Oil and gas field fracturing flow-back fluid treatment process

A fracturing flowback fluid and treatment process technology, applied in mining wastewater treatment, water/sewage multi-stage treatment, water/sludge/sewage treatment, etc. Large-scale production practice, unsatisfactory CODcr removal effect, etc., to achieve better adsorption effect, reduce blockage of saturated blocks, and reduce burden

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0016] Embodiment 1, a kind of treatment process of oil and gas field fracturing flowback liquid, as attached figure 1 As shown, it includes regulating tanks, grit settling and grease traps, air flotation tanks, primary oxidation tanks, Fenton oxidation towers, and active coke filtration and adsorption tanks connected in sequence through pipelines, valves, and lift pumps. Among them, the adjustment tank is provided with perforated aeration pipes for blast aeration; the sand and grease trap is provided with polypropylene inclined pipes, and the inclined pipes are installed with a horizontal angle of 60°; the air flotation coagulation tank is provided with a dosing device. The coagulants added are PAC (polyaluminum chloride) and PAM (polyacrylamide), and the air flotation method adopts dissolved air flotation; the primary oxidation pool uses sodium hypochlorite as the primary oxidant, and there is a dosing device and a reaction stirring device; the Fenton oxidation tower is in t...

Embodiment 2

[0025] Embodiment 2. Using the treatment process of the present invention, the fracturing flowback fluid produced in the oil recovery process of an oil field is treated. Designed for continuous operation 24 hours a day.

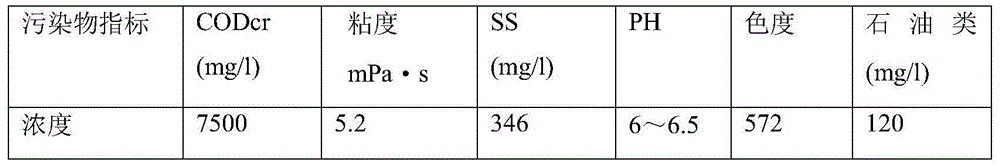

[0026] 1. Design water quality

[0027]

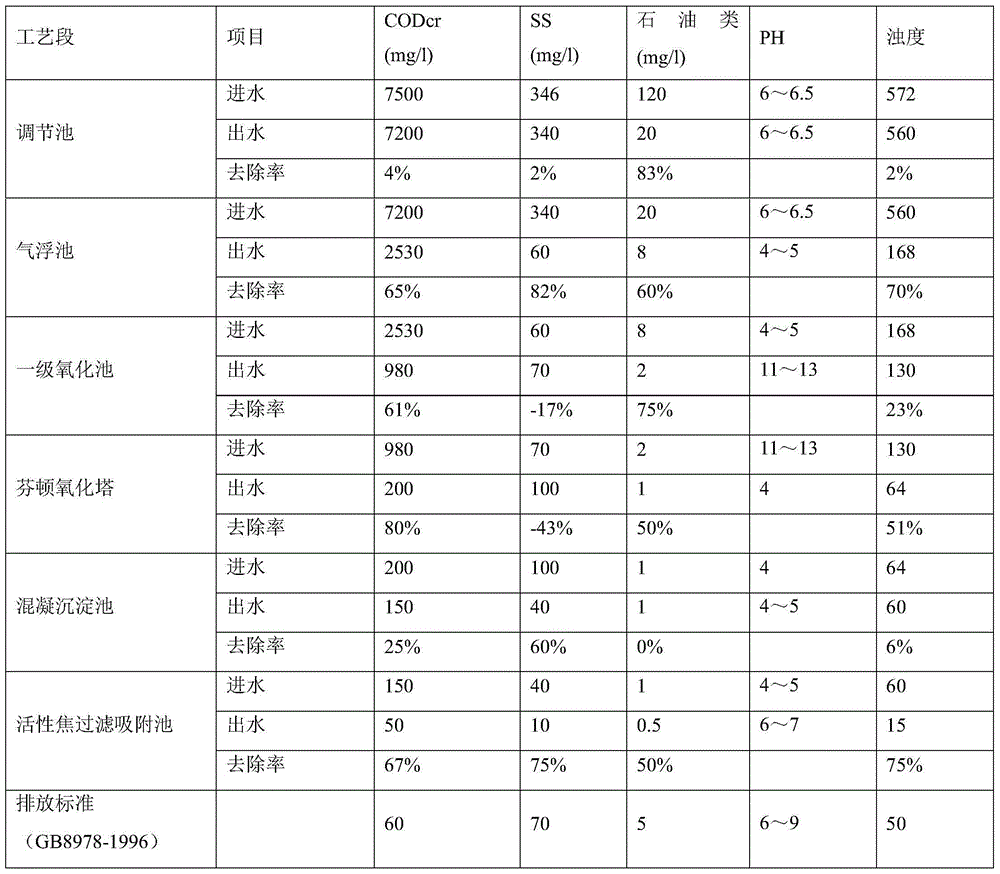

[0028] 2. Process parameter design

[0029] (1) A grill is set in the regulating tank to remove coarse suspended matter and floating matter in the wastewater. The adjustment tank adopts perforated aeration tube to blow and aerate the air volume to 0.05m 3 / m 2 .min. The residence time of the regulating tank is 4h; the homogenized and evenly distributed wastewater enters the grit degreasing tank, and the surface load is 0.75m 3 / m 2 .h, the length of the inclined pipe is 1 meter, and it is installed according to the horizontal angle of 60°. It settles to remove the sediment entrained by the flowback liquid and removes the oil slick; (2) The outlet water of the regulating tank is lifted into the coagulation air...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Surface load | aaaaa | aaaaa |

| Iodine value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com