Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

798 results about "Electro spinning" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

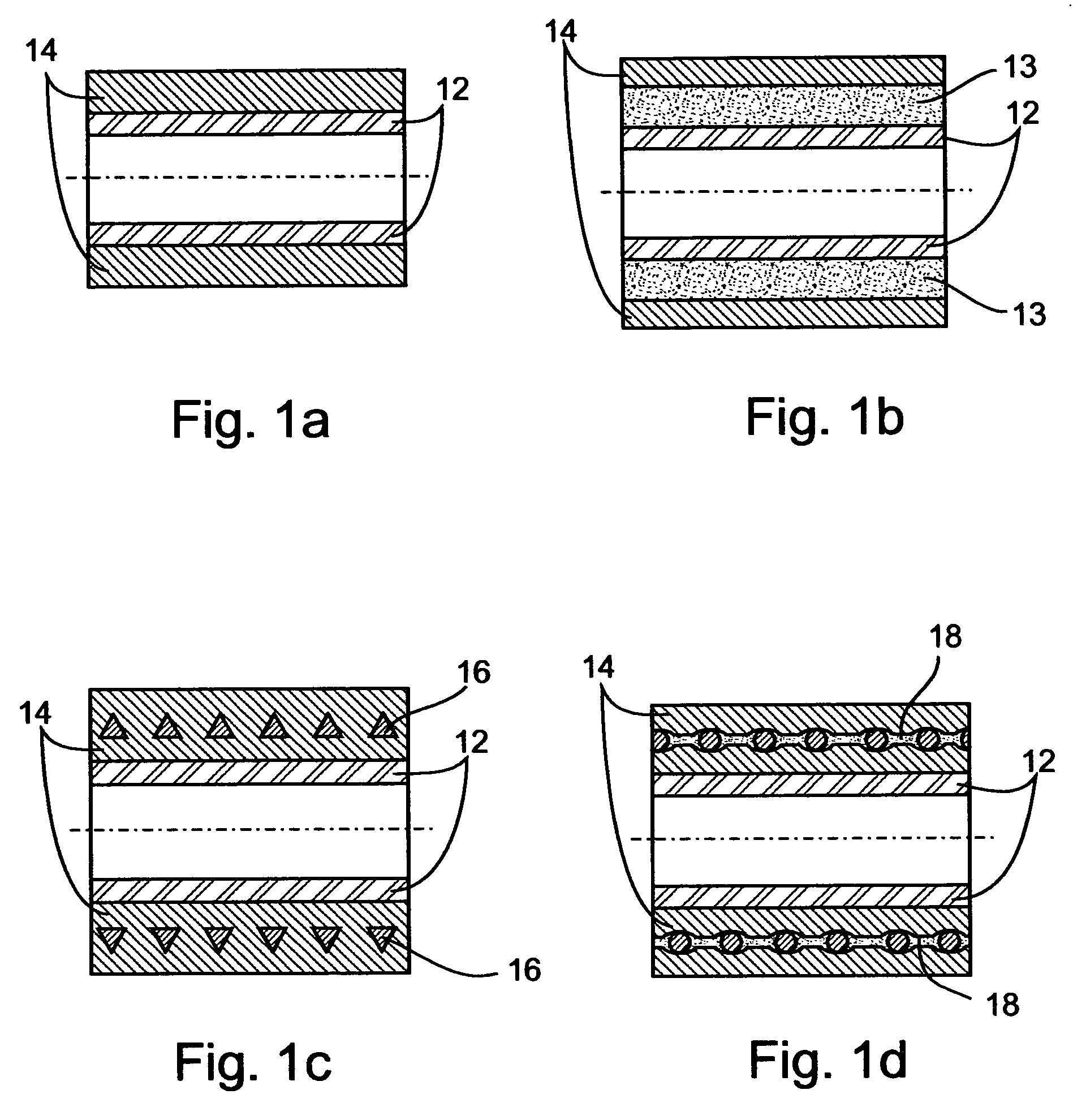

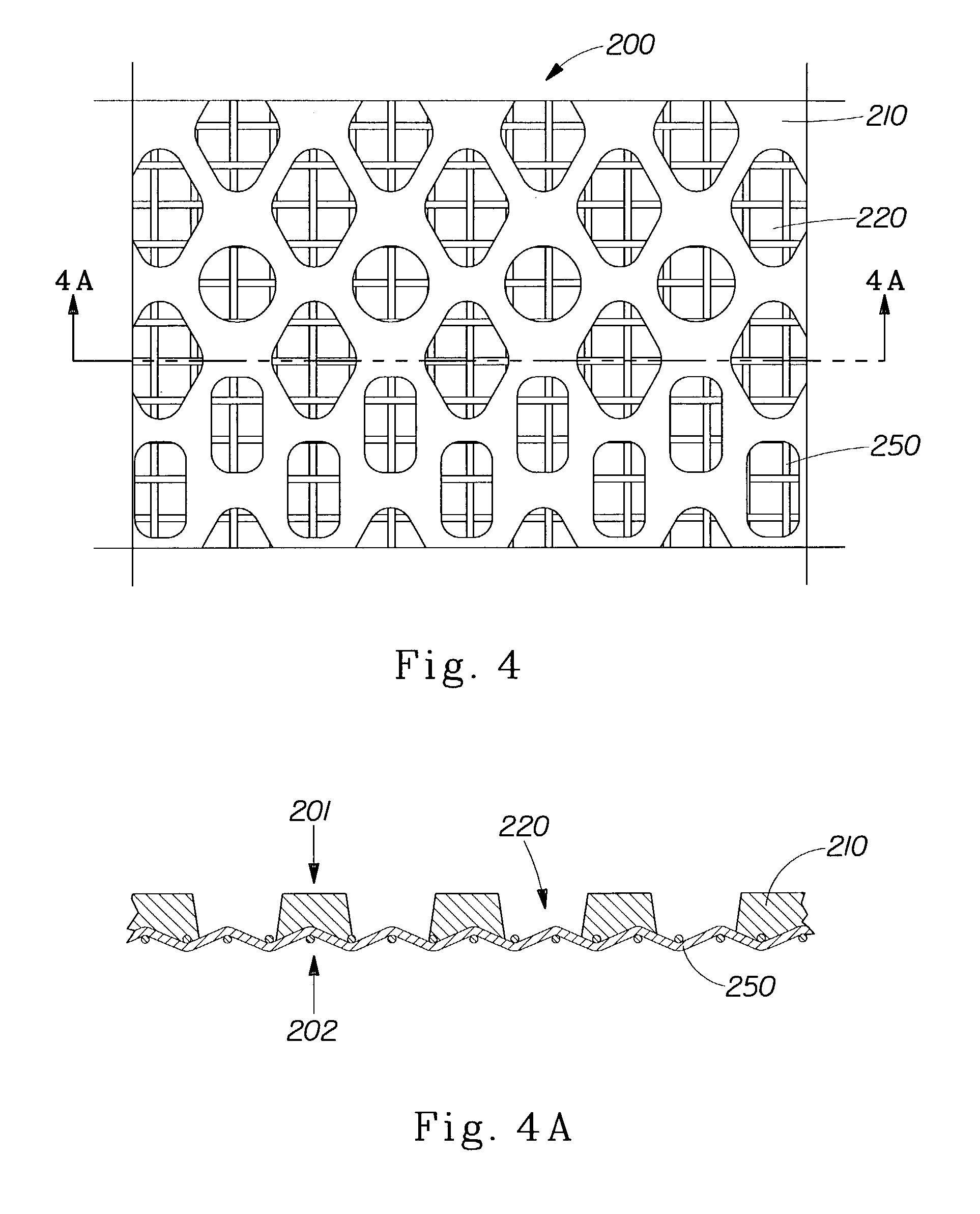

Medicated polymer-coated stent assembly

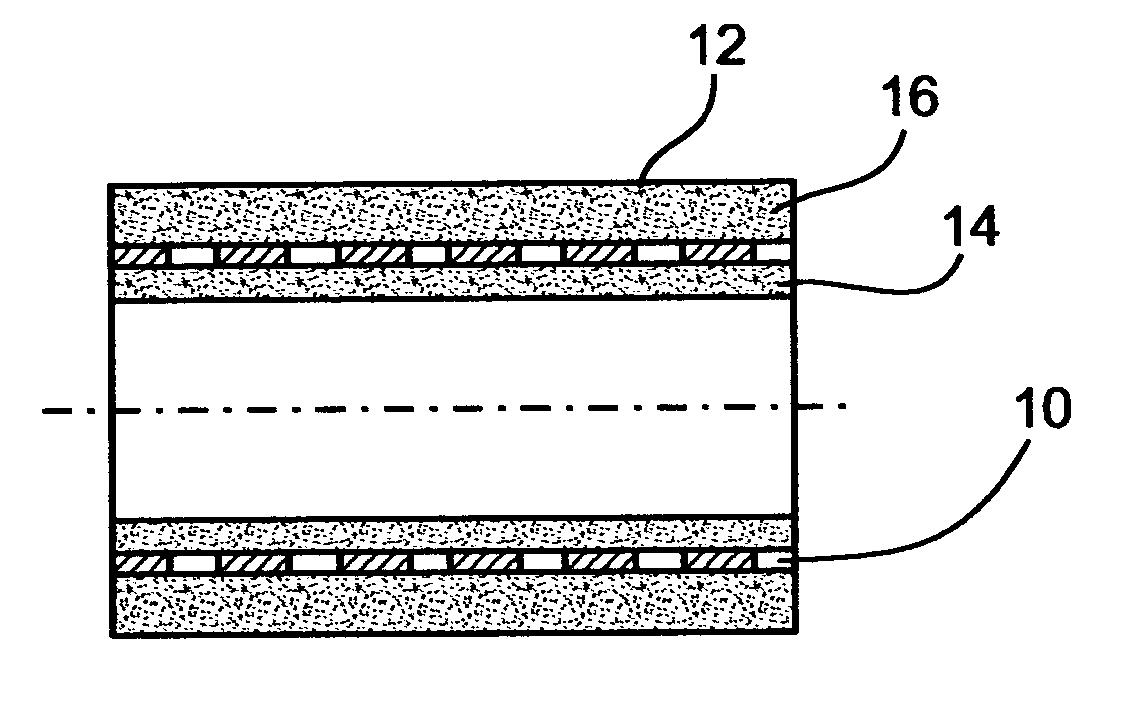

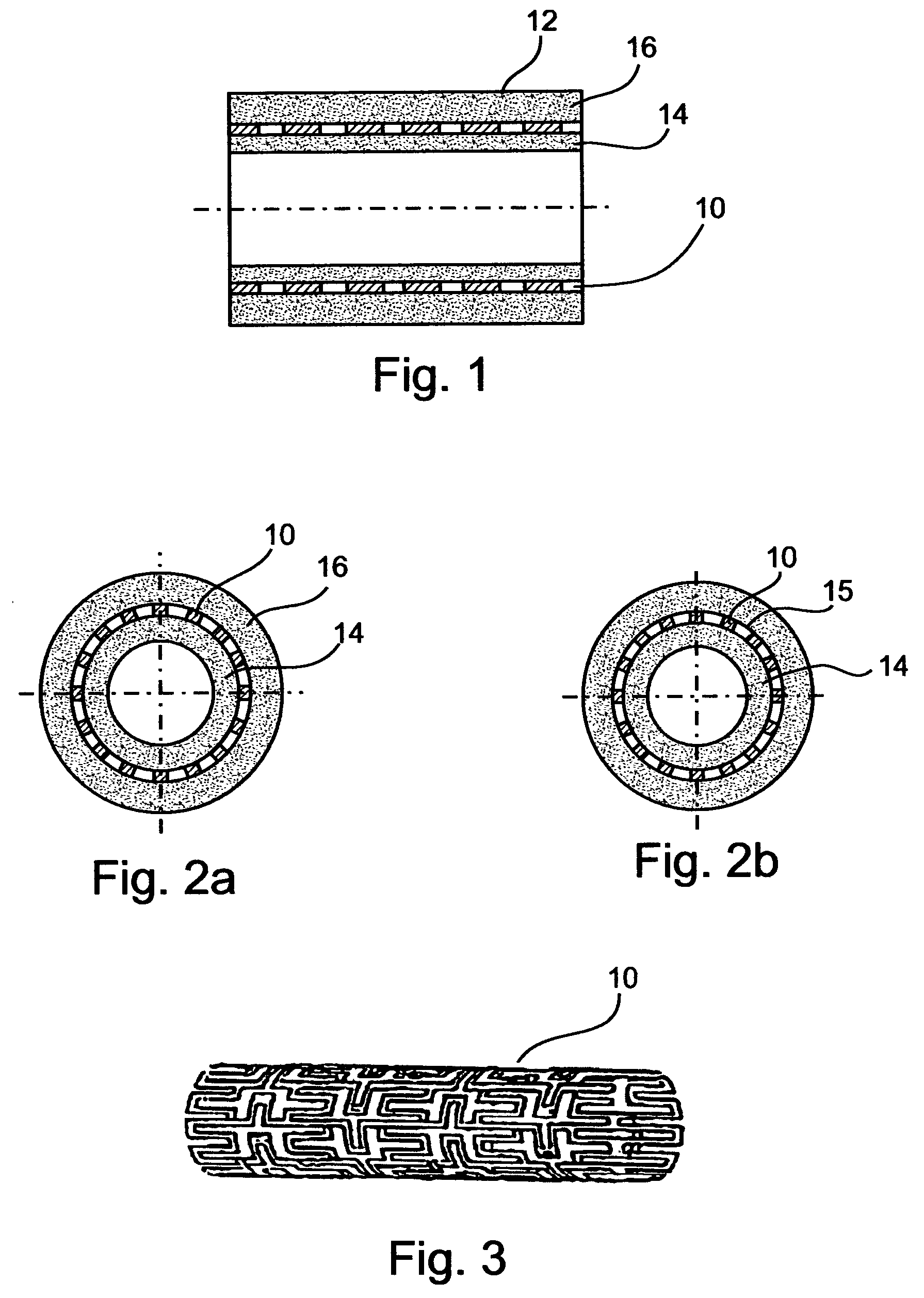

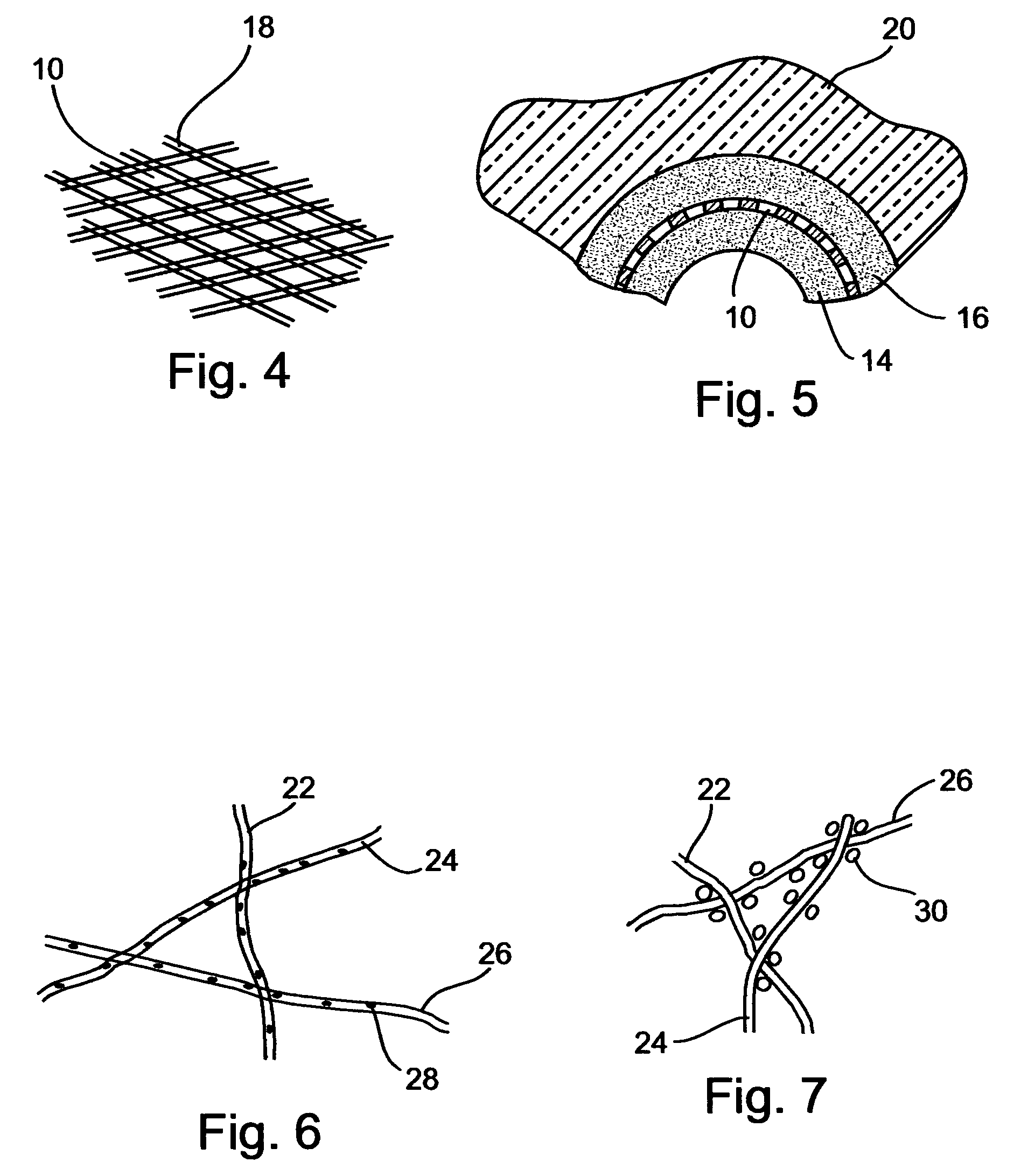

A stent assembly comprising an expensible tubular supporting element and at least one coat of electrospun polymer fibers, each of the at least one coat having a predetermined porosity, the at least one coat including at least one pharmaceutical agent incorporated therein for delivery of the at least one pharmaceutical agent into a body vasculature during or after implantation of the stent assembly within the body vasculature.

Owner:NICAST LTD

Vascular prosthesis and method for production thereof

A vascular prosthesis comprising a first layer having a predetermined first porosity and a second layer having a predetermined second porosity, wherein the first layer and the second layer are each made of first and second electrospun polymer fibers.

