High-performance micro-nano multilevel-structure MoS2 material and preparation method and application thereof

A high-performance, micro-nano technology, applied in the direction of structural parts, chemical instruments and methods, additives, etc., can solve the problems that have not been reported in the preparation research, and achieve the effects of shortening the adsorption time, improving the adsorption efficiency, and uniform particle size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] 1) Dissolve 1.236g of ammonium molybdate in 35ml of deionized water and stir until dissolved to obtain a transparent solution;

[0028] 2) Add 2.284g of thiourea to the above solution and stir for 10min until dissolved to obtain a mixed solution, then add 3g of PEG6000 and stir for 1h;

[0029] 3) Place the mixed solution obtained in the above 2) in an ultrasonic device, and ultrasonicate for 30 minutes at a power of 100w;

[0030] 4) Transfer the solution obtained in 3) to a 50ml hydrothermal reaction kettle, heat at 180°C for 24h, cool after the reaction, centrifuge the obtained black precipitate, wash three times with distilled water and absolute ethanol respectively, The obtained product was dried at 50°C to obtain MoS with micro-nano hierarchical structure 2 Powder.

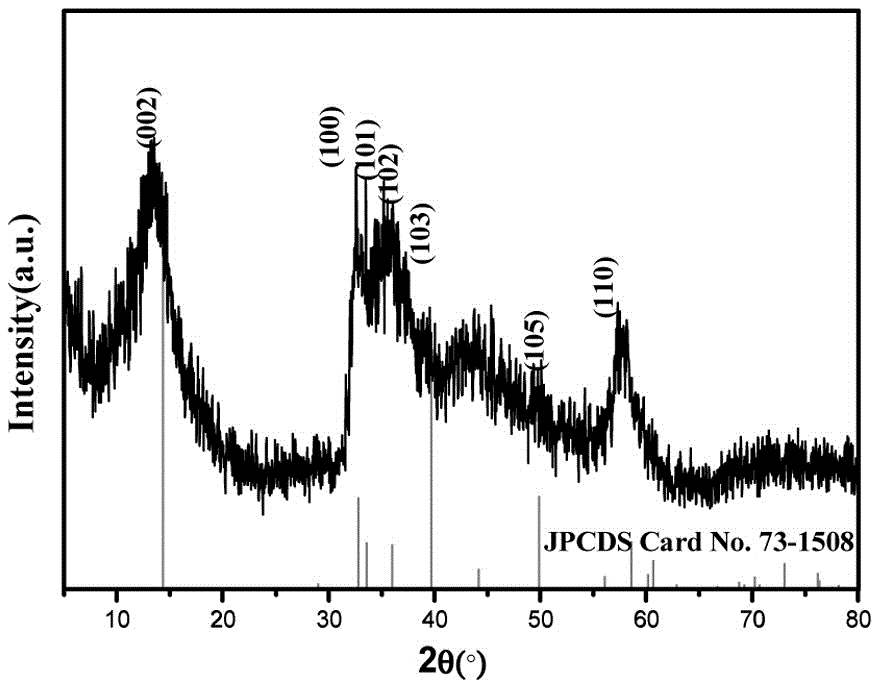

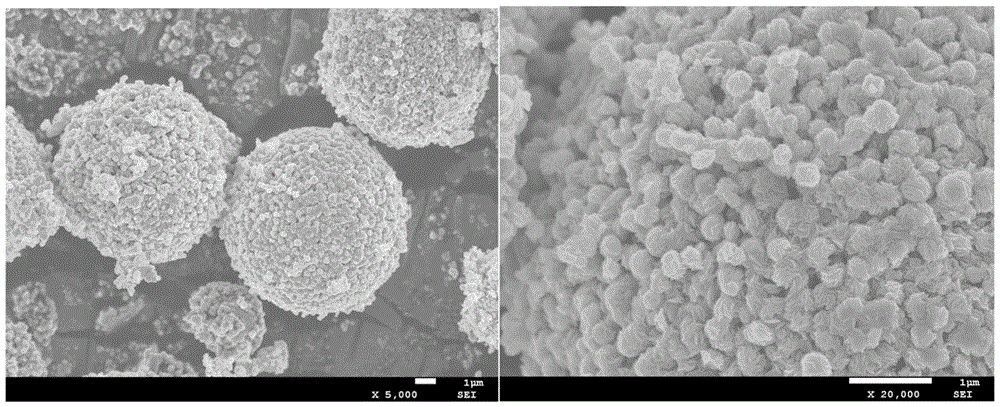

[0031] The micro-nano hierarchical structure MoS prepared above 2 The X-ray diffraction pattern of the powder is as figure 1 As shown, its diffraction peaks are consistent with the standard spectr...

