Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

79 results about "Process scaling" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

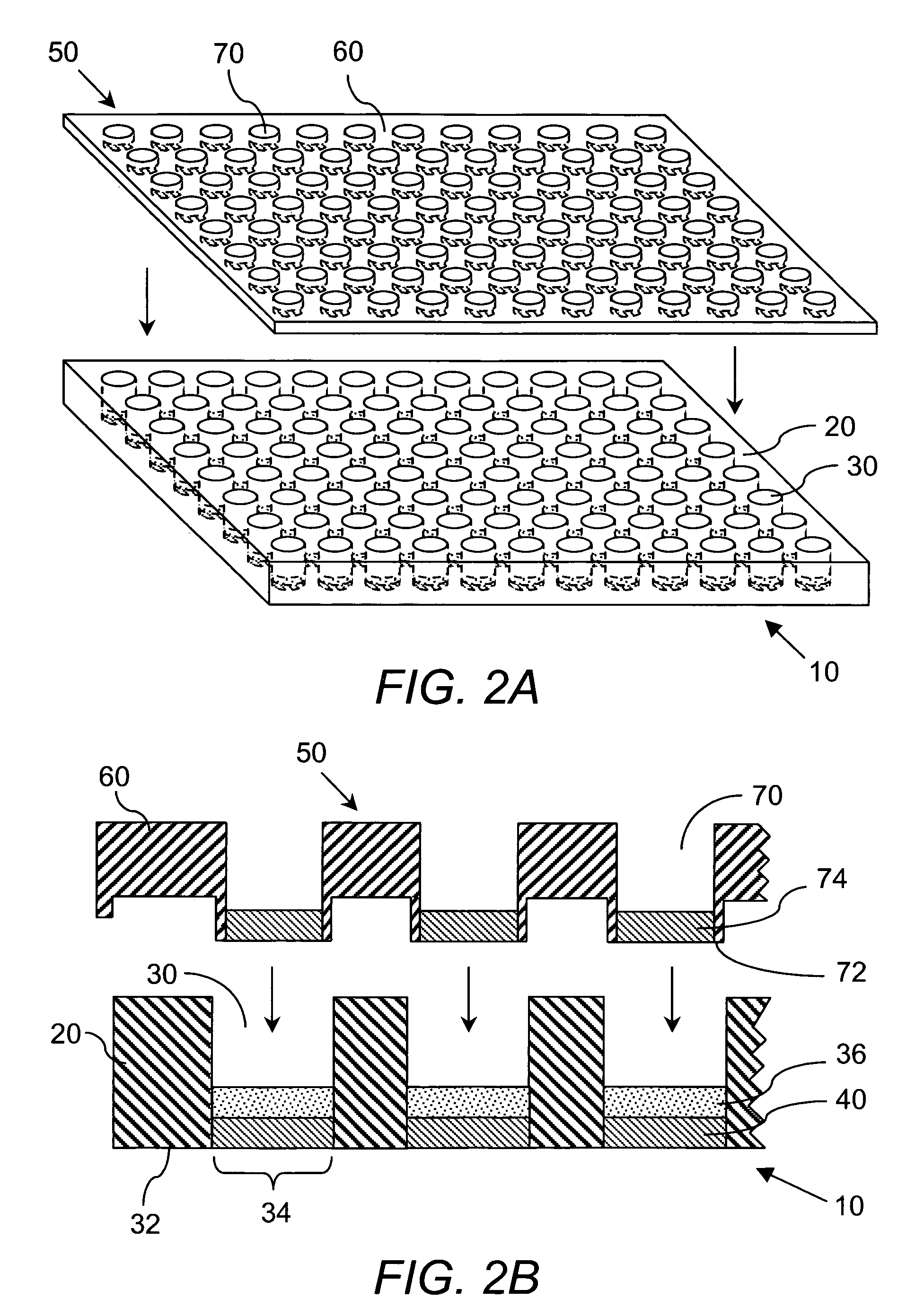

Apparatus, kits and methods for evaluating binding interactions, for detecting and quantifying binding molecules, and for sample preparation

InactiveUS20060019410A1Reduce amountBioreactor/fermenter combinationsBiological substance pretreatmentsProcess scaleProcess scaling

The present invention provides apparatus, kits and methods for evaluating binding between one or more binding molecules (e.g., a protein) and one or more ligands. The invention also provides apparatus, kits and methods for detecting and / or quantifying a binding molecule, for example, a protein. Also provided are apparatus, kits and methods for “stripping” a complex biological matrix of low molecular weight components. The invention can be carried out on a smaller process scale, and therefore be more efficient, than previously known methods. The present invention is particularly suitable for use in high-throughput assays, which can be partially or completely automated.

Owner:QUALYST

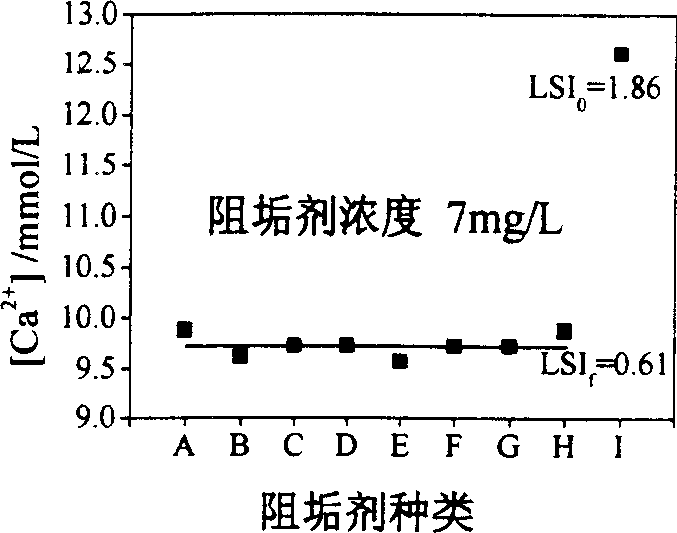

E-Fenton oxidation technique of dirty blocking agent in reverse osmosis concentrating liquid

InactiveCN1541757AHigh salt concentrationImprove conductivityWater/sewage treatment bu osmosis/dialysisReverse osmosisElectrolysisProcess scaling

The electric Fenton oxidation process for processing scale inhibitor in reverse osmosis concentrated liquid adopts anode of iron plate and cathode of porous graphite and ventilated with air pump and processes reverse osmosis concentrated liquid through electrolyzing in stirring, stirring coagulation via adding aluminum sulfate and filtering the coagulated solution. Bivalent iron ion produced intelligent the electric Fenton process is made to react with hydrogen peroxide to produce strong oxidizing free hydroxy radical oxidizing and destructing the scale inhibitor; and the subsequent coagulation separates out scaling salt to lower the scaling trend, so that the concentrated liquid may be utilized as influent water to raise the water recovering rate of reverse osmosis system.

Owner:SHANGHAI JIAO TONG UNIV

Methods and compositions for chromatography

InactiveUS6942804B2Easy to createIon-exchange process apparatusOther chemical processesProcess scaleChromatographic separation

The present invention is directed to methods and compositions for separating and isolating target molecules. In particular, the present invention comprises devices, such as CCDs, that contain particles without the need for support structures. Chromatography separation techniques, including but not limited to, ion exchange, size separation, affinity chromatography, ion exclusion, ligand exchange, reversed phase and normal phase partitioning, are used in the CCD. Methods also include low, medium and high pressure liquid chromatography. Such methods can be used for analytical, semi-preparative processes, initial clarification, preparative filtration and process scale applications.

Owner:SARTORIUS STEDIM NORTH AMERICA INC

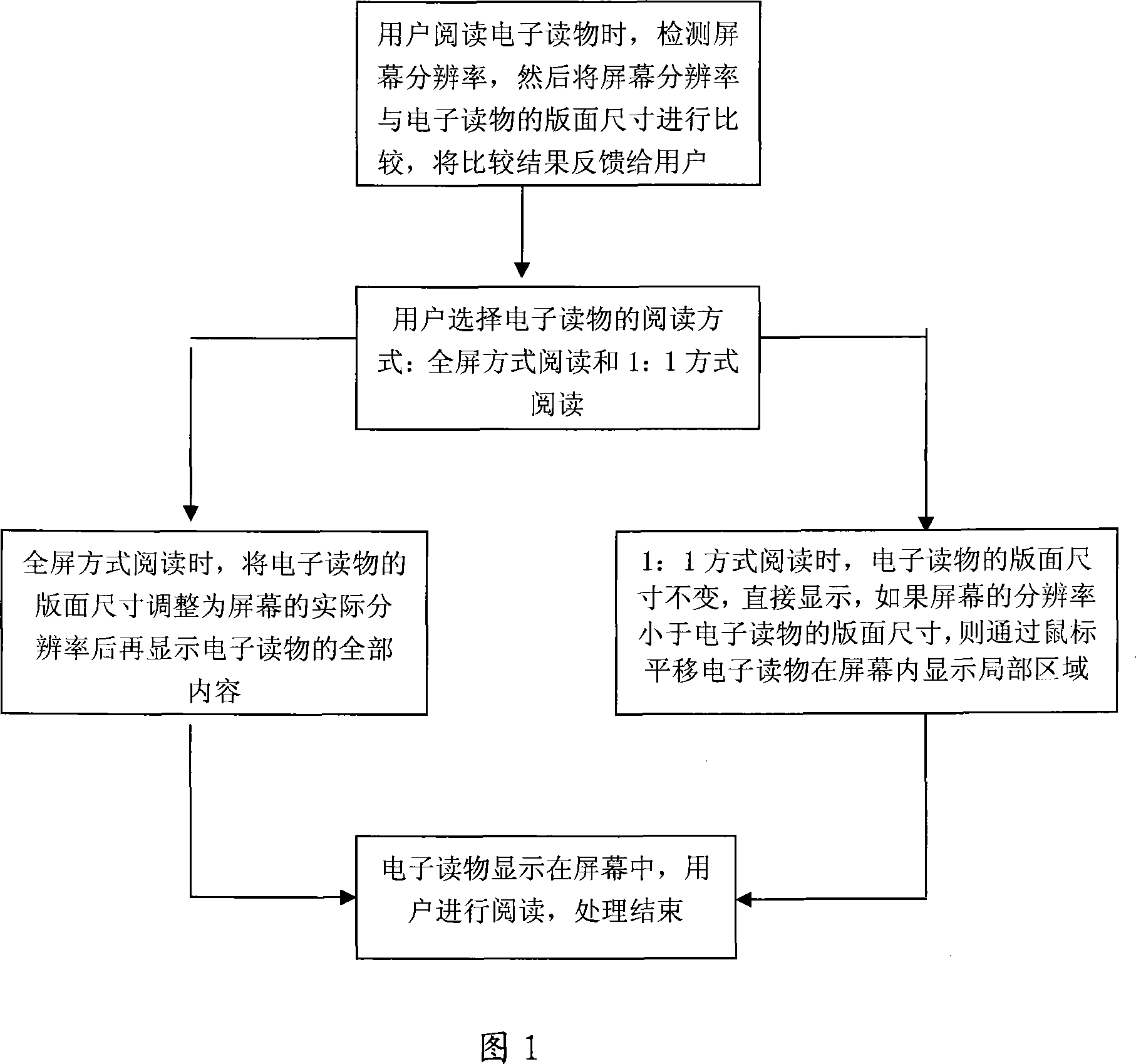

Electronic reading processing method and system adapting to screen resolution

ActiveCN101241416AImprove reading experienceGeometric image transformationElectrical appliancesProcess scaleComputer architecture

The present invention belongs to electronic reading application field, in particular relating to an electronic reading processing method and system fit for screen resolving capability. The present electronic reading adopts dynamic layout technology to adjust layout size, or adopting fixed layout size; the former can not achieve original edition recurrence because of need re-layout, when re-layout, need mass calculations lead lower efficiency; the back can achieve original edition display effect, having high display efficiency, since the size of the layout is fixed, it is presented by the fixed size in the fixed place of the user screen. The method and system of the invention processes scale of the electronic reading by comparing the screen resolving capability and the electronic reading resolving capability, capable of selecting proper reading style according to the needs. The method and system of the invention make the electronic reading having different size display in the screen having different screen resolving capability, making overall plans to the reading needs of all kinds of users.

Owner:NEW FOUNDER HLDG DEV LLC +2

Manufacturing method for phase change RAM with electrode layer process

ActiveUS7605079B2Simple structureSmall reset currentSolid-state devicesSemiconductor/solid-state device manufacturingProcess scalePhase-change memory

A method for manufacturing a phase change memory device comprises forming an electrode layer. Electrodes are made in the electrode layer using conductor fill techniques that are also used inter-layer conductors for metallization layers, in order to improve process scaling with shrinking critical dimensions for metallization layers. The electrode layer is made by forming a multi-layer dielectric layer on a substrate, etching the multi-layer dielectric layer to form vias for electrode members contacting circuitry below, forming insulating spacers on the vias, etching through a top layer in the multi-layer dielectric layer to form trenches between the insulating spacers for electrode members contacting circuitry above, filling the vias and trenches with a conductive material using the metallization process. Thin film bridges of memory material are formed over the electrode layer.