Owner:NICAST LTD

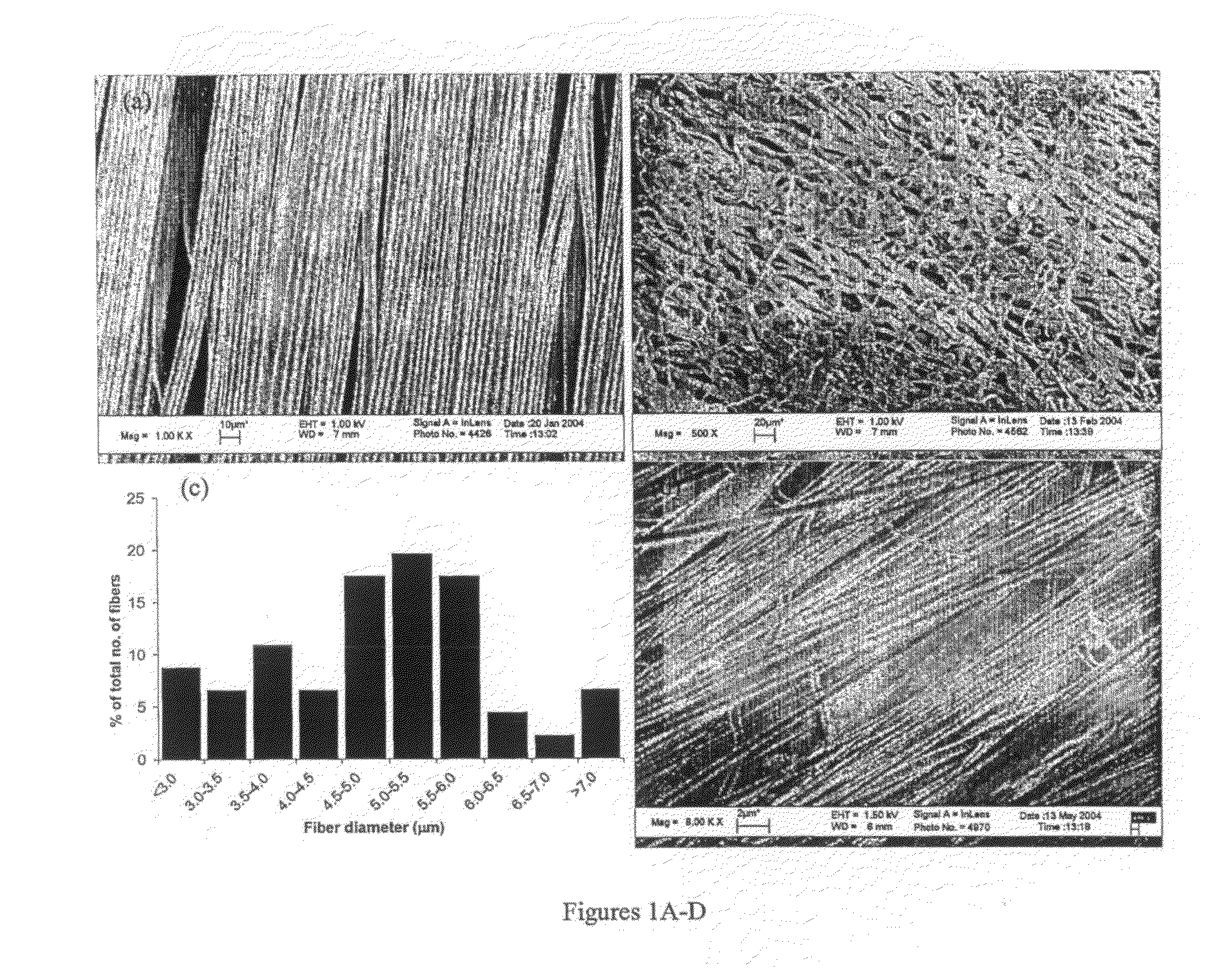

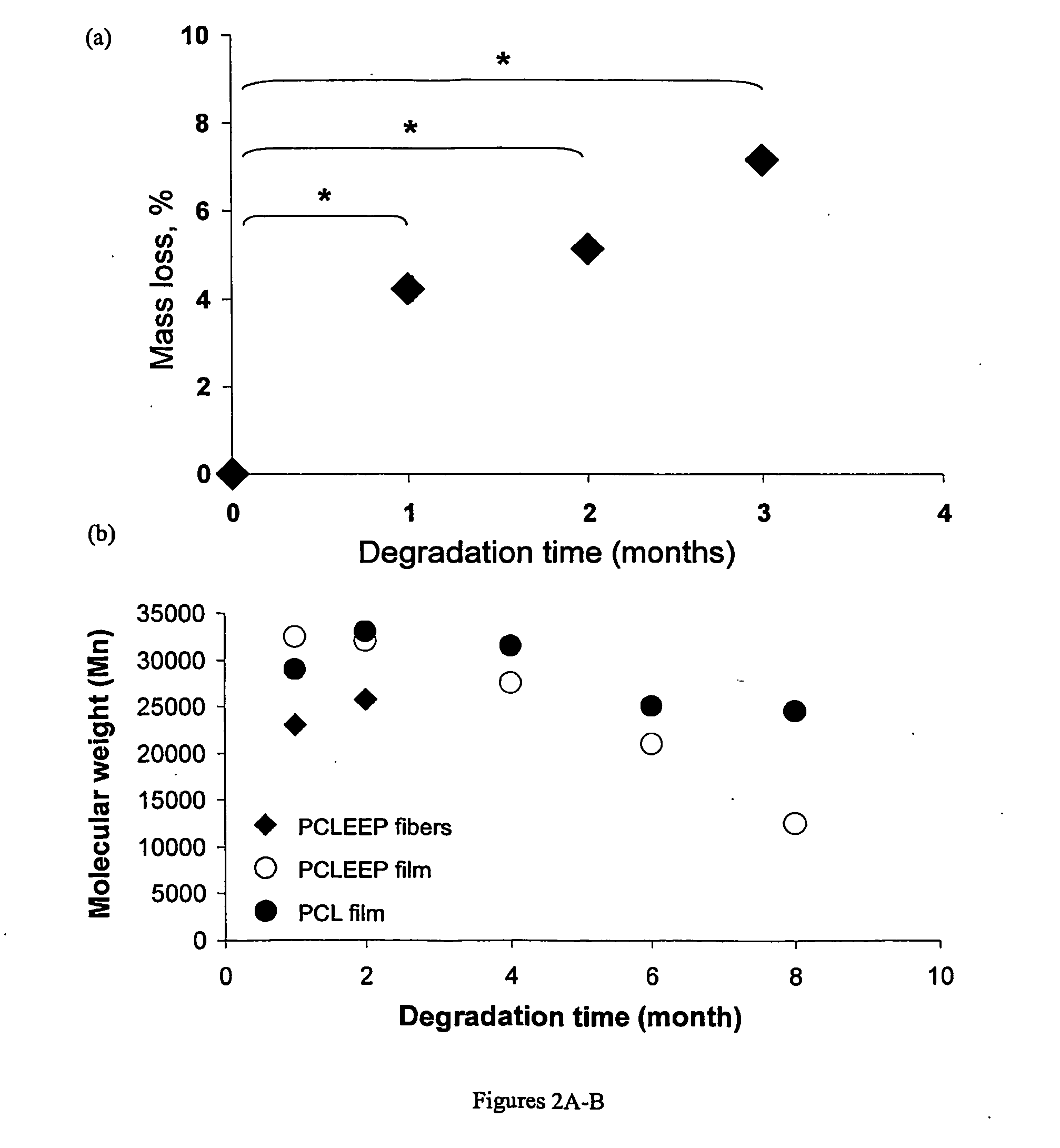

Electrospun matrices for delivery of hydrophilic and lipophilic compounds

InactiveUS20100166854A1Monocomponent protein artificial filamentElectric discharge heatingFiberCompound a

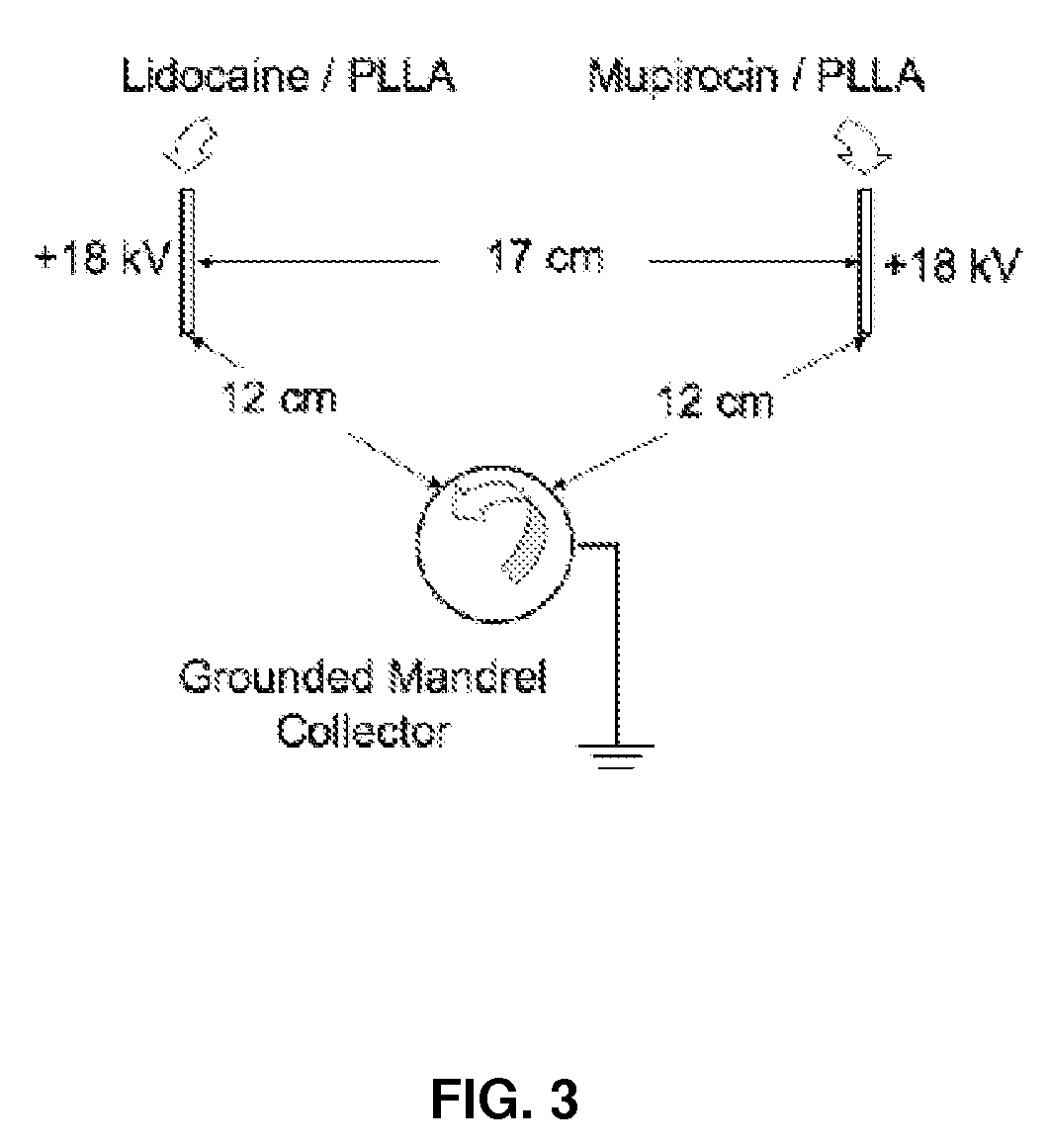

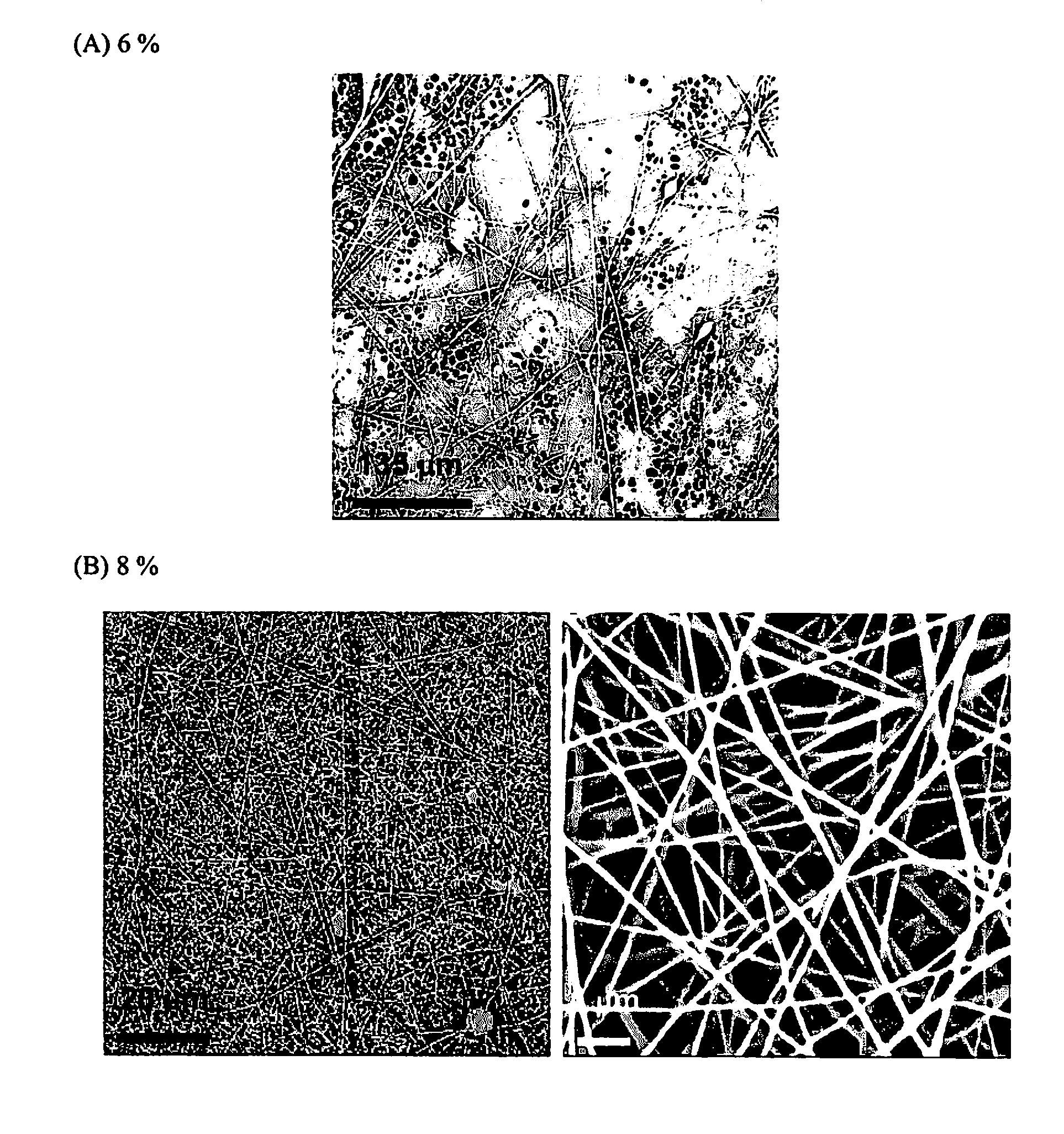

A method of forming electrospun fiber mats from a plurality of different biodegradable polymeric fibers is provided, in which a plurality of up to six different biodegradable polymer solutions are electrospun together by a method comprising the steps of providing a plurality of up to six different biodegradable polymer solutions each containing at least one biologically or pharmaceutically active material and each in communication with a needle for electrospinning a biodegradable polymer fiber from the solution, and pumping each solution through its respective needle into an electric field under conditions effective to produce uncontrolled charged jet streams of the polymer solutions directed at a grounded rotating mandrel, thereby forming fiber threads of the biologically or pharmaceutically active compounds and polymers in the solutions that are deposited on the mandrel to form an electrospun non-woven fiber mat, wherein the needles are positioned for co-deposition of the fiber threads from the polymer solution streams together on the mandrel to form a fiber mat.

Owner:RUTGERS THE STATE UNIV

Apparatus for electro-blowing or blowing-assisted electro-spinning technology and process for post treatment of electrospun or electroblown membranes

