Recovering and separation method for iodine in cefepime waste liquid

A recovery method and waste liquid technology, applied in the direction of iodine, iodine/hydrogen iodide, etc., can solve the problems of difficult iodine recovery, imminent recovery of iodine, waste of iodine, etc., and achieve the effects of less entrained impurities, cost saving, and simple process route

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

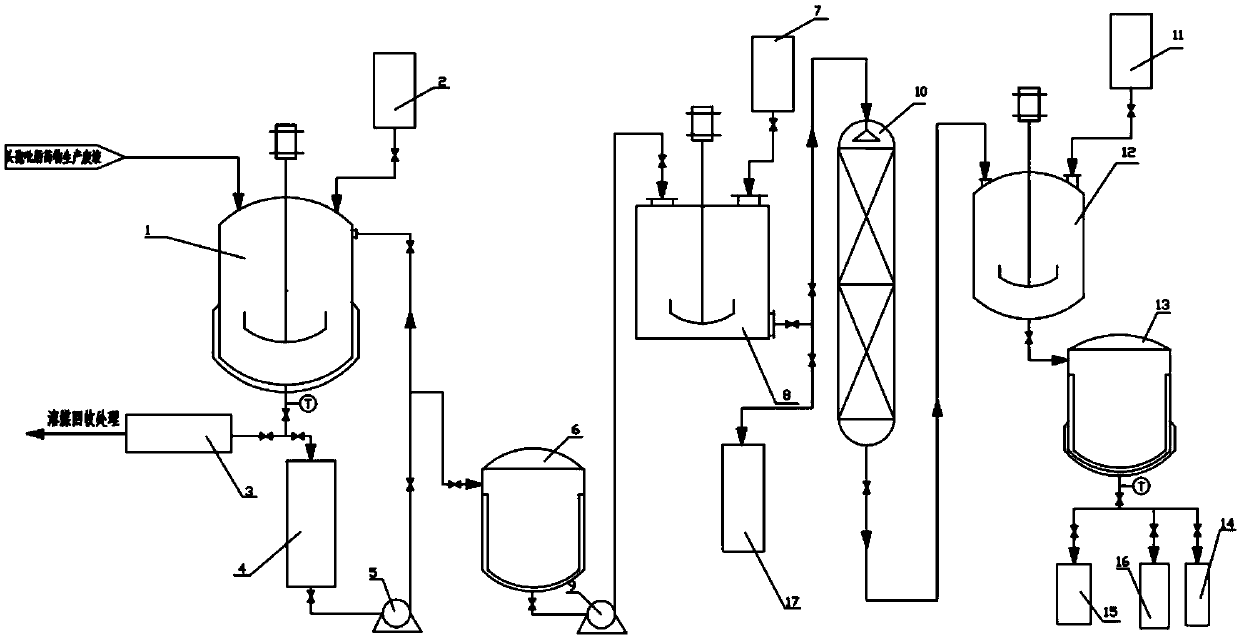

Image

Examples

Embodiment 1

[0026] Add 3L of cefepime waste liquid into the stirred reactor, the lye is 20% sodium hydroxide, adjust the pH=12 to separate the lye, stir and heat to hydrolyze, the heating temperature is 90℃, after separating the organic phase, add 36% Adjust pH to 0.5 with hydrochloric acid, continue to heat and hydrolyze for 3h, recover the water phase, cool, pass into the oxidation extraction tower, 25.8g sodium nitrite for oxidation reaction for 10min, then spray methylene chloride on the top of the tower, extract until the purple color disappears in the water phase , The organic phase flows into the vacuum distillation kettle, the pressure is 0.15MPa, the temperature is 12°C, and most of the extractant dichloromethane is evaporated for recycling. The remaining components continue to be sealed and heated to 30°C under vacuum, and the temperature rises by 1°C every 10 minutes. The elemental iodine is sublimated, and then the distillation kettle is cooled down, and the iodine is sublimed t...

Embodiment 2

[0028] Add 4L cefepime waste liquid into the stirred reactor, the lye is 20% potassium hydroxide, adjust the pH=13 to separate the lye, stir and heat to hydrolyze, the heating temperature is 120℃, after separating the organic phase, add 36% Adjust pH=2 with hydrochloric acid, continue to heat and hydrolyze for 3h, recover the water phase, cool, pass into the oxidation extraction tower, 90g sodium nitrite for oxidation reaction for 20min, then spray ether at the top of the tower, extract until the purple color disappears in the water phase and the organic phase Flow into the vacuum distillation kettle, the pressure is 0.08MPa, the temperature is 18°C, most of the extractant ether is distilled out for recycling, and the remaining components continue to be sealed and heated to 30°C under vacuum, and the iodine elemental substance is sublimated every 15 minutes. The distillation kettle is cooled down and the iodine is sublimed to obtain a pure product with a recovery rate of 98.7% a...

Embodiment 3

[0030] Add 1L of cefepime waste liquid into the stirred reactor, the lye is 30% sodium hydroxide, adjust the pH=13 to separate the lye, stir and heat to hydrolyze, the heating temperature is 120℃, after separating the organic phase, add 36% Adjust pH to 1.5 with hydrochloric acid, continue to heat and hydrolyze for 2h, recover the water phase, cool, pass into the oxidation extraction tower, 20g sodium nitrite for oxidation reaction for 30min, then spray methylene chloride on the top of the tower, extract until the purple color disappears in the water phase. The organic phase flows into the vacuum distillation kettle, the pressure is 0.1MPa, the temperature is 15°C, and most of the extractant dichloromethane is evaporated for recycling. The remaining components continue to be sealed and heated to 30°C under vacuum, and 1°C rises every 15 minutes. The simple substance is sublimated, and then the distillation kettle is cooled and the temperature is lowered to obtain a pure product ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com