Owner:MACRONIX INT CO LTD

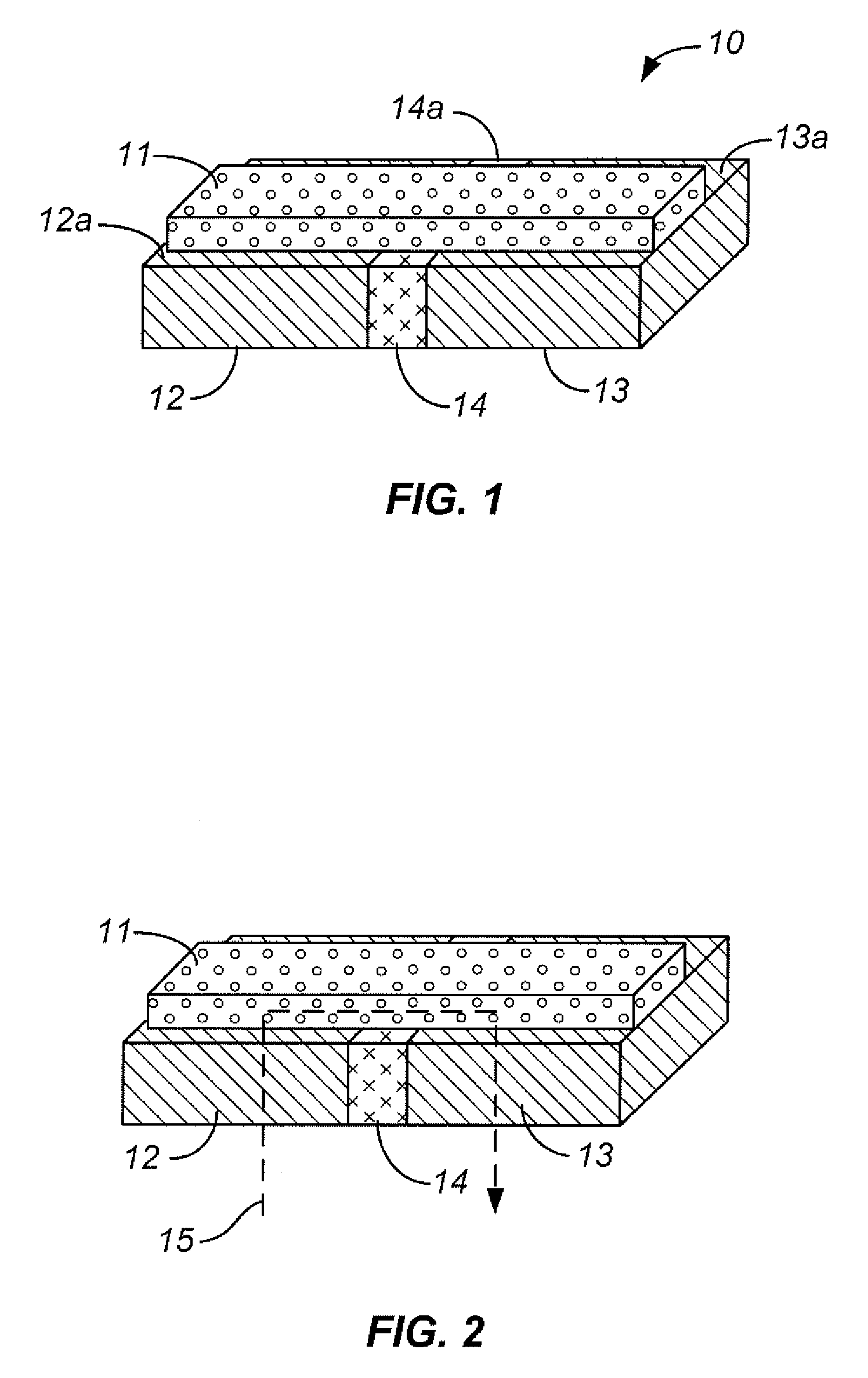

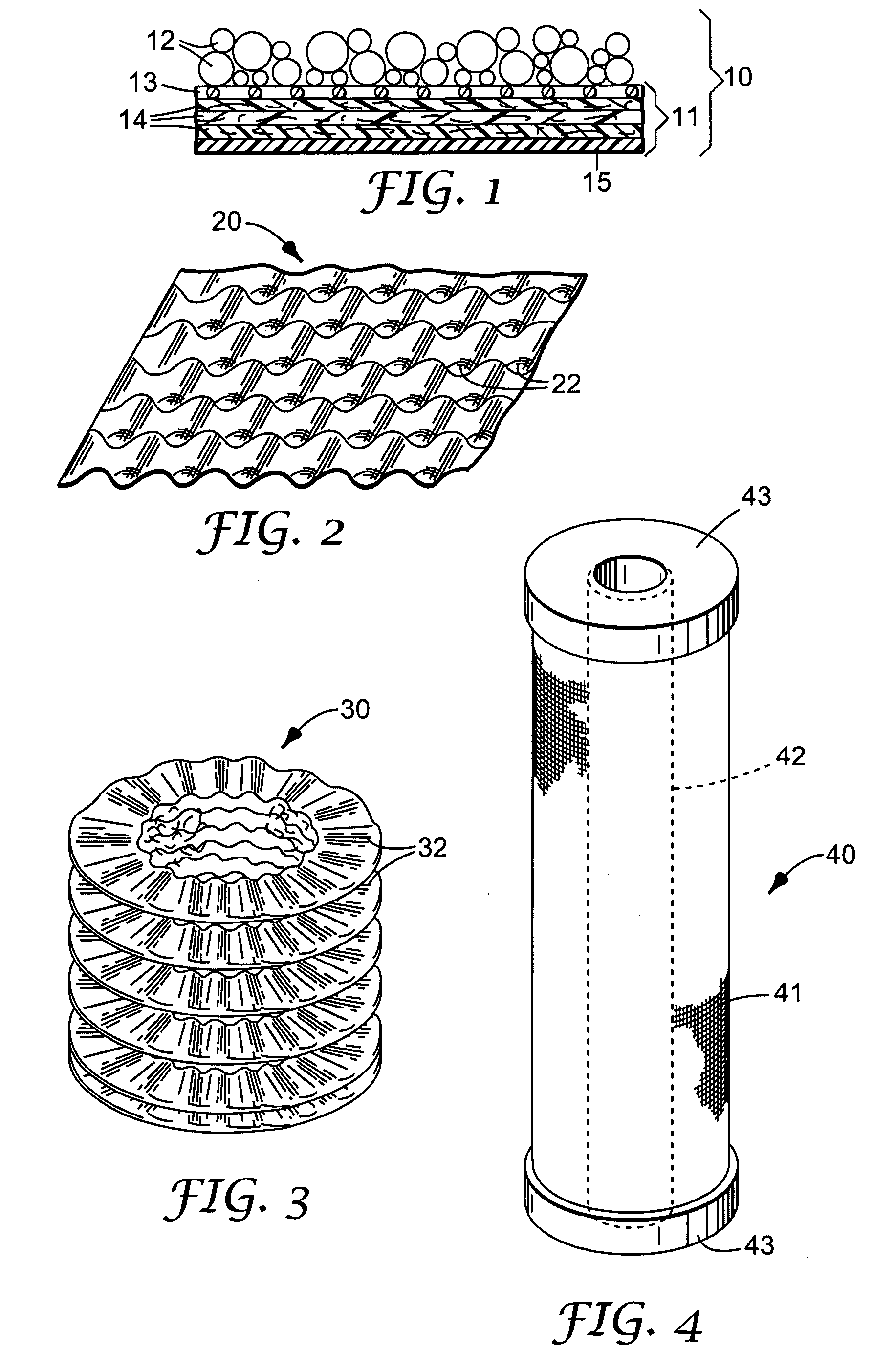

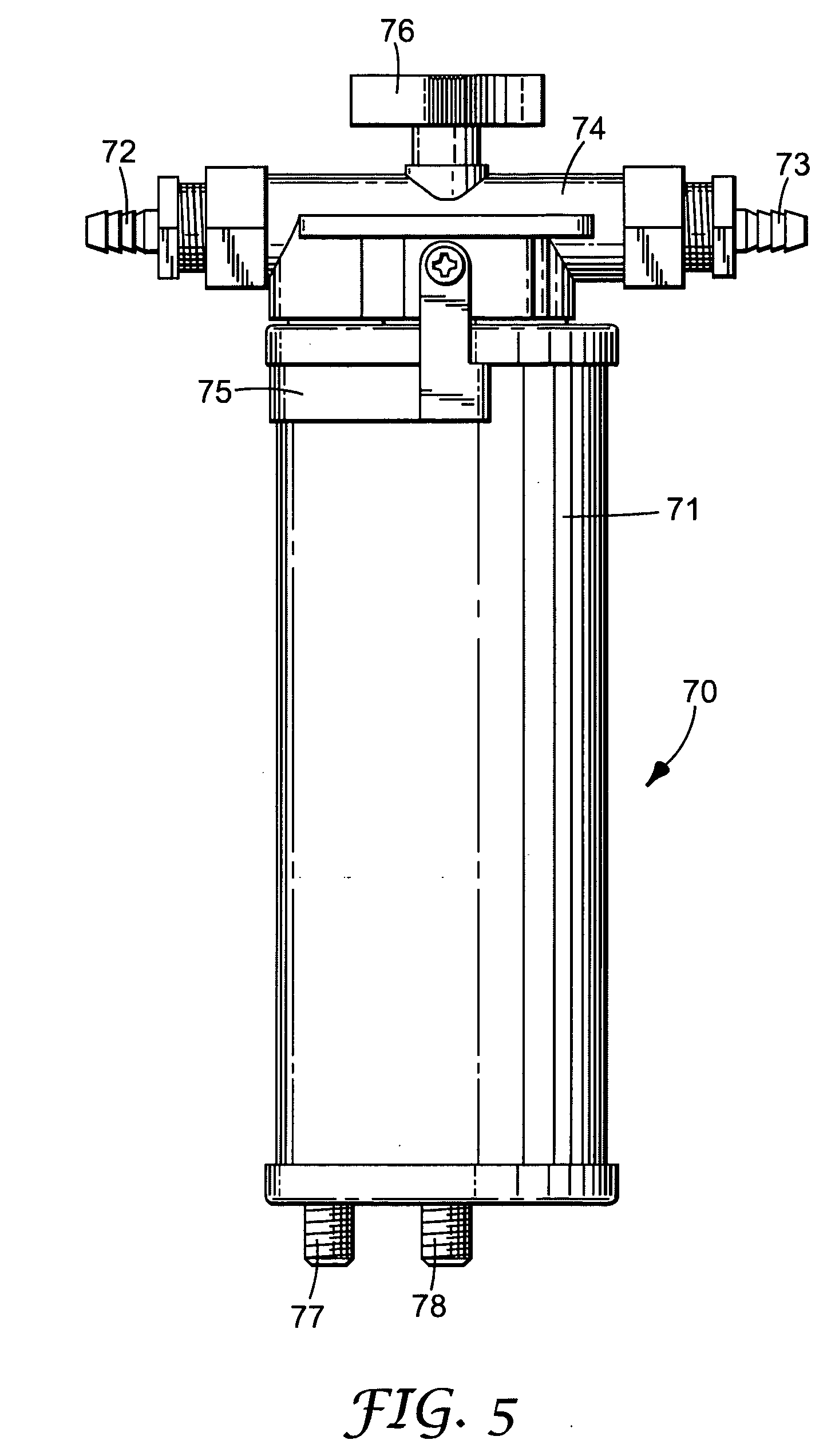

Composite filtration article

InactiveUS20060070950A1Reduce porosityIncreased operating system pressureIon-exchange process apparatusIon-exchanger regenerationParticulatesSorbent

A composite filter medium comprising a filter element comprising at least one porous fibrous filtration layer, and at least one layer of a sorbent, stationary phase particulates selected from organic or inorganic particulates having an average diameter of less than 50 micrometers, soft particulates, and ground monolithic particulates. The particulates are capable of binding target molecule by, for example, adsorption, ion exchange, hydrophobic binding, and affinity binding. The particulates provide higher binding capacities than can be achieved using filter media incorporating conventional process scale chromatography resin particulates.

Owner:3M INNOVATIVE PROPERTIES CO

Novel crystal form of roxadustat and preparation method of novel crystal form

The invention provides a novel crystal form of roxadustat and a preparation method of the novel crystal form. The crystal form ARZ-A has better stability and solubility than existing crystal forms. The preparation process of the crystal form is simple and feasible, a used solvent has low toxicity, stability of the crystal form is good, and the crystal form is more suitable for process scale-up production.

Owner:ANLITE SHANGHAI PHARMA TECH CO LTD +2

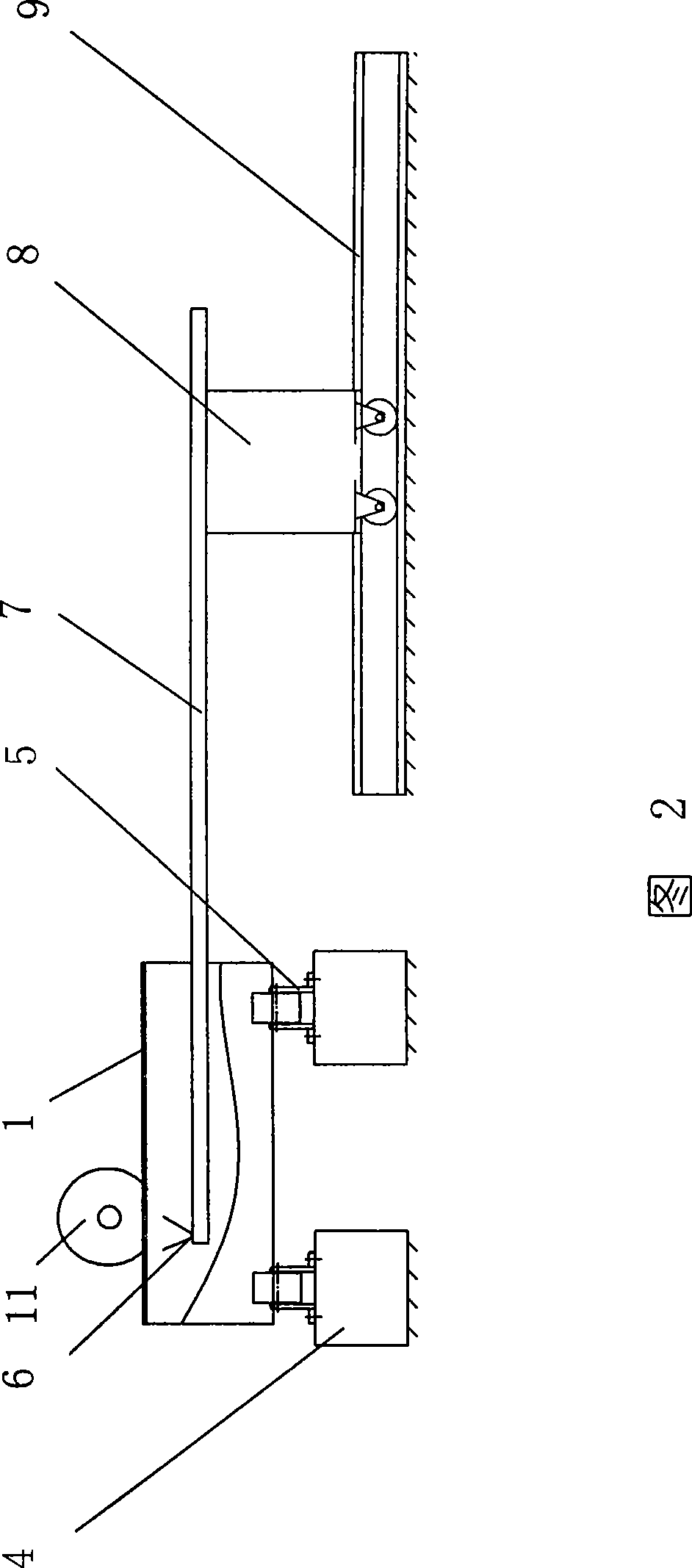

Instantaneous ejection type steam explosion machine

ActiveCN105642188AAchieving suddennessGuarantee the same effect of steam explosionPressurized chemical processProcess scaleTime extension

The invention relates to production equipment for steam explosion treatment of micropore structure substances, and the equipment is key treatment equipment of biomass utilization, biochemical engineering, fermentation brewing, solid waste treatment and other industries. The invention provides an instantaneous ejection type steam explosion machine utilizing the steam ejection principle to complete the steam explosion process. Opening of an explosion channel of the steam explosion machine utilizes the steam ejection pressure generated by section difference, thus overcoming the problem of prolonged deflation time along with treatment volume increase in traditional hot blow process. With the increase of the cylinder volume, the section difference also increases accordingly, so that the cylinder ejection velocity can maintain consistent, thus laying the foundation for process scale-up.

Owner:中集竹链科技有限公司

Composite steel pipe with plastic tape winded externally and plastic coated internally, and its processing method

InactiveCN101430029AImprove anti-corrosion performanceImprove performanceCoatingsRigid pipesProcess scaleAbrasive blasting

The invention provides a composite steel pipe which is wound with a plastic tape on the outer wall and sprayed and coated with plastics on the inner wall; the outer wall of the composite steel pipe is provided with a plastic tape winding layer, and the inner wall thereof is provided with a plastic coating layer. A processing method comprises: A. the steel pipe is placed on a roller wheel bracket to rotate, and the inner and the outer walls of the steel pipe are cleaned by spraying sand; B. the steel pipe is placed on the roller wheel bracket to rotate and preheated to 160-180 DEG C; C. the steel pipe is placed on the roller wheel bracket to rotate and is thermally wound with the plastic tape winding layer of 3-5mm at the outer wall; D. the steel pipe is placed on the roller wheel bracket to rotate and is sprayed and coated with the plastic coating layer on the inner wall by utilizing the excess heat of the steel pipe. The invention can form commercial process scale only by using the existing plastic tape extrusion equipment as well as adding two roller wheel brackets and a set of spraying equipment, and can produce any clad pipe having the diameter within the range of 300mm-3000mm. As the outer wall of the steel pipe is wound with PE material which is hard wearing and shockproof, and the inner wall is sprayed with polyurea material that is environment-friendly and has stable performance, the composite steel pipe has good antiseptic property, and the outer wall has very high damage resistance, thus being safe and environment-friendly and greatly improving the production efficiency and the combination property.

Owner:福建纳川管业科技有限责任公司

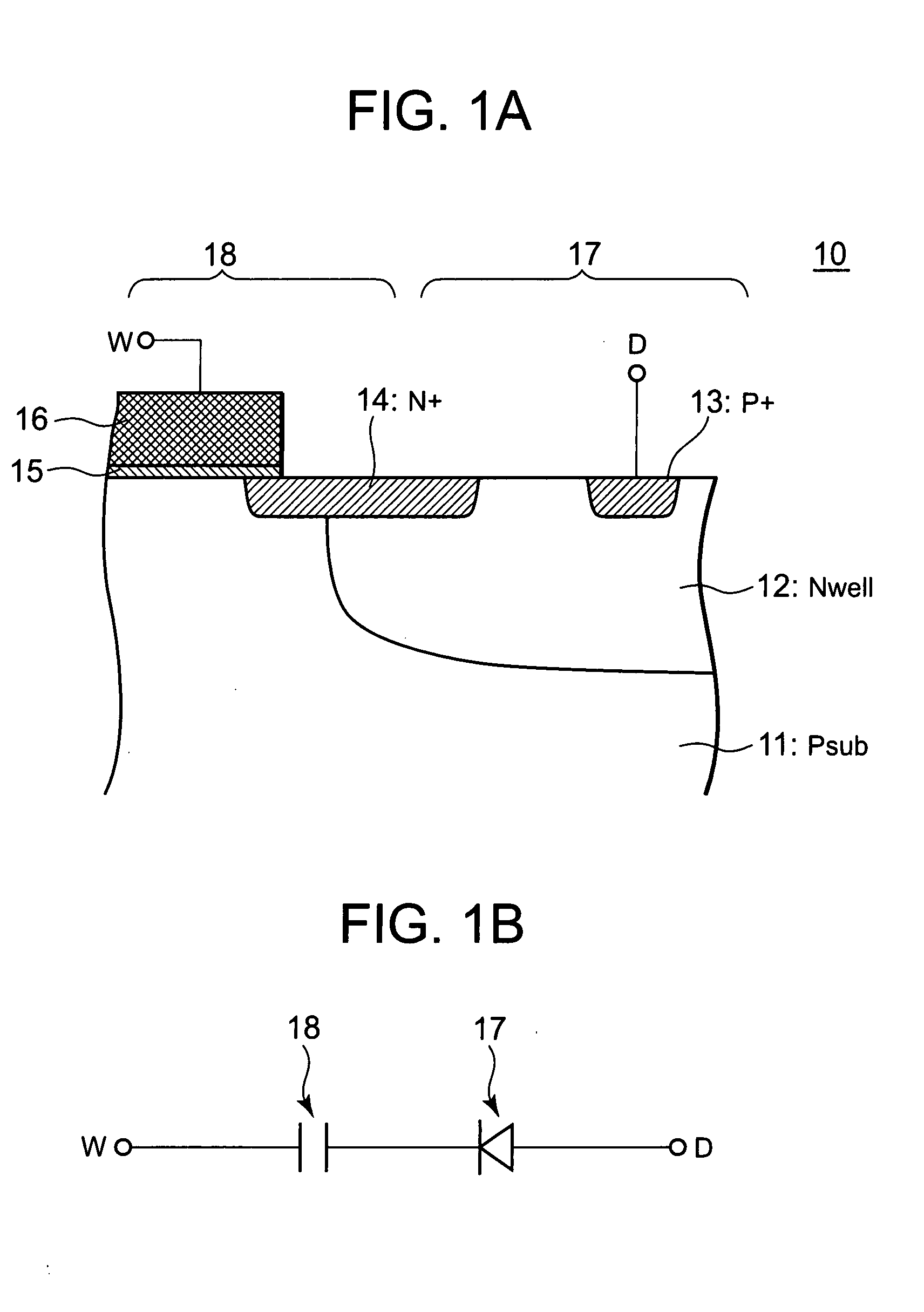

Semiconductor memory device

InactiveUS20080042235A1Improve performanceTransistorSemiconductor/solid-state device detailsProcess scaleDielectric

A semiconductor memory device for reliably inducing a breakdown in the dielectric when utilizing an antifuse to write on the dielectric film even when the process scale has become more detailed. The semiconductor memory device includes an antifuse serving as the memory node, and a current regulator connected in serial with the antifuse. The current controller is comprised of a P-type semiconductor substrate and a reverse-conduction N-type well, a diode coupled to a P+ diffusion substrate of the same conducing type as the P-type semiconductor substrate. The antifuse contains at least a structure where an electrode is formed via a dielectric film on the reverse-conducting N+ diffusion layer and the P-type semiconductor substrate. The N+ diffusion layer is connected to the N-type well of diode, and the diode regulates the current.

Owner:NEC ELECTRONICS CORP

Mixed diamine monomer adopted chlorine-resistant nanofiltration membrane and preparation method therefor

The invention relates to a mixed diamine monomer adopted chlorine-resistant nanofiltration membrane and a preparation method therefor. An aqueous-phase monomer is prepared through mixing 2,2'-di(1-hydroxyl-1-trifluoromethyl-2,2,2-trifluoroethyl)-4,4'-methylene dianiline with piperazine. The preparation method comprises the following steps: (1) adjusting the temperature and humidity of an experimental environment; (2) carrying out basement membrane pretreatment; (3) preparing an aqueous-phase mixed monomer solution and an organic-phase solution; (4) carrying out an interface polymerization reaction; (5) carrying out heat treatment; (6) preparing an active chlorine solution; and (7) integrally submerging the prepared nanofiltration membrane into the active chlorine solution for oxidation treatment, thereby obtaining the final mixed diamine monomer adopted chlorine-resistant nanofiltration membrane. The mixed diamine monomer adopted chlorine-resistant nanofiltration membrane and the preparation method therefor have the advantages that the process is simple, process scale-up is facilitated, and the range of choice of basement membranes is enlarged, so that the industrial actual application value is remarkable.

