent to 5 percent of Al, 0.09 percent to 0.11 percent of C, and 3 percent to 7 percent of W. The coating provided by the invention has a small influence on heat exchange of a base body, high bonding strength, and good corrosion resistance, so that the boiler heat exchange pipe has excellent corrosion resistance, the service life of the boiler heat exchange pipe can be effectively prolonged, and the use cost of a boiler is reduced; and meanwhile, the coating provided by the invention is simple in preparation process, high in practicability and high in high performance cost ratio.

Owner:SHANDONG UNIV

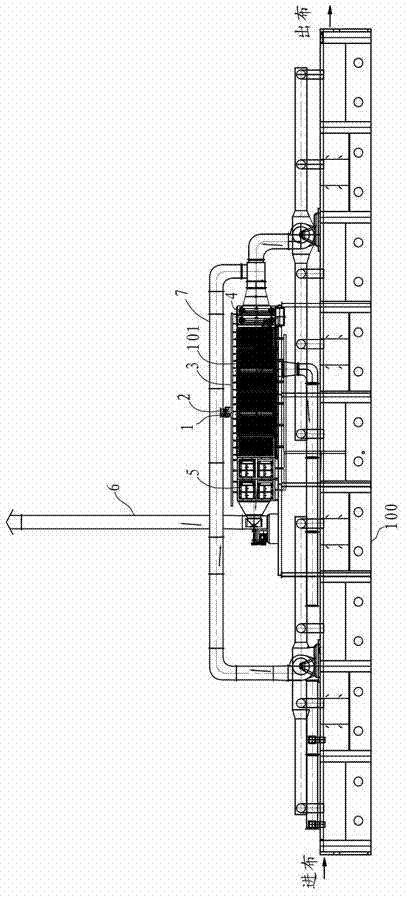

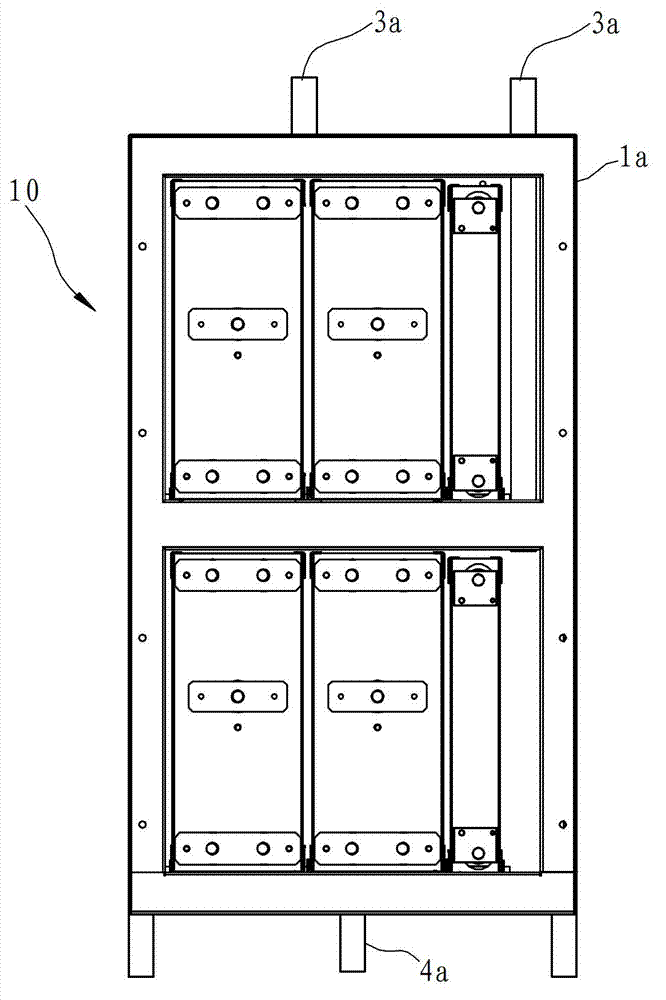

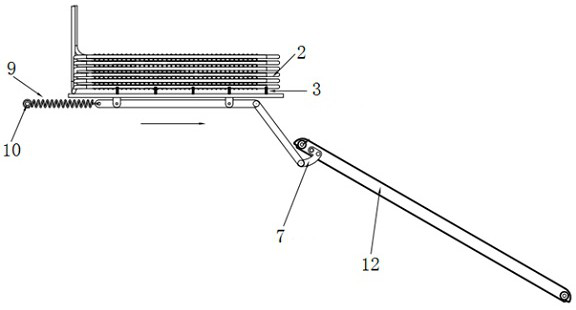

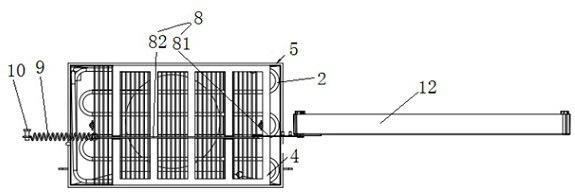

Multi-station automatic thermal transfer printer

InactiveCN102935760AEasy to handleDoes not affect heat transferTransfer printingPrinting press partsGratingEngineering

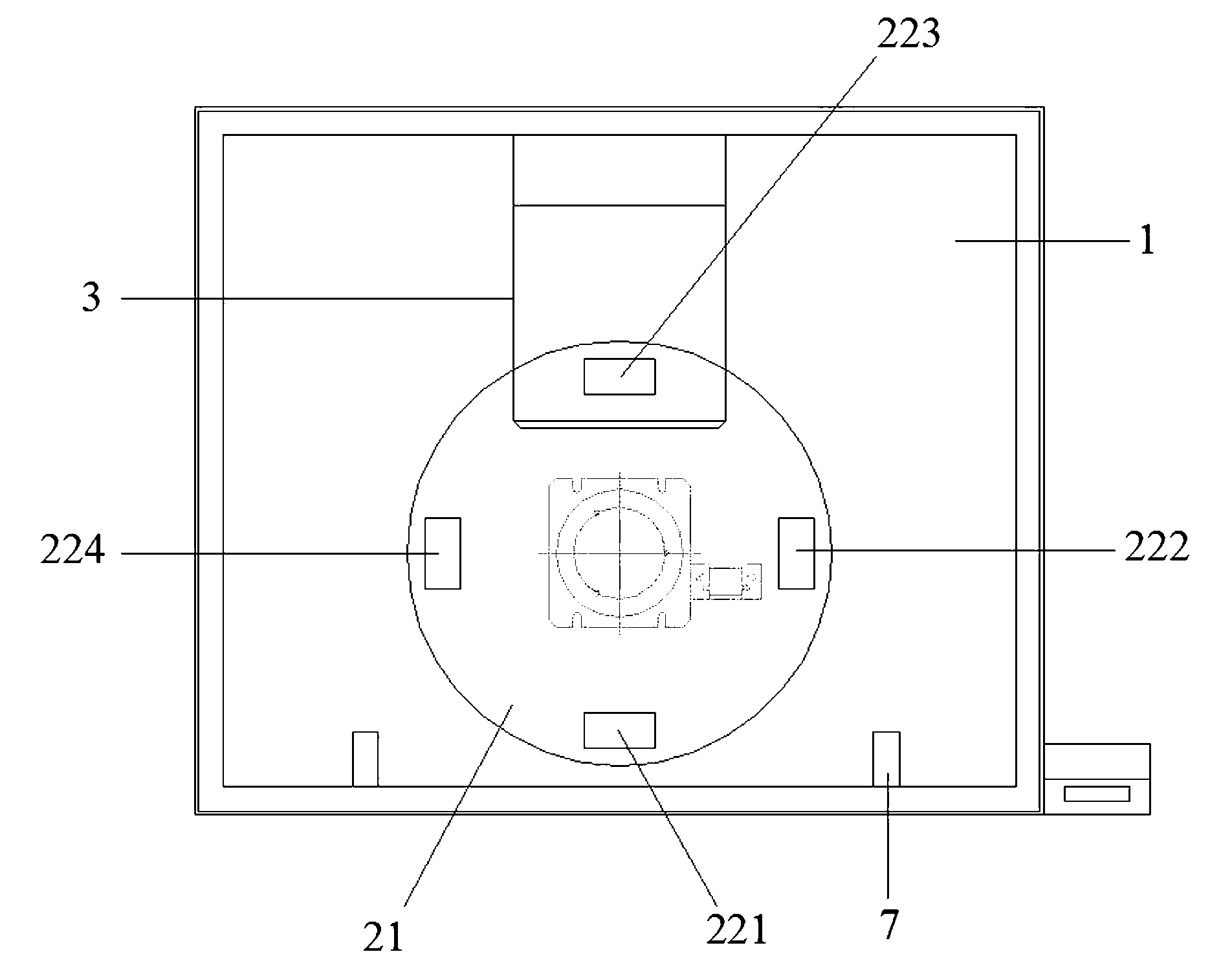

The invention discloses a multi-station automatic thermal transfer printer, which is characterized by comprising a machine table, a material conveying mechanism, a heat transfer printing mechanism, a receiving and emptying mechanism, a control mechanism, a safety grating, and an alarm in signal connection with the safety grating, wherein the material conveying mechanism comprises an index plate and a carrying station arranged on the front of the index plate; and the heat transfer printing mechanism comprises a heating plate, a cylinder which drives the heating plate to move up and down, and a temperature controller which controls the temperature of the heating plate. The multi-station automatic thermal transfer printer has the beneficial effects that the materials are conveyed through the index plate, the thermal transfer printing operation is not influenced by feeding and discharging, the thermal transfer printing step is compact, and the working efficiency is improved; according to the safety grating and alarm, an alarm is given in the first time when a fault occurs, so that the fault is conveniently discovered and treated by a worker, and the time is saved; and moreover, operation of other mechanisms is controlled by the control mechanism, so that the degree of automation is greatly improved, and ordered and stable operation between processes is guaranteed.

Owner:SUZHOU ITIS ELECTRON MFG TECH

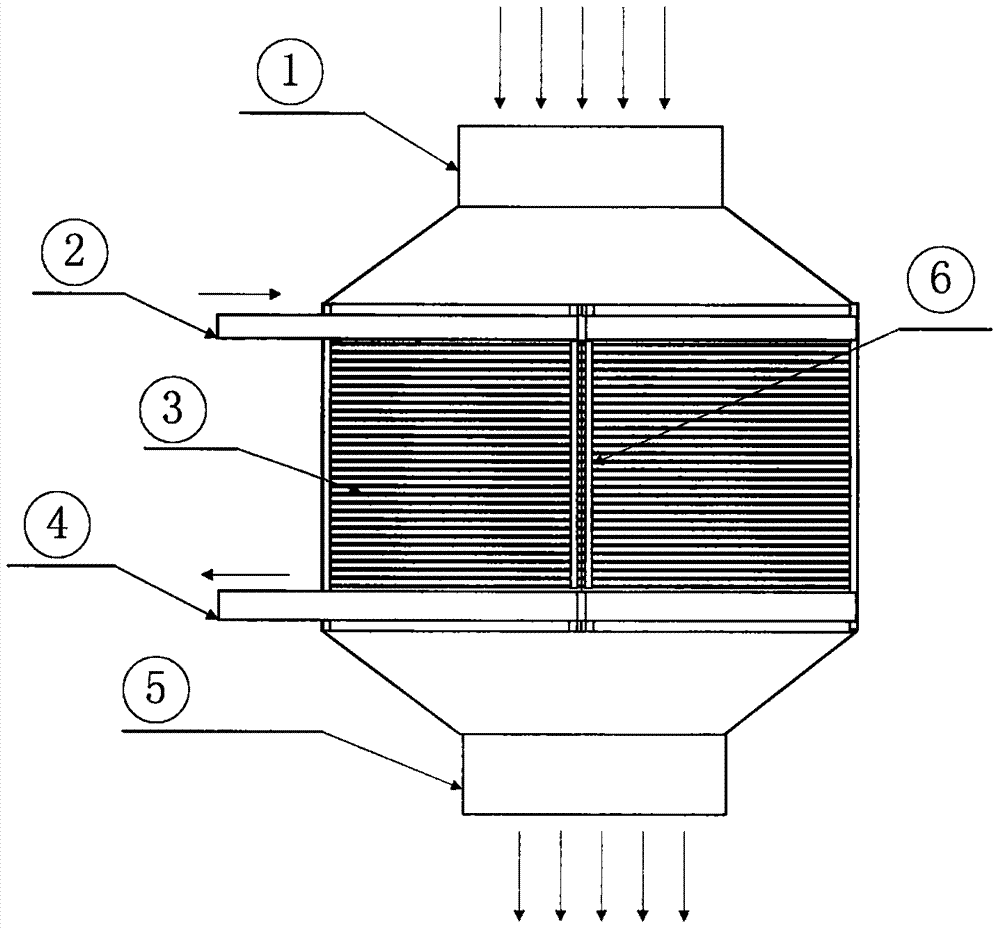

Surface air cooler with wet films of composite structures

ActiveCN104197588ANot easy to reachReduce in quantityEvaporators/condensersAir conditioning systemsTap waterEngineering

A wet-film surface air cooler of a composite structure comprises a plurality of fins and a plurality of heat-exchanging pipes, wherein the fins are arranged in parallel at intervals and the heat-exchanging pipes penetrate through the fins. A wet-film layer is arranged on the surfaces of the fins. At least one water absorption belt is extended outwards from the wet-film layer and is used for leading water into the wet-film layer. The wet-film surface air cooler of the composite structure is simple in structure, low in cost, free of power and high in reliability. On one hand, the heat-dissipation efficiency and the COP of condensate water or tap water applied to the surface air cooler of an air conditioner are improved, the air-discharging pressure is reduced when the air conditioner is used for cooling, the COP of a common air cooling air conditioner used for cooling is increased from 3.2 to 4.1, energy is saved by over 30%, and on the other hand, the surface air cooler of the air conditioner is prevented from being frosted in winter.