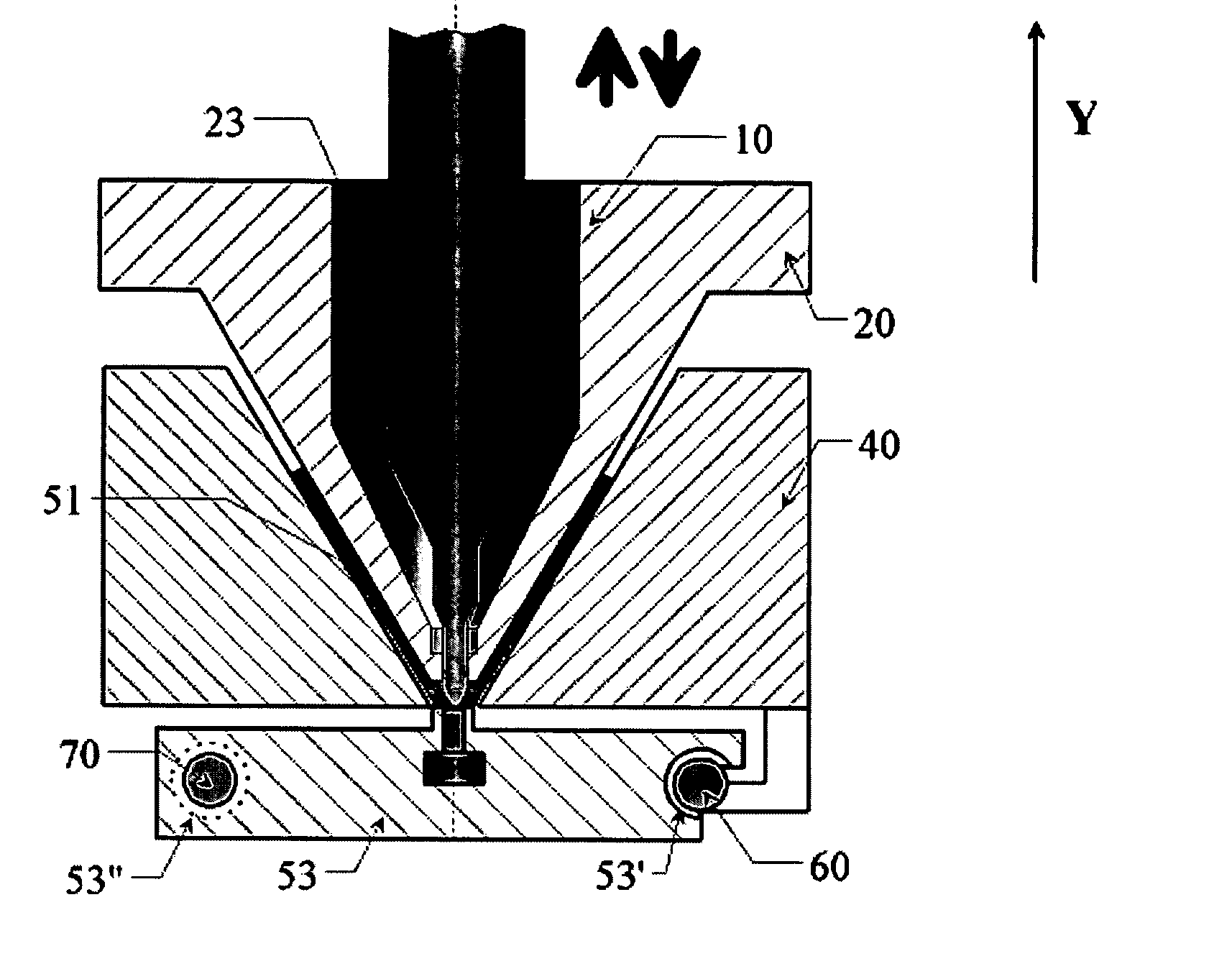

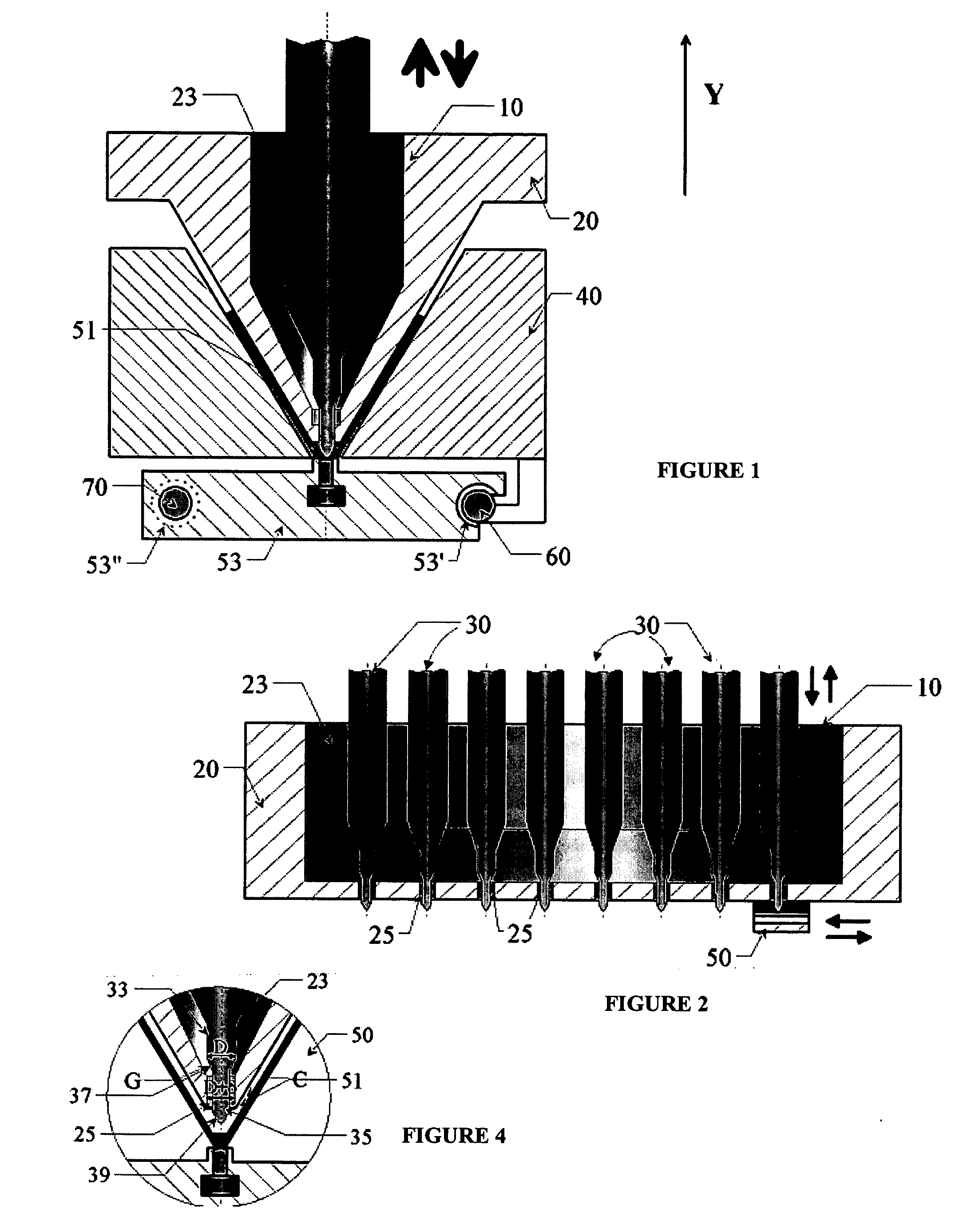

InactiveUS20060049542A1Improve throughputElectric discharge heatingMouldsEngineeringMembrane configuration

Owner:THE RES FOUND OF STATE UNIV OF NEW YORK

High flux high efficiency nanofiber membranes and methods of production thereof

A membrane is provided including a coating layer having cellulose nanofibers produced from oxidized cellulose microfibers and an electrospun substrate upon which the coating layer is applied. The nanofibers of the electrospun substrate have a diameter greater than that of the cellulose nanofibers. The membrane also has non-woven support upon which the electrospun substrate is disposed. Microfibers of the non-woven support have a diameter greater than that of the nanofibers of the electrospun substrate. Application of electrospun membrane is in microfiltration area, while the cellulose nanofiber membrane serves in ultra-filtration, nanofiltration, and reverse osmosis after chemical modification.

Owner:THE RES FOUND OF STATE UNIV OF NEW YORK

Electro-spinning process for making starch filaments for flexible structure

A flexible structure includes a plurality of starch filaments. The structure includes at least a first region and a second region, each of the first and second regions having at least one common intensive property selected from the group consisting of density, basis weight, elevation, opacity, crepe frequency, and any combination thereof. The common intensive property of the first region differs in value from the common intensive property of the second region.

Owner:THE PROCTER & GAMBLE COMPANY

Antibiotic nanometer fibrous material and method for preparing the same

InactiveCN1467314ASimple processing technologyGood effectArtifical filament manufactureFiberRepair tissue

An antibacterial nano-class fibre material contains superfine high-molecular fibres (60-98 wt.%) and antibacterial agent (2-40 wt.%), and is prepared through dispersing or dissolving one or more high-molecular material in solvent to become transparent solution or mixture, dispersing the superfine particle of antibacterial agent (less than 20 microns) in said solution, and electric spinning. It can be used as protecting material, disinfecting filter material and tissue covering material for repairing tissue or promoting healing of tissue.

Owner:SOUTHEAST UNIV

Therapeutic Electrospun Fiber Compositions

InactiveUS20100303881A1Promote nerve growthEfficient releaseBiocideNervous disorderFiberActive agent

The instant invention provides electrospun fiber compositions comprising one or more polymers and one or more biologically active agents. In specific embodiments, the biologically active agents are nerve growth factors. In certain embodiments, the electrospun fiber compositions comprising one or more biologically active agents are on the surface of a film, or a tube. The tubes comprising the electrospun fiber compositions of the invention can be used, for example, as nerve guide conduits.

Owner:THE JOHN HOPKINS UNIV SCHOOL OF MEDICINE

Titanium dioxide nanorod and preparation method thereof

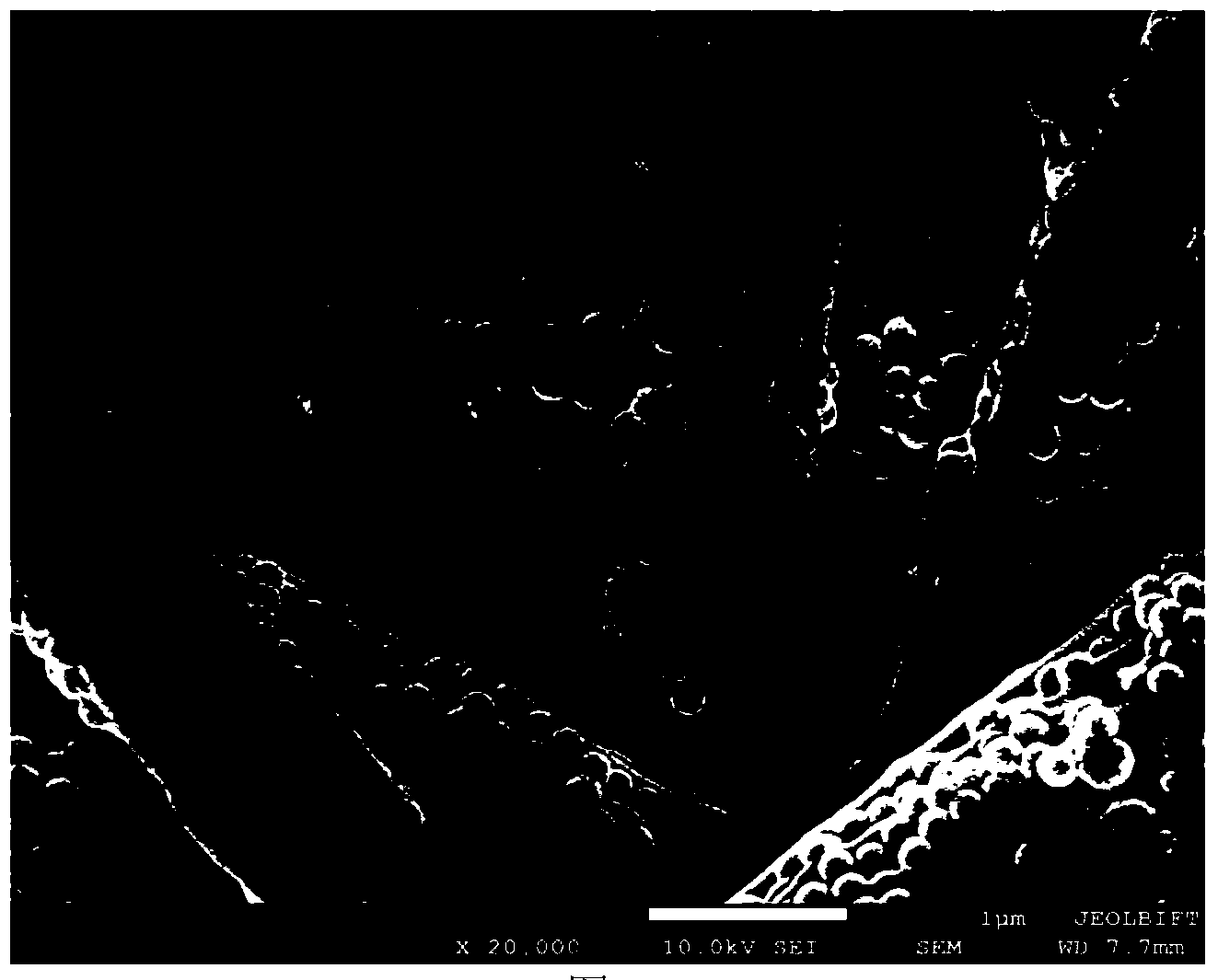

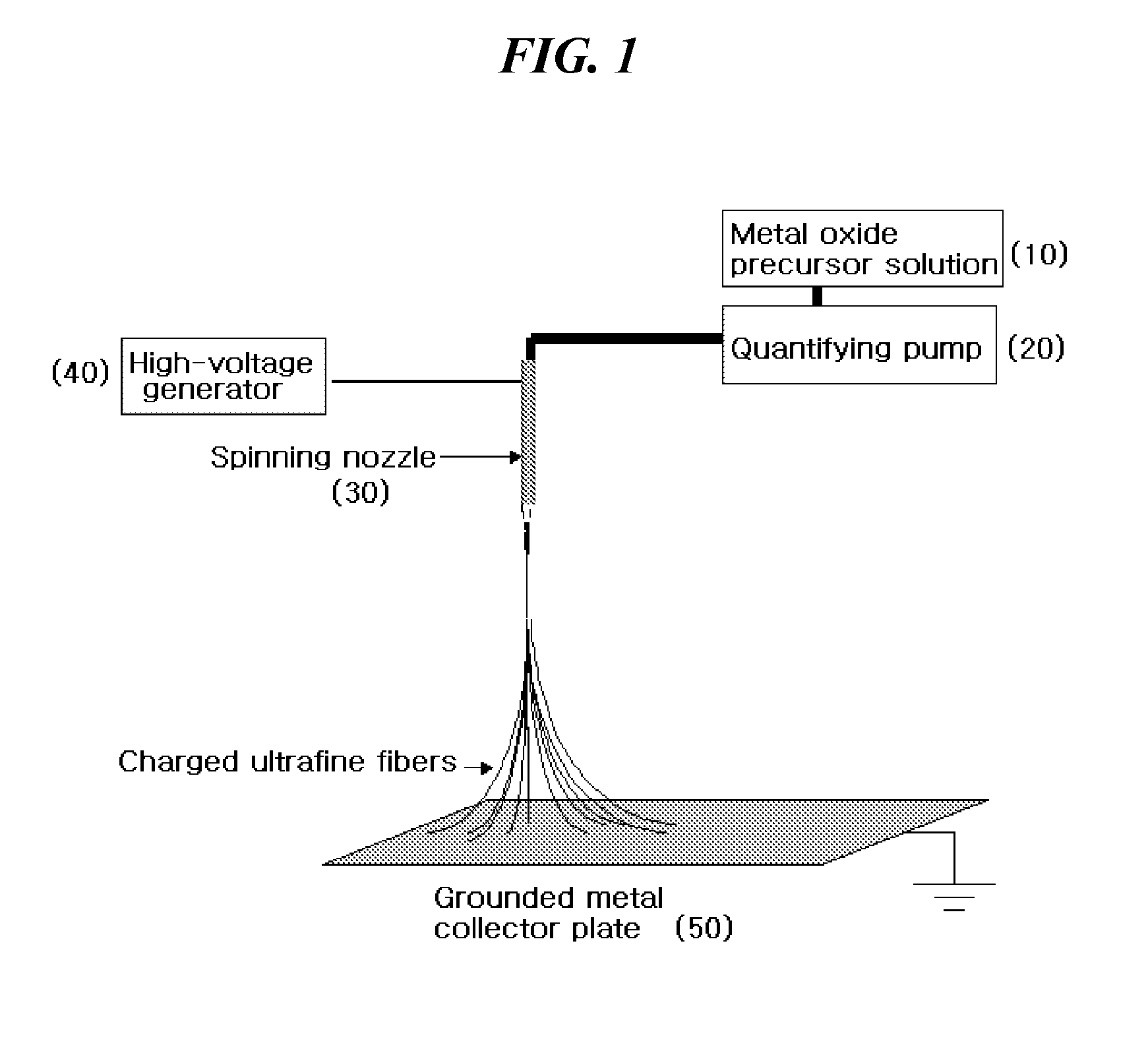

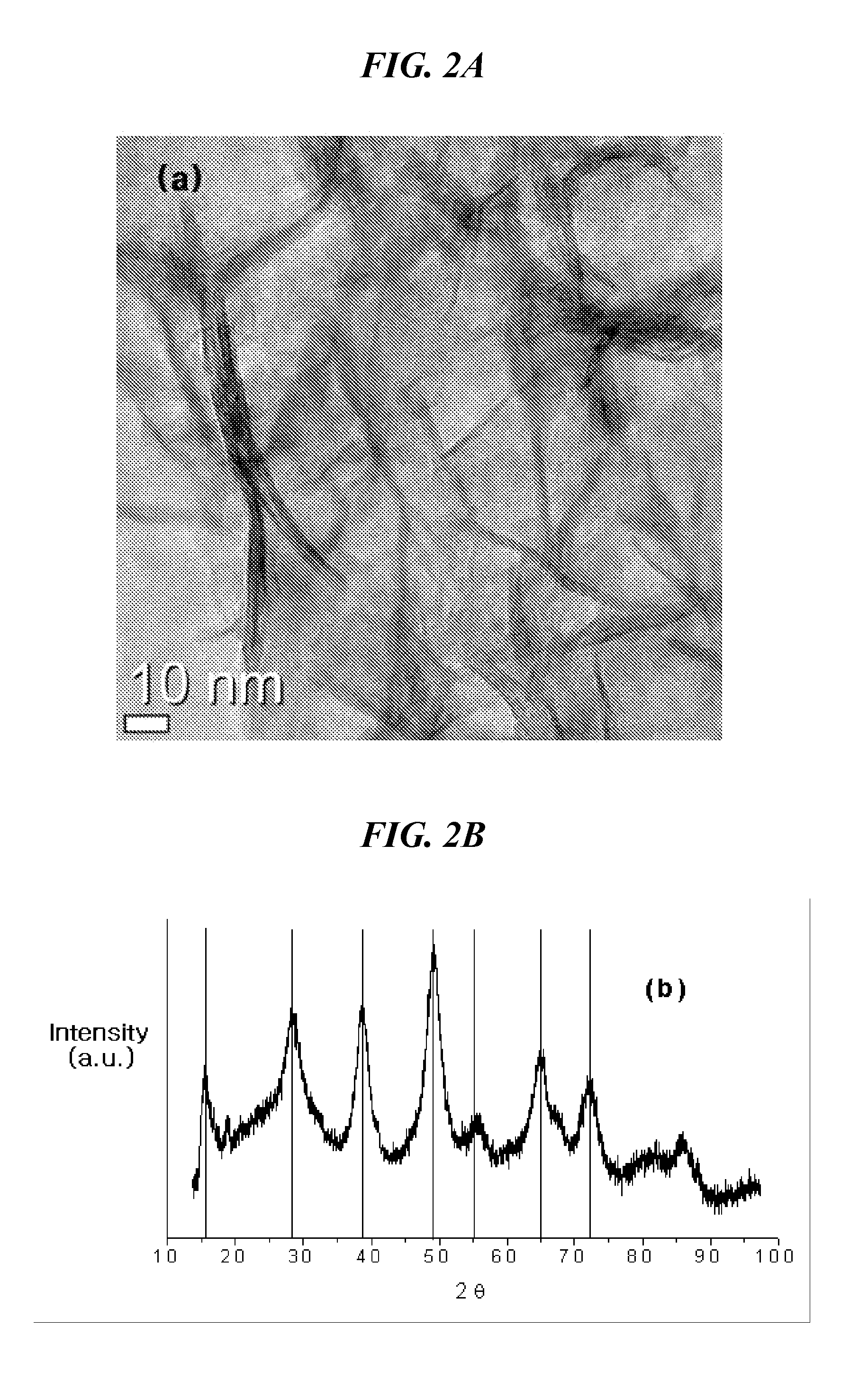

InactiveUS20070116640A1Easy to prepareMaterial nanotechnologyPigmenting treatmentFiberSingle crystal

A titanium dioxide nanorod having anisotropy and a preparation method thereof in which, particularly, an ultrafine composite fiber of polymer and titanium dioxide precursor and a single crystal titanium dioxide nanorod using a phase separation are prepared, wherein a mixed solution containing titanium dioxide precursor, polymer which is compatible with the precursor and solvent is prepared, the mixed solution is electrospun to form titanium dioxide polymer composite fiber containing ultrafine fibril structure therein by the phase separation between the titanium dioxide precursor and the polymer, the composite fiber is heat-pressed, and the polymer material is removed from the composite fiber, so as to obtain titanium dioxide nanorod, which can be used as dye-sensitized solar cells, various sensors, and photocatalysts.