Owner:EAST CHINA UNIV OF SCI & TECH

Method for ultrasound-assisted two-aqueous-phase extraction of resveratrol

InactiveCN105039426AHigh extraction efficiency at one timeLess organic solventOrganic chemistryOrganic compound preparationHydrolysateProcess scaling

Owner:JIANGNAN UNIV

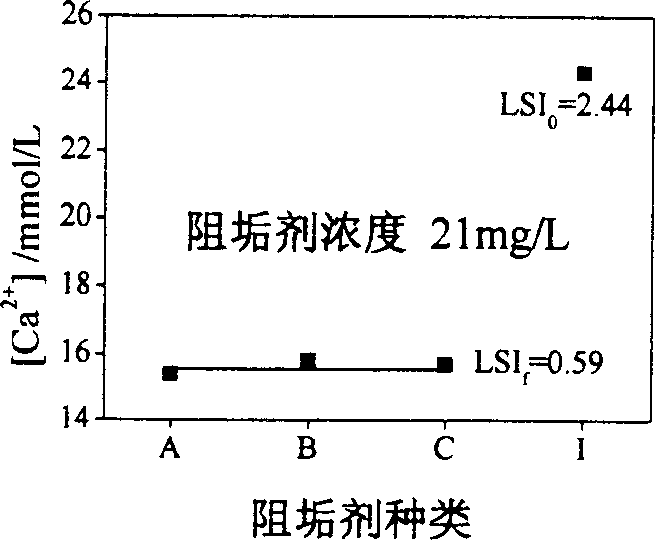

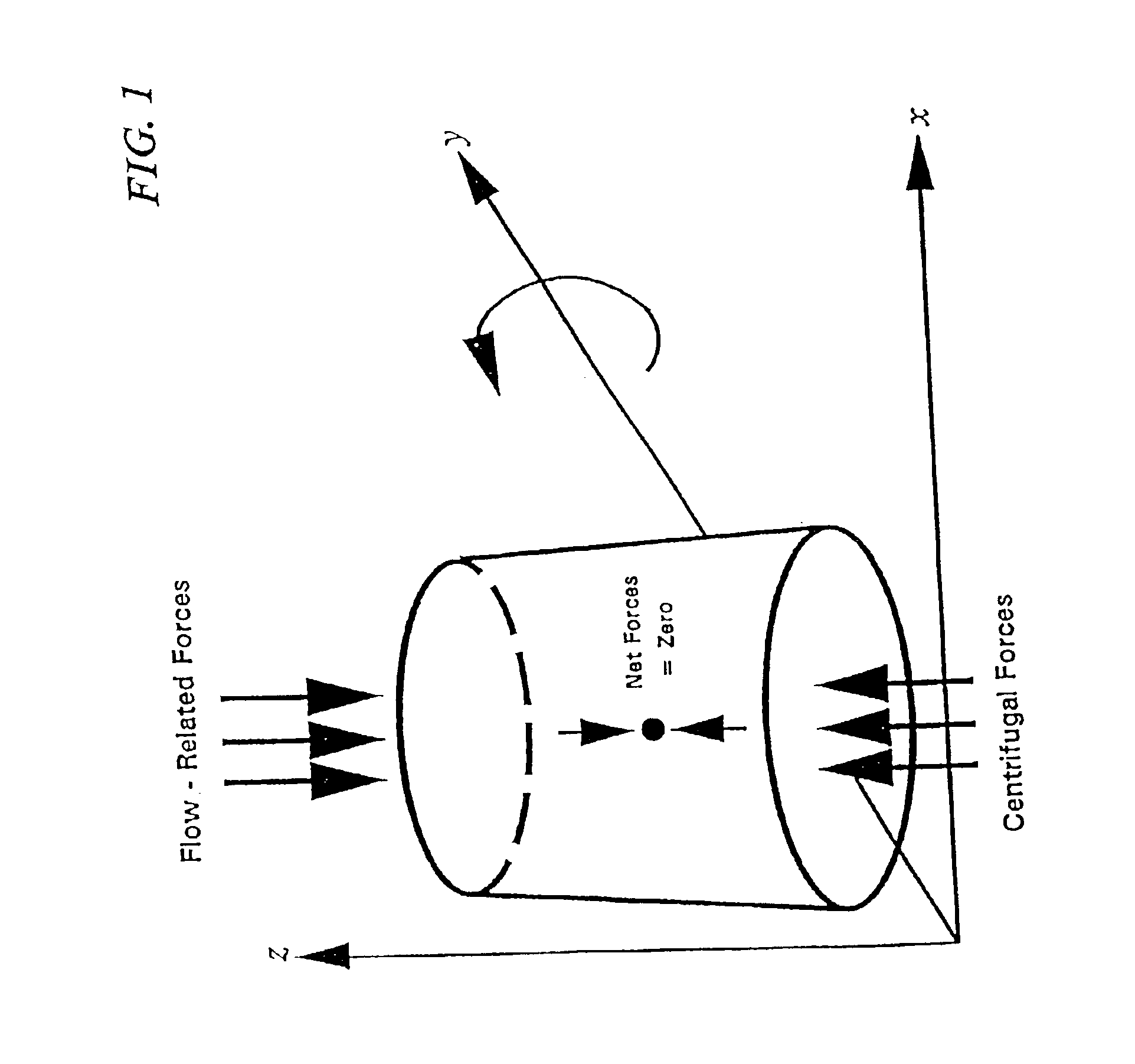

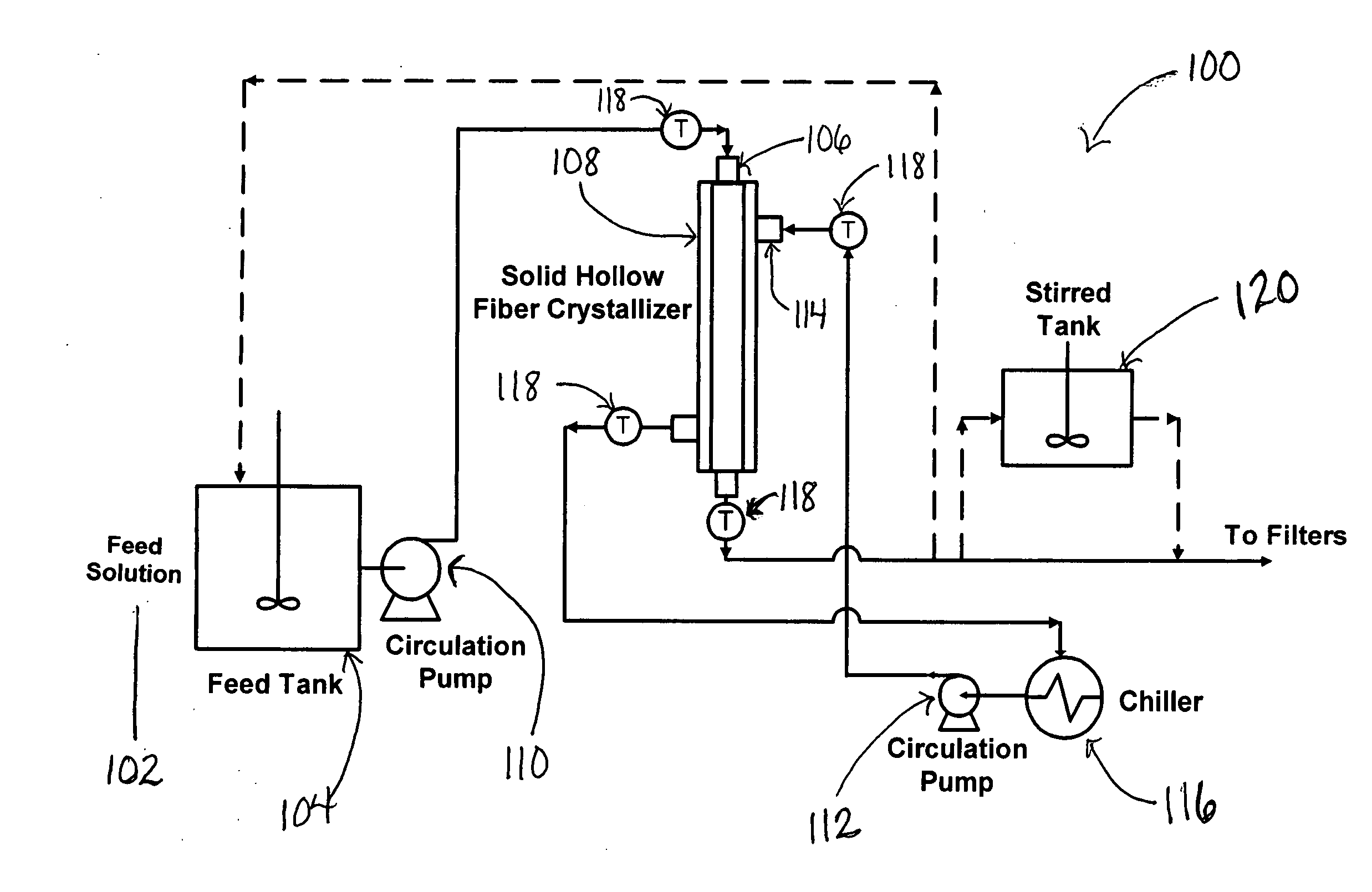

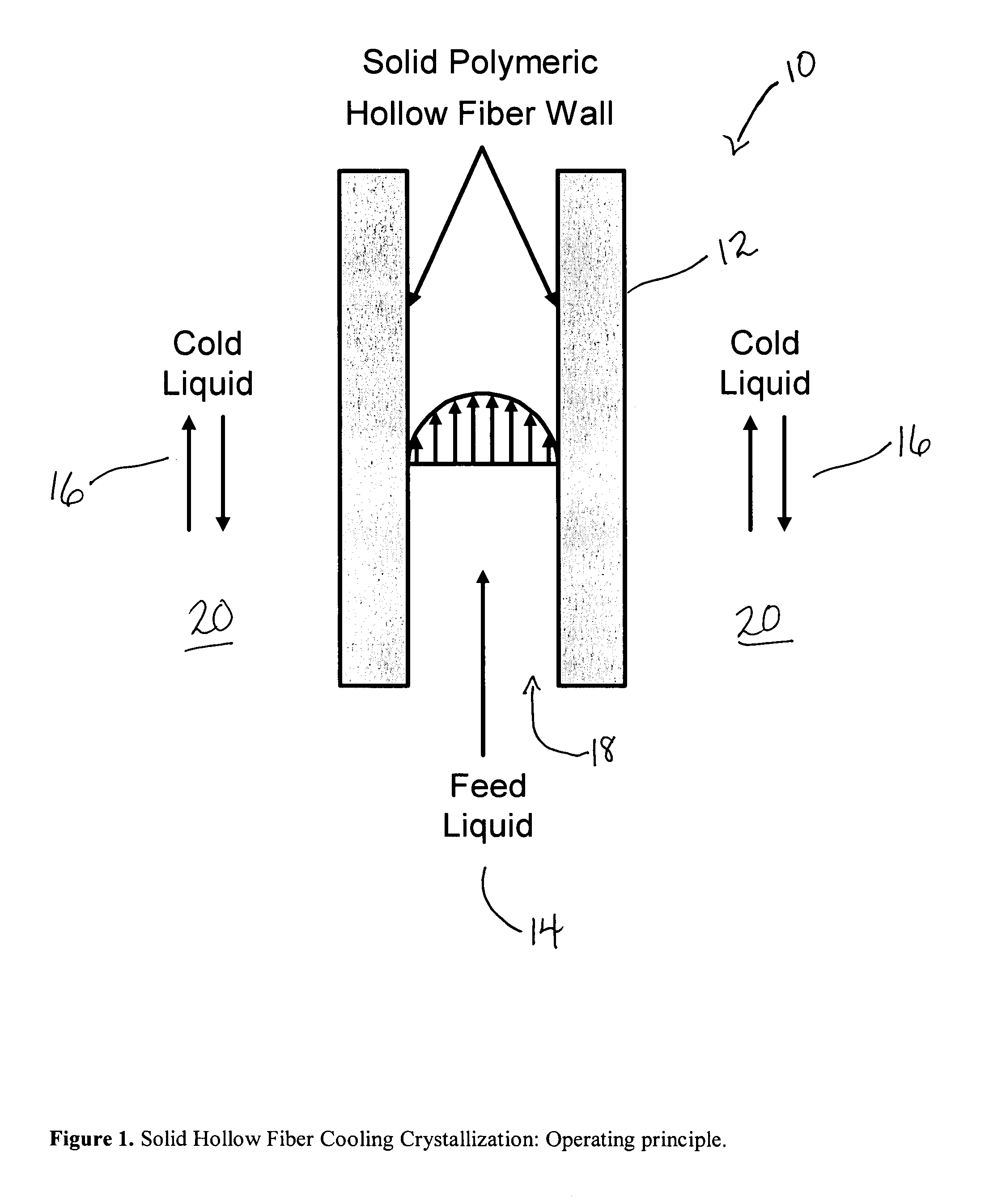

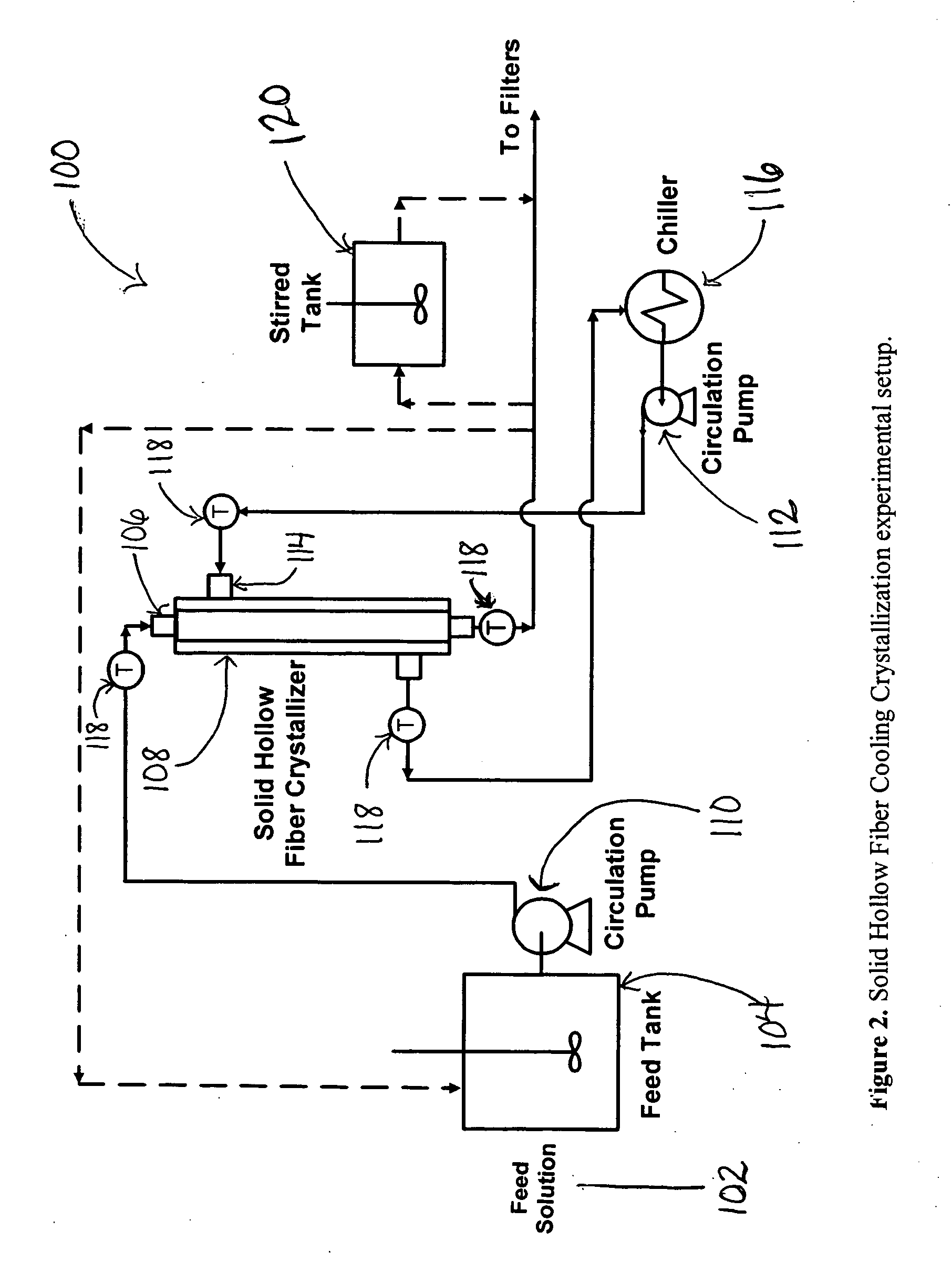

Solid hollow fiber cooling crystallization systems and methods

InactiveUS20060096525A1Increase nucleation rateNarrow crystal size distributionAfter-treatment apparatusPolycrystalline material growthFiberHollow fibre