Owner:童军

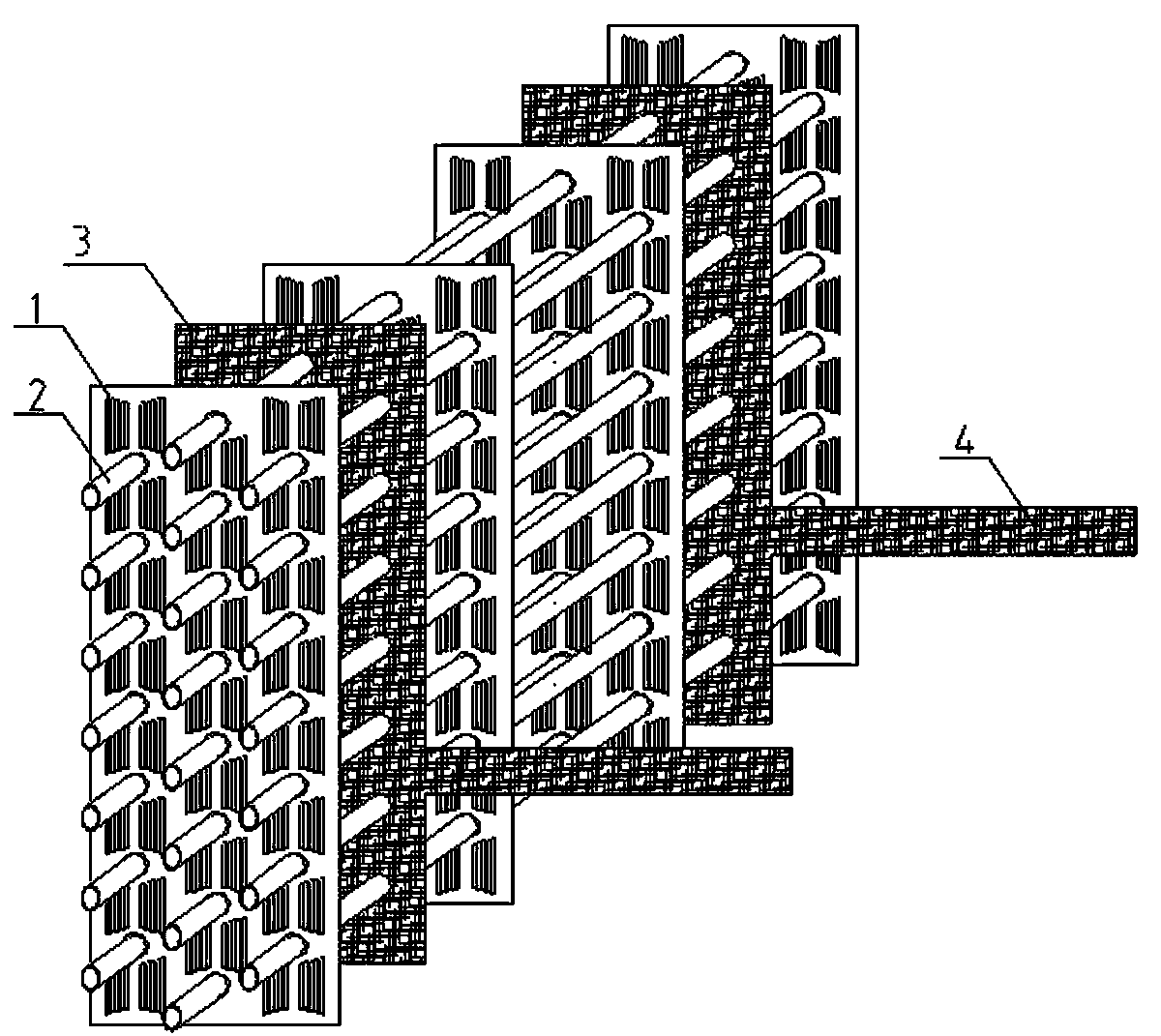

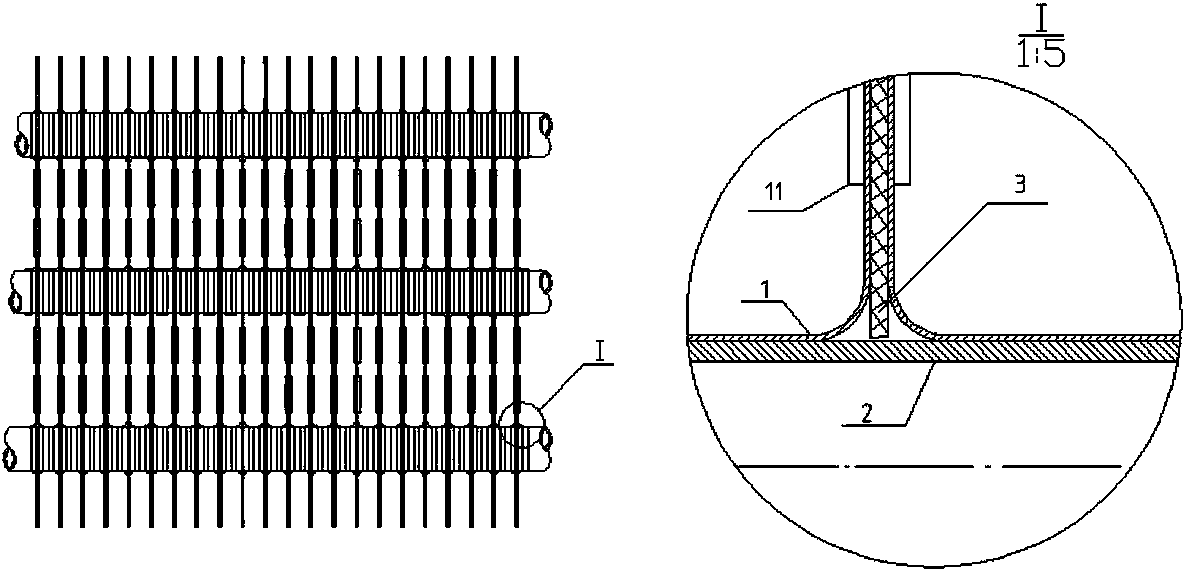

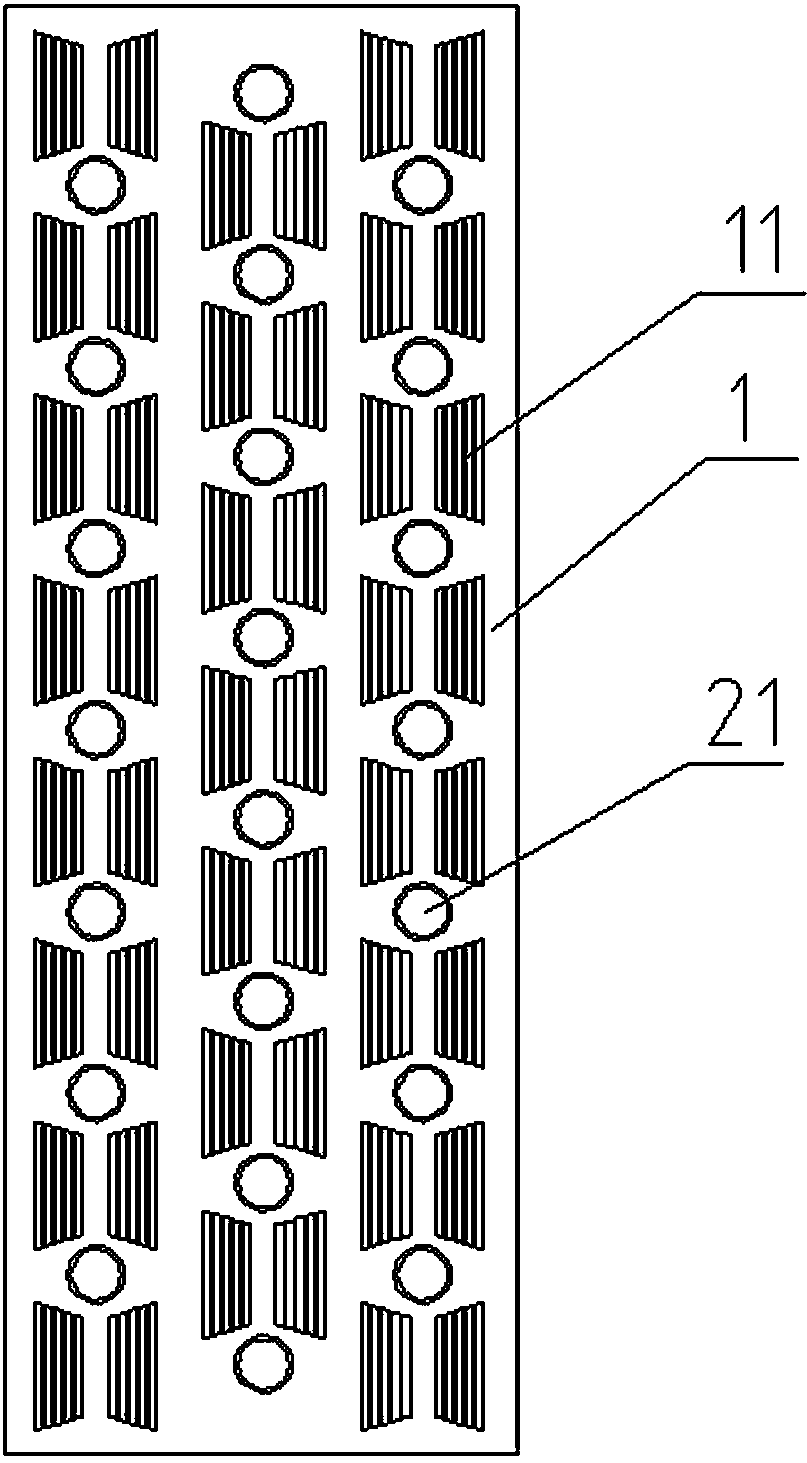

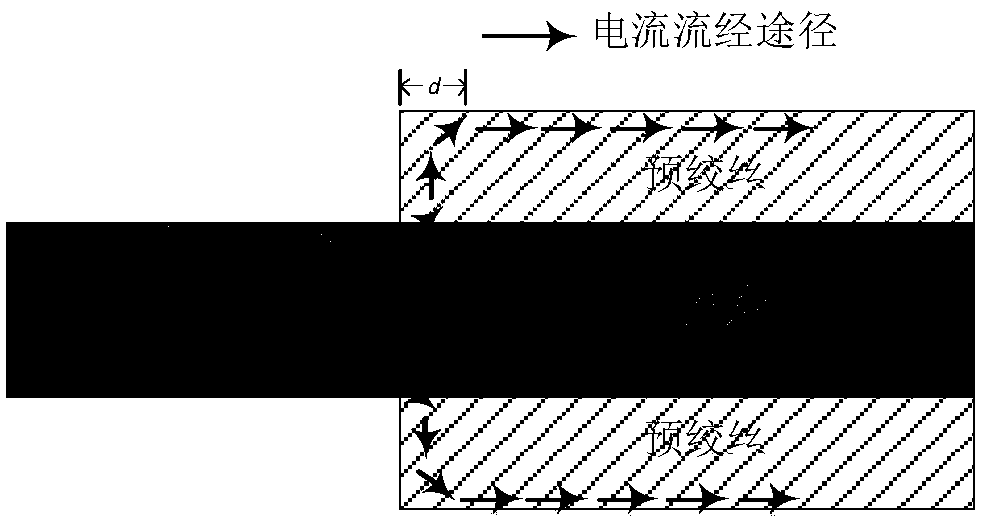

Finite element thermal analysis equivalent method for contact resistance of ground wire and pre-twisted wire contact port

InactiveCN108416097AAccurate analysis of temperature riseAvoid geometric modelingDesign optimisation/simulationSpecial data processing applicationsElectrical resistance and conductanceEngineering

The invention discloses a finite element thermal analysis equivalent method for contact resistance of a ground wire and pre-twisted wire contact port. The method comprises the steps of firstly obtaining a resistance value of the contact resistance of the overhead ground wire and pre-twisted wire contact port through an experiment; performing calculation to obtain a contact area corresponding to the contact resistance; according to the contact resistance and the contact area, calculating out thermal flow density; building three-dimensional models of a ground wire and a pre-twisted wire, and loading the calculated thermal flow density at the contact area of the contact port; and finally, designing a large-current temperature rise experiment, and verifying a finite element simulation result.The method avoids modeling requirements on a complex contact interface in finite element simulation, and has significance of general popularization and use.