Owner:KOREA INST OF SCI & TECH

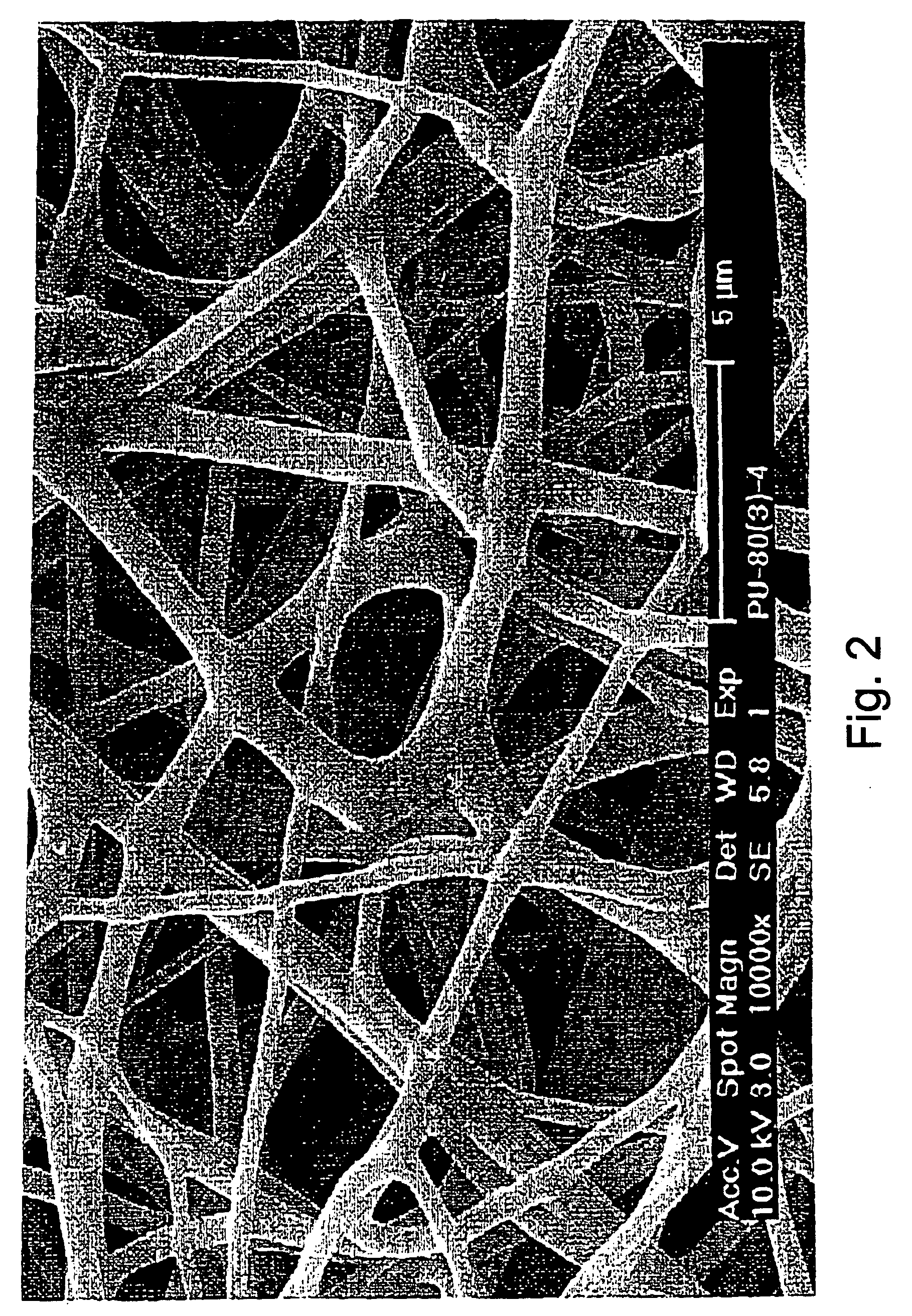

Efficient oil and water separation composite fiber film and preparation method thereof

InactiveCN103866492ASelf-supportingRealize multiple reuseFilament/thread formingNon-woven fabricsFiberHydrophobic polymer

The invention discloses an efficiency oil and water separation composition fiber film and a preparation method thereof, and belongs to the field of functional nanometer fiber materials. Hydrophobic polymers such as polyurethane, polystyrene and polymethyl methacrylate or polycaprolactone are used as the main raw materials of the fiber film, the main raw materials are dissolved in an organic solvent to form a polymer solution, hydrophobic nanometer particles are added into the polymer solution in the preparation process, after the mixture is evenly mixed, electro-spinning is conducted on the mixed solution by means of the electrostatic spinning method, and then a fiber film material which is formed by micro-nanometer composite structures and is in the shape of non-woven fabric is obtained. The electro-spun fiber film of the micro-nanometer structure has super-hydrophobic / super-oleophylic property in the air and excellent oil adsorption performance, and the contact angle to oil is nearly zero. The efficient oil and water separation composite fiber film is simple in preparation method, low in energy consumption, high in efficiency, high in oil and water separation speed, and capable of being widely used in the fields such as oily water efficient purification.

Owner:BEIJING INSTITUTE OF CLOTHING TECHNOLOGY

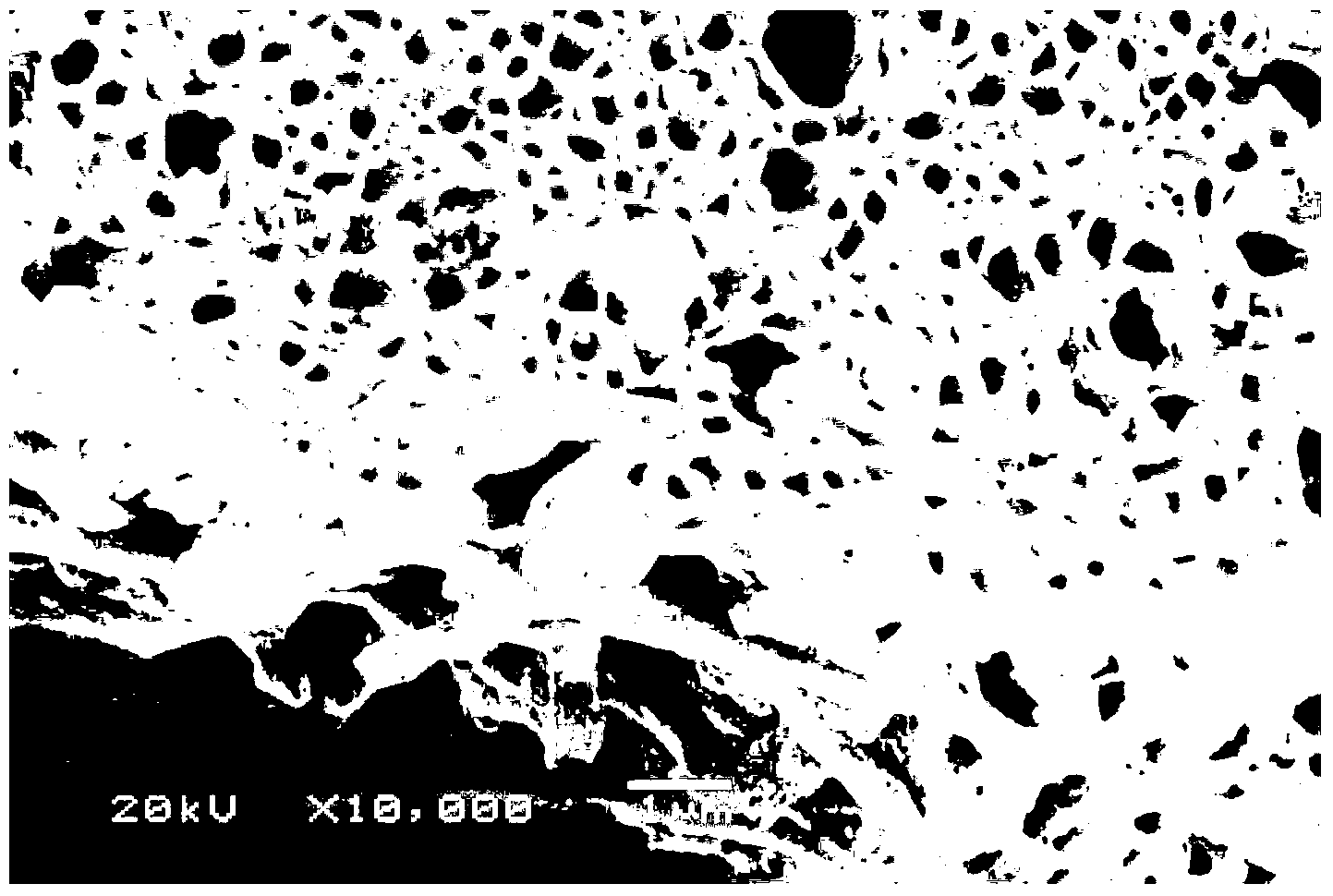

Preparation method of silicon-carbide-fibrofelt-enhanced silica aerogel composite material

The invention relates to a preparation method of a silicon-carbide-fibrofelt-enhanced silica aerogel composite material, and relates to an aerogel composite material. According to the invention, a carbon-rich silicon carbide micro-nano ceramic fibrofelt with small fiber diameter, high porosity, communicating pores, fast impregnation speed, and good compatibility with a substrate is prepared with a static electro-spinning technology combined with a precursor conversion method; a silica sol is prepared with an acid-alkali two-step method; with an infiltration technology, the electro-spun silicon carbide ceramic fibrofelt or precast is soaked into the sol; and through processes such as gel process, aging, curing, solvent exchange, supercritical drying, and the like, the silicon-carbide-fibrofelt-enhanced silica aerogel composite material is obtained. The prepared composite material has the characteristics of low density, large specific surface area, super-hydrophobicity, low thermal conductivity, and the like. The strength and toughness of the material are also greatly improved. The carbon-rich silicon carbide fiber has an infrared shielding effect, such that composite material thermal insulation effect and ultra-high-temperature stability can be improved.

Owner:ZHONGKE RUNZI (CHONGQING) ENERGY SAVING TECH CO LTD

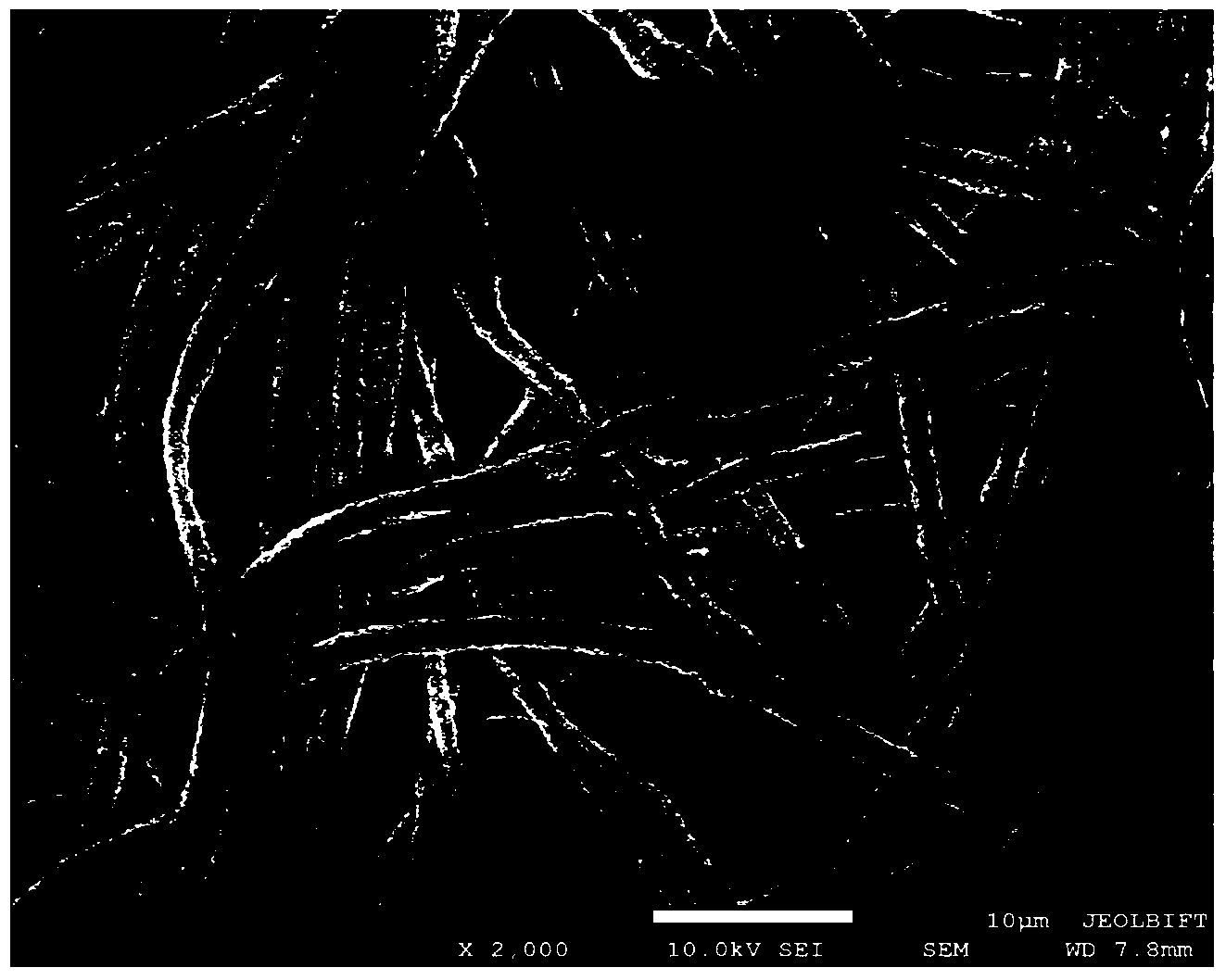

Orientation electro-spinning nanometer fiber spinning method and device thereof

InactiveCN103132194AHigh degree of axial orientationSuppress spinning instabilityDrafting machinesFilament/thread formingBobbinEngineering

The invention discloses an orientation electro-spinning nanometer fiber spinning method and a device thereof. A metal shower nozzle which exerts positive and negative high pressure is adopted to spin two strands of nanometer fibers with opposite charges, an electric field line of a spinning electric field, relative to a common spinning electric field, is straight, stability of spinning is effectively restrained, and the spinning nanometer fibers are straight. Two strands of the fibers surround the yarn tail and form a cone-shaped twisting trigonum on the upper portion of a metal twisting machine, and enable the nanometer fibers to be further oriented and twisted to form yarn through electric field force, tractive force of the yarn and acting force of the metal twisting force. The spinning nanometer fiber yarn is conducted heat shaping through a heat processing device under certain tensile force, degree of orientation of the nanometer fibers along the axial direction of the yarn, breaking force and yarn levelness are further improved, and the yarn after shaped is collected by a winding bobbin. The device can achieve the aim that orientation nanometer fiber yarn can be continuously prepared, is simple in device, convenient to operate, and good in resultant yarn continuity, yarn breaking strength and yarn levelness, and not only can spin pure nanometer fiber yarn, but also can spin nanometer fibers / filament core composite yarn. The orientation nanometer fiber spinning method and the device thereof have important application value in the fields, such as a biomedical field and a sensor field.

Owner:杨恩龙 +1

Electro-spinning nano fibre nonwoven production apparatus

ActiveCN101476167AImprove melting effectSolve insulation problemsFilament/thread formingNon-woven fabricsSynchronous motorNanofiber