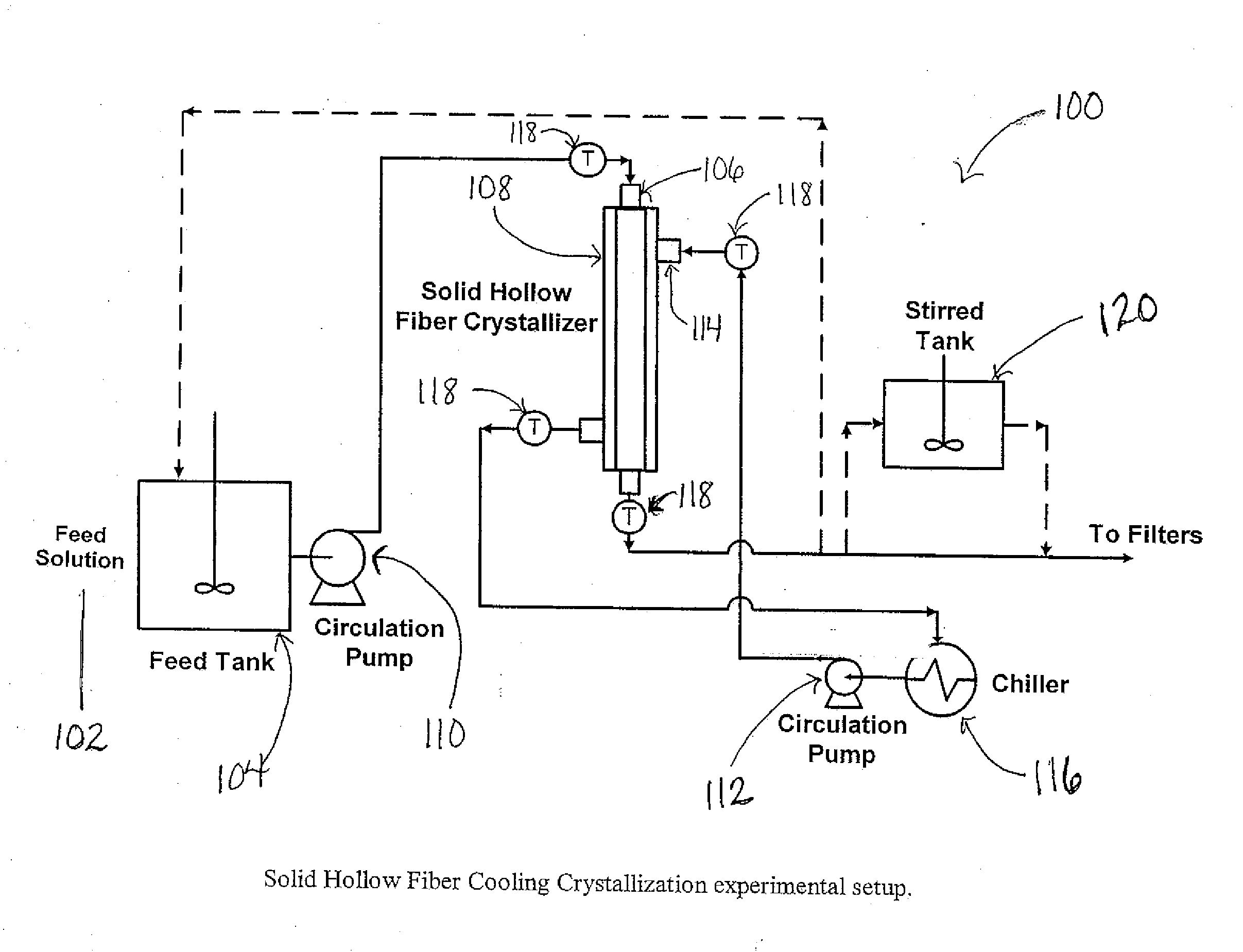

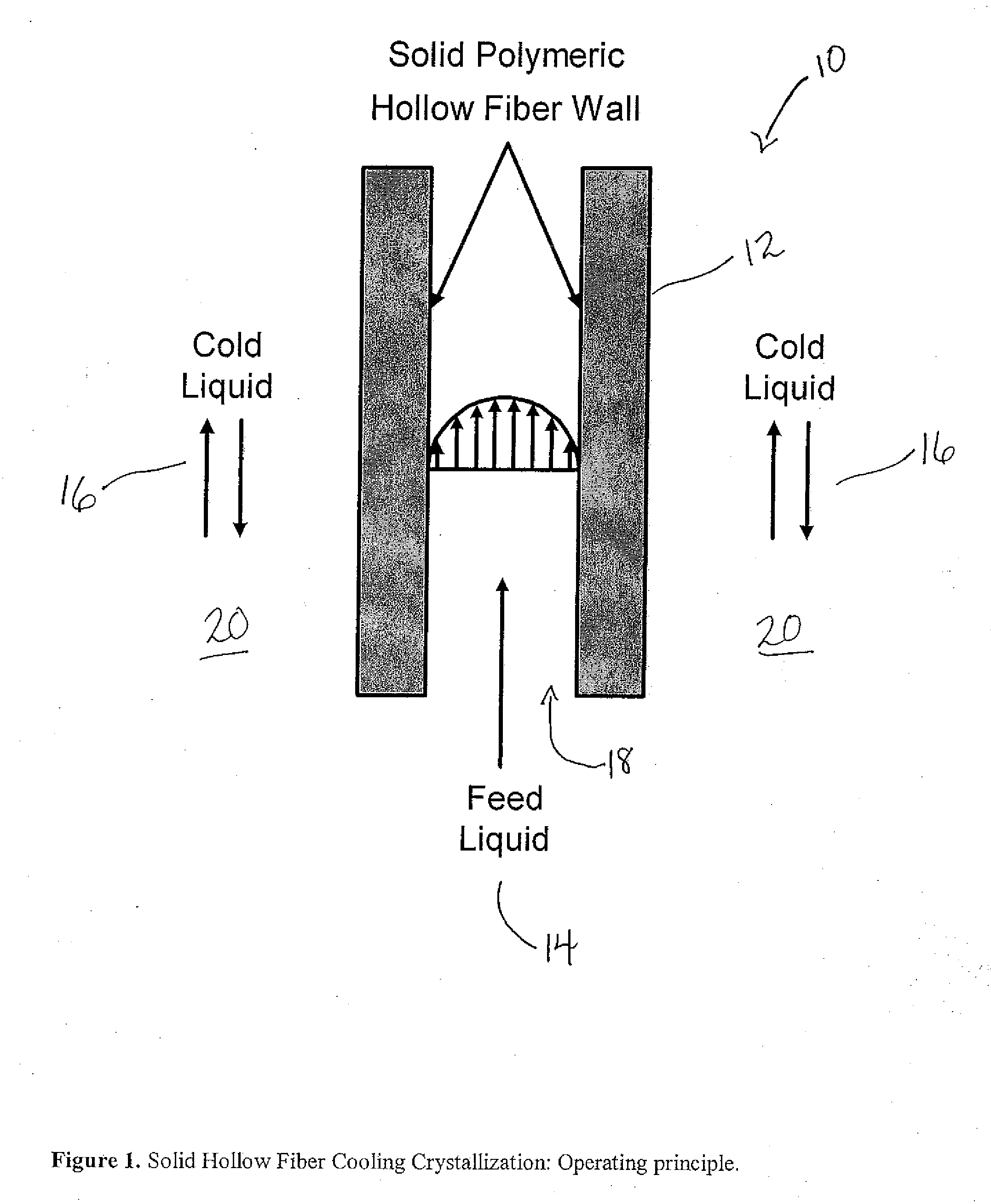

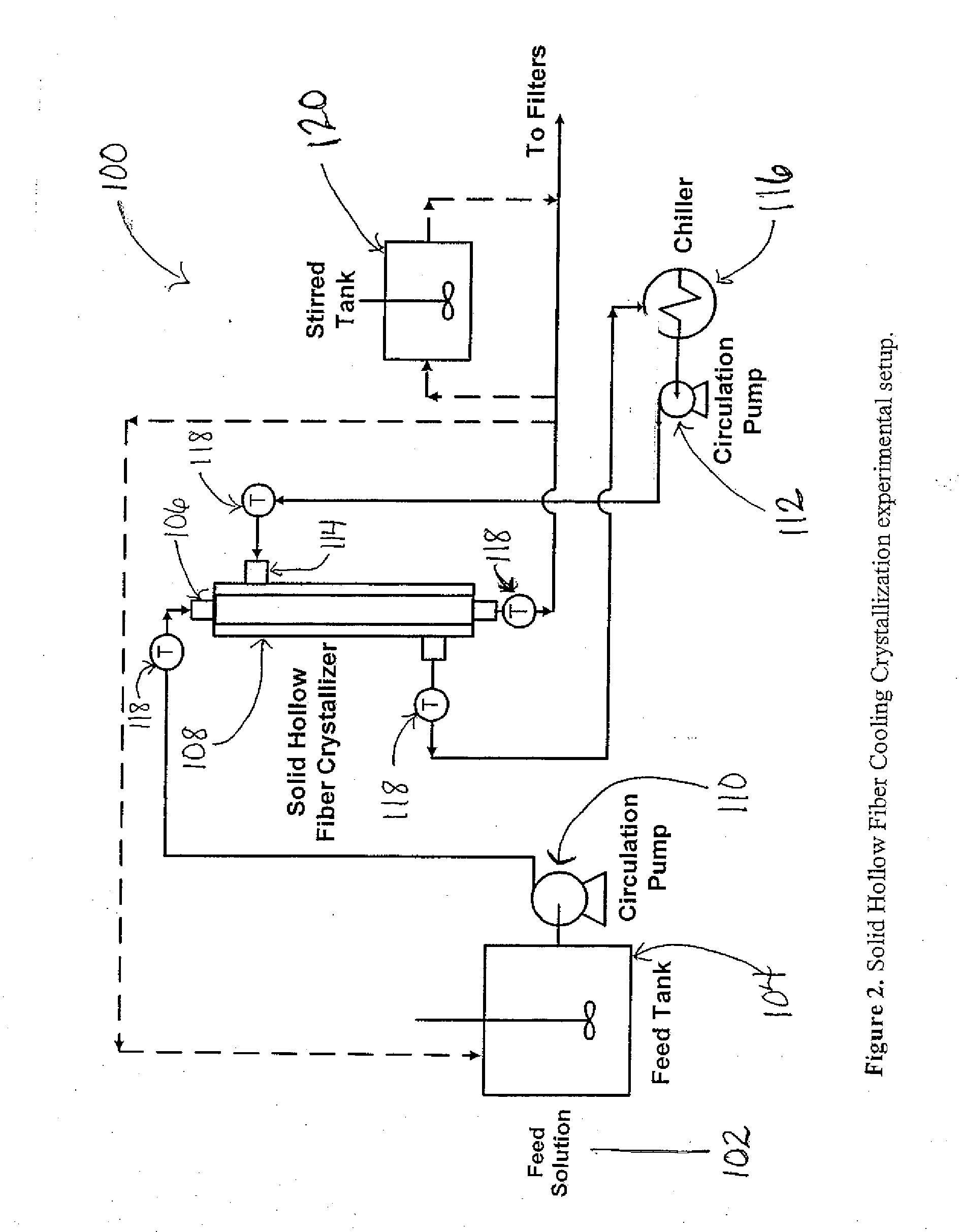

A solid hollow fiber cooling crystallizer and method for crystallizing aqueous and organic solutions are provided. The solid hollow fiber crystallizer (SHFC) for carrying out cooling crystallization of inorganic / organic microsolutes / macrosolutes from solution generally includes a bundle of non-porous hollow fibers mounted within a shell where a feed solution for crystallization flows through the lumen side of the hollow fibers and a cooling solution flows through the shell side to form nuclei and subsequently crystals in the feed solution at a temperature below its saturation temperature. The solid hollow fiber crystallizer may be combined with a mixing device, such as a completely stirred tank or static mixer, to further effectuate crystallization. The solid hollow fiber crystallizer may be operated in a number of modes including feed recycle mode, once through mode, SHFC-in-line static mixer in series mode, and SHFC-CST in series mode. The advantages of solid hollow fiber cooling crystallization in comparison to conventional crystallization processes include improved temperature control between crystallizing solution and coolant, higher nucleation rates, improved control of crystal size and crystal size distribution, smaller crystal size, capability for decoupling crystal nucleation and crystal growth, decreased fouling of process equipment, and improved process scale-up.

Owner:NEW JERSEY INSTITUTE OF TECHNOLOGY

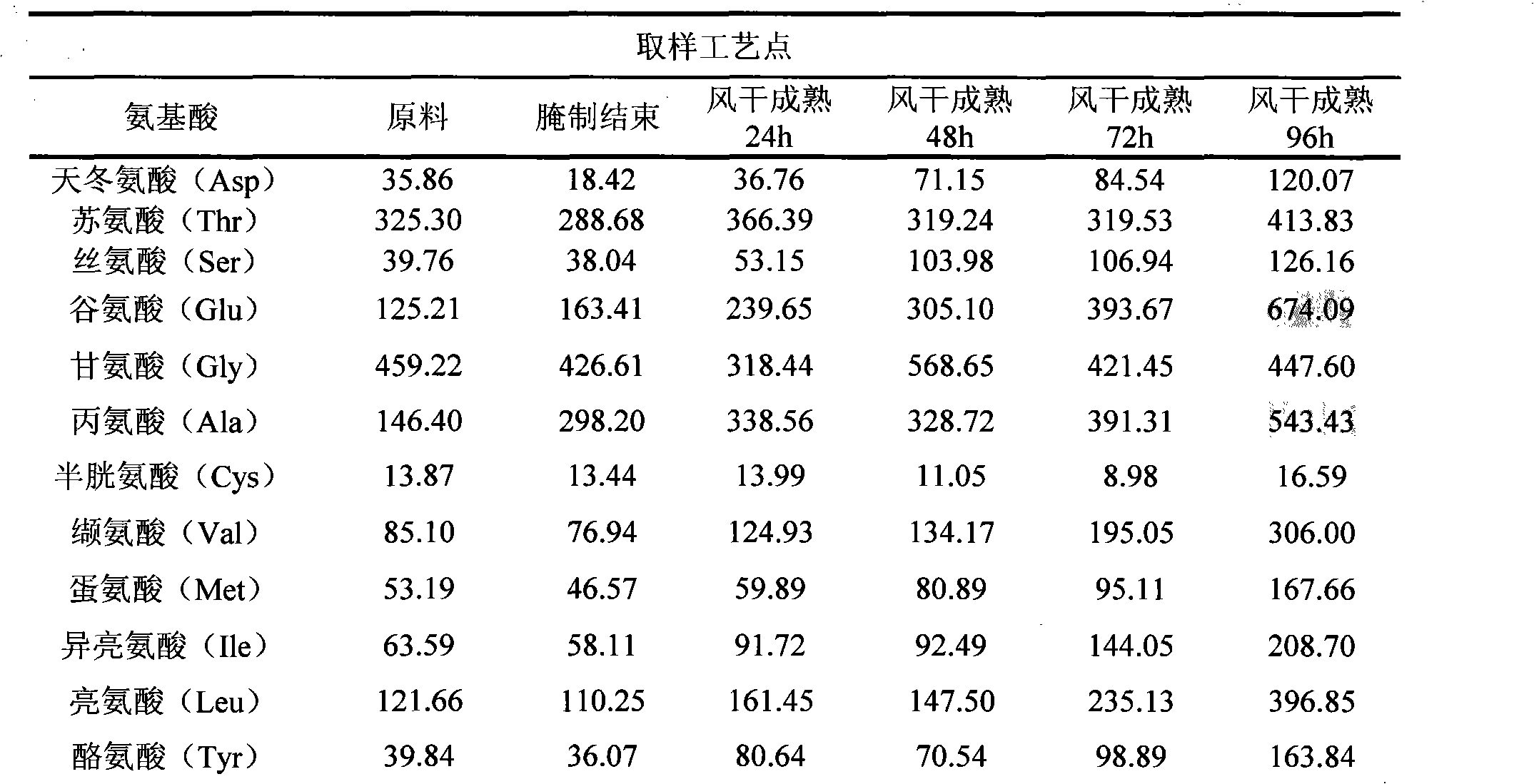

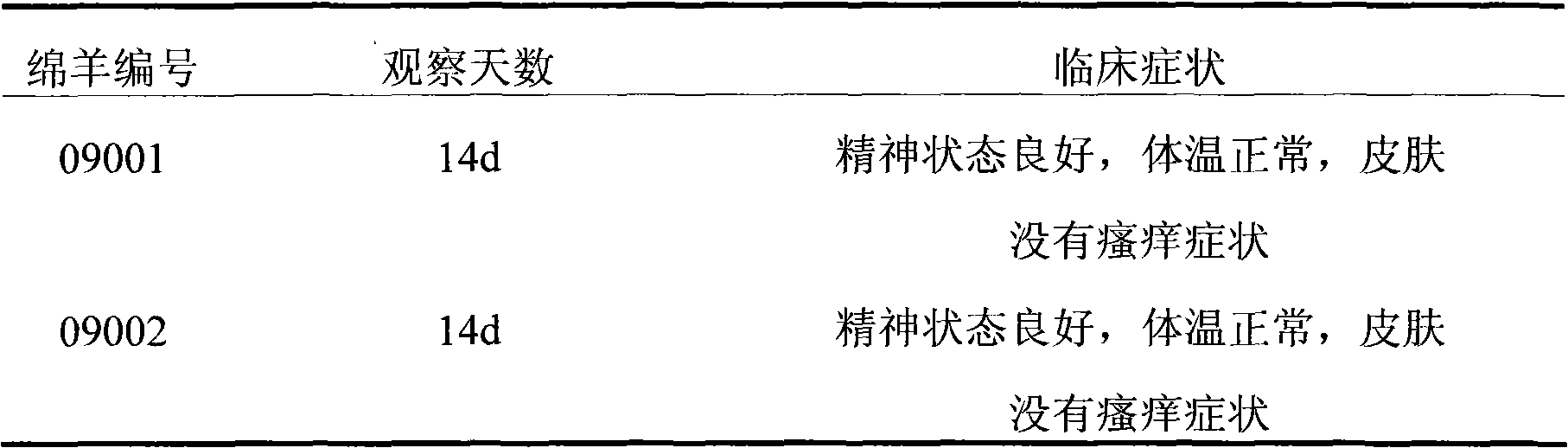

New technology for salting, air drying and maturing weever

ActiveCN101779697AIncrease endogenous proteaseHigh activityClimate change adaptationMeat/fish preservation using acidsProcess scalingHydrolysis

The invention relates to new technology for salting, air drying and maturing weever and belongs to the technical field of deep processing for aquatic products. The new technology for salting, air drying and maturing the weever comprises the following steps: washing blood on the surface of fresh weever and draining; applying 3.5 to 5.5 percent of salt on the surface of the weever uniformly and salting the weever for 45 to 55 hours under the conditions that the temperature is between 0 and 4 DEG and the RH is (83+ / -8) percent; and raising the temperature gradually for air drying and maturing the weever for 3 to 5 days under the conditions that the humidity is 65 to 88 percent (RH), and the temperature is between 15 and 31 DEG to ensure that the water content of the air-dried and matured weever products is in a range of 53 to 60 percent, and the salt content is in a range of 2.5 to 3.3 percent. In the new technology for salting, air drying and maturing the weever, the corrosion initiated by the growth of microbes is suppressed by regulating and controlling the temperature and humidity of the air drying and maturing process, and hydrolysis and oxidation of proteins and fat in muscles are quickened and the flavor-forming speed is improved. Therefore, the product maintains the flavor quality characteristics of the traditional air-dried fishes, the limit of traditional seasonal production is broken through, and mass production of modern technology for the air-dried fish products is realized.

Owner:CHANGSHU YIHAO FOOD PACKAGING MATERIAL TECH +1

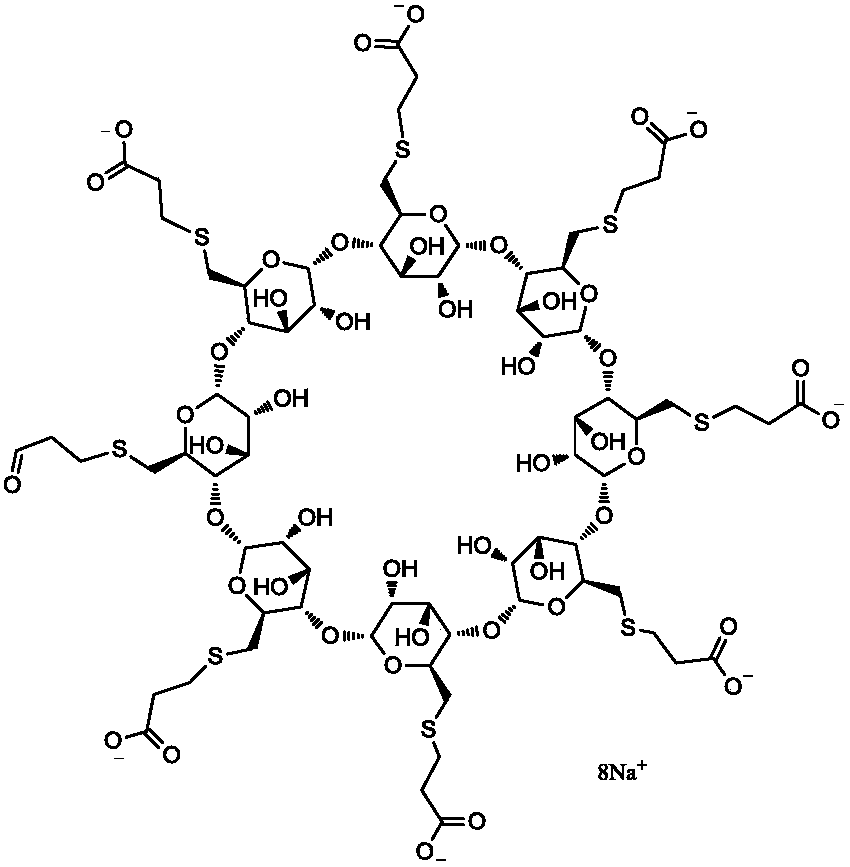

Purifying method of sugammadex sodium

The invention provides a purifying method of sugammadex sodium. The purifying method specially comprises the following steps: putting a sugammadex sodium crude product to a chromatography column usingsilica gel C18 as a filling, and performing purifying, wherein the purity of the obtained sugammadex sodium is greater than 99%. Through adoption of the purifying method disclosed by the invention, the quality of the products can be guaranteed, and the purifying method is suitable for process scaled production.