Owner:SOUTH CHINA UNIV OF TECH

Online cleaning agent composition for heat conduction oil and cleaning method

InactiveCN107118851AImprove solubilityDoes not affect heat transferOrganic detergent compounding agentsSurface-active detergent compositionsClearing AgentCleansing Agents

The invention relates to the technical field of cleaning agents, particularly provides an online cleaning agent composition for heat conduction oil and a cleaning method, and aims at solving the problem that heat conduction oil cannot be cleaned in an online way. The cleaning agent composition comprises the following raw materials in parts by weight: 20 to 30 parts of base oil, 2 to 12 parts of an ashless dispersant, 18 to 28 parts of a clearing agent, 2 to 12 parts of a surfactant, and 30 to 45 parts of washing agent. According to the online cleaning method, online cleaning is performed on heat conduction oil through the cleaning agent composition, cooling is not required under the condition that a heat conduction oil system is normally operated, the cleaning agent composition is added into the heat conduction oil system, coked oil dirt on pipe walls is cleaned according to a compatibility principle, the online cleaning of the heat conduction oil is realized, the normal operation of the system is not affected, the phenomenon that pipes are blocked by dirt does not occur, the cleaning efficiency is higher than 98 percent, heat conduction can be improved, and energy consumption can be reduced.

Owner:SHANDONG ENKLI CHEM

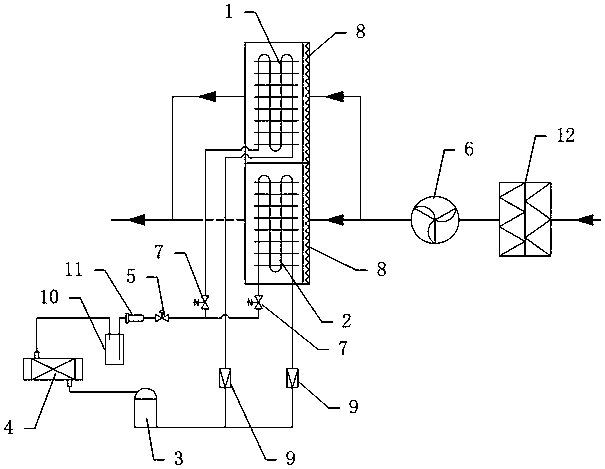

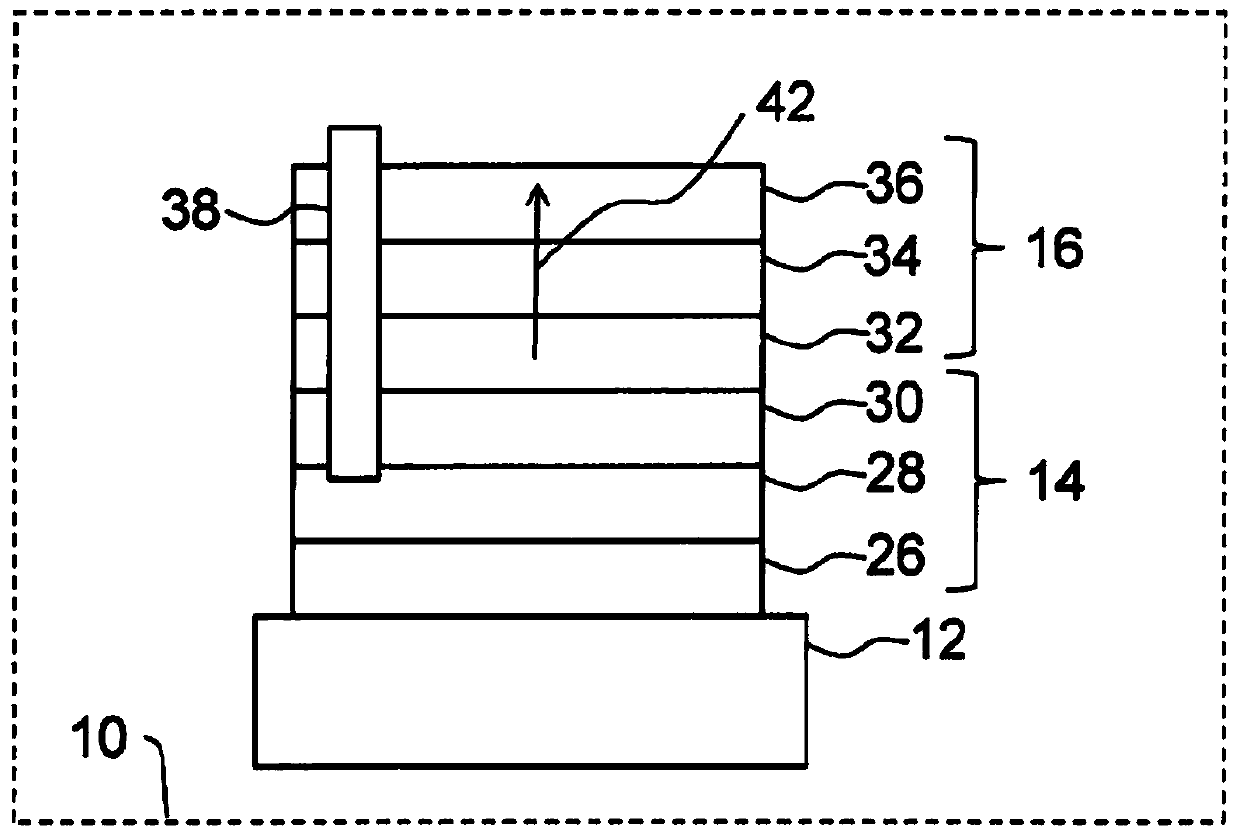

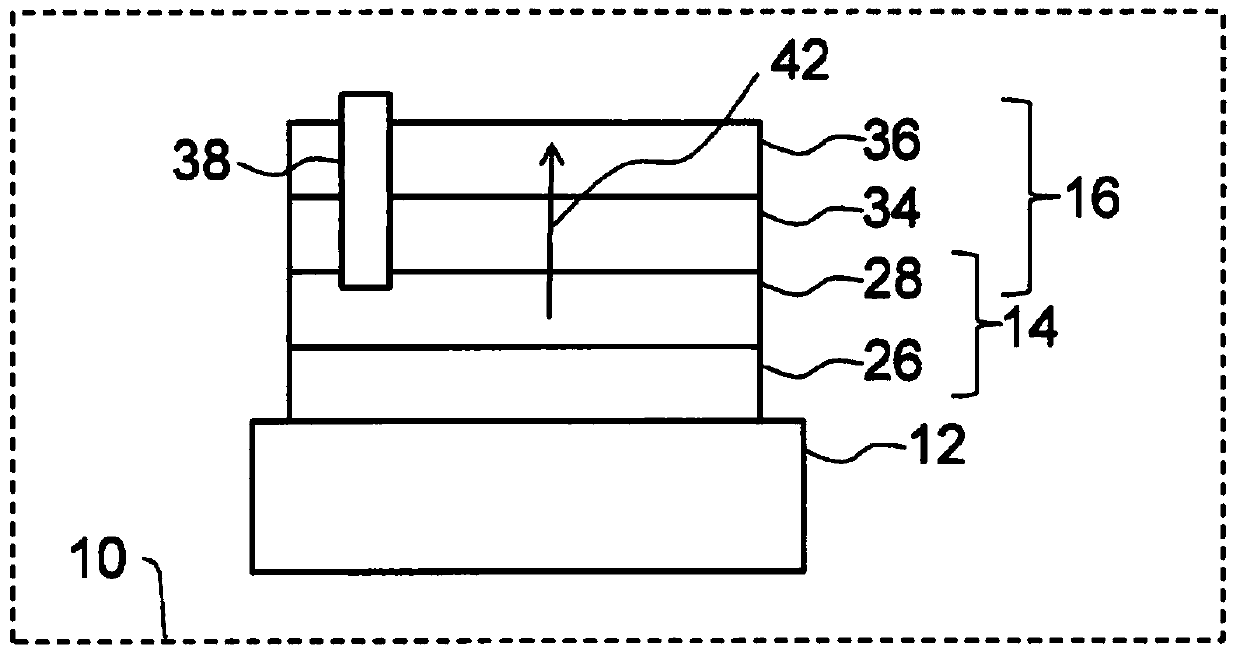

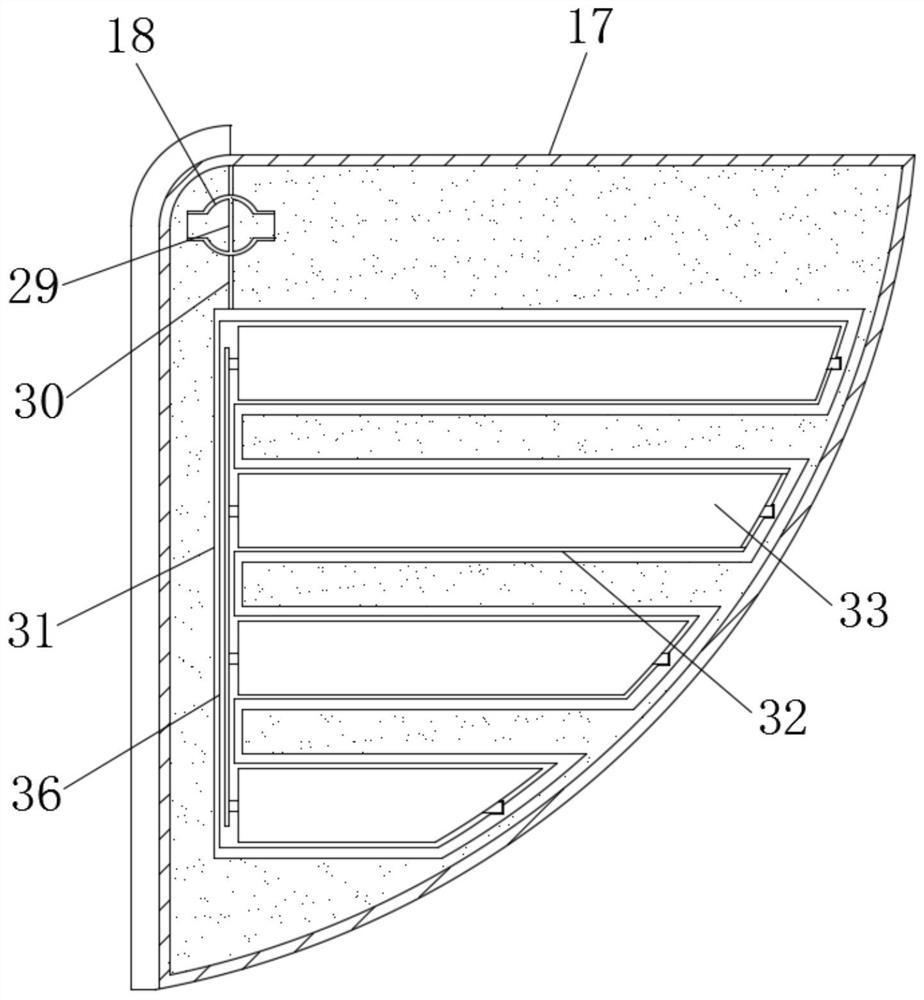

Air-cooled heat pipe radiator for high-capacity SVG

PendingCN107466194AThermal resistance does not affectDoes not affect thermal resistanceModifications for power electronicsHeat pipeHeat spreader

The invention discloses an air-cooled heat pipe radiator for high-capacity SVG. The air-cooled heat pipe radiator for the high-capacity SVG comprises a substrate and a fin group which is arranged on the front surface of the substrate; the back surface of the substrate is connected with a radiator piece; a plurality of embedding grooves which are formed in parallel are formed in the front surface of the substrate; a comb-shaped heat pipe is embedded into each embedding groove; the bottom of each comb-shaped heat pipe is in contact with the radiated piece; the top end of each comb-shaped heat pipe is inserted into the fin group. The radiator has the advantages of being simple in structure, high in reliability, and capable of reducing total thermal resistance remarkably.

