Method and product for loading semiconductor photocatalyst on surface of electrospun fiber

A photocatalyst and surface loading technology, applied in the field of nanomaterials, can solve the problems of small impact on the specific surface area of composite materials, small photocatalyst loading, and difficulty in large-scale production, and achieve separation and recycling, reusable, low cost, and fiber diameter. small effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] A method for loading a semiconductor photocatalyst on the surface of an electrospun fiber, comprising the following steps:

[0031] (1) Electrospinning template fiber material: Add polyvinylidene fluoride powder to a mixed solvent composed of dimethylformamide (DMF) and acetone and stir in a water bath at 40°C to obtain an electrospinning precursor solution. The mass ratio of dimethylformamide (DMF) and acetone is 1:1, and the mass percent of polyvinylidene fluoride contained in the electrospinning precursor solution is 20%; prepare flexible micro-nano by electrospinning Fibrous membrane, the spinning voltage is 9 kV, the spinning distance is 11 cm, the collector pole of the electrospinning device used is the drum collector pole, and the polyvinylidene fluoride nanofiber membrane is obtained as the template fiber material on the collector pole, and the obtained The template material is cut into small square pieces of 1.5 cm x 1.5 cm and set aside;

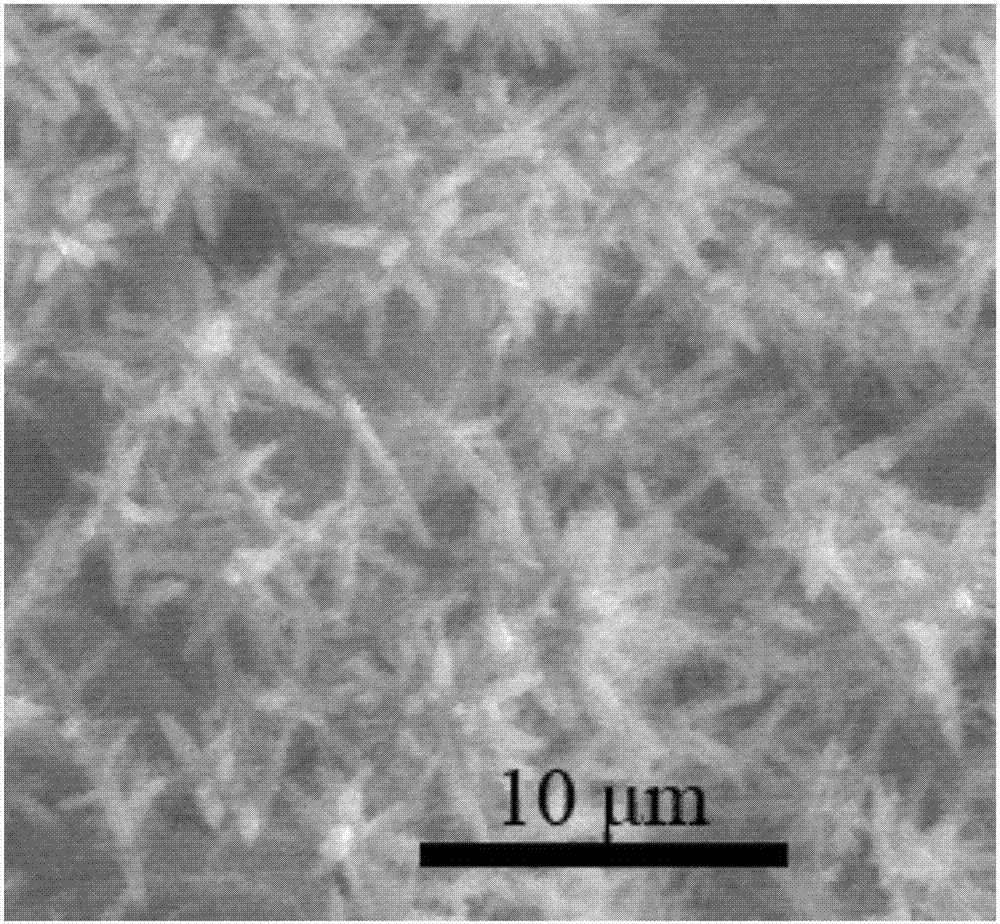

[0032](2) Prepare t...

Embodiment 2

[0038] A method for loading a semiconductor photocatalyst on the surface of an electrospun fiber, comprising the following steps:

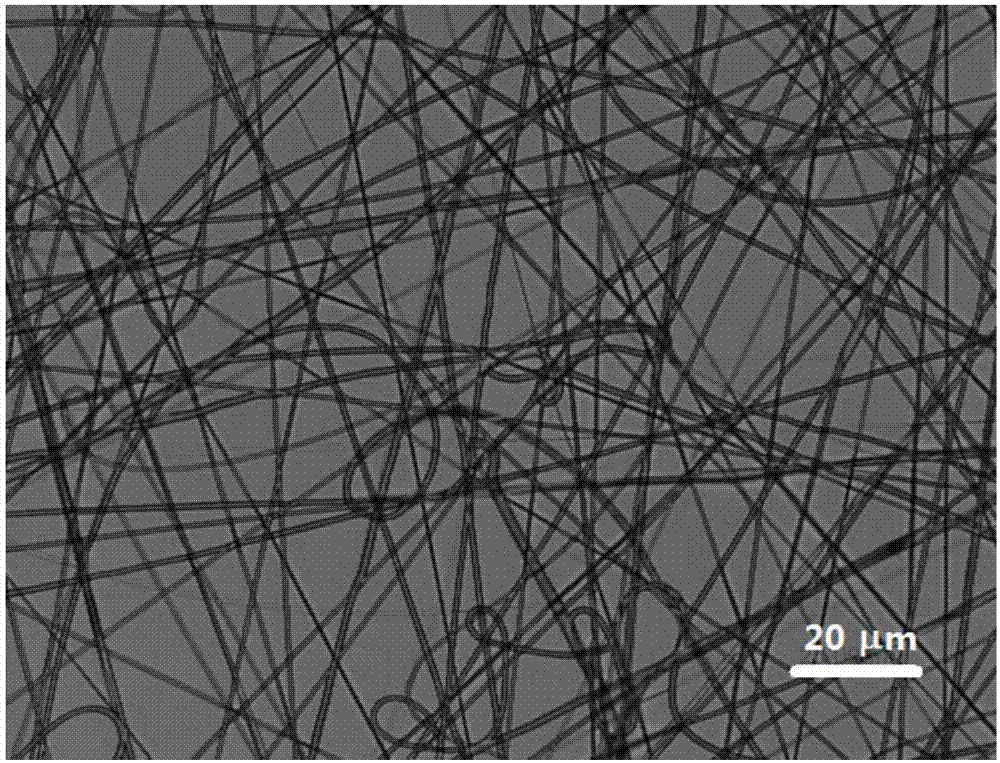

[0039] (1) Electrospinning template fiber material: Add TPU into a mixed solvent composed of DMF and THF, and magnetically stir for 2 hours to obtain an electrospinning precursor solution. The mass ratio of DMF and THF in the mixed solvent is 1:1, The mass percentage of TPU contained in the electrospinning precursor solution is 12%; the flexible micro-nano fiber membrane is prepared by electrospinning, the spinning voltage is 12 kV, and the spinning distance is 15 cm. Obtain TPU fiber membrane (morphology such as image 3 As shown, the magnification is 1000 times) as the template fiber material, the resulting template material is cut into square pieces of 1.5 cm × 1.5 cm, and set aside;

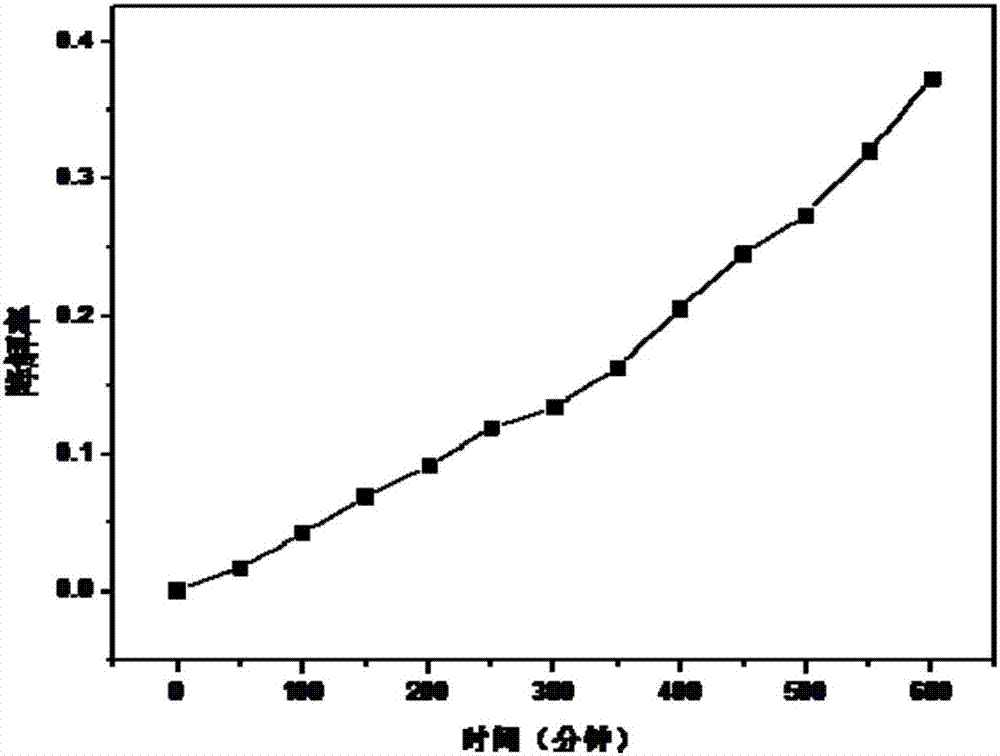

[0040] (2) Prepare the reaction solution: under normal temperature conditions, weigh 75ml of deionized water and Zn(NO 3 )·6H 2 O 3.5 g was added to the conta...

Embodiment 3

[0044] A method for loading a semiconductor photocatalyst on the surface of an electrospun fiber, comprising the following steps:

[0045] (1) Electrospinning template fiber material: polyacrylonitrile PAN was added to DMF, and magnetically stirred for 2 hours to obtain an electrospinning precursor solution. The mass percentage of PAN contained in the electrospinning precursor solution was 12%; The flexible micro-nano fiber membrane was prepared by electrospinning, the spinning voltage was 15 kV, and the spinning distance was 10 cm. The PAN fiber membrane was obtained on the collector as the template fiber material, and the resulting template material was cut into 1.5 cm × 1.5 cm square pieces, set aside;

[0046] (2) Prepare the reaction solution: under normal temperature conditions, weigh 15 ml of deionized water and 15 ml of hydrochloric acid solution into the container, then add 1 ml of butyl titanate while stirring, and continue stirring for 20 minutes to obtain a hydroth...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com