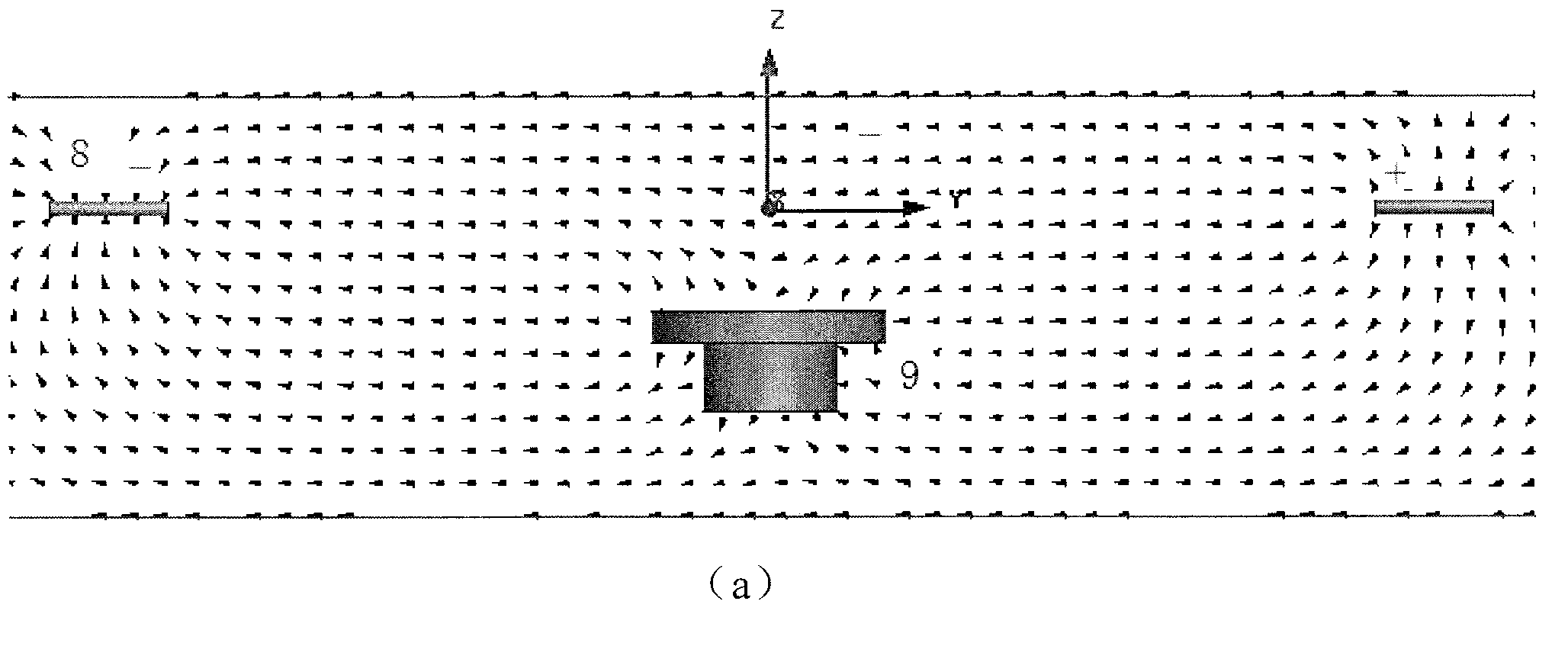

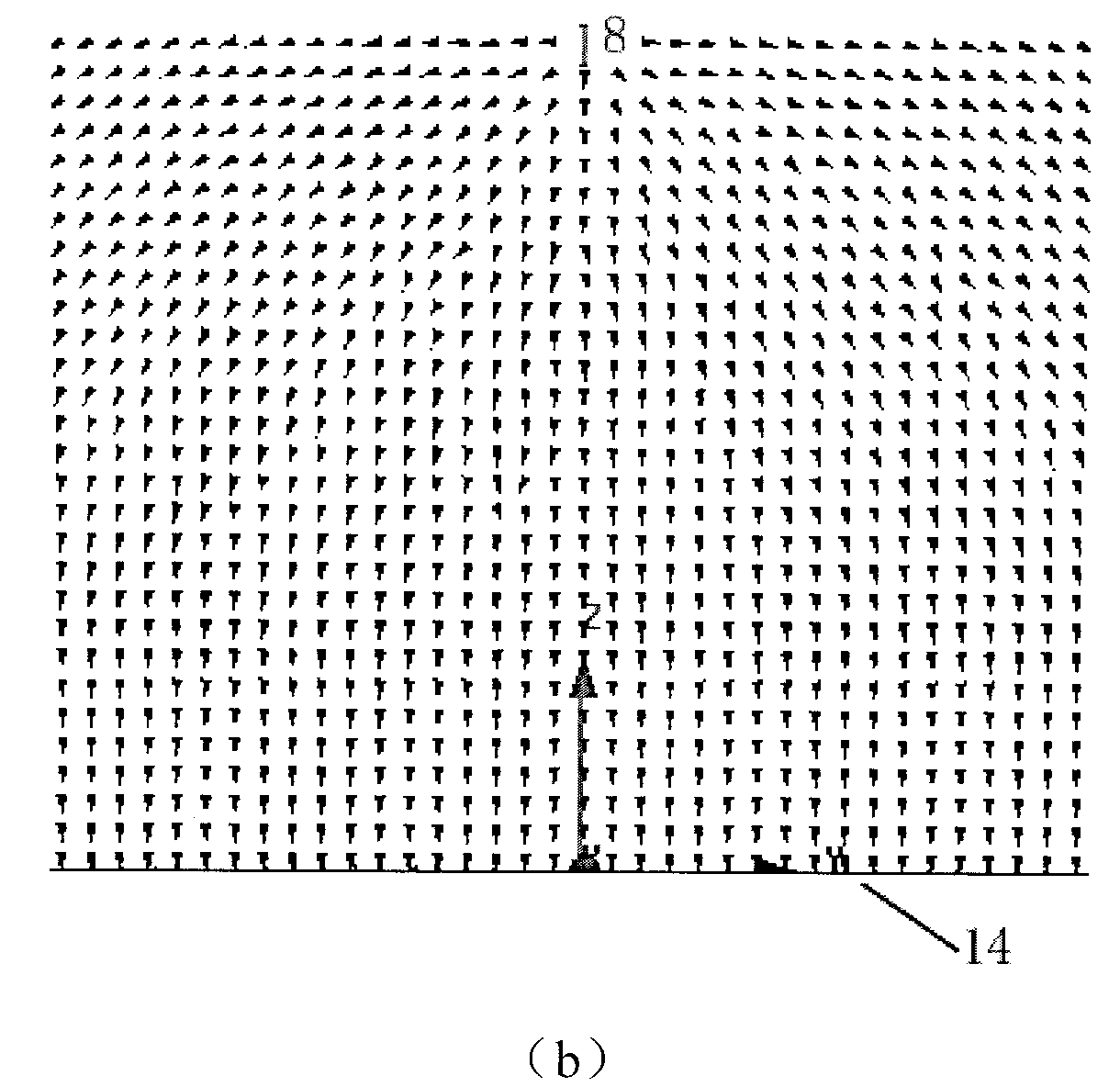

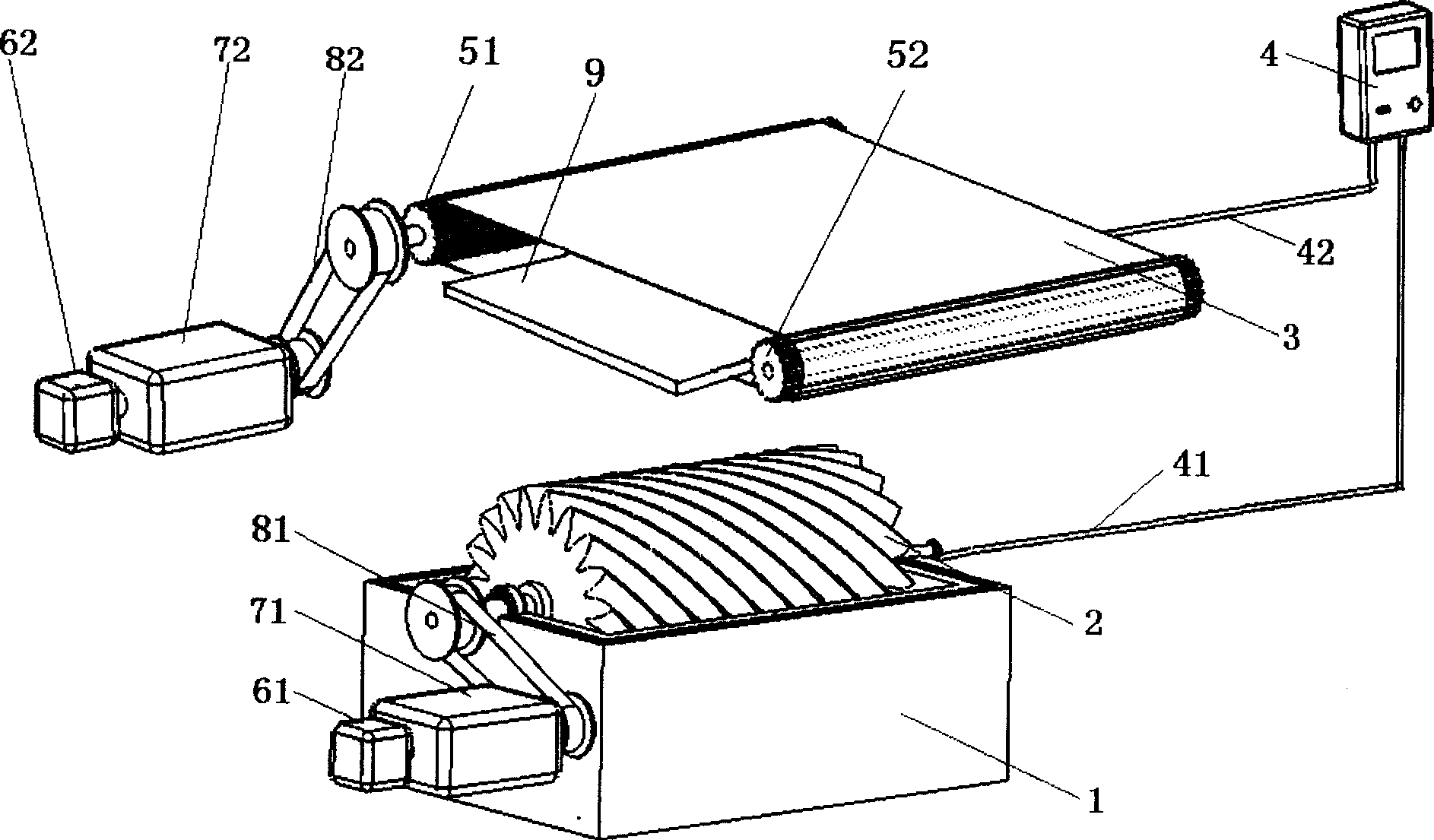

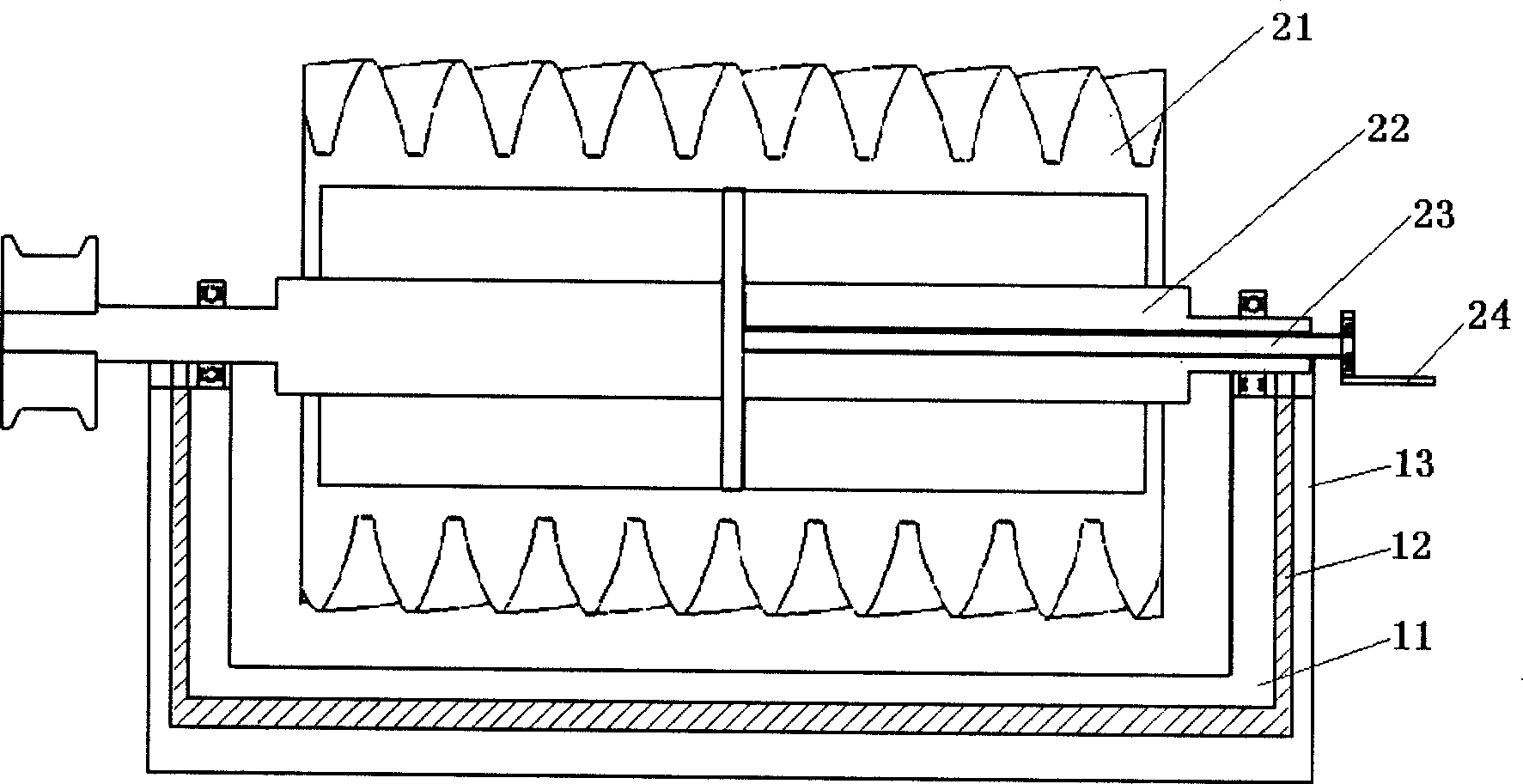

The invention provides a production unit for mass producing electro-spinning nano fibre non-weaving cloth which includes: a meltdown pool 1, a metal roller 2, a receiving lace curtaining 3, a high voltage static generator 4, an initiative guide roll 51 and a passivity guide roll 52, a roller synchronous motor 62, a roller reductor 71, a roller belt pulley 72, a lace curtaining reductor 81, a lace curtaining belt pulley 82, an earth metal plate 9. Four sides and bottom of the meltdown pool 1 is composed of a ceramic outside wall 13, a middle heating layer 12 and a ceramic inner wall 11, the sandwich design structure has better insulation effect and solves heating problem of polymer melt. Compared with prior electro-spinning mass production, the unit can satisfy melt electro-spinning need, and also can be used for solution electro-spinning for realizing multi-use of one machine.