Owner:JIANGSU HENGRUI MEDICINE CO LTD

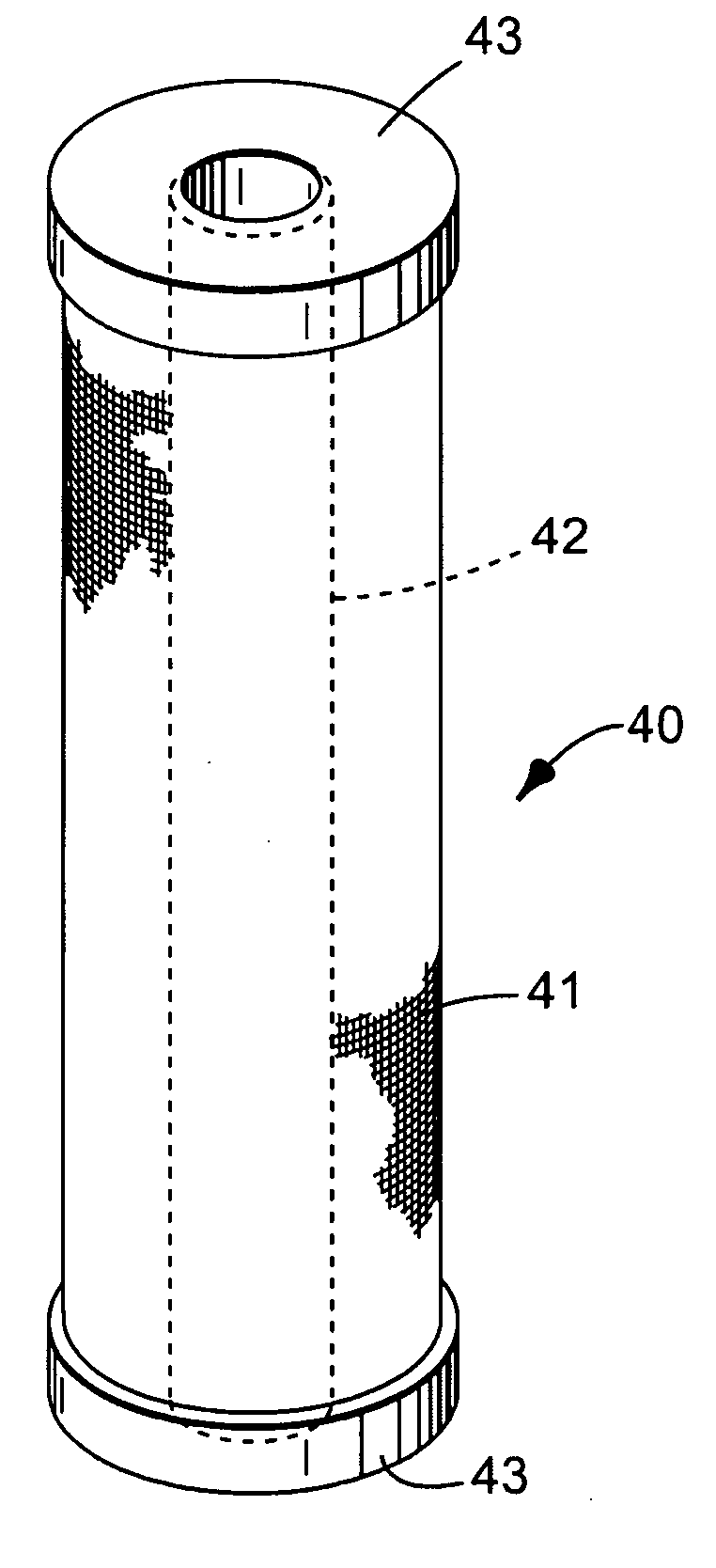

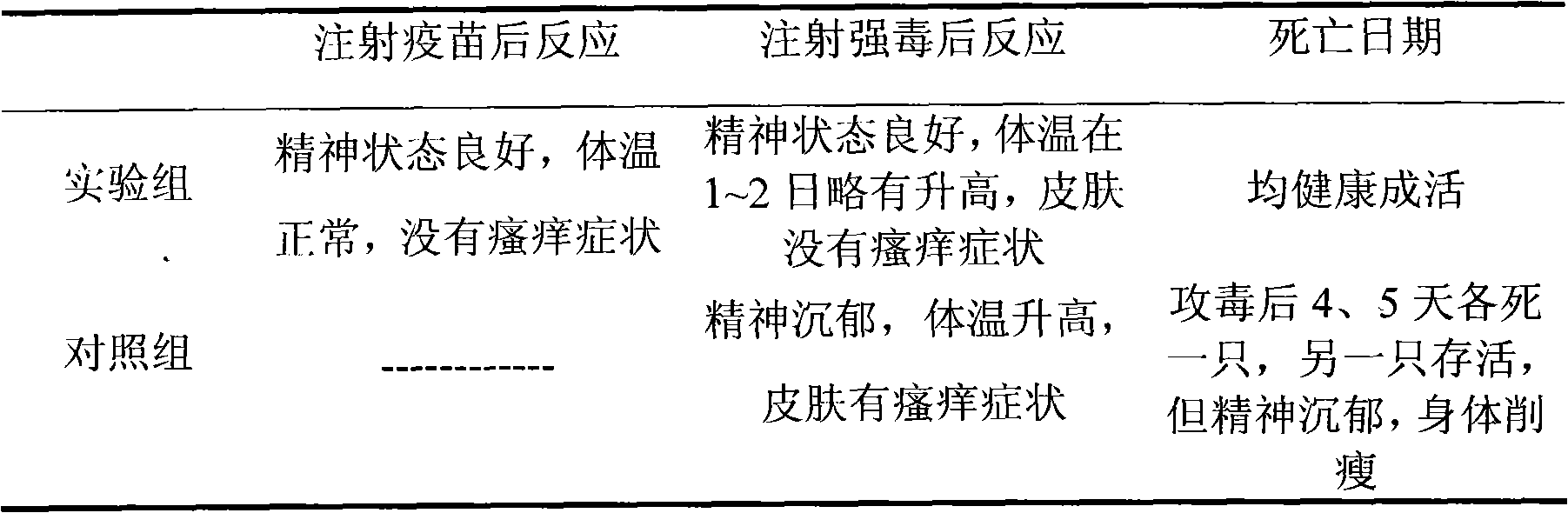

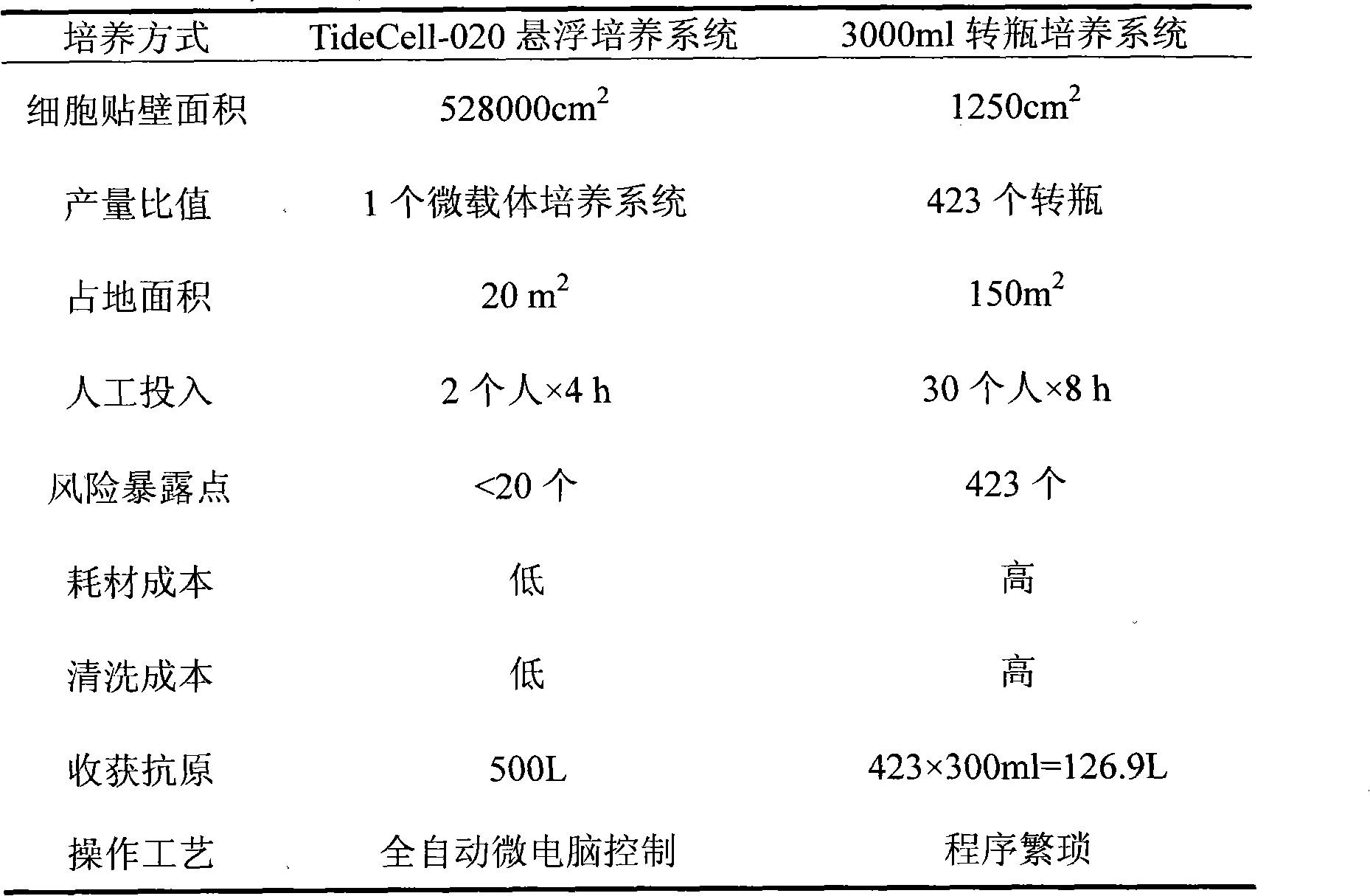

Method for mass production of pseudorabies virus vaccine

InactiveCN101804203ASolve the problems of low production output, high labor intensity and high costExpand production scaleAntiviralsTissue/virus culture apparatusFiberPolyester

The invention discloses a method for mass production of pseudorabies virus vaccine, comprising the following steps: (a) adding netty polyester fiber which serves as a carrier into a bioreactor provided with a tide type micro-carrier suspension culture system and inoculating cells for producing vaccine; (b) inoculating pseudorabies virus vaccine when the culture cell grows to a certain intensity, so that the cells are infected by the pseudorabies virus vaccine; (c) reproducing the virus in great numbers under appropriate conditions; (d) harvesting the virus when cytopathic rate reaches above 70%; (e) carrying out freeze thawing on the harvested virus for once or twice to lead the cells to completely come off and disperse and then adding freeze-drying protective agent, evenly mixing the mixture, packaging the mixture in fixed volume and freeze-drying.The method of the invention has the advantages of good stability, explicit process control indicators, good controllability, easy operation, large process scale and the like.

Owner:PU LIKE BIO ENG

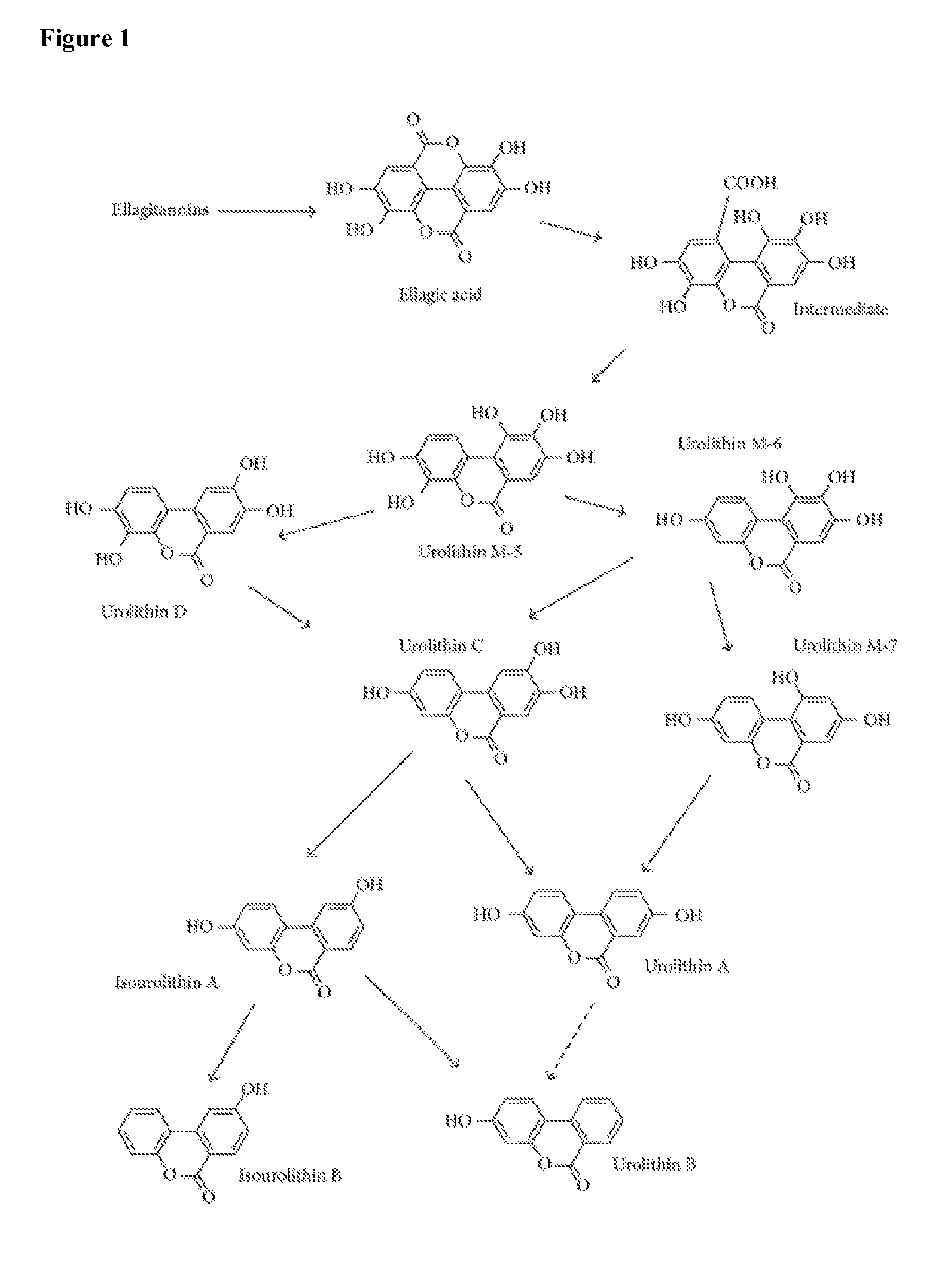

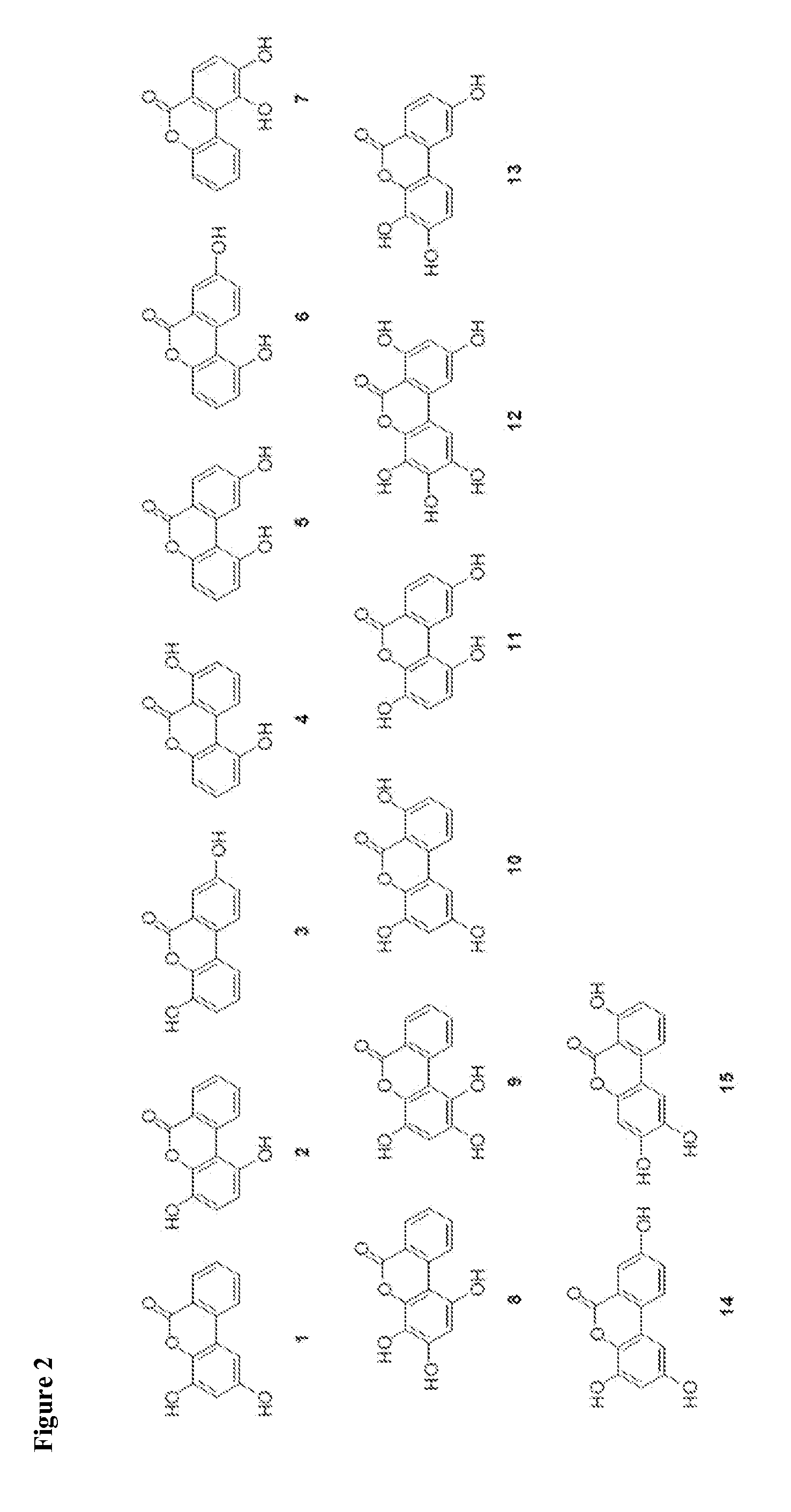

Process-Scale Synthesis of Urolithins

Disclosed is a method of preparing a urolithin, or an intermediate or analog thereof, having a dibenzo[b,d]pyran-6-one core. The method is especially advantageous for the large-scale preparation of urolithins or intermediates or analogs thereof. The method may optionally include the preparation of a urolithin, or an intermediate or analog thereof, as a pharmaceutically acceptable salt.