Embodiment 2

[0037] 1) Dissolve 2.56g of ammonium molybdate in 35ml of ethylene glycol and stir until dissolved to obtain a transparent solution;

[0038] 2) Add 1.84g of thiourea to the above solution and stir for 10min until dissolved to obtain a mixed solution, then add 1.2g of PEG6000 and stir for 1h;

[0039] 3) Place the mixed solution obtained in the above 2) in an ultrasonic device, and ultrasonicate for 1 hour at a power of 60w;

[0040] 4) Transfer the solution obtained in 3) to a 50ml hydrothermal reaction kettle, heat at 160°C for 24h, cool after the reaction, centrifuge the obtained black precipitate, wash three times with distilled water and absolute ethanol respectively, The obtained product was dried at 70°C to obtain MoS with micro-nano hierarchical structure 2 Powder.

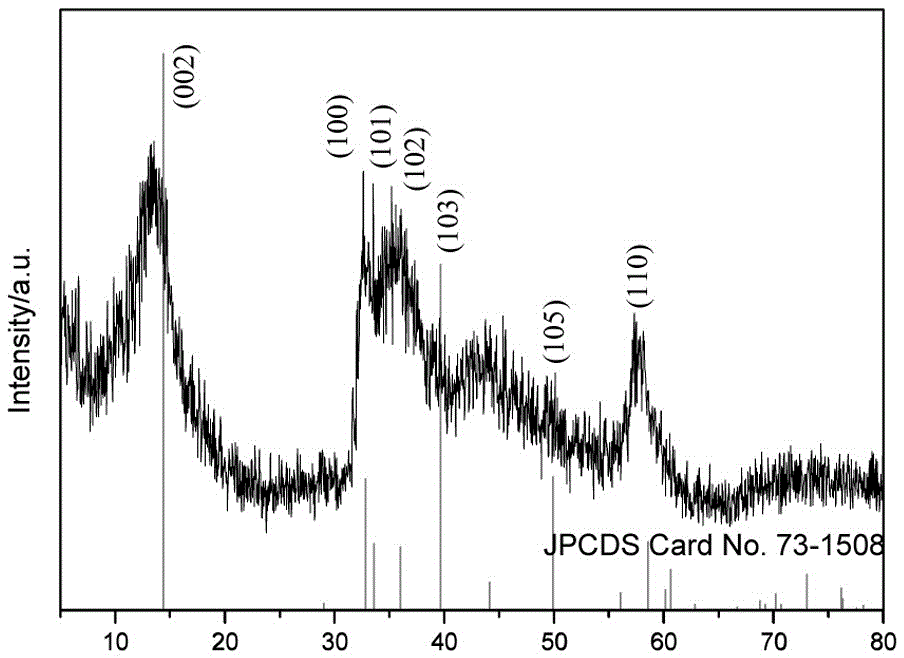

[0041] The micro-nano hierarchical structure MoS prepared above 2 The X-ray diffraction pattern of the powder is as image 3 As shown, its diffraction peaks are consistent with the standard spectrum of...

Embodiment 3

[0047] 1) Dissolve 2.5g of sodium molybdate in 35ml of DMF and stir until dissolved to obtain a transparent solution;

[0048] 2) Add 5 g of thiourea to the above solution and stir for 10 min until dissolved to obtain a mixed solution, then add 1.2 g of PEG1500 and stir for 1 h;

[0049] 3) Place the mixed solution obtained in the above 2) in an ultrasonic device, and ultrasonicate for 15 minutes at a power of 80w;

[0050] 4) Transfer the solution obtained in 3) to a 50ml hydrothermal reaction kettle, heat at 200°C for 18h, cool after the reaction, centrifuge the obtained black precipitate, wash with distilled water and absolute ethanol three times respectively, The obtained product was dried at 50°C to obtain MoS with micro-nano hierarchical structure 2 Powder.

[0051] The micro-nano hierarchical structure MoS prepared above 2 The average particle size of powder microspheres is about 3.5 μm, MoS 2 The BET test results of the powder are as follows Figure 4 As shown, Mo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com