Owner:TIANJIN WEICHER TECH

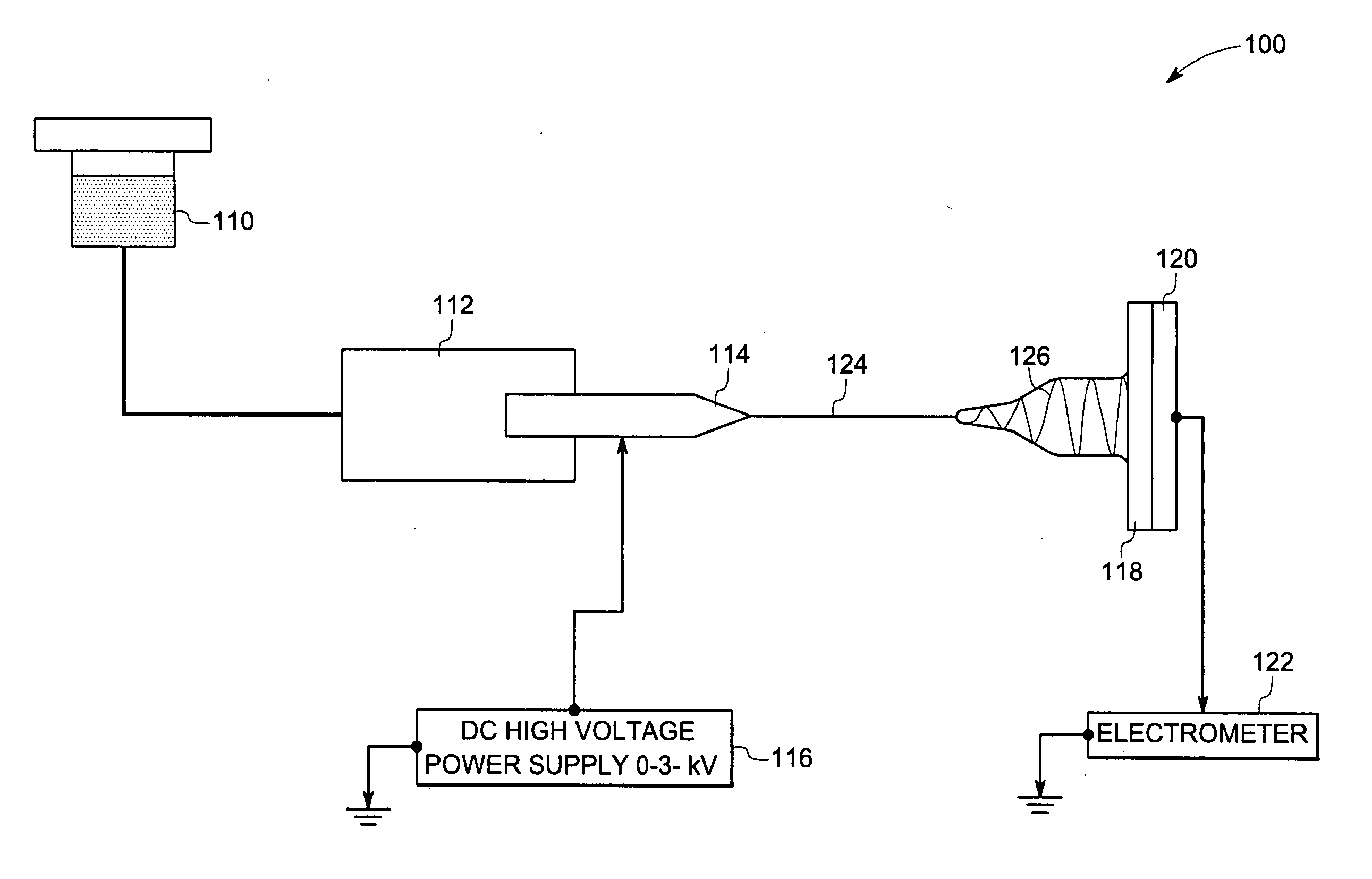

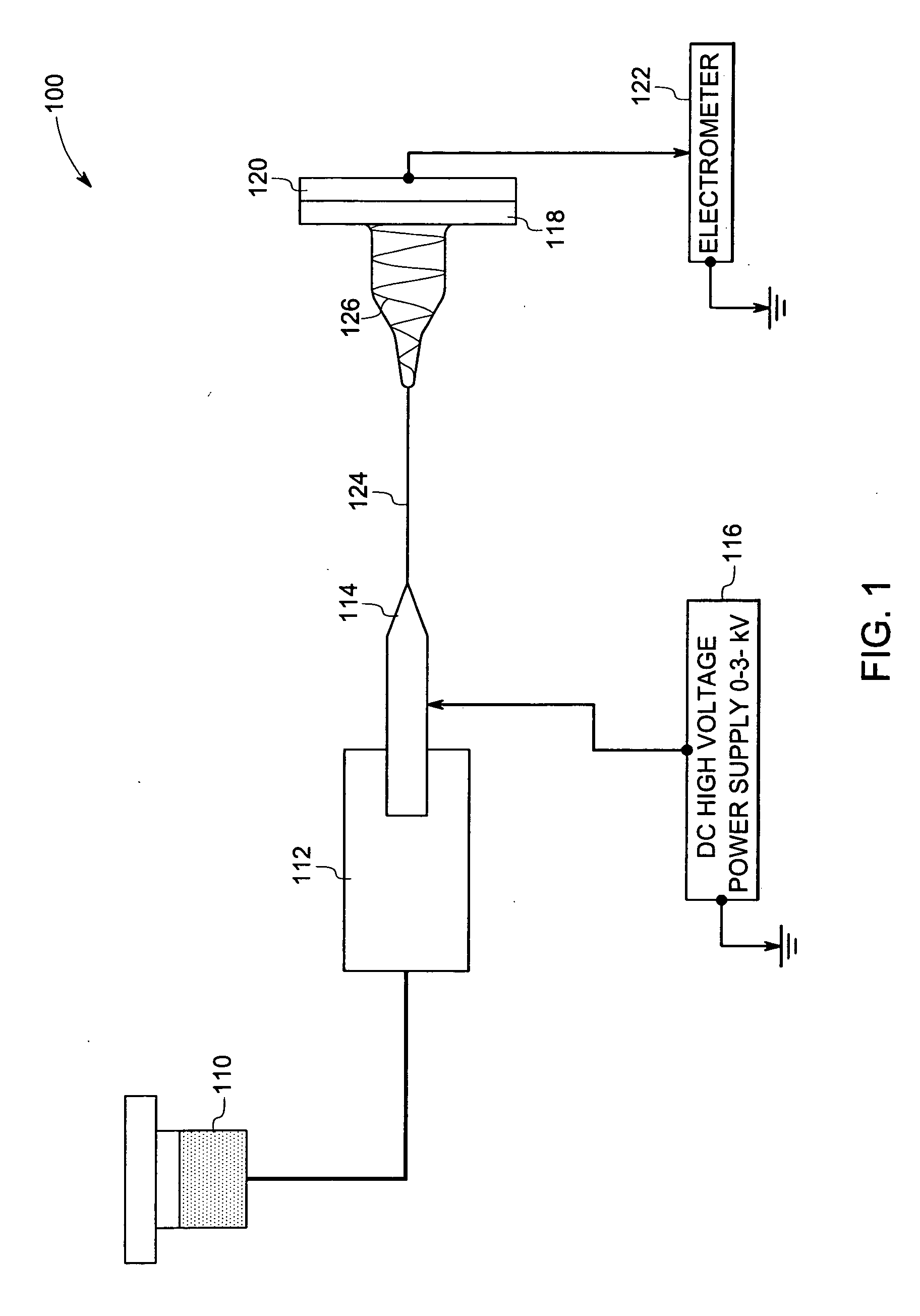

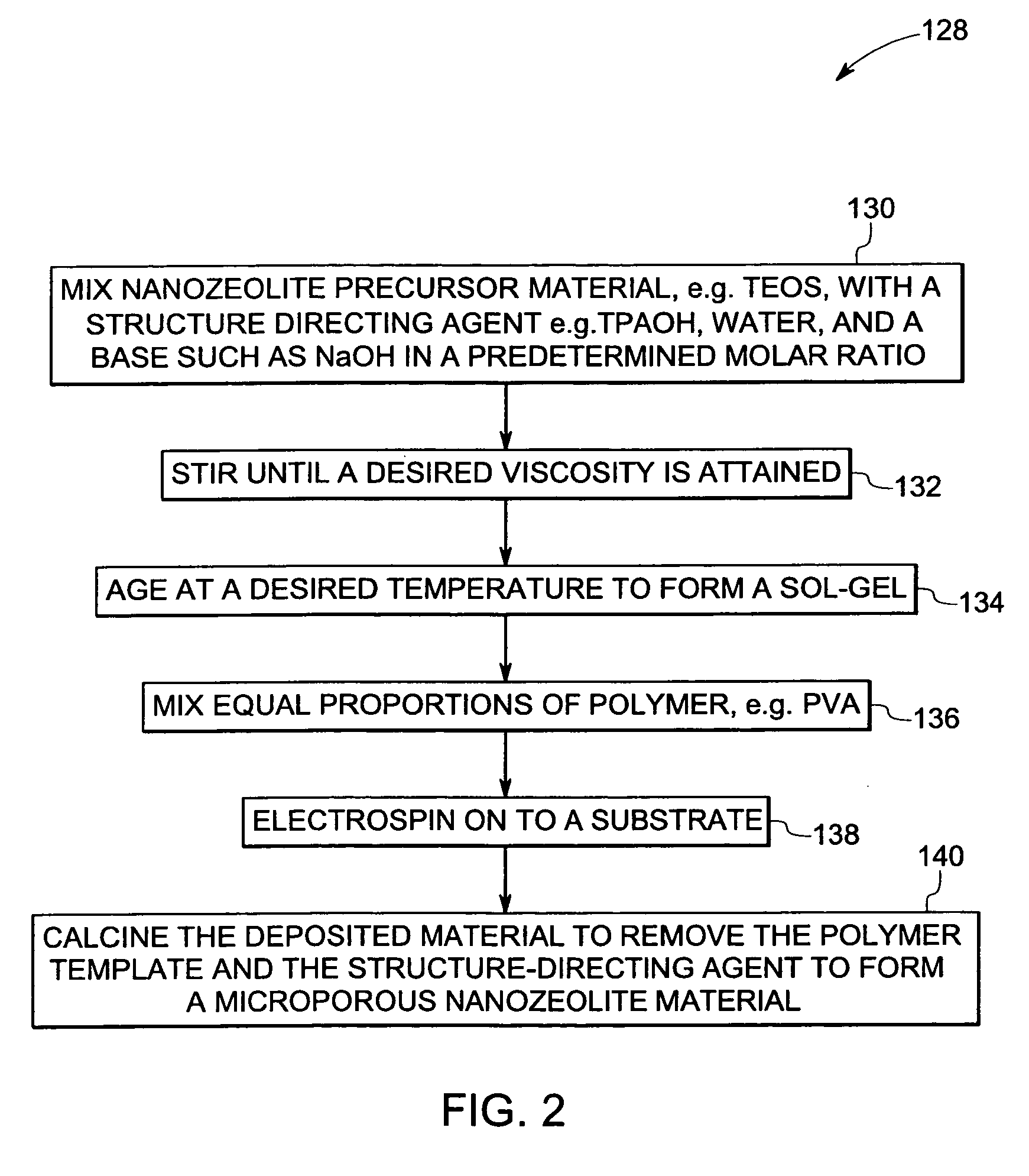

Molecular structures for gas sensing and devices and methods therewith

InactiveUS20060293169A1Material nanotechnologyMolecular sieve catalystsAqueous solutionMaterials science

A porous nanozeolite material having a first dimension less than about 1 micron and a second dimension less than about 100 microns. The nanozeolite material comprises pores having an average diameter less than about 50 nm. A method of making microporous nanozeolites is provided. The method comprises the steps of providing an aqueous solution comprising at least one nanozeolite precursor material or zeolite particles, and electrospinning the aqueous solution onto a substrate to form an electrospun material. The electrospun material comprises microporous nanozeolites. A method of making mesoporous nanozeolites is also provided. The method comprises the step of providing an aqueous solution comprising a nanozeolite precursor material and at least one structure directing agent, and electrospinning the aqueous solution onto a substrate to form an electrospun mesoporous nanozeolite material. A gas sensor device is provided. The device comprises nanozeolite sensing material.

Owner:GENERAL ELECTRIC CO

Method for preparing galvanic deposit calcium phosphorus mineralized layer superfine fibre bone material

The invention relates to a method for preparing superfine fiber bone materials of an electrodeposition calcium phosphate mineralized layer, which comprises the following steps: firstly, high-polymer superfine fibers are prepared on the surface of a metal electrode by adoption of electrostatic spinning and taken as an electrochemical deposition template; a layer of bone salt ingredients which are rich in calcium and phosphor is deposited on the surface of the fibers by the constant-voltage or constant-current deposition technology; mineralized superfine fibers are soaked into 0.1 to 1.0 mol per liter of NaOH solution for 1 to 24 hours; mineralized electro spinning fibers are subjected to die stamping into blocks under the pressure of between 10 and 40 MPa; and the porous bone materials with a porosity between 50 and 90 percent and a pore diameter between 50 and 500 micrometers are processed by the salt particle leaching / gas foaming technology, and are used for bone defect restoration after freeze-drying sterilization. The porous bone materials prepared by the method have better biocompatibility; and the electrochemical deposition technology can prepare organic-inorganic composite materials with higher bone salt content within a shorter period; and the preparation time is short and the preparation conditions are mild.

Owner:DONGHUA UNIV

Antibacterial type blended electro spinning nanometer fiber membrane biological dressing and the preparing method thereof

InactiveCN101062426AIncrease the areaHigh porosityFilament/thread formingAbsorbent padsFiberPolyvinyl alcohol

The invention discloses a blending electric spun nanometer fiber film biological compress and preparing method in medicinal biological compress technical domain, which is characterized by the following: choosing chitose or polyvinyl alcohol or water-soluble antibacterial drugs as main raw material; adopting electrostatic spinning method; producing nanometer fiber film. This product possesses the advantages of higher strength, good air perviousness and good biological compatibility.

Owner:BEIJING UNIV OF CHEM TECH

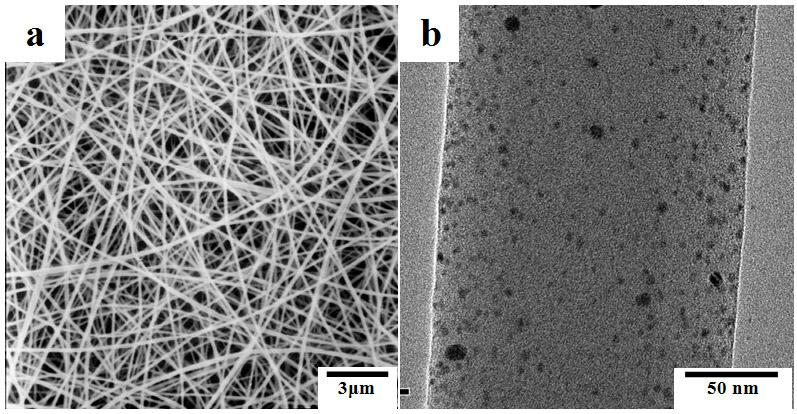

Fuel cell ordered porous nano-fiber single electrode, membrane electrode and preparation method

InactiveCN103413947AShorten the transmission distanceIncrease profitMaterial nanotechnologyCell electrodesPorositySlurry

The invention discloses a fuel cell ordered porous nano-fiber single electrode, a membrane electrode and a preparation method. Polymer nano-fibers are deposited on one side of a gaseous diffusion material through an electro-spinning technology; metal nanoparticles with catalytic activity are deposited on the surfaces of the polymer nano-fibers by using magnetron sputtering and vacuum evaporation methods, or catalyst slurry is directly sprayed to one side of a nano-fiber thin film to form a porous single electrode; then two single electrodes and a layer of proton exchange membrane are combined into a three-in-one membrane electrode. The fuel cell ordered porous nano-fiber single electrode, the membrane electrode and the preparation method have the beneficial effects that the conventional micro-porous layer is substituted by the nano-fiber layer with high porosity and high specific surface area, prepared by electro-spinning, so that the catalytic activity area is increased and the three-phase reaction interface and the mass transfer are facilitated, and an active metal catalytic layer formed by magnetron sputtering and vacuum evaporation has high adhesion, is uniform in coating and has controllable thickness, so that the using amount of the active metal catalyst is reduced and the utilization rate of the catalyst is also greatly increased.

Owner:WUHAN UNIV OF TECH

Nanofibrous electrocatalysts

ActiveUS20140093790A1Promoting mass transportImproves thermalMaterial nanotechnologyFuel and secondary cellsNanofiberMetal

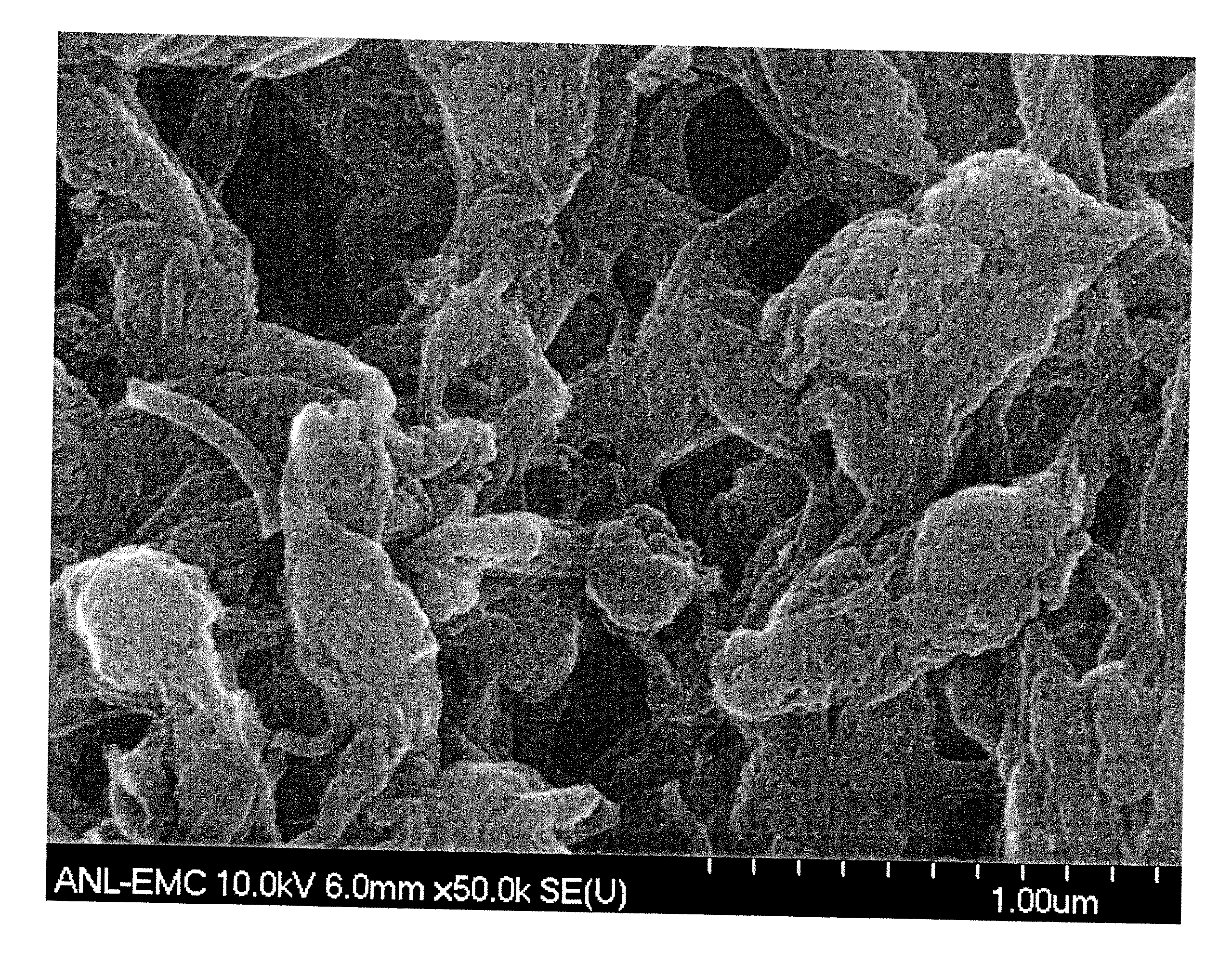

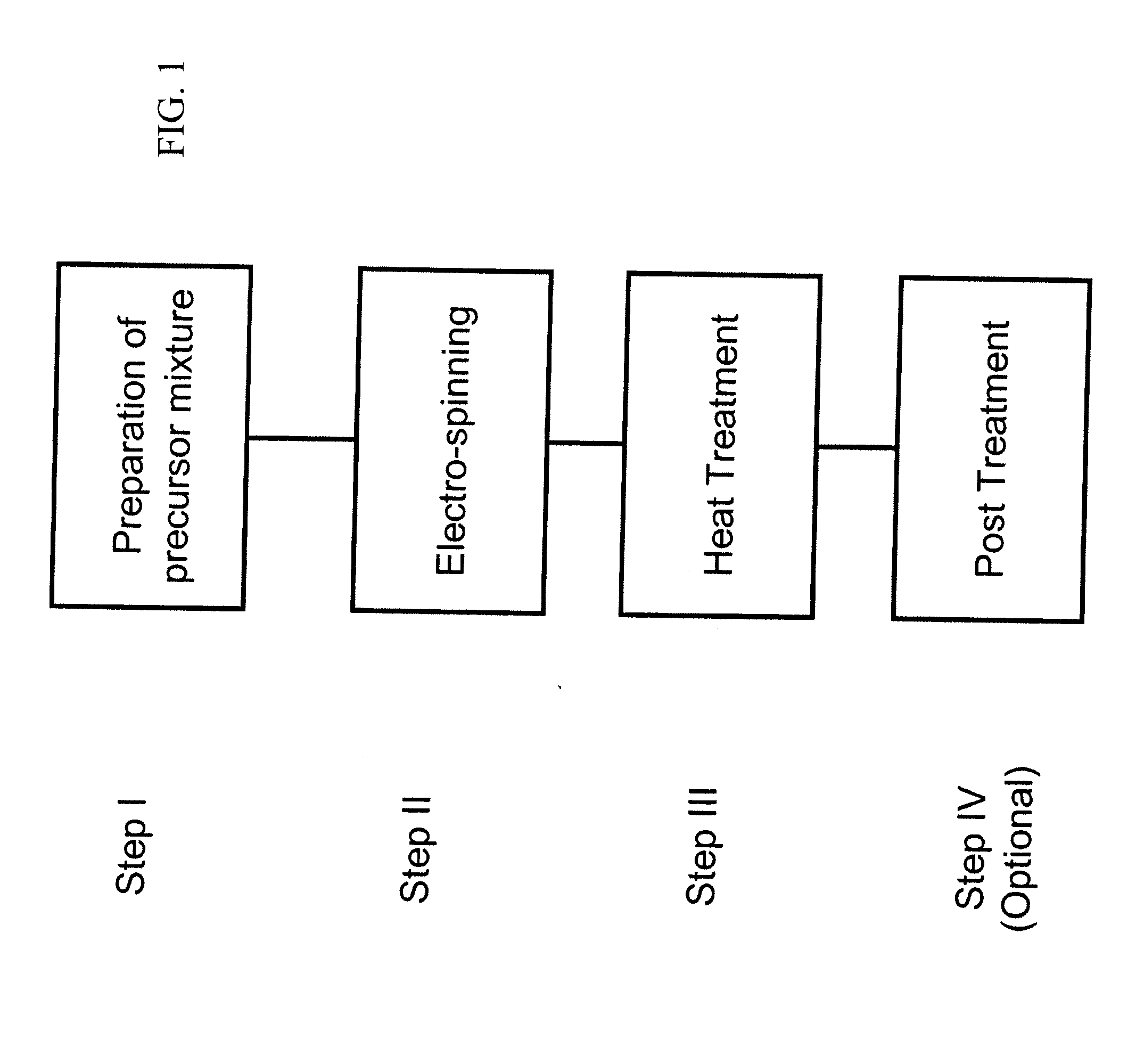

A nanofibrous catalyst and method of manufacture. A precursor solution of a transition metal based material is formed into a plurality of interconnected nanofibers by electro-spinning the precursor solution with the nanofibers converted to a catalytically active material by a heat treatment. Selected subsequent treatments can enhance catalytic activity.