Owner:STATE GRID HUNAN ELECTRIC POWER +3

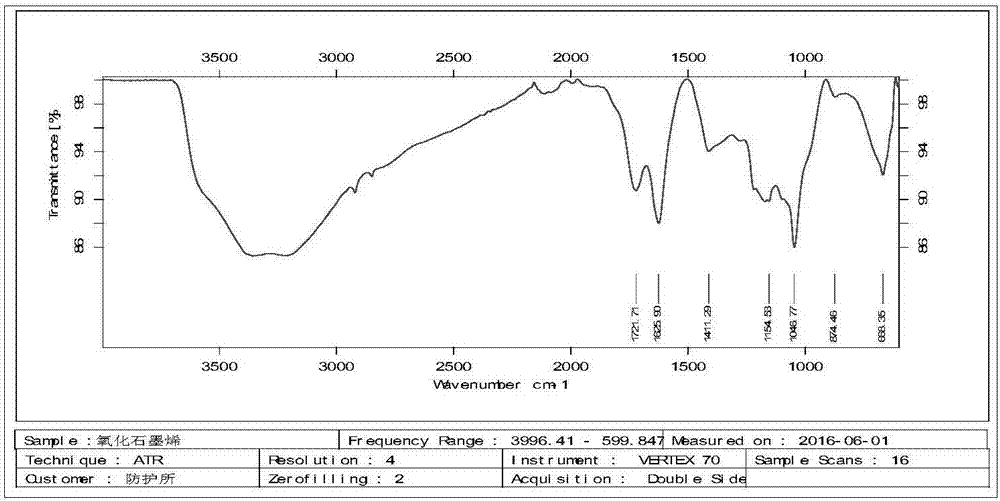

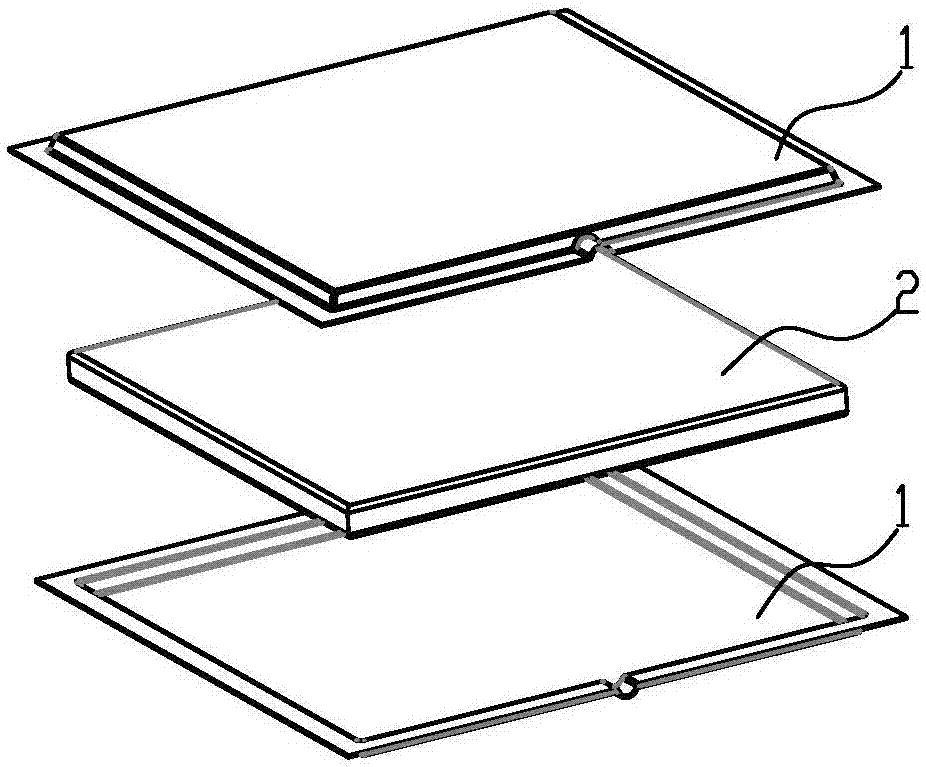

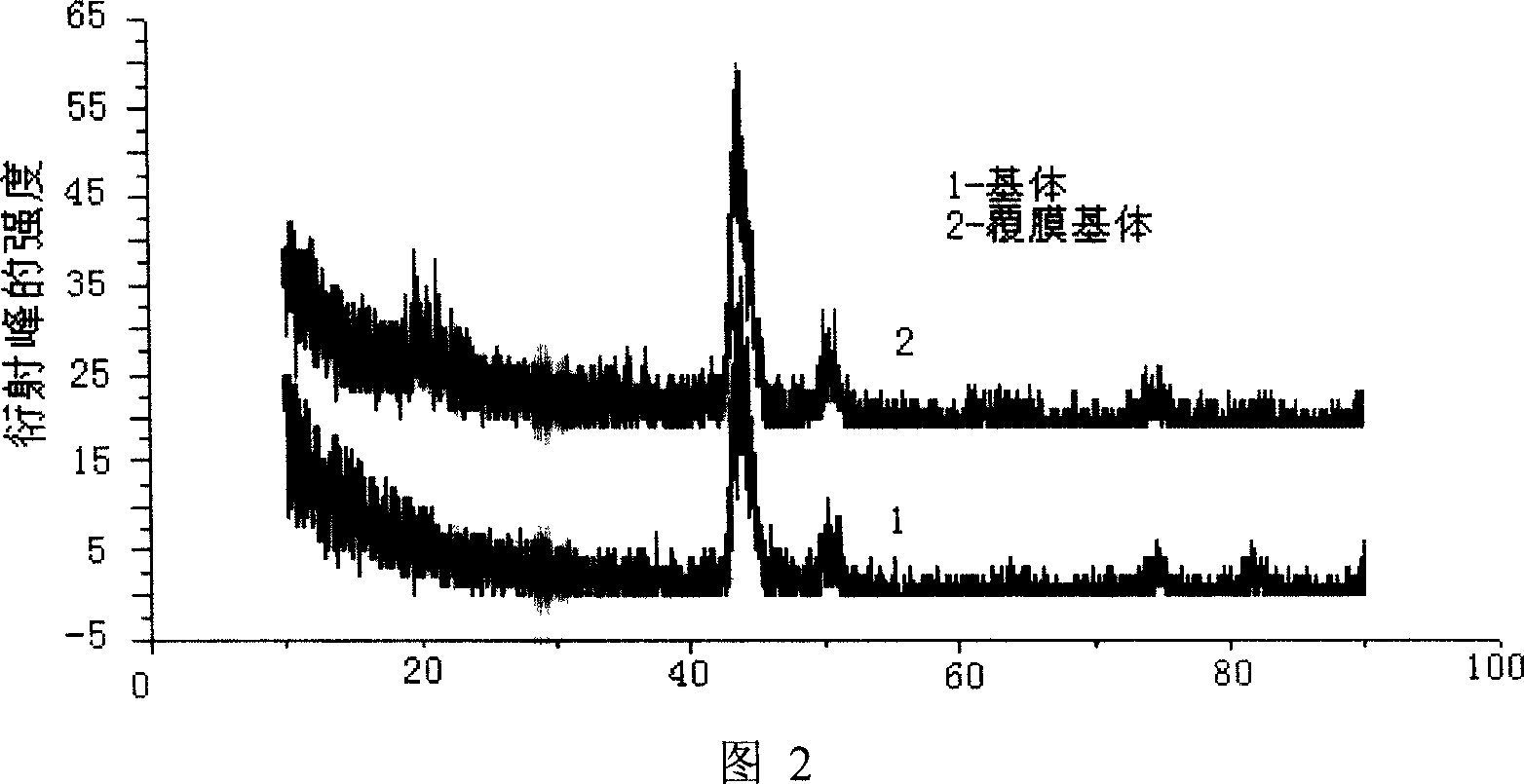

Method for preparing large-area graphene material by adopting suturing method

The invention relates to a method for preparing a large-area graphene material by adopting a suturing method. The preparation method comprises the following steps: adding graphene oxide into a conicalflask filled with one of ethylenediamine, diethylenetriamine, triethylenetetramine and paraphenylenediamine according to a mass ratio of 1 to (100 to 600); then performing dispersion for 30 to 60 minutes by using an ultrasonic dispersing machine, uniformly dispersing the solutions and instantly transferring the solutions into a three-neck flask; heating the flask while stirring, controlling a reaction temperature to be between 100 and 200 DEG C, and performing reaction for 20 to 24 hours; taking reaction solutions after the reaction is finished and uniformly coating a steel plate which is ground and smoothed in advance and is cleaned and dried by using absolute ethyl alcohol with the reaction solutions, and putting the steel plate in a baking oven to be dried for 3 hours at 120 DEG C so as to obtain a graphene film with a sutured continuous structure. According to the method disclosed by the invention, the method for suturing the micron-scale graphene oxide into the graphene film withlarge area, high heat conduction and capability of being firmly adhered on the surface of metal by utilizing a suture agent is innovatively provided.

Owner:SHAANXI RES DESIGN INST OF PETROLEUM CHEM IND

Preparation method of rotary target material comprising adaptive buffering layer

ActiveCN108004514ANot exceed yield strengthAlleviate uneven cooling shrinkageVacuum evaporation coatingSputtering coatingThermal conductivityHot isostatic pressing

The invention discloses a preparation method of a rotary target material comprising an adaptive buffering layer. The internal structure of the buffering layer is porous, and the exterior structure ofthe buffering layer is in a ring shape (is cylindrical). Firstly, an adaptive buffering layer of which the thickness is 1 / 5 to 1 / 7 of the thickness of a target material green body, the yield strengthis high (higher than a hot isostatic pressure), the thermal expansion coefficient is moderate (between the thermal expansion coefficient of the target material green body and the thermal expansion coefficient of a substrate), the thermal conductivity is good and the porosity factor is 30% to 40% is prepared on the surface of the substrate by adopting a thermal spraying method; and subsequently, the target material green body is prepared on the surface of the adaptive buffering layer by adopting a hot isostatic pressure method. The porous buffering layer has a mechanical self-compensation function; when the adaptive buffering layer and the target material green body are in hot isostatic pressure and cooling processes, the thermal mismatch strain, caused in hot pressing and cooling processes, between the target material green body and a substrate interface can be effectively absorbed by changes of the internal average pore diameter in the porous buffering layer, so the effect of protecting the target material from cracking is played.

Owner:FUZHOU UNIVERSITY

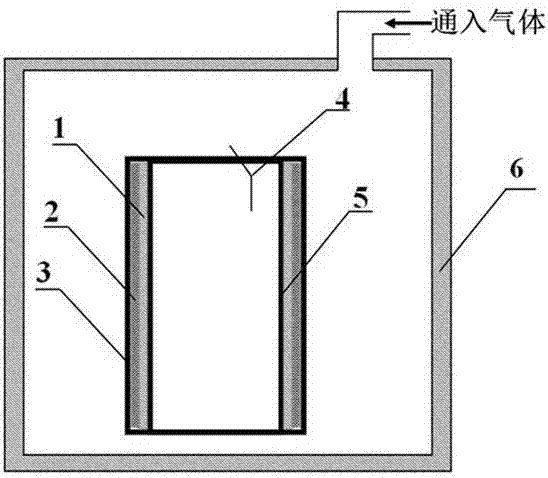

Natural defrosting low-temperature evaporation system and control method thereof

PendingCN109539617ALow failure rateDoes not affect heat transferMechanical apparatusCompression machines with several evaporatorsFailure rateSolenoid valve

The invention provides a natural defrosting low-temperature evaporation system. The natural defrosting low-temperature evaporation system comprises a first evaporator, a second evaporator, a compressor, a condenser, an expansion valve, and a fan, wherein the compressor, the condenser and the expansion valve sequentially communicate with one another, refrigerant outlets of the first evaporator andthe second evaporator are connected in parallel to an inlet of the compressor, and refrigerant inlets of the first evaporator and the second evaporator are connected in parallel to an outlet of the expansion valve; solenoid valves are arranged at the refrigerant inlets of the first evaporator and the second evaporator separately, the fan can blow air to the first evaporator and the second evaporator, and air valves are arranged on the front sides of the first evaporator and the second evaporator separately. The natural defrosting low-temperature evaporation system performs rotation work and natural defrosting through the two evaporators, the heat exchange amount of the natural defrosting low-temperature evaporation system cannot be affected during defrosting, and the failure rate is low.

Owner:GUANGDONG SHENLING ENVIRONMENT SYST CO LTD

Integral kitchen air conditioner

InactiveCN106642388AAchieve installationDoes not affect heat transferDucting arrangementsLighting and heating apparatusEvaporation chamberFlue

The invention provides an integral kitchen air conditioner, and relates to the technical field of air conditioners. In order to simplify installation and maintenance, lower the cost and avoid soot inside a kitchen, the integral kitchen air conditioner comprises a shell and a filter component, the interior of the shell is divided into an evaporation chamber and a condensation chamber through a partition plate, the evaporation chamber is provided with an air inlet and an air outlet, an air flue is formed between the air inlet and the air outlet, and a fan and an evaporator are arranged inside the air flue; the filter component is arranged between the air inlet and the evaporator, and the filter component can filter soot entering air inside the shell from the air inlet. The integral kitchen air conditioner is used for air conditioner manufacturing.

Owner:HISENSE (GUANGDONG) AIR CONDITIONER

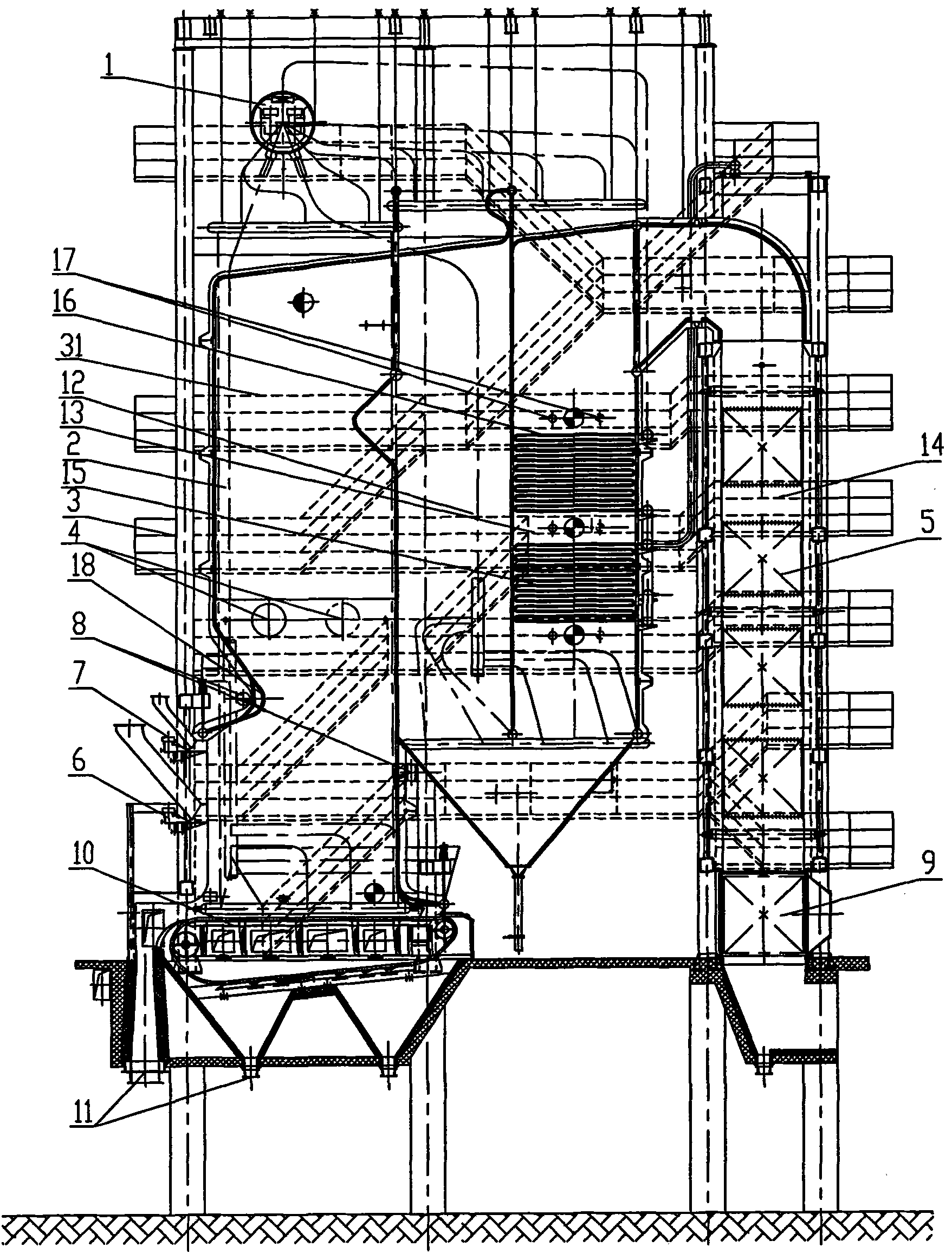

Boiler for derived fuel RDF, waste plastics RPF and waste wood of combustion of refuses