Owner:AMAZENTIS

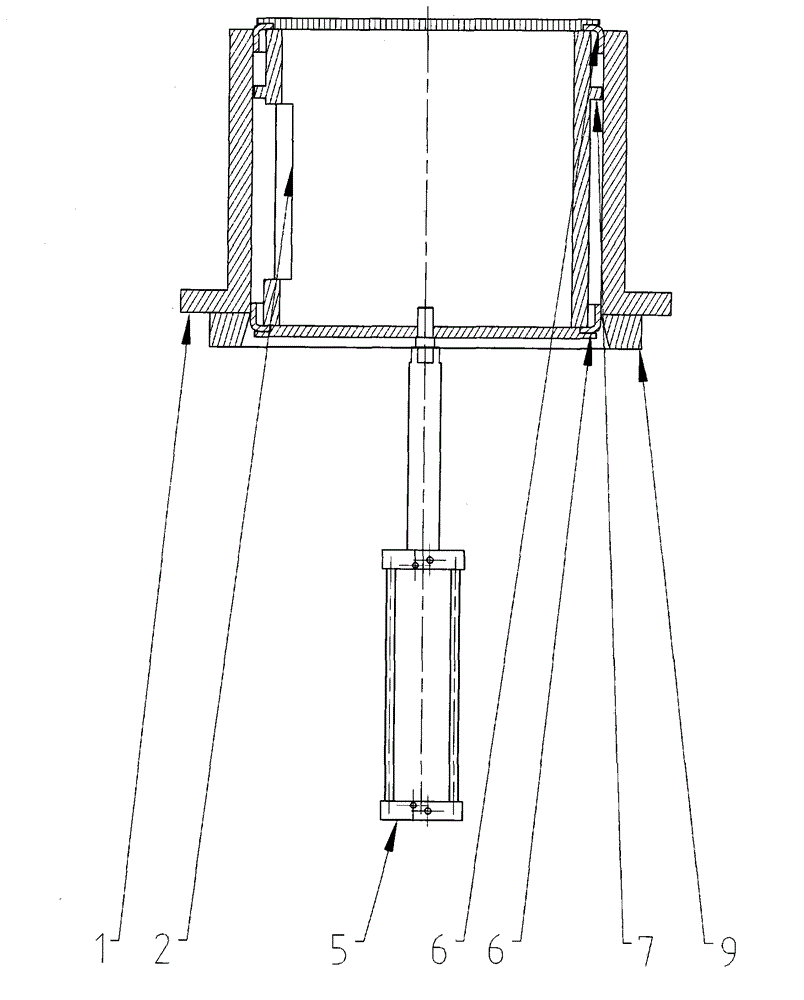

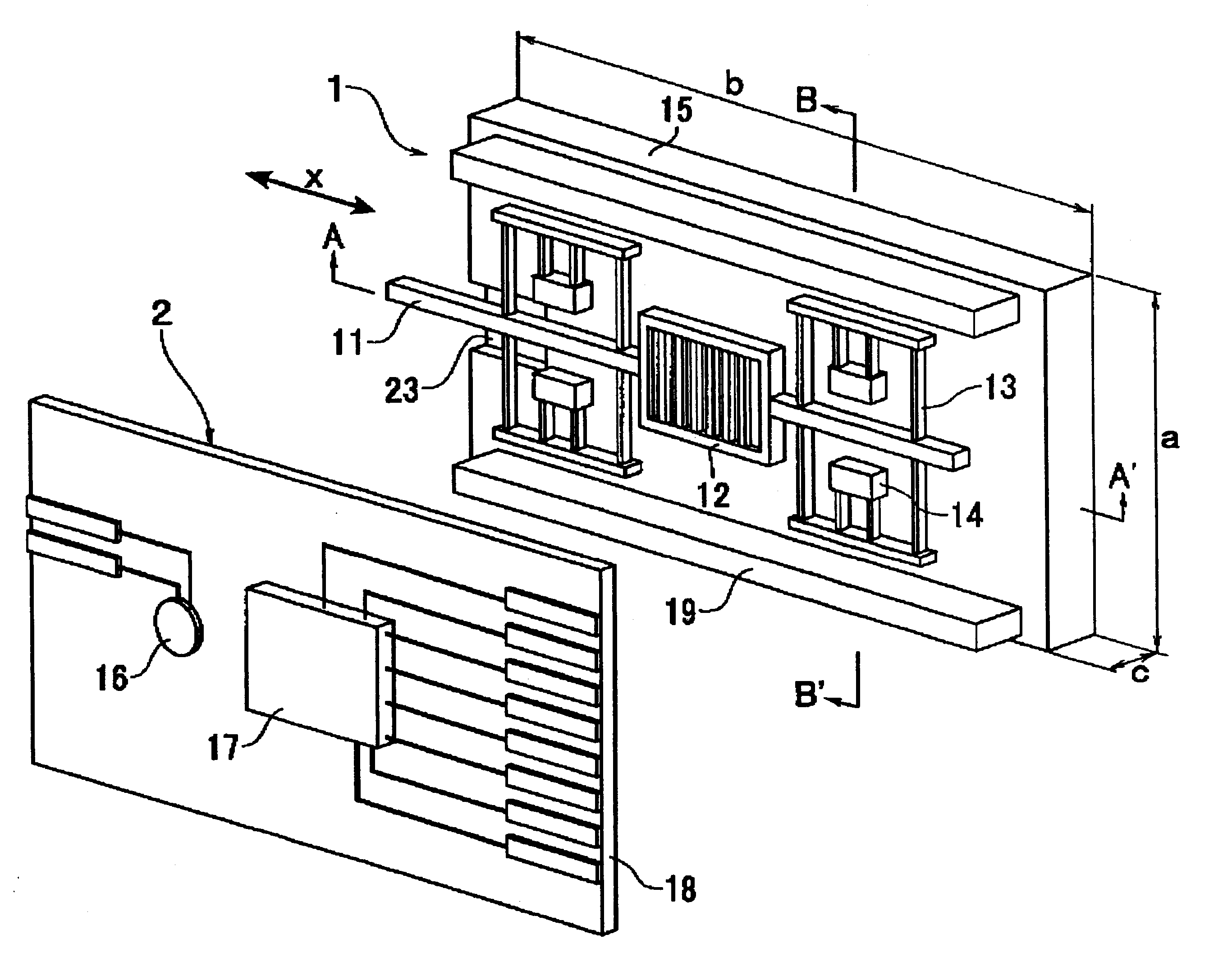

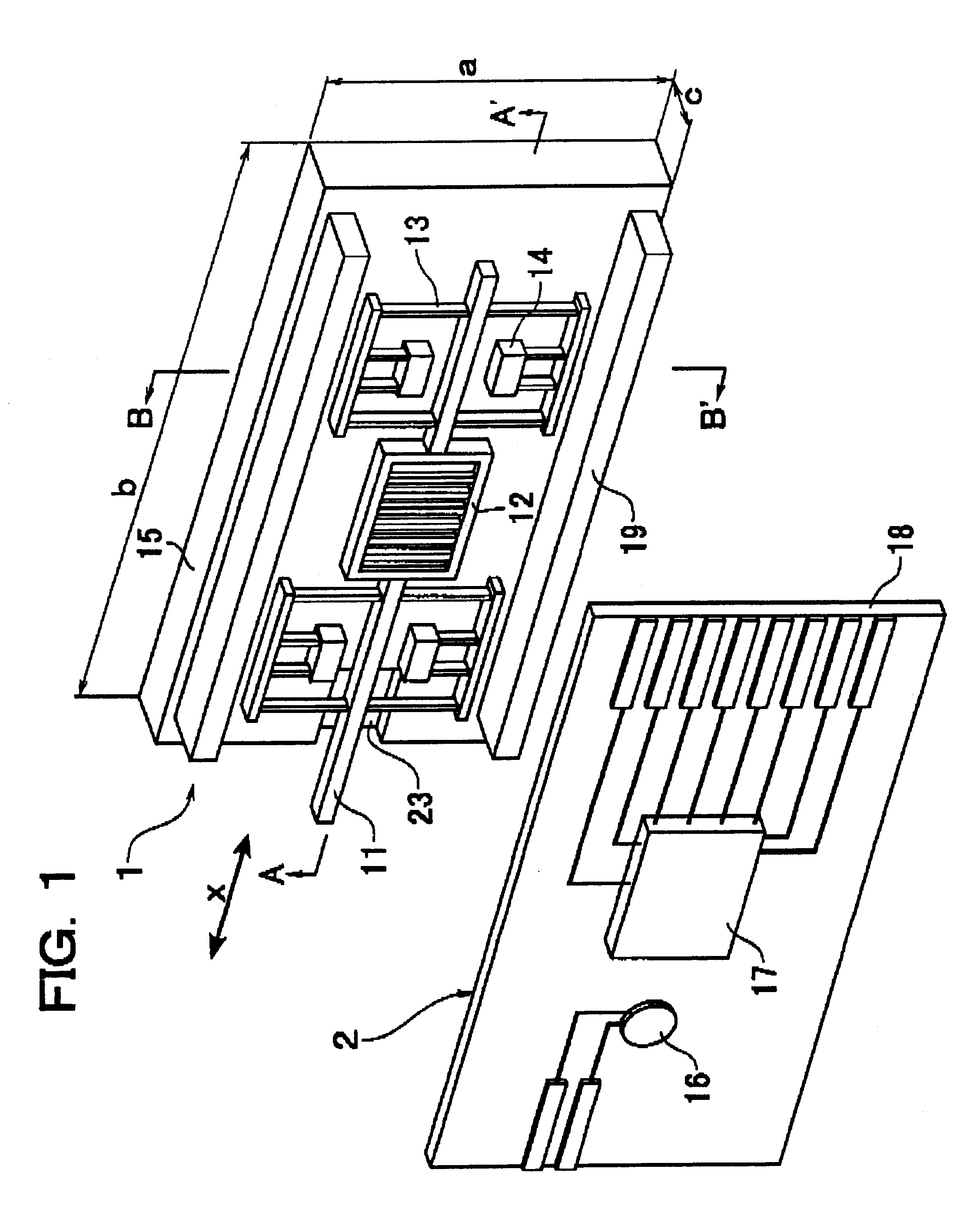

Scale member, method of producing the same and displacement measuring apparatus therewith

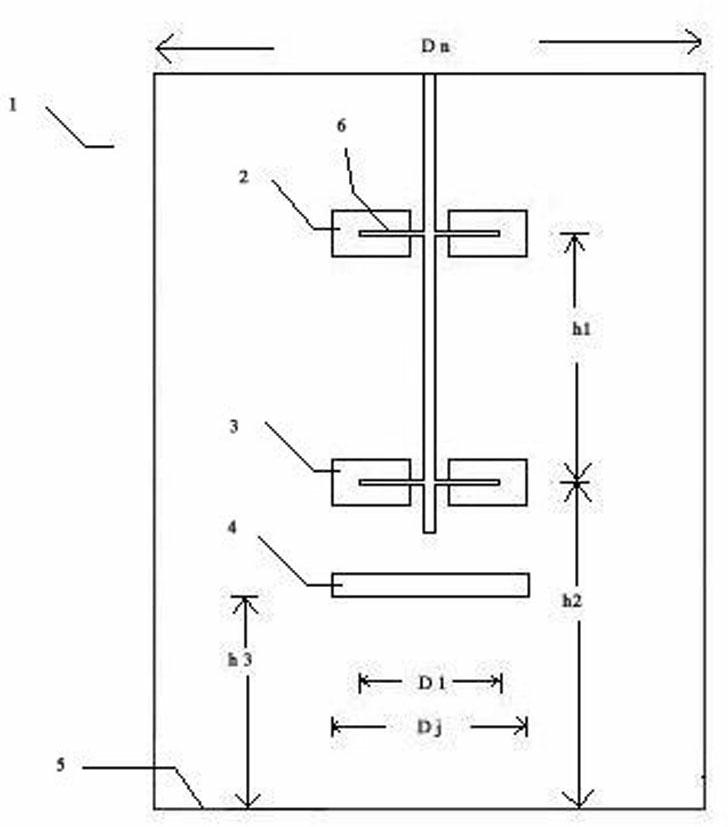

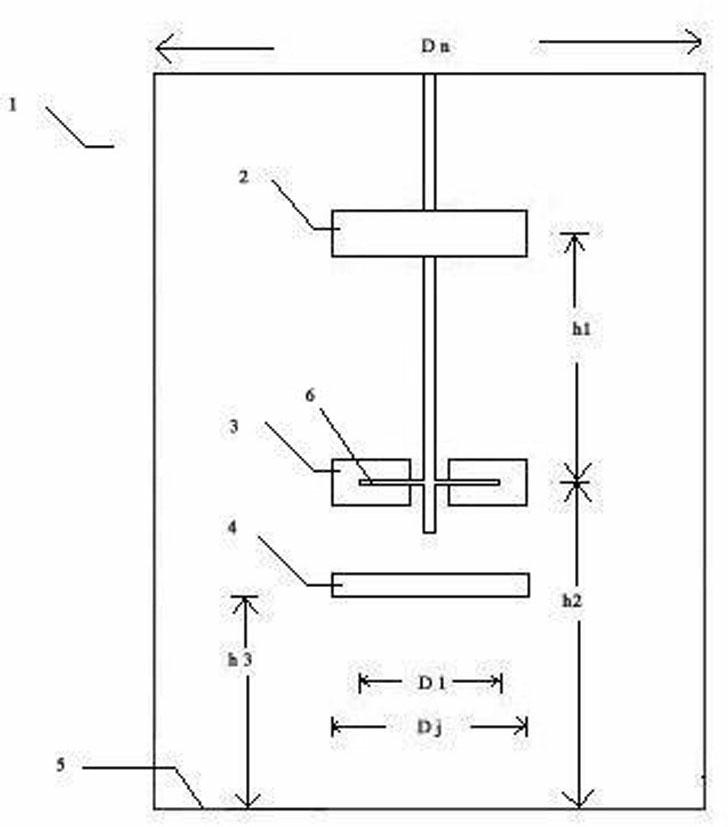

There is provided a displacement measuring apparatus efficiently productive and easily applicable to high precise measurement of displacement with contact probe detection for hardly-measurable works in the art such as micro-works and deep parts in complicated structures. A scale member includes a spindle and a scale both supported by a parallel leaf spring movable on a scale substrate. The spindle is arranged in coaxial with a measurement axis in the scale member. The L & S slit-processed scale is integrated with the spindle and supported by the parallel leaf spring to move together with the spindle along the measurement axis. The spindle, scale and parallel leaf spring are coupled to the scale substrate interposing an anchor of the parallel leaf spring therebetween. The spindle, scale and parallel leaf spring are formed in an integral structure and only the anchor contacts the scale substrate while the spindle, scale and parallel leaf spring slightly float from the scale substrate. A displacement sensor comprises a sensor substrate arranged opposite to the scale substrate. A light source and a photosensitive device are located on the sensor substrate.

Owner:MITUTOYO CORP

Method for improving dissolution rate of ezetimibe tablet

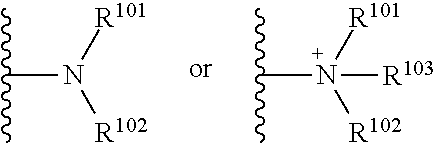

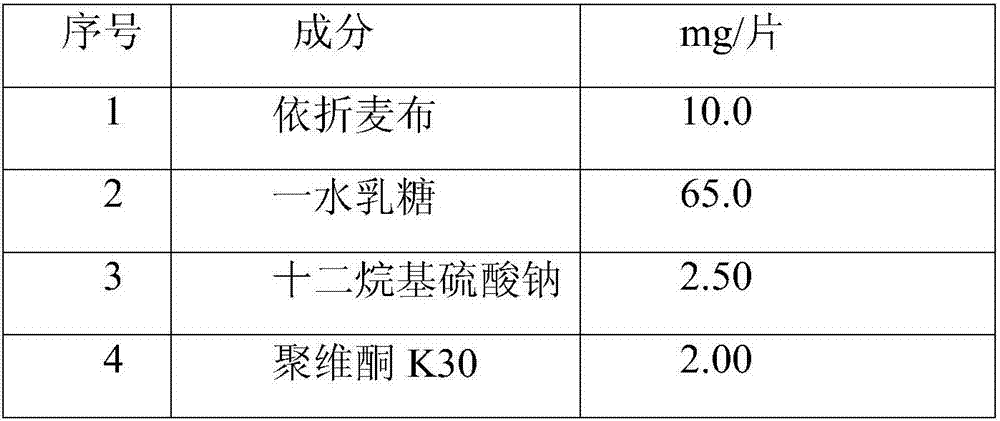

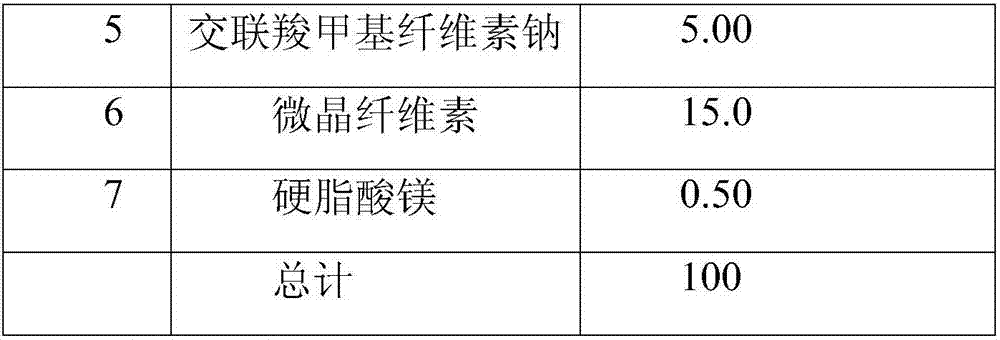

InactiveCN107397732ALower requirementImprove securityOrganic active ingredientsMetabolism disorderProcess scaleProcess scaling

Belonging to the field of pharmaceutical preparations, the invention in particular relates to a method for improving the dissolution rate of an ezetimibe tablet. The method uses ordinary air jet comminution to acquire bulk drugs, and employs ethanol of appropriate concentration to replace purified water for granulation, thus obtaining a product with a dissolution behavior consistent with ezetimibe tablet. The preparation technology has lowered requirement for bulk drugs, can acquire bulk drugs meeting the preparation requirements only by means of ordinary air jet comminution, is easy for process scale-up, and guarantees smooth preparation production.