Owner:UCHICAGO ARGONNE LLC

Medical anti-sticking membrane and preparation method thereof

The invention provides a medical anti-sticking membrane and a preparation method thereof. The anti-sticking membrane comprises a nanometer frame and hydrosol attached thereon. The hydrosol is internally packed with one or several kinds of styptic medicament or / and anti-sticking medicament. The invention also provides a preparation method of the anti-sticking membrane, comprising the following steps of: preparing electro-spinning solution, styptic medicament and / or anti-sticking medicament-containing hydrosol solution and crosslinker solution; receiving static spinning with the crosslinker solution to obtain the nanometer frame; printing the styptic medicament and / or anti-sticking medicament-containing hydrosol solution onto the nanometer frame by an ink-jet printer, and solidifying the hydrosol solution to obtain the anti-sticking membrane. The anti-sticking membrane has good capability and biological compatibility, and nontoxicity as well as nonirritant, can be completely degraded and absorbed, is compounded with controllably released styptic medicament or / and anti-sticking medicament, has controllable degrading time and speed, and conquers defects of the prior art.

Owner:MEDPRIN REGENERATIVE MEDICAL TECH

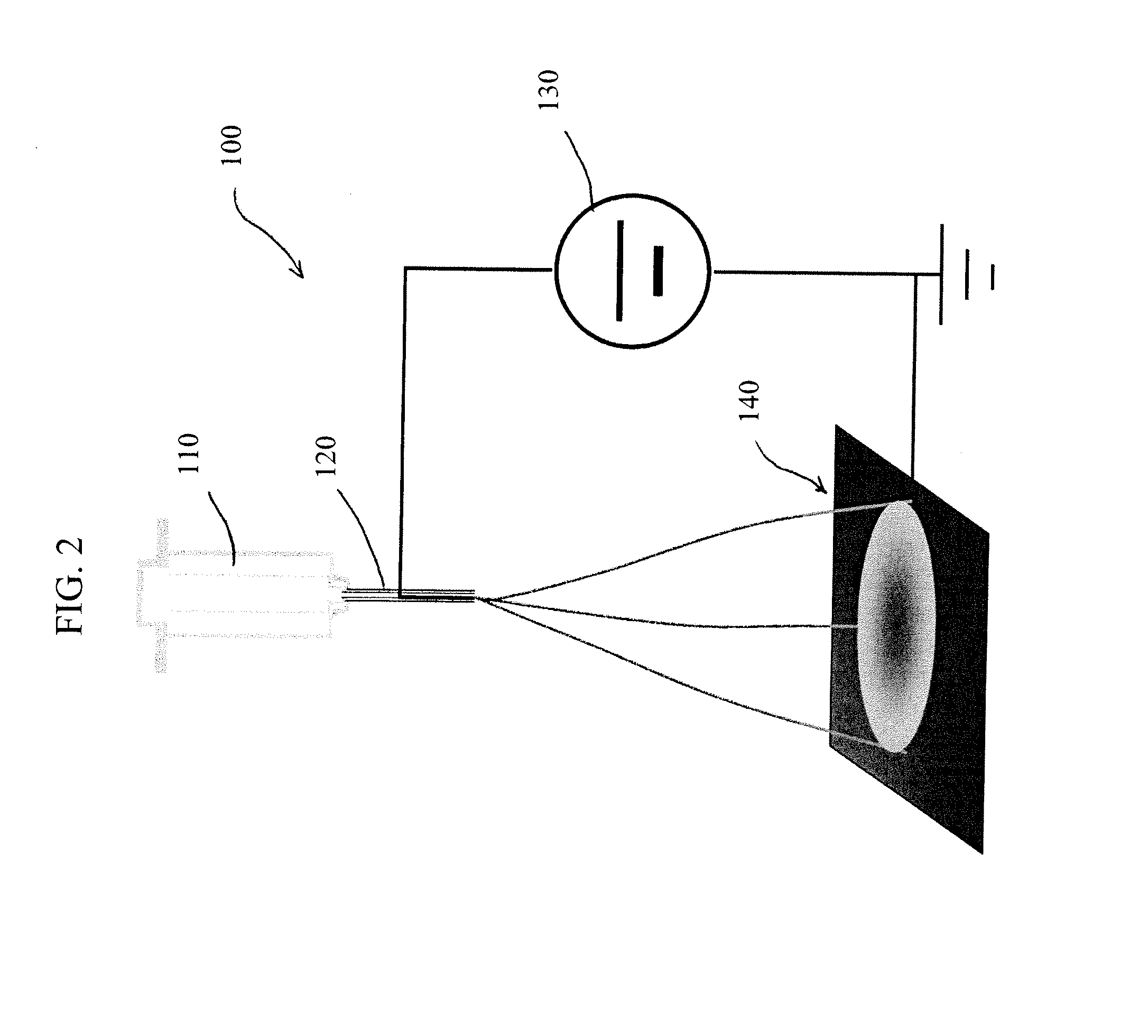

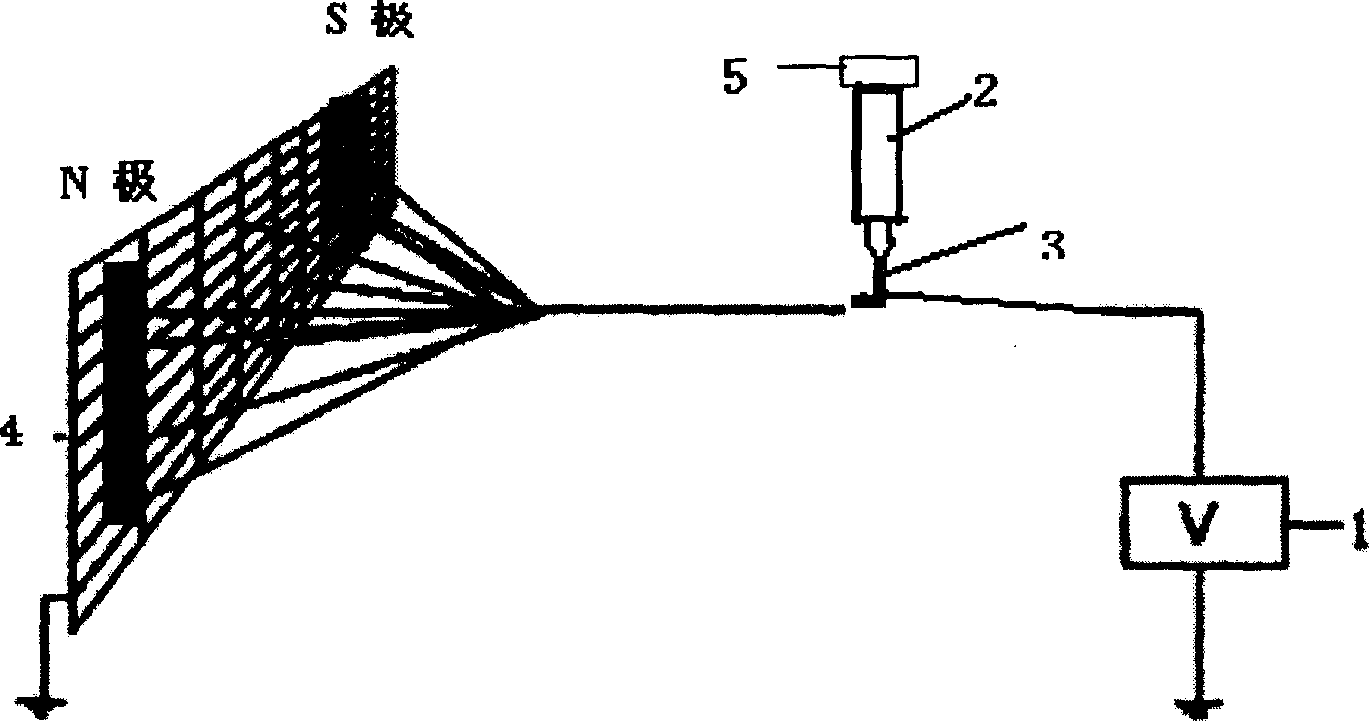

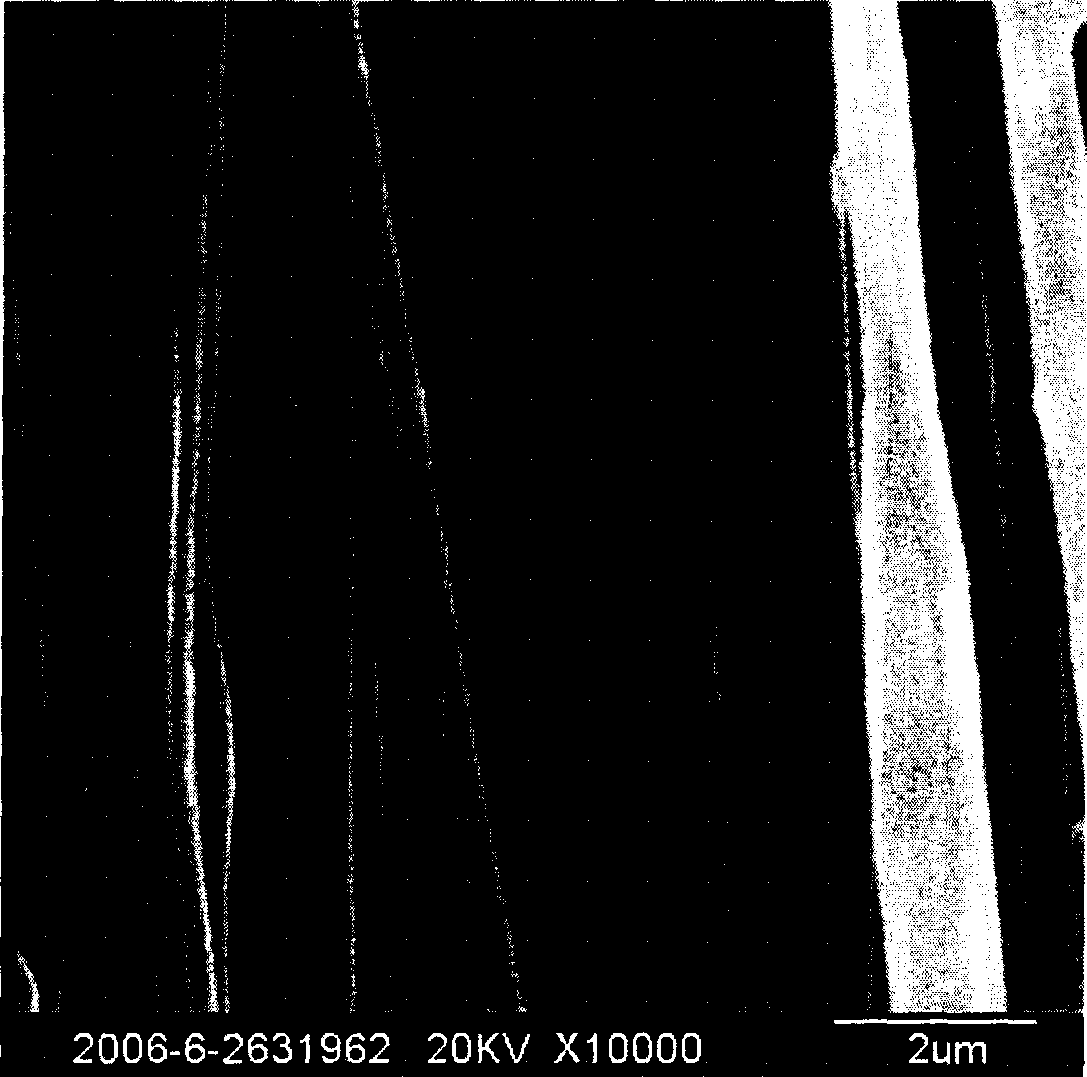

Directional magnetic electrical spinning Nano fibers, preparation method and equipment needed

InactiveCN1873064ASimple preparation processEasy to operate and repeatFilament/thread formingMonocomponent polyesters artificial filamentNormal positionEngineering

A method for preparing directional magnetic nanofiber of electric-spinning type includes utilizing Fe3O4 magnetic fluid and high polymer solution as raw material and applying normal position composite means to carry out electric-spinning under certain conditions, setting magnetic field at receiving unit to use magnetic field to induce high polymer nanofiber containing Fe3O4 to be directionally arranged along magnetic field direction for obtaining nanofiber being set with diameter of 100-600nm and being directionally arranged along magnetic direction. The device for realizing said method is also disclosed.