ActiveCN101852422AAvoid cokingHigh volatile contentCasings/liningsSteam boilersRefuse-derived fuelSocial benefits

The invention discloses a boiler for derived fuel RDF, waste plastics RPF and waste wood of combustion of refuses, mainly comprising a hearth, a burnout chamber, a superheater chamber and a rear flue duct, wherein the burnout chamber, the superheater chamber and the rear flue duct are successively connected behind the hearth; a drum is arranged above the hearth, and a reverse chain fire grate is arranged on the lower part of the hearth; slag trapping and ash discharging equipment is arranged below the reverse chain fire grate; the front wall of the lower part of the hearth is provided with a waste wood spray seeding device and a refuse derived fuel RDF and waste plastics RPF spray seeding device which are communicated with the inner part of the hearth, and the waste wood spray seeding device is arranged below the refuse derived fuel RDF and waste plastics RPF spray seeding device. In the invention, the steam produced by using refuse derived fuel RDF, the waste plastics RPF and the waste wood to be combusted in a boiler is used for generating electricity and supplying steam. The invneiton has the social benefit of saving energy and reducing environmental pollution and has favourable economic benefit.

Owner:ZHEJIANG WEIMING ENVIRONMENT PROTECTION

Air conditioner external unit protection cover

InactiveCN107421019ADoes not affect heat transferProtected from the sun and windLighting and heating apparatusAir conditioning systemsWindow shutterEngineering

The present invention relates to the technical field of air-conditioning accessories, in particular to the protective cover of an air-conditioning external unit; Shutters, left baffle; the bottom of the brace is welded to the upper part of the crossbar end of the L-shaped bracket; the right-angled sides of the side triangular plate are welded to the brace and the L-shaped bracket respectively; the two sides of the right baffle are welded to the right Between the horizontal bar and the vertical bar of the L-shaped bracket; the two ends of the reinforced square steel are respectively welded on the L-shaped bracket and the installation square steel; the bottom of the L-shaped bracket is welded on the end of the installation square steel; the bottom edge of the top baffle is welded On the connecting square steel; the two L-shaped brackets are welded through the connecting square steel; shutters are welded between the vertical bars between the L-shaped brackets; the left baffle is welded to the cross bar of the left L-shaped bracket and Between the vertical poles; the protective cover of the air conditioner external unit of the present invention can protect the air conditioner external unit from the wind and the sun, and does not affect the heat exchange of the air conditioner external unit.

Owner:刘倩

Self-cleaning type low-temperature flue gas heat exchanger

InactiveCN107401950AImprove corrosion resistanceAvoid easy cloggingCoatingsHeat exchange apparatusFlue gasEngineering

The invention discloses a self-cleaning type low-temperature flue gas heat exchanger which comprises a flue gas inlet, a flue gas outlet, a water outlet, a water inlet, a coil and a support. A winding pipe fin has a polytetrafluoroethylene coating, the polytetrafluoroethylene material has the advantages of high acid-base corrosion resistance, high-low temperature resistance, smooth and non-sticky surface and the like, the self-cleaning type low-temperature flue gas heat exchanger is used for a low-temperature flue gas recycling system with the temperature lower than or equal to 350 DEG C, the system scaling blocking resistance is good, and the corrosion resistance is high.

Owner:涉县亿玮坤节能科技有限公司

Nanometer metal ceramic coating

InactiveCN111944334AImprove impact resistanceImprove thermal shock resistanceAntifouling/underwater paintsChemical industryCeramic coatingNanoceramic

The invention provides a nanometer metal ceramic coating, belonging to the field of environment-friendly coatings. The nanometer metal ceramic coating is prepared from the following raw materials in parts by weight: 20-45 parts of a nanometer ceramic filler, 20-45 parts of a binder, 5-15 parts of nanometer metal powder and 10-20 parts of water. Compared with the prior art, the nanometer metal ceramic coating has excellent corrosion resistance, high blackness, good energy-saving effect, good surface self-lubricating effect, high contamination resistance, small possibility in falling and cracking, and no influence on heat transfer of four pipes of a boiler.

Owner:北京麦特斯普瑞防腐工程有限公司

Purifier with cleaning function

The invention discloses a purifier with cleaning function, which comprises a purifier body, an instillation pipe or spray pipe and an oil-water separator, wherein the purifier body comprises a shell and a circuit board arranged in the shell, the bottom of the shell is provided with a waste liquid outlet, the top of the shell is provided with a cleaning medium inlet, the liquid inlet end of the instillation pipe or spray pipe is provided with a cleaning medium valve and a cleaning agent valve, the liquid outlet end is communicated with the cleaning medium inlet; the oil-water separating device comprises a waste liquid inlet, a waste oil outlet and a waste water outlet, wherein the waste liquid inlet is communicated with the waste liquid outlet of the purifier main body. With the adoption of the purifier, the cleaning is realized without dismounting, the whole cleaning process is convenient and fast, the cleaning time is short, and the normal heat exchanging work is unaffected basically.

Owner:苏州源林纺织机械科技有限公司

Ethylene oligomerization method

ActiveCN104109068ADoes not affect heat transferEasy to handleHydrocarbons from unsaturated hydrocarbon additionPolymer scienceReaction temperature

The invention relates to an ethylene oligomerization method. The method comprises the following steps: (a) placing an inner kettle in a reactor, wherein the outer wall of the inner kettle is matched with the inner wall of the reactor; (b) adding a reaction solvent into the inner kettle, setting the reaction temperature to be 0 to 40 DEG C, controlling the reaction pressure to be in a range of 0 to 6 MPa through a pressure reducing valve; (c) introducing an ethylene-containing raw material flow into the reaction solvent to carry out reactions; (d) stopping the reaction, and discharging the reaction fluid. When wall hanging in the inner kettle reaches a certain degree, the inner kettle can be rapidly exchanged, thus next reaction can be carried out immediately, the reactors with the wall hangings do not need to be washed during the industrial production process, a lot of time and labor are saved, time and cost are reduced, and the production efficiency is improved. Nonconventional high-efficient method can be conveniently used to wash the polymers in the wall hangings in the replaced inner kettles, the method utilizing a large amount of solvent to wash the polymer is abandoned, and thus the solvent consumption is greatly reduced.

Owner:CHINA PETROLEUM & CHEM CORP +1

Flue gas waste heat recovery device

PendingCN112880459AExtend the pathImprove efficiencyRecuperative heat exchangersDrying gas arrangementsExhaust fumesFlue gas

The invention relates to a flue gas waste heat recovery device which comprises an outer shell, a vertical inner air duct and a circulating water system. An air inlet pipe is arranged on one side of the outer shell, an air outlet pipe and the circulating water system are arranged on the other side of the outer shell, the air inlet pipe is communicated with the vertical inner air duct, and a spiral blade is arranged in the vertical inner air duct. The spiral blade is of a spiral rising structure around a circulating water vertical pipe, and four receiving hoppers which are connected up and down are arranged in the outer shell. In industrial production, waste heat of waste gas accounts for a large amount of heat losses, high-temperature flue gas exhausted by an asphalt mixing plant contains a large amount of water vapor and carries a large amount of waste heat, the waste heat in the flue gas can be recycled, a large amount of energy can be saved, fuel is saved for subsequent stone drying, and air pollution is greatly reduced. And meanwhile, the production cost of enterprises can be reduced, and important practical significance is also achieved for meeting the strategic requirements of energy conservation and emission reduction.

Owner:CA LONG ENG MACHINERY CO LTD

Vehicle heater and method for producing a vehicle heater

ActiveCN104137647AGuaranteed to workFast heat conductionThermometers using electric/magnetic elementsUsing electrical meansEngineeringElectrical and Electronics engineering

Owner:WEBASTO AG

Soaking plate structure

PendingCN107388863ADoes not affect heat transferHigh densityIndirect heat exchangersPorosityEngineering

The invention relates to a soaking plate structure. The soaking plate structure comprises an upper shell plate and a lower shell plate which are buckled together, wherein a support structure is arranged between the upper shell plate and the lower shell plate; the support structure is coated with the upper shell plate and the lower shell plate; a lower surface of the upper shell plate is fixedly connected to an upper surface of the support structure; an upper surface of the lower shell plate is fixedly connected to a lower surface of the support structure; the support structure comprises a porous structure layer; the porous structure layer is made from a porous material; and the porous material has a pore density of 5-30ppi and a porosity of 80%-99%. The porous material with a low pore density and a high porosity is taken as the support structure of a soaking plate, and the structure is uniform in support point position distribution, high in density, reliable in support effect, free from influence on heat transfer performance of the soaking plate, capable of being used for manufacturing soaking plates with various shapes, simple to produce, low in cost, and suitable for batch production.

Owner:SOUTH CHINA UNIV OF TECH +1

Preparing method and application for corrosion resistant composite SiO2 film

ActiveCN101033542AImprove bindingEffective interspersedLiquid/solution decomposition chemical coatingSolventBiological activation

This invention relates to a preparation method for anti-corrosion films on metal surfaces characterizing in improving a high temperature water-heating method by applying Na-Ca glass as a main Si source, LiBr solution as the Si solvent and an activation agent of metal base as well, therefore, the activation of the metal base and the SiO2 deposition are carried out at the same time, and film composition can be interluded effectively, successive heat treatment is not necessary and an inorganic heat-preservation and anti-corrosion film is prepared. The main components of the film are SiO2 and oxide of Fe and Cr and oxidation films of different components can be prepared by adjusting the activation speed of the base and deposition speed of Si.

Owner:DALIAN UNIV OF TECH

Metal collector slab core diversion pipe anticorrosive film and preparation process and film plating process thereof

InactiveCN103087599AImprove anti-corrosion performanceDoes not affect heat transferShellac coatingsAnti-corrosive paintsShellacAlcohol

The invention relates to a technology for corrosion protection of metal pipes, and in particular relates to a metal pipe anticorrosive film and a preparation process and a film plating process thereof. The invention discloses a metal collector slab core diversion pipe anticorrosive film and a preparation process and a film plating process thereof, wherein the anticorrosive film is prepared from the following components in parts by weight after mixing: 15 to 25 parts of polytetrafluoroethylene emulsion, 1 to 2 parts of sodium polyacrylate, 6 to 10 parts of shellac, 15 to 20 parts of absolute ethyl alcohol and 40 to 60 parts of water. The metal collector slab core diversion pipe anticorrosive film has good corrosion resistance, and can protect metal pipes while heat transfer is not influenced.