Owner:CHONGQING HUAPONT PHARMA

Solid Hollow Fiber Cooling Crystallization Systems and Methods

InactiveUS20090000080A1Improve cooling effectEffective decouplingFrom normal temperature solutionsSolvent extractionFiberHollow fibre

A solid hollow fiber cooling crystallizer and method for crystallizing aqueous and organic solutions are provided. The solid hollow fiber crystallizer (SHFC) for carrying out cooling crystallization of inorganic / organic microsolutes / macrosolutes from solution generally includes a bundle of non-porous hollow fibers mounted within a shell where a feed solution for crystallization flows through the lumen side of the hollow fibers and a cooling solution flows through the shell side to form nuclei and subsequently crystals in the feed solution at a temperature below its saturation temperature. The solid hollow fiber crystallizer may be combined with a mixing device, such as a completely stirred tank or static mixer, to further effectuate crystallization. The solid hollow fiber crystallizer may be operated in a number of modes including feed recycle mode, once through mode, SHFC-in-line static mixer in series mode, and SHFC-CST in series mode. The advantages of solid hollow fiber cooling crystallization in comparison to conventional crystallization processes include improved temperature control between crystallizing solution and coolant, higher nucleation rates, improved control of crystal size and crystal size distribution, smaller crystal size, capability for decoupling crystal nucleation and crystal growth, decreased fouling of process equipment, and improved process scale-up.

Owner:NEW JERSEY INSTITUTE OF TECHNOLOGY

Recovering and separation method for iodine in cefepime waste liquid

The invention discloses a recovering and separation method for iodine in cephalosporin medicine waste liquid. The method comprises the following steps that alkali is added into the cephalosporin medicine waste liquid, methyl alcohol, acetone and alkali liquid are extracted and separated, the alkali liquid is circularly heated and hydrolyzed, and after filtering, the alkali liquid is conveyed intoan acidizing groove for acidification; organic matter which cannot be dissolved in water is removed through standing and layering, then a water-phase oxidation reaction tower oxidizes I- into IO3-, the alkali liquid is introduced in a reduction kettle, and the IO3- is reduced into I2; simple substance iodine is separated out, after filtering and recovering, crude iodine is obtained, and heating, sublimation and condensation continue to obtain the simple substance iodine. According to the method, precious metal iodine in the waste liquid is recovered, through alkali addition for hydrolyzing andacidizing, iodine exists in the waste liquid in a free state, and the organic matter which cannot be dissolved in water is separated out. According to the method, it is not necessary to strictly control the dosage of an oxidizing agent, the operation is simple and safe, the rate of recovering iodine reaches 98.5% or above, and the method is suitable for process scale-up production.

Owner:SHANDONG LUOXIN PARMACEUTICAL GROUP STOCK CO LTD +2

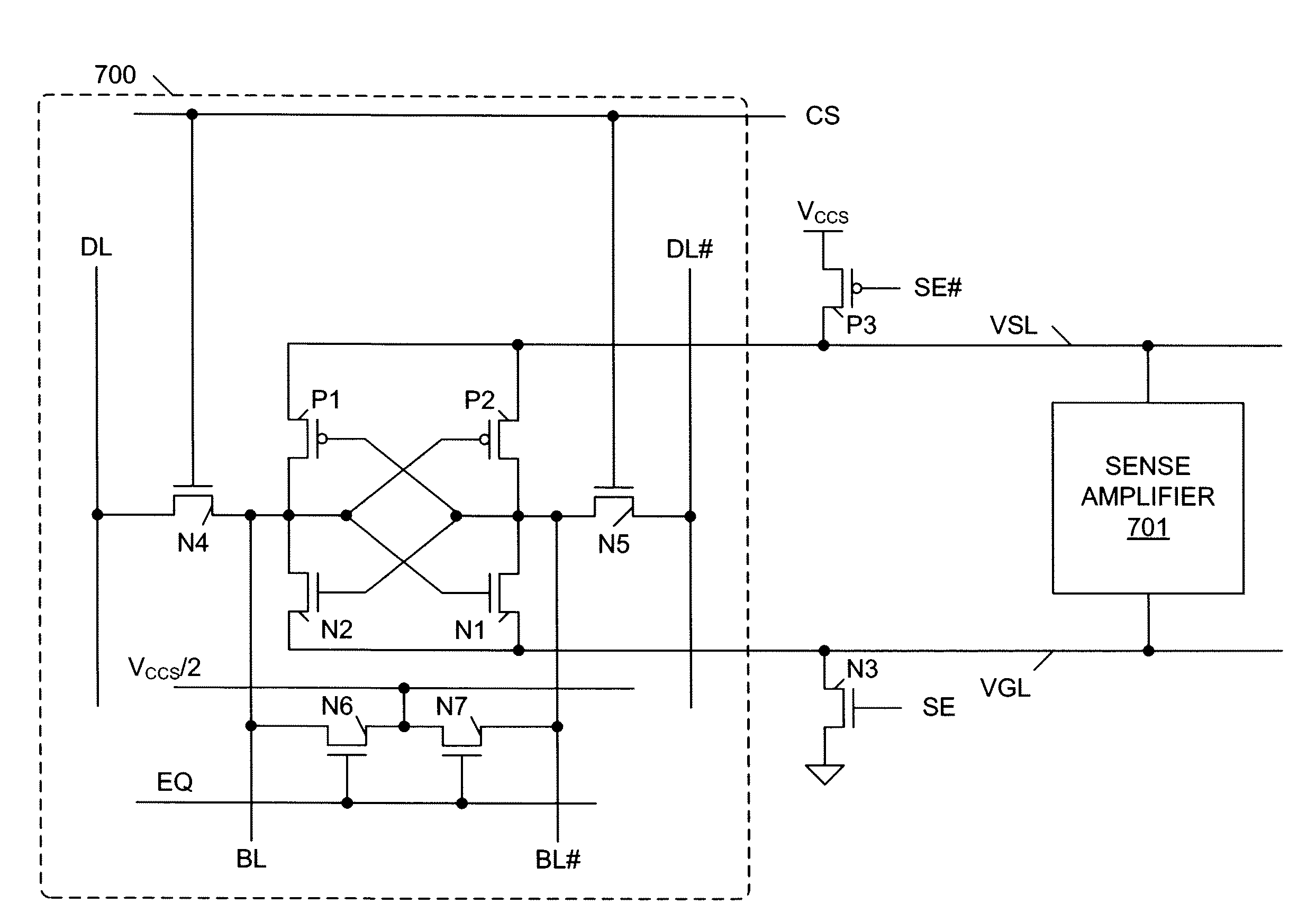

Scalable Embedded DRAM Array

A method and apparatus for scaling an embedded DRAM array from a first process to a second process, wherein the scaling involves reducing the linear dimensions of features by a constant scale factor. From the first process to the second process, DRAM cell capacitor layout area is reduced by the square of the scale factor, while cell capacitance is reduced by the scale factor. The voltage used to supply the logic transistors is scaled down from the first process to the second process. However, the voltage used to supply the sense amplifiers remains constant in both processes. Thus, in an embedded DRAM array of the second process, sense amplifiers are supplied by a greater voltage than the logic transistors. This allows the sensing voltage of DRAM cells to be maintained from one process generation to another, while allowing memory size to scale with the square of the process scale factor.

Owner:MOSYS INC

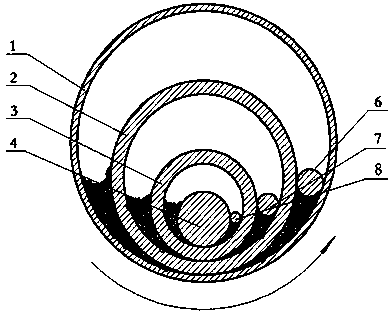

Grinding device for scale-like metal powder

A grinding device for scale-like metal powder comprises a driving rolling drum, a primary grinding drum, a secondary grinding drum, a grinding roller and a seal assembly, wherein the driving rolling drum is in a drum structure with one end sealed, the seal assembly seals the primary grinding drum, the secondary grinding drum and the grinding roller in the driving rolling drum, the lengths of the primary grinding drum, the secondary grinding drum and the grinding roller are slightly smaller than that of an inner cavity formed by the driving rolling drum and the seal assembly, the primary grinding drum is located in the driving rolling drum, the outer diameter bottom of the primary grinding drum contacts with the inner diameter bottom of the driving rolling drum, the secondary grinding drum is located in the primary grinding drum, the outer diameter bottom of the secondary grinding drum contacts with the inner diameter bottom of the primary grinding drum, the grinding roller is located in the secondary grinding drum, and the outer diameter bottom of the grinding roller contacts with the inner diameter bottom of the secondary grinding drum. All parts rotate by mutual friction, the gravity forms grinding force, and the difference of rotational linear speed forms rolling. The grinding device has the advantages that the processed scale-like micro powder is high in flattening ratio and stable in quality, the processing is quick and efficient, and the service life of the grinding device is long.

Owner:江苏宝纳电磁新材料有限公司

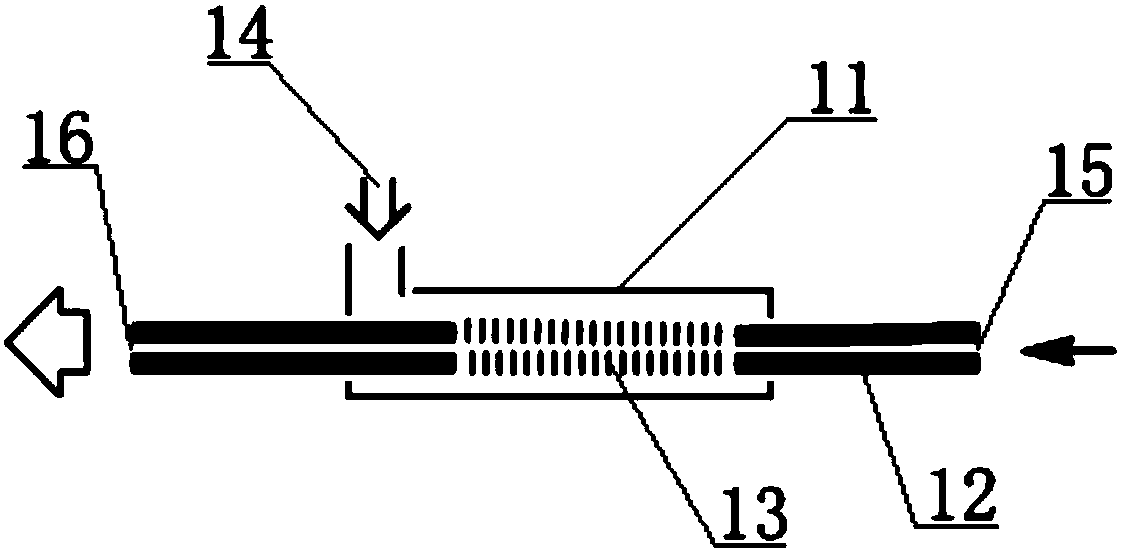

Microporous eddy double-tube reactor and application thereof

ActiveCN108325483AEasy to adjustEasy to separateChemical/physical/physico-chemical microreactorsProcess scaleDouble tube

The invention provides a microporous eddy double-tube reactor and application thereof. The microporous eddy double-tube reactor comprises basic combination units, every basic combination unit is composed of an outer tube and an inner tube, the inner tube comprises a continuous phase inlet and outlet, one end of the outer tube is a dispersed phase inlet, and the other end of the outer tube is a closed end; between both ends of the inner tube, a group of continuous microporous arrays or a plurality of groups of discontinuous microporous arrays are distributed in the circumferential and axial directions of the tube wall, so that dispersed phase can form eddies inside the inner tube when passing through the wall of the inner tube. The microporous eddy double-tube reactor enables the dispersedphase to form eddies inside the inner tube after passing through the pores of the wall of the inner tube to strengthen mixing of process fluid, and particularly, can retard the phase separating process for processes long in reaction time. Meanwhile, the microporous eddy double-tube reactor can effectively divide the mass transfer and heat exchange process of dispersed phase and continuous phase into a plurality of different sections to effectively relieve acute heat exchange processes during process scale-up.

Owner:睦化(上海)流体工程有限公司

Method for separating and purifying curcin from seeds of jatropha curcas

InactiveCN101891798BHigh purityImprovement of process separation and purification capacityPeptide preparation methodsPlant peptidesProcess scaleBasic research

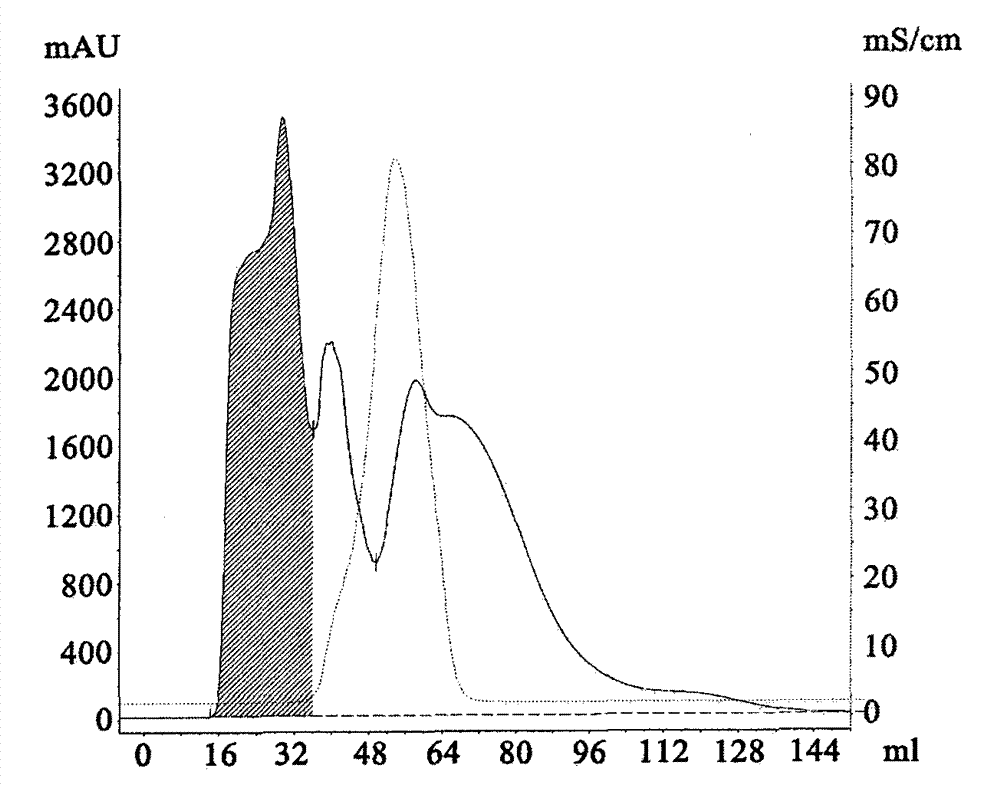

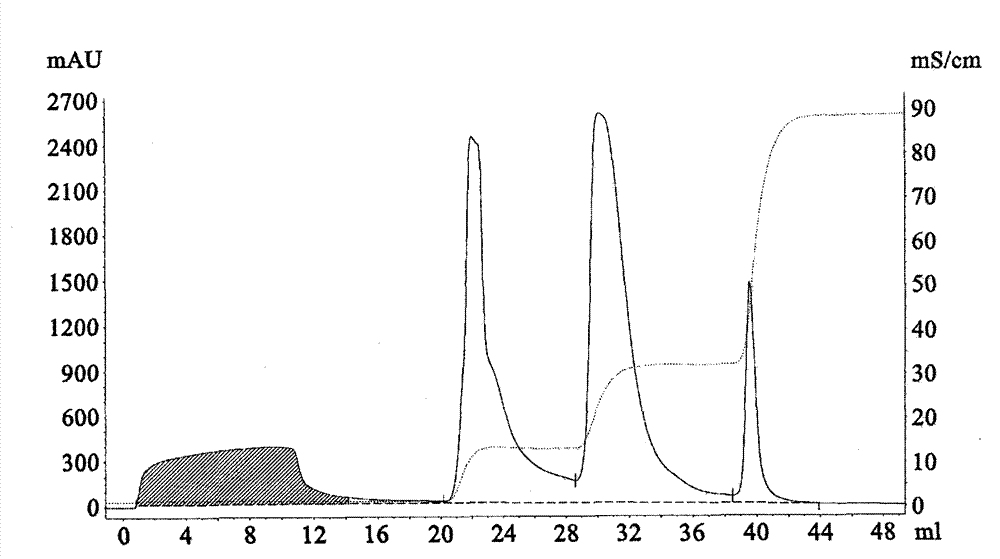

The invention discloses a method for separating and purifying curcin from seeds of jatropha curcas, which comprises the following steps: firstly carrying out desalinization and buffer solution exchange on prepared curcin crude extract solution, collecting a component of a fist 280nm absorption peak after sample loading, then carrying out anion exchange chromatography on the collected component, collecting a penetrating component after the sampling loading, diluting the collected penetrating component by using buffer solution, finally carrying out cation exchange chromatography on the component solution after dilution, and collecting the component of the highest 280nm absorption peak, which is a just final curcin pure product. As the separation and purification capacity of the method is high, the method can not only improve the purity and the activity of the final product and improve the yield of the final product, but also greatly shorten the time consumption of the process cycle, andhave good process scaling-up property and low production cost, thereby providing the powerful support for research and development of various products of the curcin and deep and refined basic research based on the curcin.

Owner:SICHUAN UNIV

Method for separating and purifying curcin from seeds of jatropha curcas

InactiveCN101891798AHigh purityImprovement of process separation and purification capacityPeptide preparation methodsPlant peptidesProcess scaleBasic research

The invention discloses a method for separating and purifying curcin from seeds of jatropha curcas, which comprises the following steps: firstly carrying out desalinization and buffer solution exchange on prepared curcin crude extract solution, collecting a component of a fist 280nm absorption peak after sample loading, then carrying out anion exchange chromatography on the collected component, collecting a penetrating component after the sampling loading, diluting the collected penetrating component by using buffer solution, finally carrying out cation exchange chromatography on the component solution after dilution, and collecting the component of the highest 280nm absorption peak, which is a just final curcin pure product. As the separation and purification capacity of the method is high, the method can not only improve the purity and the activity of the final product and improve the yield of the final product, but also greatly shorten the time consumption of the process cycle, andhave good process scaling-up property and low production cost, thereby providing the powerful support for research and development of various products of the curcin and deep and refined basic research based on the curcin.