Owner:KUNMING HOLGUIN TECH

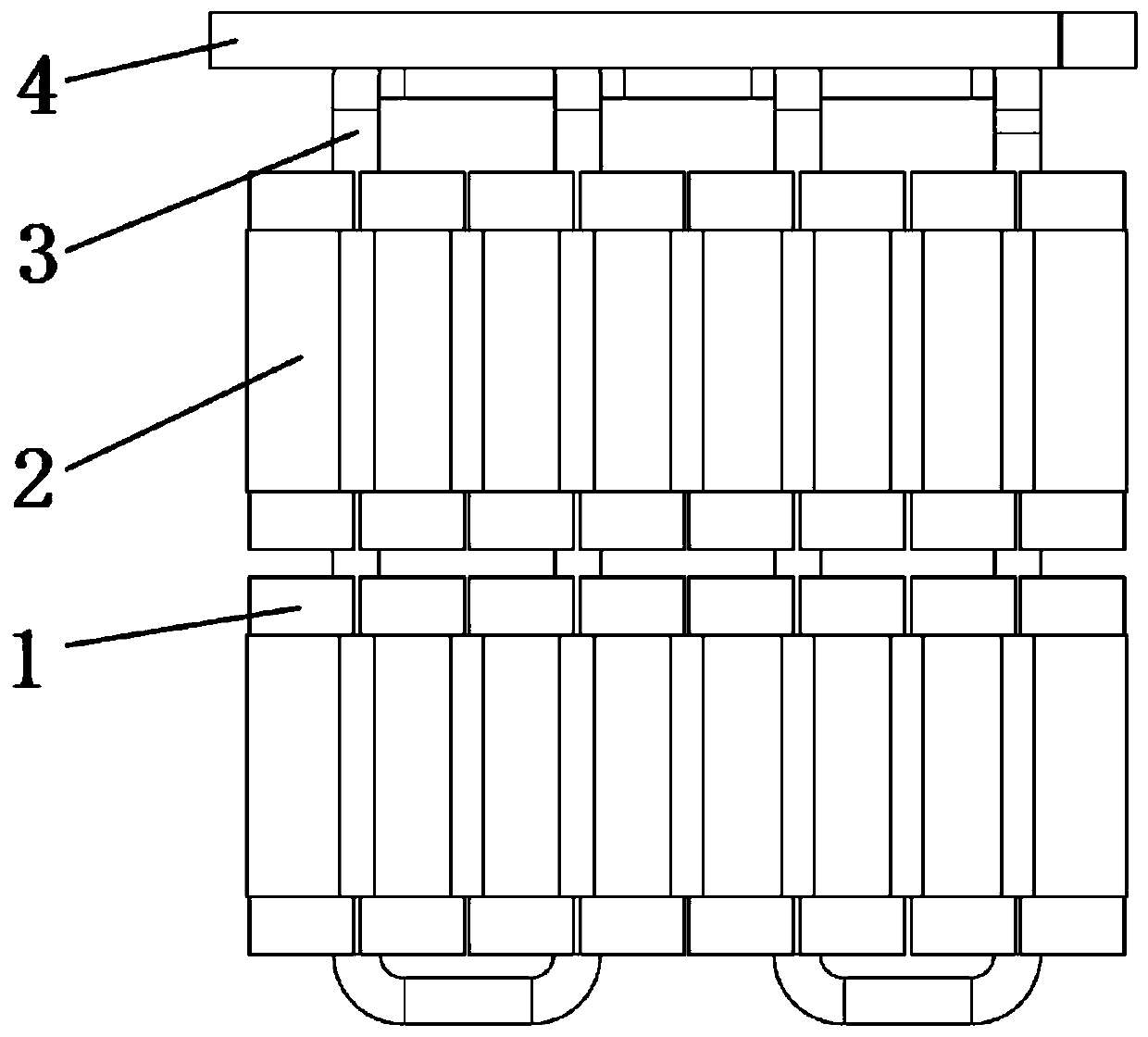

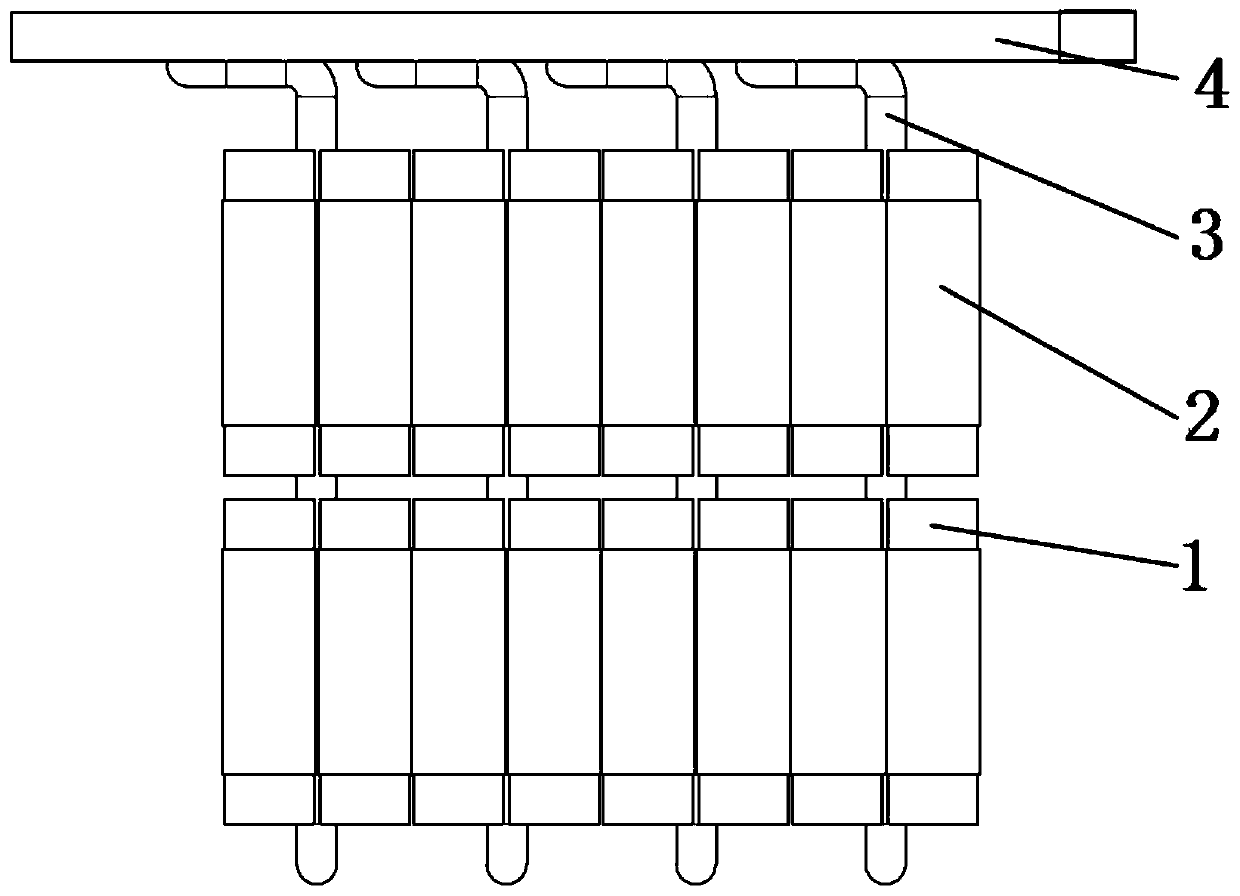

Power battery liquid cooling device and working method thereof

PendingCN109841921AReduce energy consumptionAvoid corrosionSecondary cellsCell component detailsPower batteryElectrical battery

The invention relates to the field of thermal management of power batteries, and discloses a power battery liquid cooling device. The power battery liquid cooling device comprises battery packs, battery sleeves, pulsating heat pipes and a cooling passage with coolant inside. The battery packs are respectively arranged in the battery sleeves. The evaporation section of each pulsating heat pipe is connected with the outer walls of the corresponding battery sleeves, and the condensation section of each pulsating heat pipe is connected with the cooling passage. The invention also discloses a working method of the power battery liquid cooling device. The beneficial effect is as follows: through reasonable design of the arrangement of the battery sleeves and the pulsating heat pipes, the thermalresistance of the liquid cooling device of the battery packs is reduced, the arrangement of the cooling passage on a single side of the battery packs is realized, and the temperature and temperatureuniformity of the battery packs can be well controlled.

Owner:SOUTH CHINA UNIV OF TECH

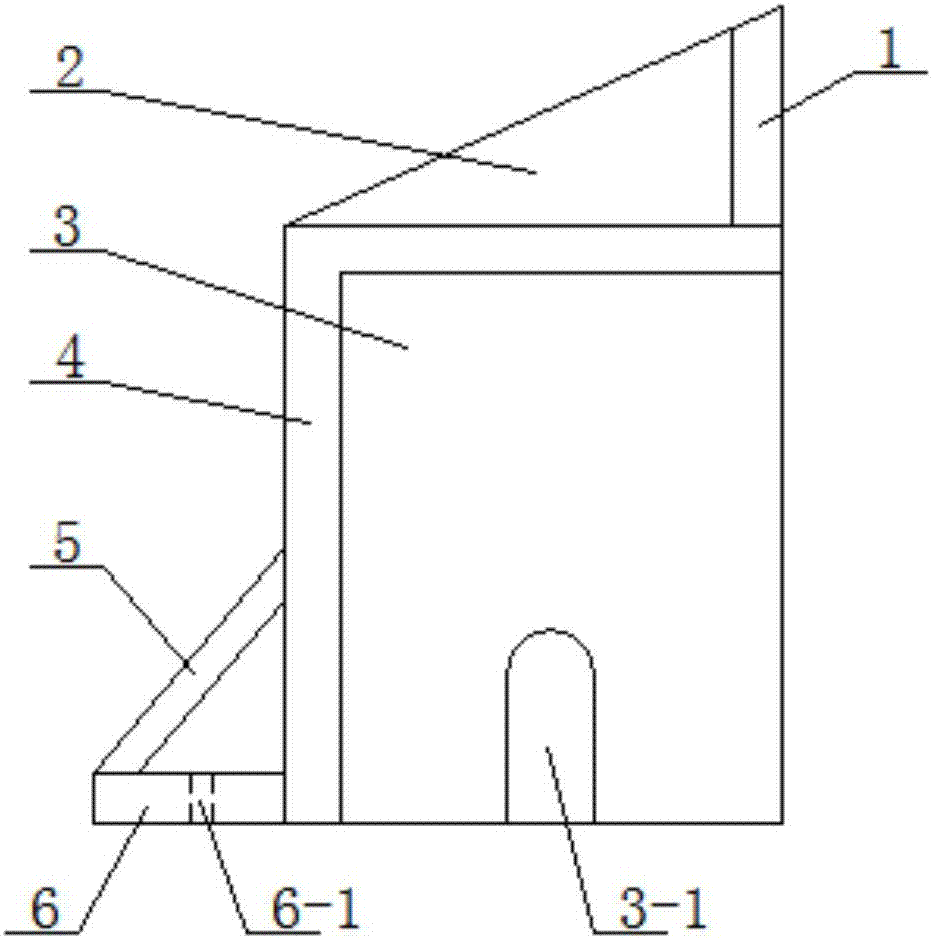

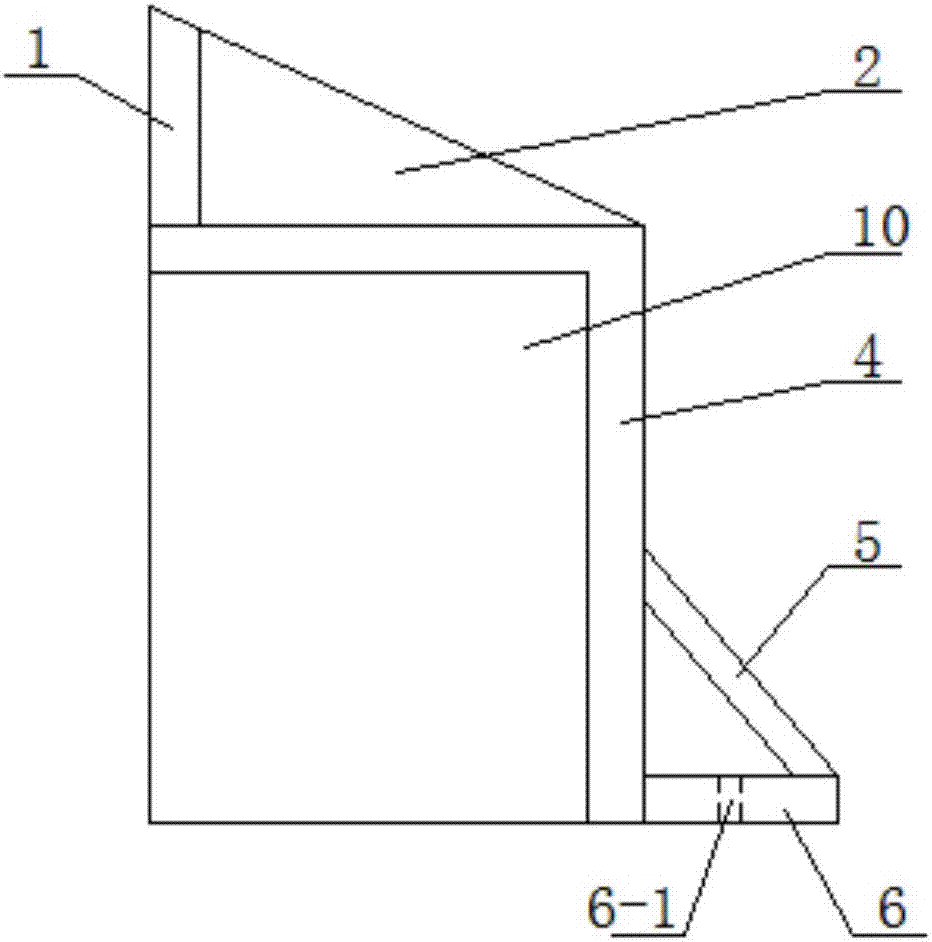

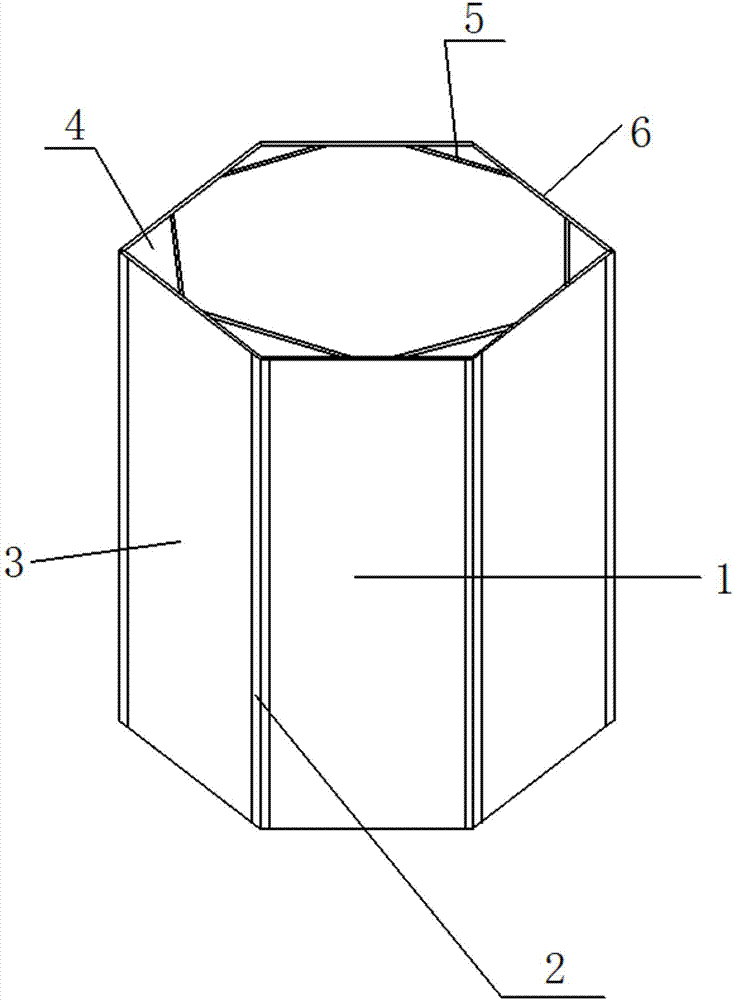

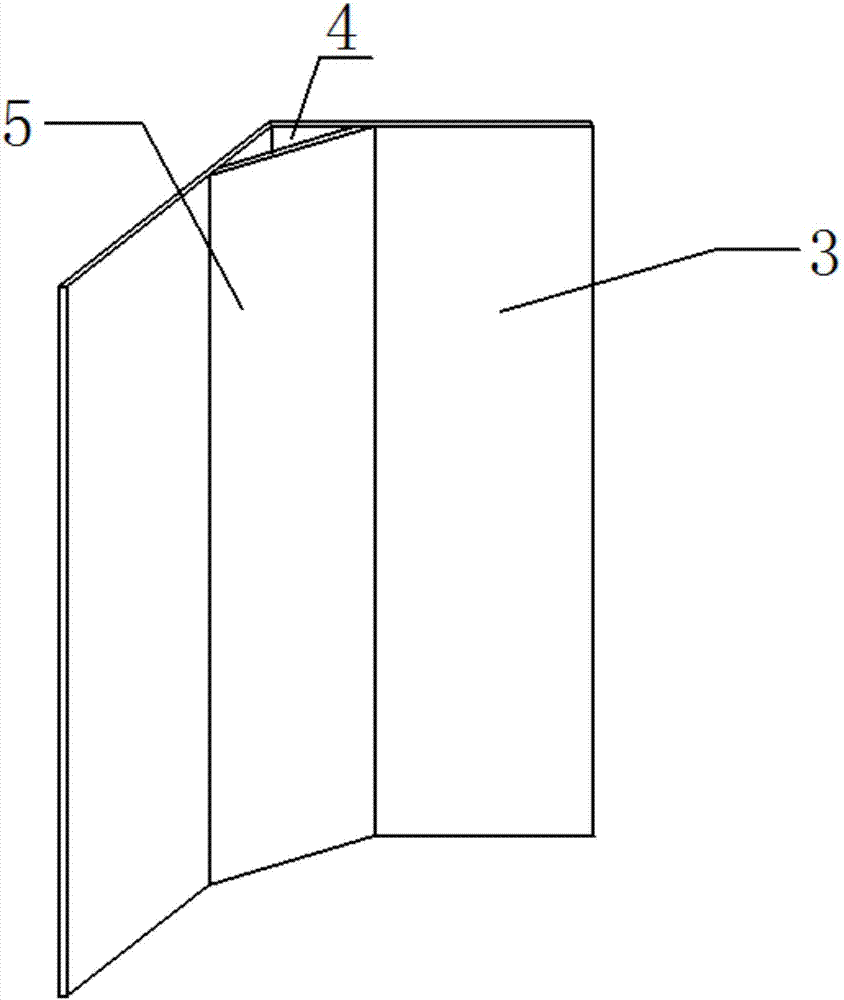

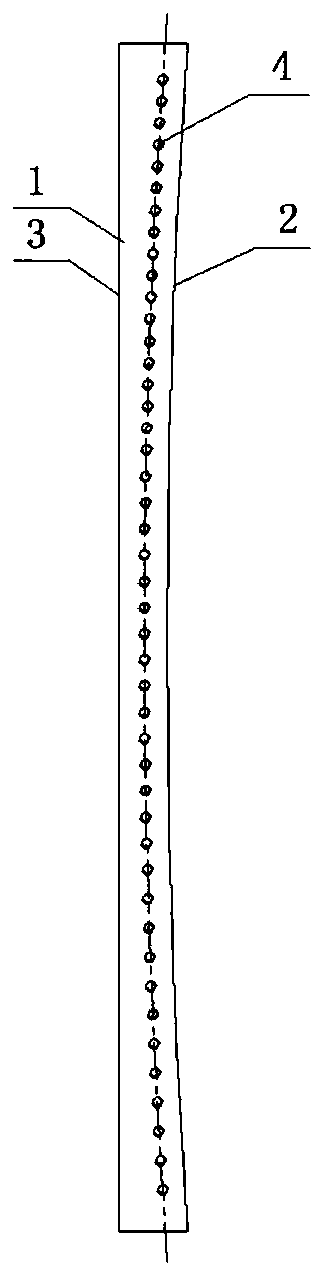

Hexagonal heat insulating furnace pipe of combustion furnace

InactiveCN107990360ALow costSave fuelDomestic stoves or rangesLighting and heating apparatusEngineeringCombustion

The invention relates to a hexagonal heat insulating furnace pipe of a combustion furnace. The hexagonal heat insulating furnace pipe is characterized in that a furnace pipe body (1) is composed of embedded strips (2), connecting blocks (3), a heat insulating layer (4), inner pipe heat insulating blocks (5) and a furnace wall single layer (6), and the furnace pipe body (1) is a hollow hexagonal cylinder body; and the furnace pipe body (1) is a hexagonal cylinder body formed by mutual connecting of the six connecting blocks (3) and the embedded strips (2). A body of a triangular heat insulatinglayer (4) formed by the inner pipe heat insulating blocks (5) are attached to the inner angles of the hexagonal cylinder body, and the furnace pipe body (1) is mounted on the combustion furnace The hexagonal heat insulating furnace pipe of the combustion furnace is simple in structure and convenient to operate.

Owner:肖桂珍

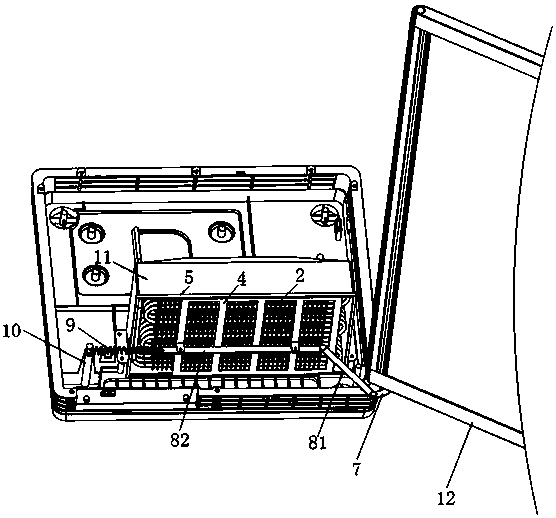

Display cabinet

ActiveCN109682153AClean up in timeSave human effortShow cabinetsCooling fluid circulationEngineeringRefrigeration

The invention relates to a display cabinet comprising a cabinet body. The bottom of the cabinet body is provided with a condenser; the display cabinet further comprises an automatic condenser cleaningdevice and a surface condensate removal door structure; the automatic condenser cleaning device comprises a brush component and a connecting rod component, and the brush component is arranged on theside face of the condenser movably, and is in contact with the surface of the condenser for cleaning the condenser; one end of the connecting rod component is connected with the brush component, and the other end of the brush component is connected with a lower door frame of a cabinet door, so that the brush component is driven by a lower door frame through the connecting rod component to move back and forth on the surface of the condenser for cleaning when the cabinet door is opened and closed; the surface condensate removal door structure comprises a door frame and door glass, and the door glass is arranged in the door frame which is further provided with a heating part internally; and the heating part is connected with a power supply, and used for heating the door frame after power-on so that the temperature of the door frame rises for avoiding formation of condensate water. The display cabinet has the advantages of a good refrigeration effect, convenient installation, the simple structure and the beautiful cabinet body.