Owner:SICHUAN UNIV

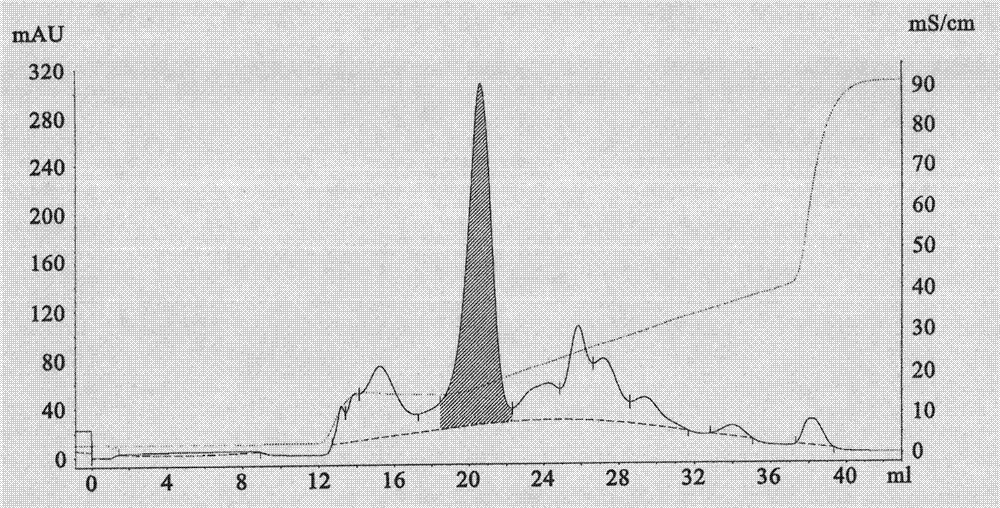

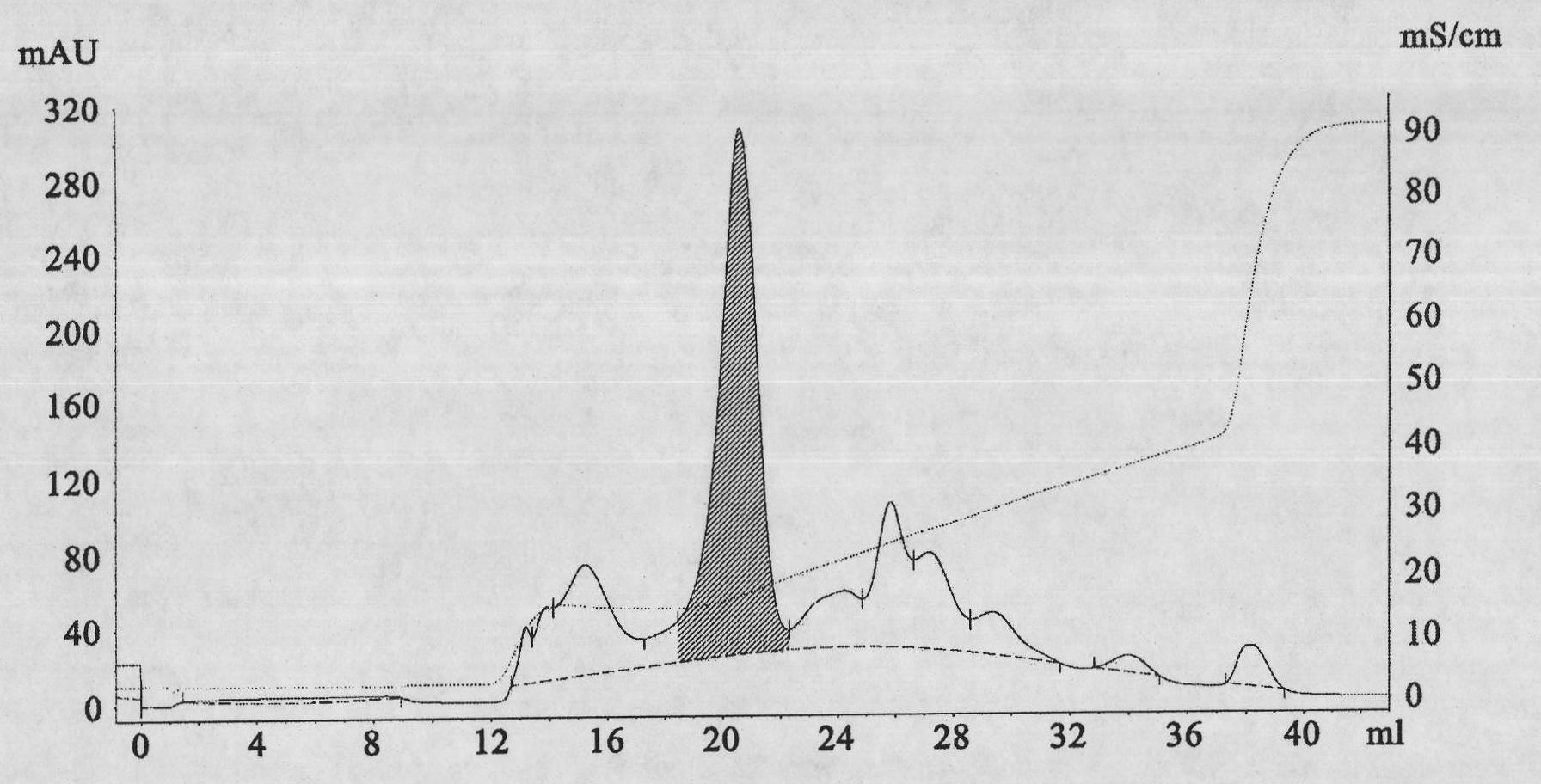

Scale-scale purification of whey protein

InactiveCN102286096ALow costIncrease productivityAlbumin peptidesPeptide preparation methodsProcess scaleProcess scaling

A large-scale purification method of whey protein in the field of bioengineering technology. Human α-lactalbumin recombinant milk is used as raw material, and after pretreatment and purification of the protein, recombinant human α-lactalbumin, recombinant human α-lactalbumin, and Bovine alpha-lactalbumin and bovine beta-lactoglobulin. The invention can purify recombinant human α-lactalbumin rapidly, conveniently, at low cost and in large quantities, reduces production cost and improves production efficiency.

Owner:SHANGHAI JIAO TONG UNIV

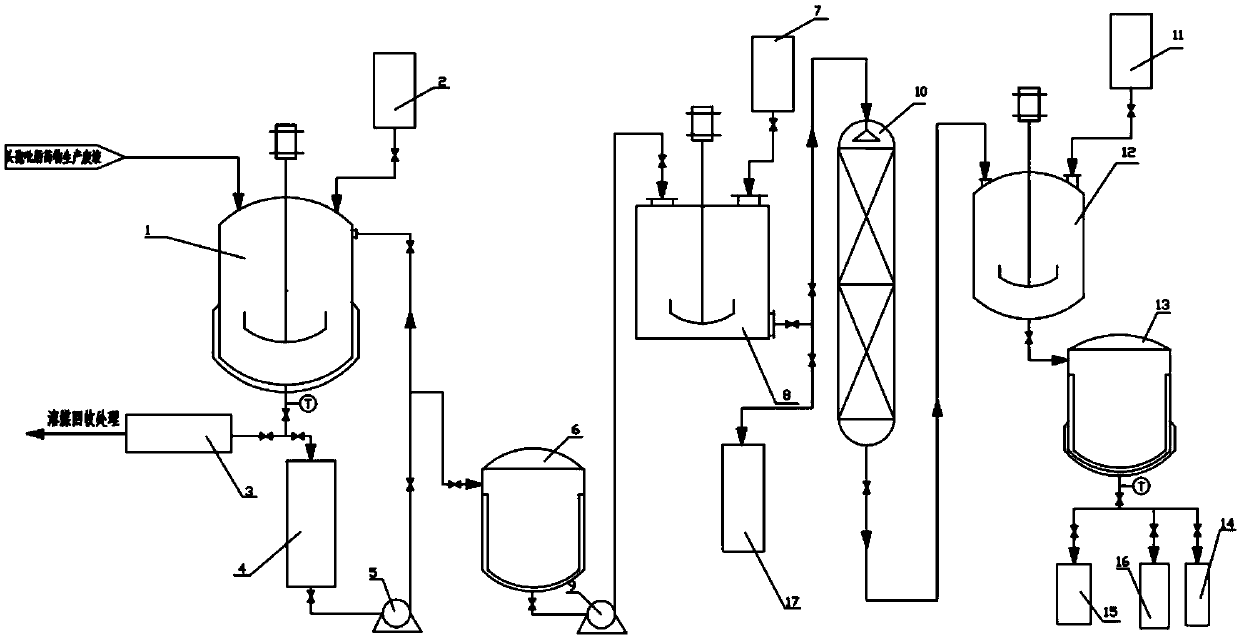

A microbial fermentation process amplification platform technology

InactiveCN102286369ASimple and fast operationHigh degree of automationBioreactor/fermenter combinationsBiological substance pretreatmentsBiotechnologyStreptococcus zooepidemicus

The invention provides a microorganism fermentation process scaling-up platform technique. In the process of fermentation, symbolic metabolites are chosen to reflect the growing state of microorganisms and the condition of fermentation medium, and by controlling the change of the symbolic metabolites, and combined with hydromechanics to calculate, design and improve the size and structure of a stirring reactor, the gas holdup is increased and the concentration of the symbolic metabolites is decreased; and fermentation conditions are optimized and the fermentation process is scaled up. The technique is applied in the production of glutathione and S-adenosine-L-methionine and the coproduction of glutathione and ergosterol by brewing yeast fermentation and the production of hyaluronic acid by streptococcus zooepidemicus fermentation. The symbolic metabolites are ethanol, glycerin, lactic acid and acetic acid. The technique ensures that the concentration of ethanol in the high-density aerobic fermentation of yeast is less than 0.5 percent and that the concentration of lactic acid as the symbolic metabolite in the production of hyaluronic acid by bacterial fermentation is less than 3 percent. The technique is easy to operate, and the automation degree is high; and the application range is wide, and the technique can be used in the yeast system as well as the bacteria system.

Owner:BEIJING UNIV OF CHEM TECH

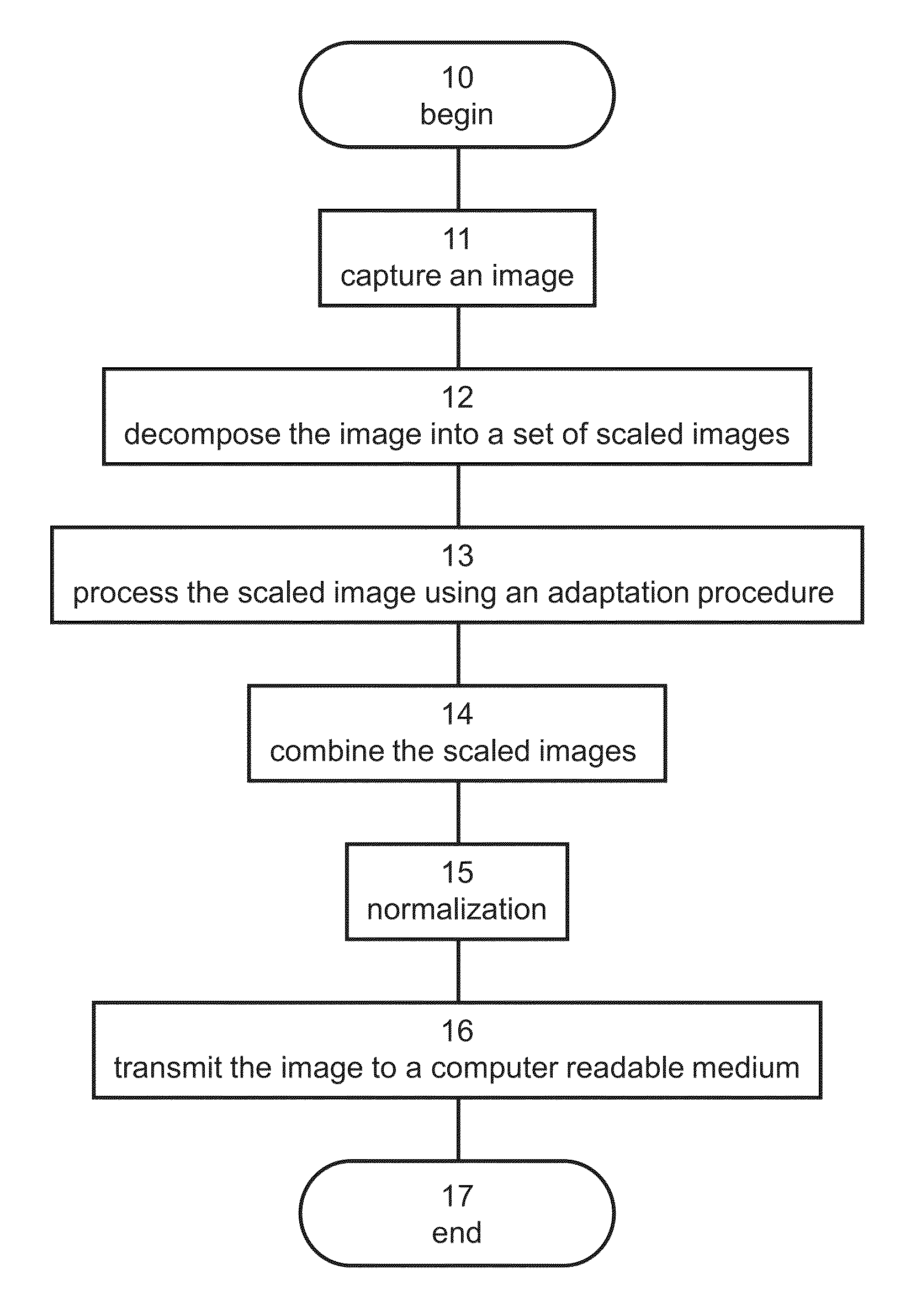

Method and system for processing an image featuring multiple scales

InactiveUS9092838B2Increase valueSolution value is not highImage enhancementTelevision system detailsProcess scaleProcess scaling

Owner:RAMOT AT TEL AVIV UNIV LTD

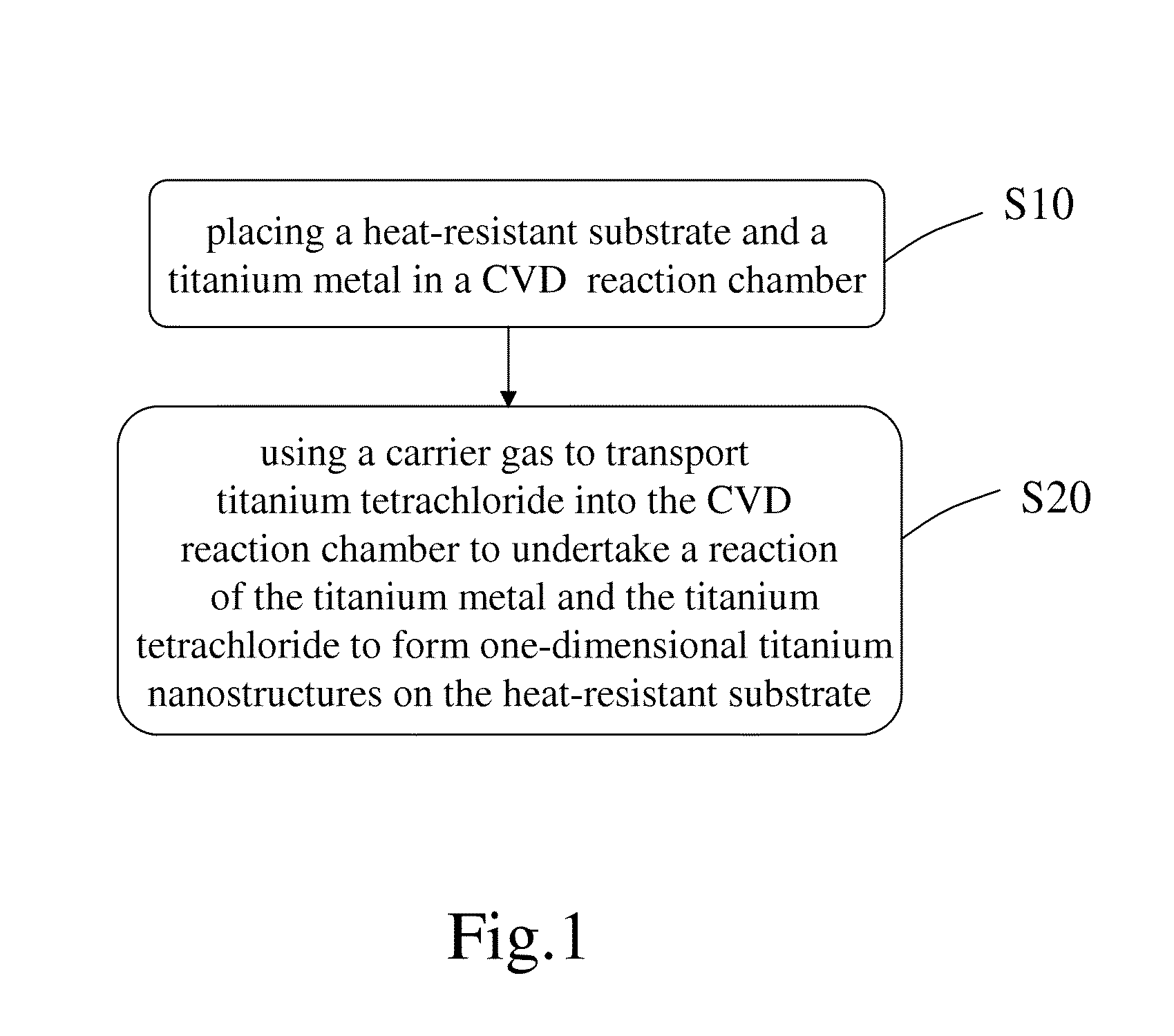

One-dimensional titanium nanostructure and method for fabricating the same

InactiveUS20140193289A1Reduce manufacturing costFabrication process can be shortenedPolycrystalline material growthTransportation and packagingNanowireTitanium metal

A one-dimensional titanium nanostructure and a method for fabricating the same are provided. A titanium metal reacts with titanium tetrachloride to form the one-dimensional titanium nanostructure on a heat-resistant substrate in a CVD method and under a reaction condition of a reaction temperature of 300-900° C., a deposition temperature of 200-850° C., a flow rate of the carrier gas of 0.1-50 sccm and a reaction time of 5-60 hours. The titanium nanostructure includes titanium nanowires, titanium nanobelts, flower-shaped titanium nanowires, titanium nanorods, titanium nanotubes, and titanium-titanium dioxide core-shell structures. The titanium nanostructure can be densely and uniformly grown on the heat-resistant substrate. The present invention neither uses a template nor uses the complicated photolithographic process, solution preparation process, and mixing-coating process. Therefore, the process scale-up, cost down, and the simplified production process are achieved.

Owner:NAT CHIAO TUNG UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com