Owner:NINGBO ROTOR ELECTRICAL APPLIANCES CO LTD

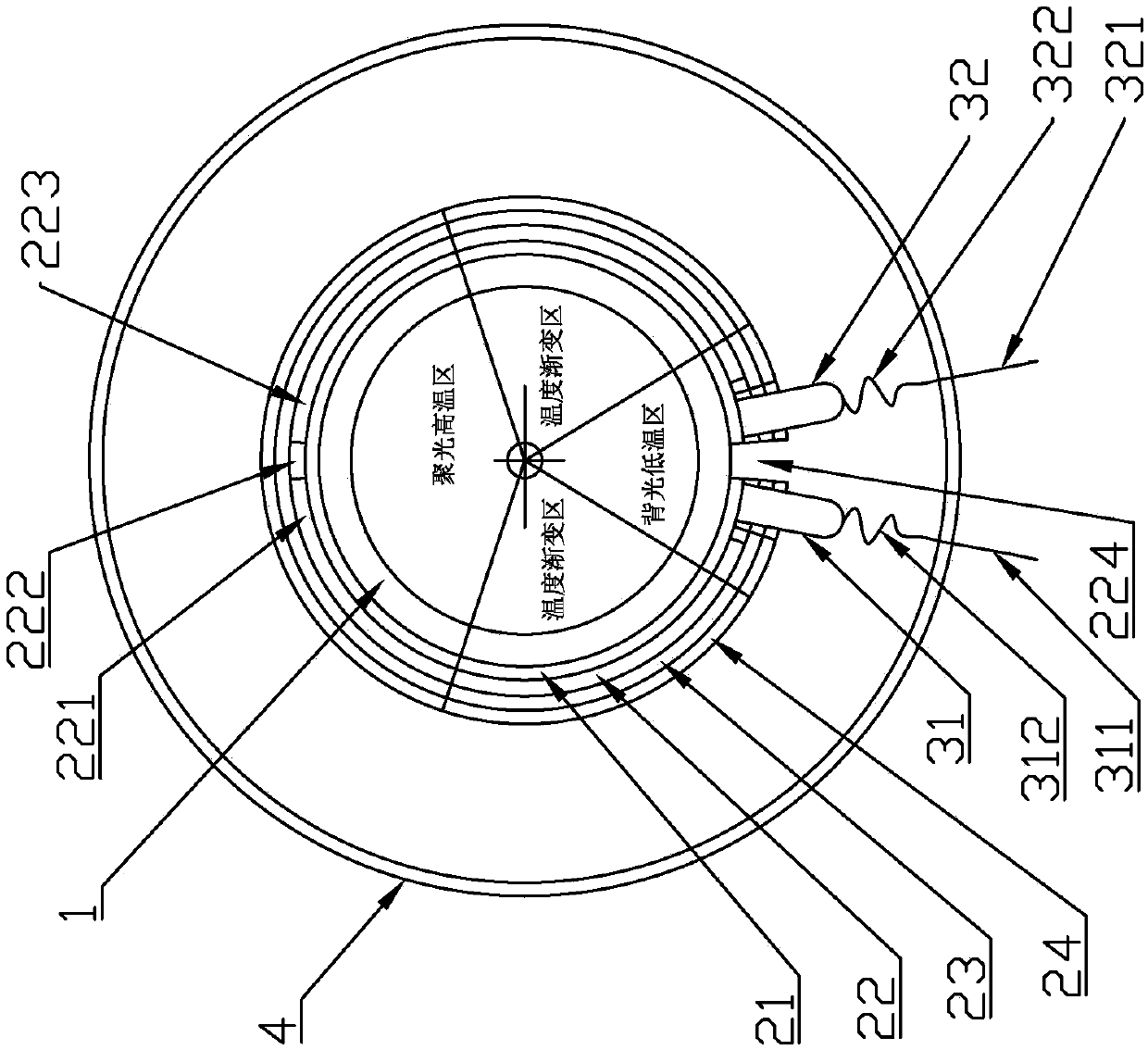

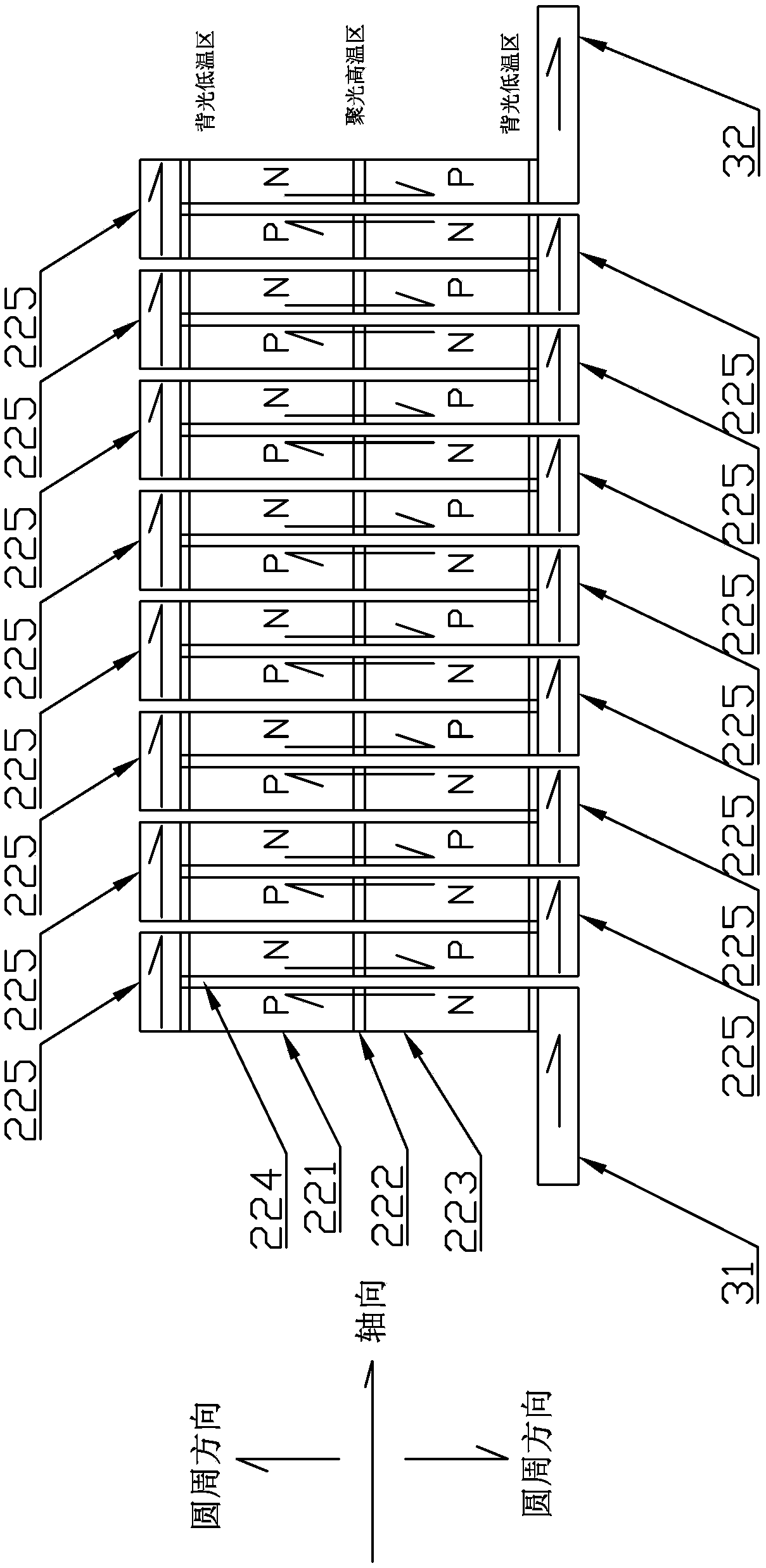

Thin film thermoelectric power generation and selective absorption coating coupled solar collector tube

PendingCN109654745AStructural advantageEasy to processSolar heating energySolar heat collector detailsTwo temperatureTemperature difference

The invention provides a thin film thermoelectric power generation and selective absorption coating coupled solar collector tube. The solar collector tube comprises a metal tube and a cover glass tube; the outer wall of the metal tube is successively provided with a first insulating layer, a PN junction layer, a second insulating layer and a selective absorption coating; the PN junction layer is connected with an extraction electrode; the two ends of the cover glass tube are each fused with a Kovar metal sleeve; the Kovar metal sleeves form a vacuum sandwich by forming a sealed connection withthe outer wall of the metal tube through a corrugated tube assembly; a wire connected with the extraction electrode forms a zigzag section in the vacuum sandwich; the tail of the zigzag section is led out of the cover glass tube through direct sealing or through a transition material. The solar collector tube especially applies to a trough solar collector tube which can make the temperature difference between the two temperature zones reach 10-50 DEG C. Therefore, the natural temperature difference of the trough solar collector tube can be fully utilized to realize thermoelectric power generation, and there is no need to actively dissipate heat in the low temperature zone.

Owner:河北道荣新能源科技有限公司

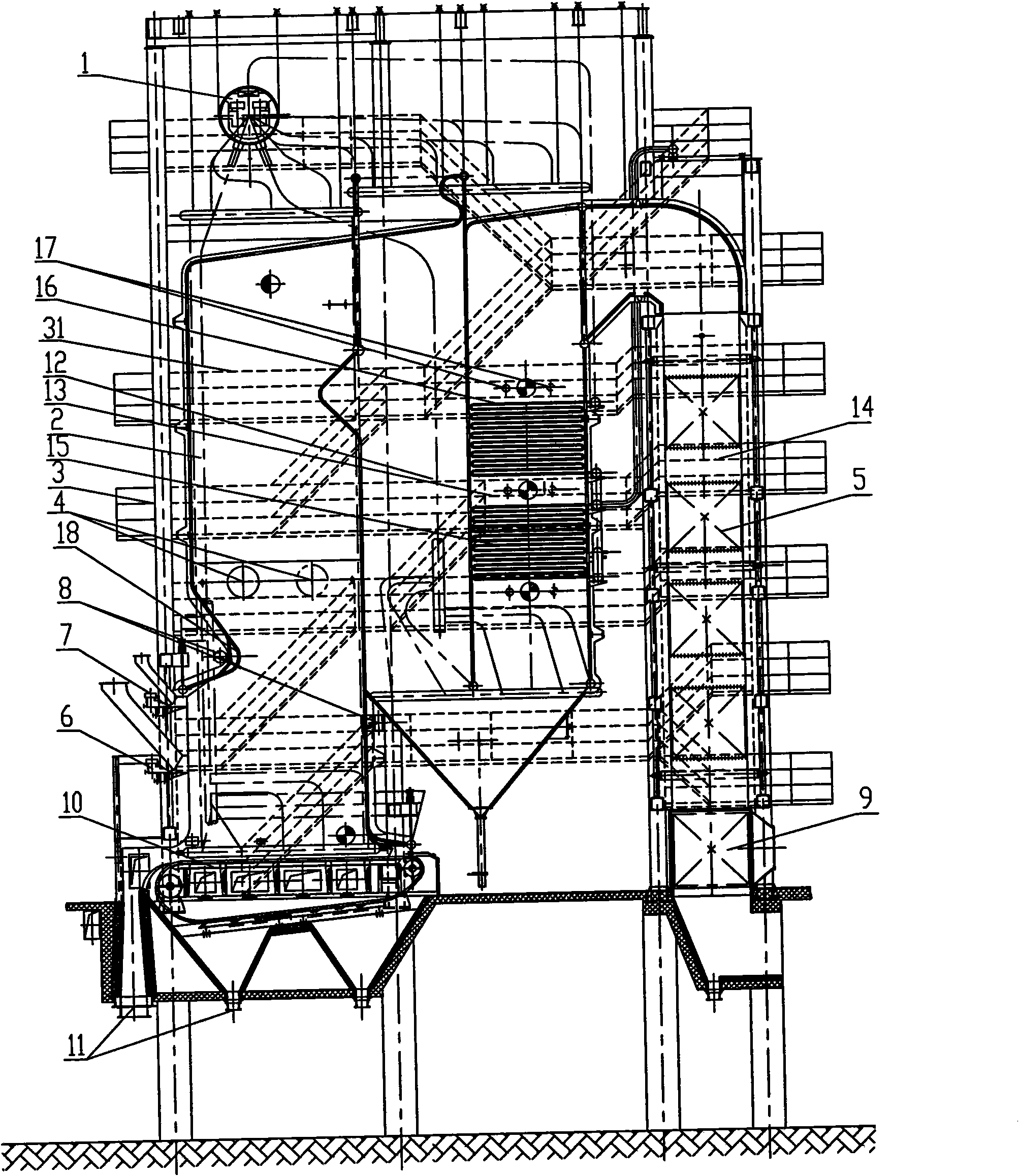

Bagasse-fired boiler

InactiveCN101793389AImprove combustion efficiencyGuaranteed uptimeAir/fuel supply for combustionCasings/liningsThermodynamicsProcess engineering

The invention relates to a bagasse-fired boiler which can ensure the smooth operation of the boiler, save resources, improve the utilization rate of the resources and protect the environment. The technical scheme is as follows: the bagasse-fired boiler comprises a furnace chamber, a feeding device, a grate, boiler drums, a tail flue, a superheater chamber, a soot blower and a boiler steel frame, wherein the grate is arranged at the lower part of the furnace chamber, the feeding device is arranged at the front part of the furnace chamber, the furnace chamber, the superheater chamber, the boiler drums and the tail flue are sequentially communicated, and the bagasse-fired boiler is characterized in that the grate is a water-cooled fixed grate specifically, the boiler drums are double boiler drums specifically, the double boiler drums are communicated through a convection bank, and the feeding device is arranged on the upper inclined side of the water-cooled fixed grate.

Owner:WUXI HUAGUANG BOILER

a display cabinet

ActiveCN109682153BClean up in timeSave human effortShow cabinetsCooling fluid circulationEngineeringDisplay cabinet

Owner:NINGBO ROTOR ELECTRICAL APPLIANCES CO LTD

An air source heat pump based on the concept of energy saving and environmental protection

ActiveCN111156738BAvoid sun exposureAvoid frostMechanical apparatusHeat pumpsSolenoid valveLiquid storage tank

Owner:山东齐昊新能源科技有限公司

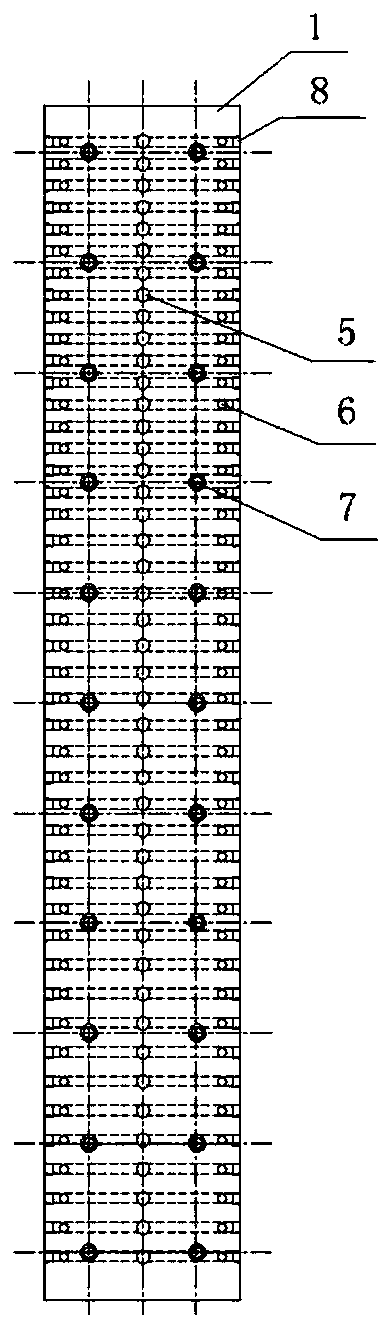

Copper plate of crystallizer of high-efficiency continuous casting machine

The invention discloses a copper plate of a crystallizer of a high-efficiency continuous casting machine. The copper plate comprises a copper plate body and a plurality of transverse cooling channelslongitudinally formed in the copper plate body at intervals; each transverse cooling channel comprises a transverse cold water hole transversely drilled in the copper plate body, a middle water hole formed in the middle of a cold surface, side water holes formed in the cold surface and located on two sides of the middle water hole as well as screw plugs fixed to the end openings of the transversecold water hole in a sealed manner, and the middle water hole and the side water holes communicate with the transverse cold water hole. According to the copper plate, the transverse cooling mode is adopted, uniform cooling is realized with the mode, with increase of the water inlet and outlet holes, the flow of cooling water can be substantially increased, the cooling effect can be improved, and essential conditions for the high casting speed can be realized.

Owner:石家庄市光达机械有限公司

Artificial leather boiler heat-conducting oil on-line detergent and preparation method thereof

ActiveCN103614198AAdd lessEasy to cleanNon-surface-active detergent solventsLubricant compositionHeat conductingPhenolic antioxidant

The invention discloses an artificial leather boiler heat-conducting oil on-line detergent and a preparation method thereof. The detergent is prepared from the following raw materials in percentage by weight: CNOOC 150SN, base oil, dialkenyl succinimide, polyisobutenyl succinimide, high-molecular-weight succinimide, high-molecular-weight phenolic antioxidant, octyl / butyl diphenylamine antioxidant and defoaming agent. The detergent implements non-shutdown on-line cleaning in deed, has the advantages of low addition amount and more obvious cleaning effect, can dissolve the solid oil coke, can improve the heat conductivity and can lower the energy consumption, and the cleaning efficiency is up to higher than 98%. The detergent has the characteristics of mild cleaning property and high operational safety, does not influence the normal operation of the system, and does not have the phenomenon of tube blockage by dirt.

Owner:AMER TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com