Owner:BEIJING UNIV OF CHEM TECH

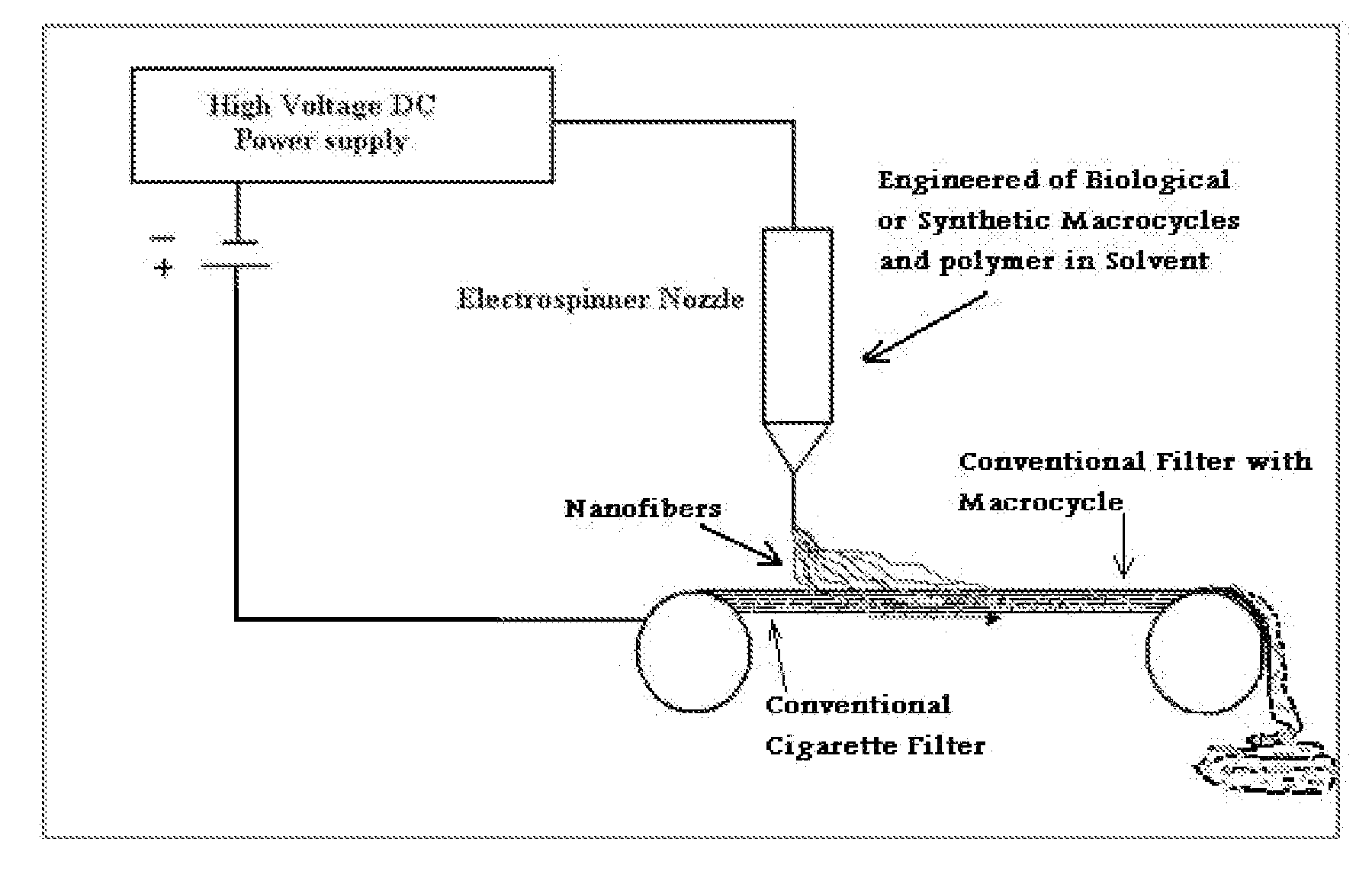

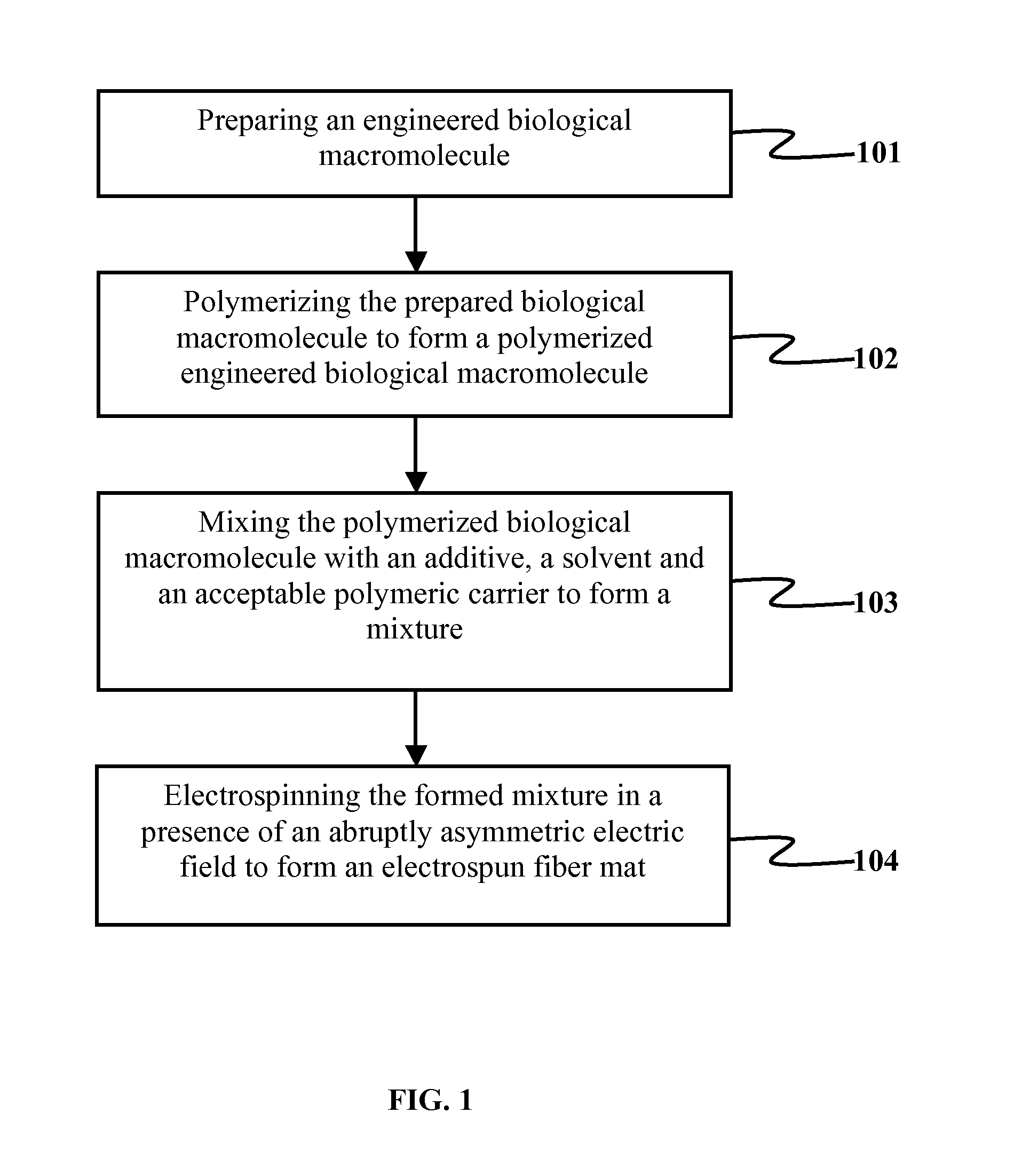

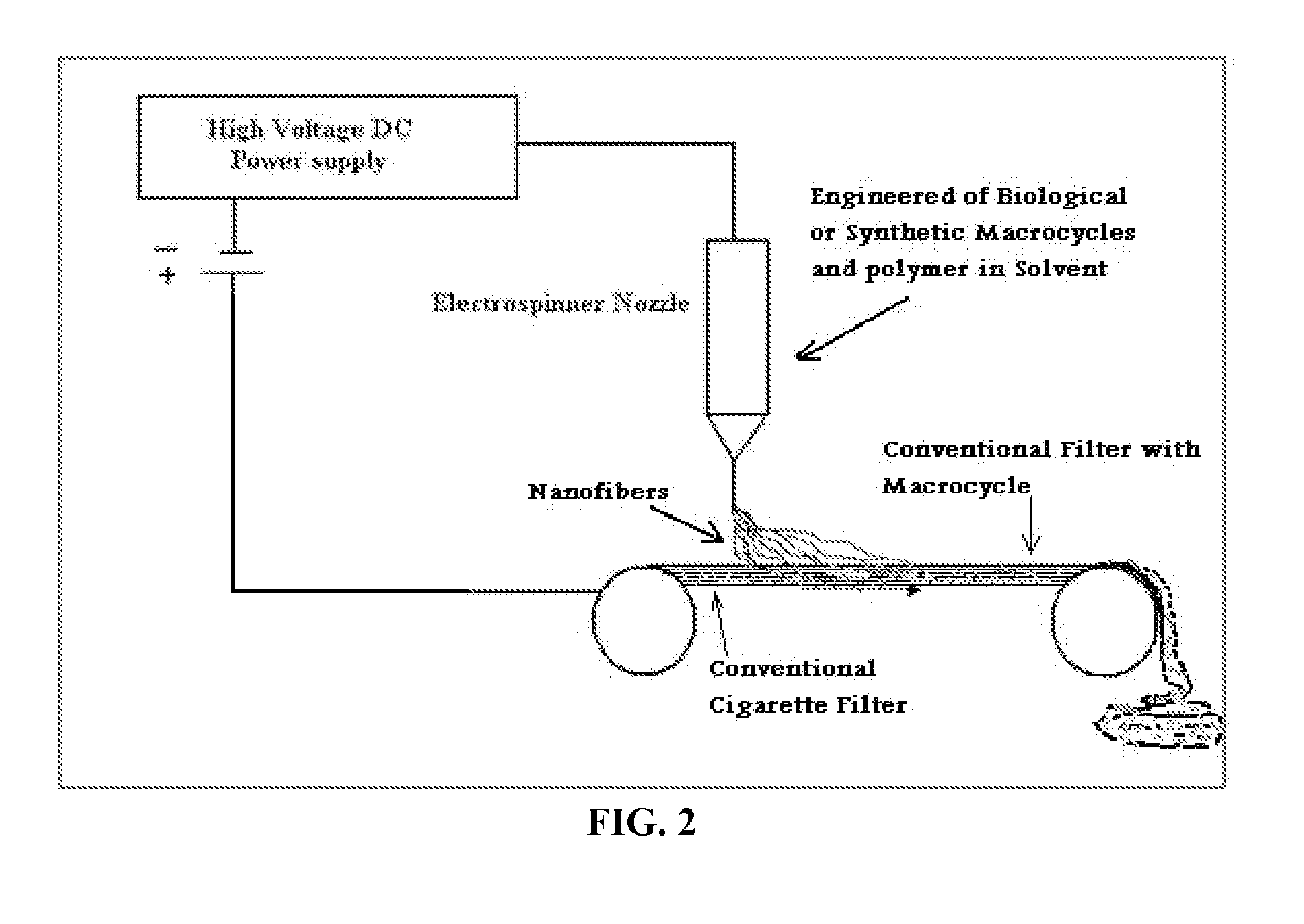

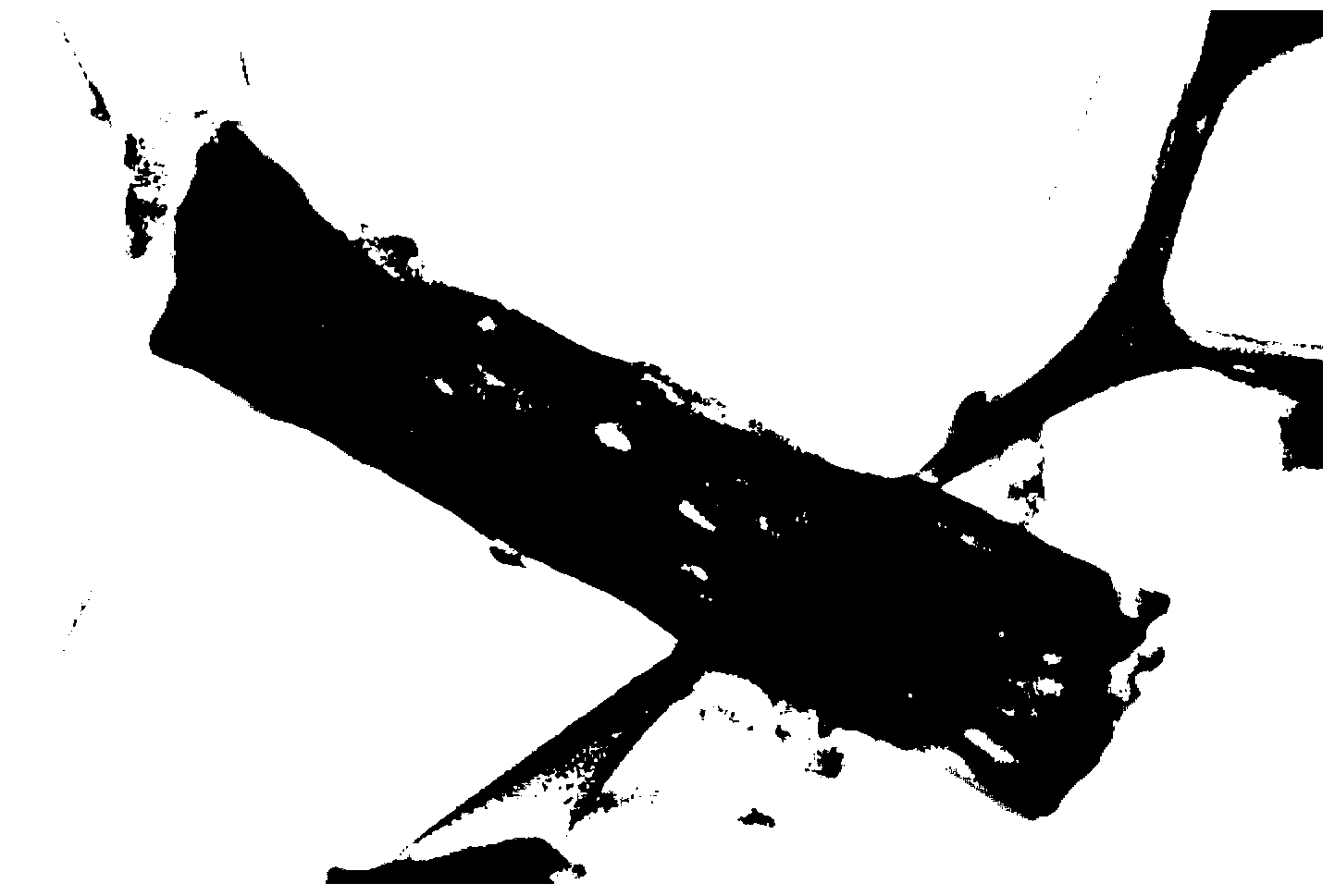

Nanostructural filter for removing toxic compounds

The various embodiments herein provide an electrospun fiber mat filter comprising a cigarette filter containing macrocycle for removing toxic compounds from a toxic material, wherein the toxic material comprises liquid, gas, and cigarette smoke and a method of synthesizing the same. The electrospun fiber mat cigarette filter comprises a biological, organic or synthetic macrocycle, plurality of additives, a solvent and an acceptable polymeric carrier. The biological macromolecules are engineered polyhemoglobin and / or chlorophyll. The biological, organic, or synthetic macrocycle are electrospun with the acceptable polymeric carrier in presence of an abruptly asymmetric electric field to form an electrospun fiber mat. The electrospun fiber mat is made up of networks of plurality of nanofibers.

Owner:GHANAVI JALALEDIN

Porous hollow carbon nanofiber as well as preparation method and application thereof

InactiveCN103233299AKeep shapeEasy hole makingHollow filament manufactureCarbonizationCarbon nanofiber

The invention discloses a method for preparing porous hollow carbon nanofiber by using metal salt pore-forming. The method comprises the following steps of: mixing metal salt with polyacrylonitrile to prepare outer-layer fluid; preparing inner-layer fluid by using soluble or volatile oil; respectively inputting the outer-layer fluid and the inner-layer fluid into the outer layer and the inner layer of a coaxial electrospinning spray head at a constant flow velocity and velocity ratio to carry out coaxial electrostatic spinning to obtain core-shell nano composite fiber; and carrying out ultrasonic washing, pre-oxidation, carbonization and ultrasonic pickling on the obtained core-shell nano composite fiber to obtain the porous hollow carbon nanofiber. The porous hollow carbon nanofiber prepared by using the preparation method has extremely wide application values in terms of gas adsorption, catalysis and battery electrode materials.

Owner:DALIAN JIAOTONG UNIVERSITY

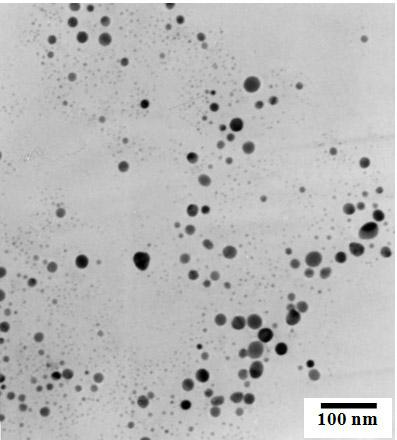

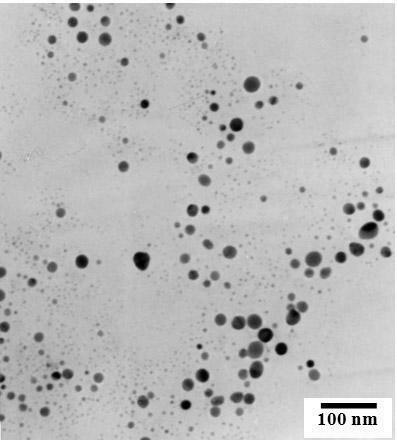

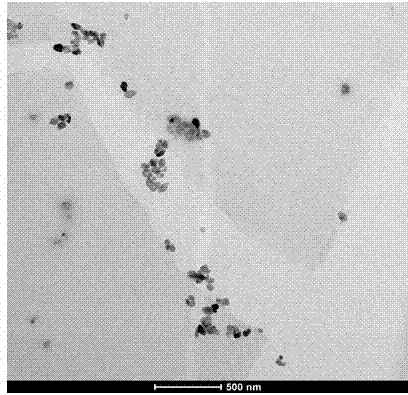

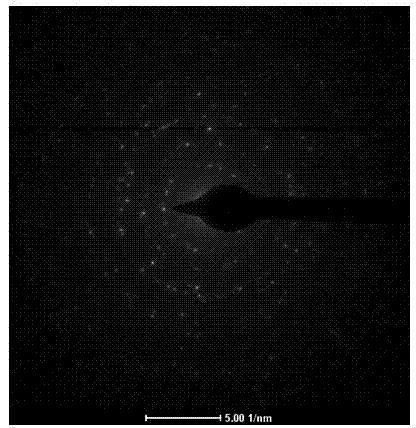

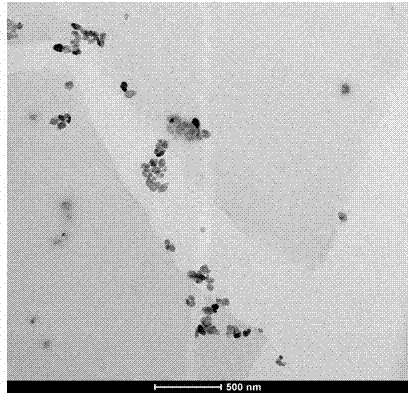

Fibroin-silver-nanoparticle composite material and preparation method thereof

The invention belongs to the technical field of composite materials and particularly provides a fibroin-silver-nanoparticle composite material and a preparation method thereof. The fibroin-silver-nanoparticle composite material comprises fiber (including electrospinning fiber), film, hydrogel and three dimensional porous materials. The preparation method comprises the following steps: after fibroin solution and silver nitrate solution are mixed, the precursor of silver is converted into silver-nanoparticles through in-situ reduction under the irradiation of sunlight or simulated sunlight, and then the material is formed and prepared; or fibroin is prepared into different forms of materials first, then the materials are soaked in silver nitrate water solution, and finally, the precursor of silver is converted into silver-nanoparticles through in-situ reduction under the irradiation of sunlight or simulated sunlight. According to the invention, fibroin is taken as material matrix and the reducing agents and stabilizing agents of silver-nanoparticles, and no other chemical agent is required to be added; and the preparation process is simple, energy-saving and environment-friendly, and the material has various forms.

Owner:FUDAN UNIV

Ultrafine continuous fibrous ceramic filter and method of manufacturing same

InactiveUS20110266213A1Increase flow rateExtend your lifeMaterial nanotechnologySemi-permeable membranesPolymer resinSpinning

An ultrafine continuous fibrous ceramic filter, which comprises a filtering layer of a fibrous porous body, wherein the fibrous porous body comprises continuous ultrafine fibers of metal oxide which are randomly arranged and layered, and powdery nano-alumina incorporated into the ultrafine fibers or coated thereon, the ultrafine fibers being obtained by electrospinning a spinning solution comprising a metal oxide precursor sol-gel solution, and optionally, a polymer resin, and sintering the electrospun fibers, in which the ultrafine fibers have an average diameter of 10˜500 nm, and the fibrous porous body has a pore size of maximum frequency ranging from 0.05 to 2 μm, exhibits high filtration efficiency at a high flow rate, and can be regenerated.

Owner:KOREA INST OF SCI & TECH

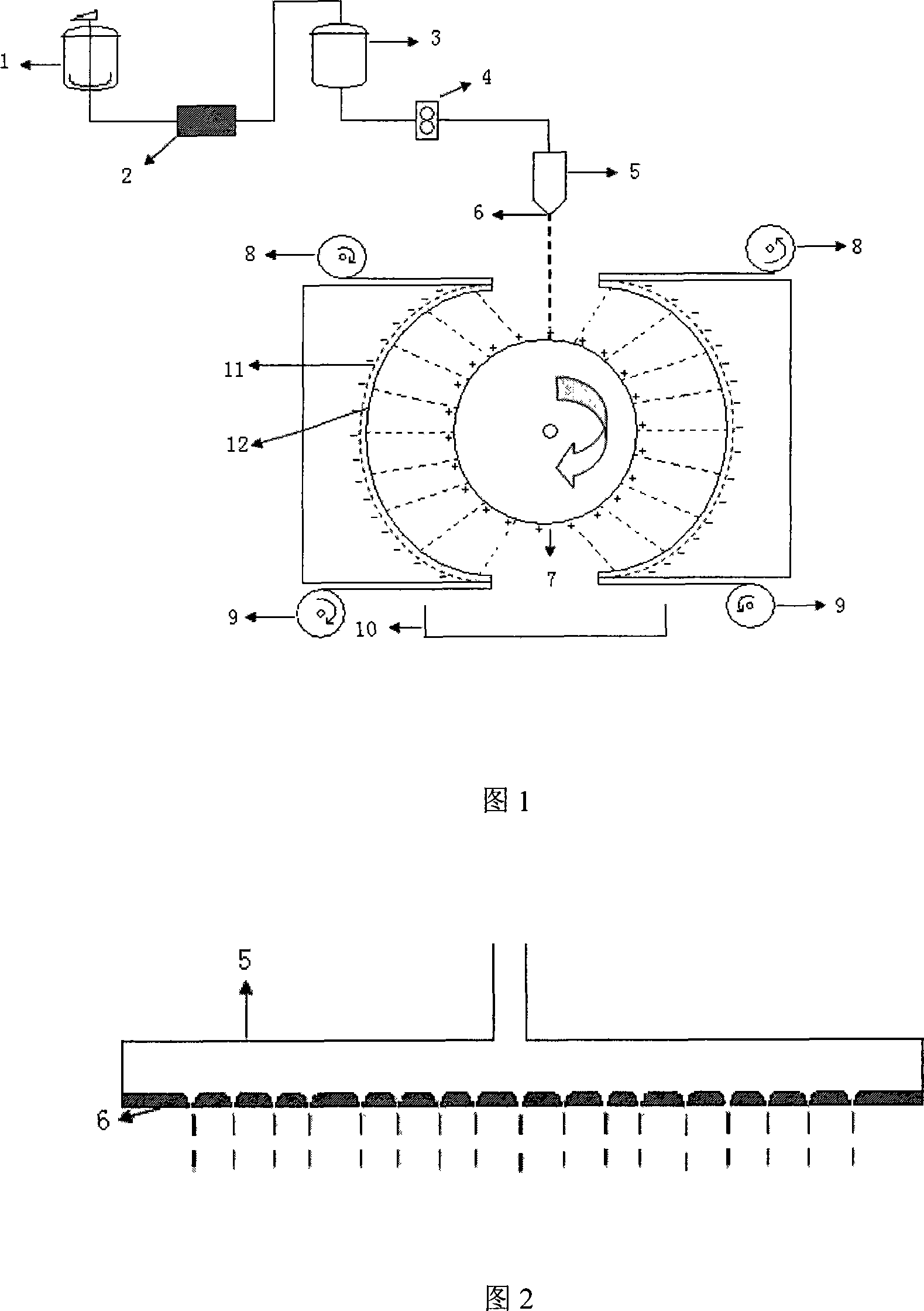

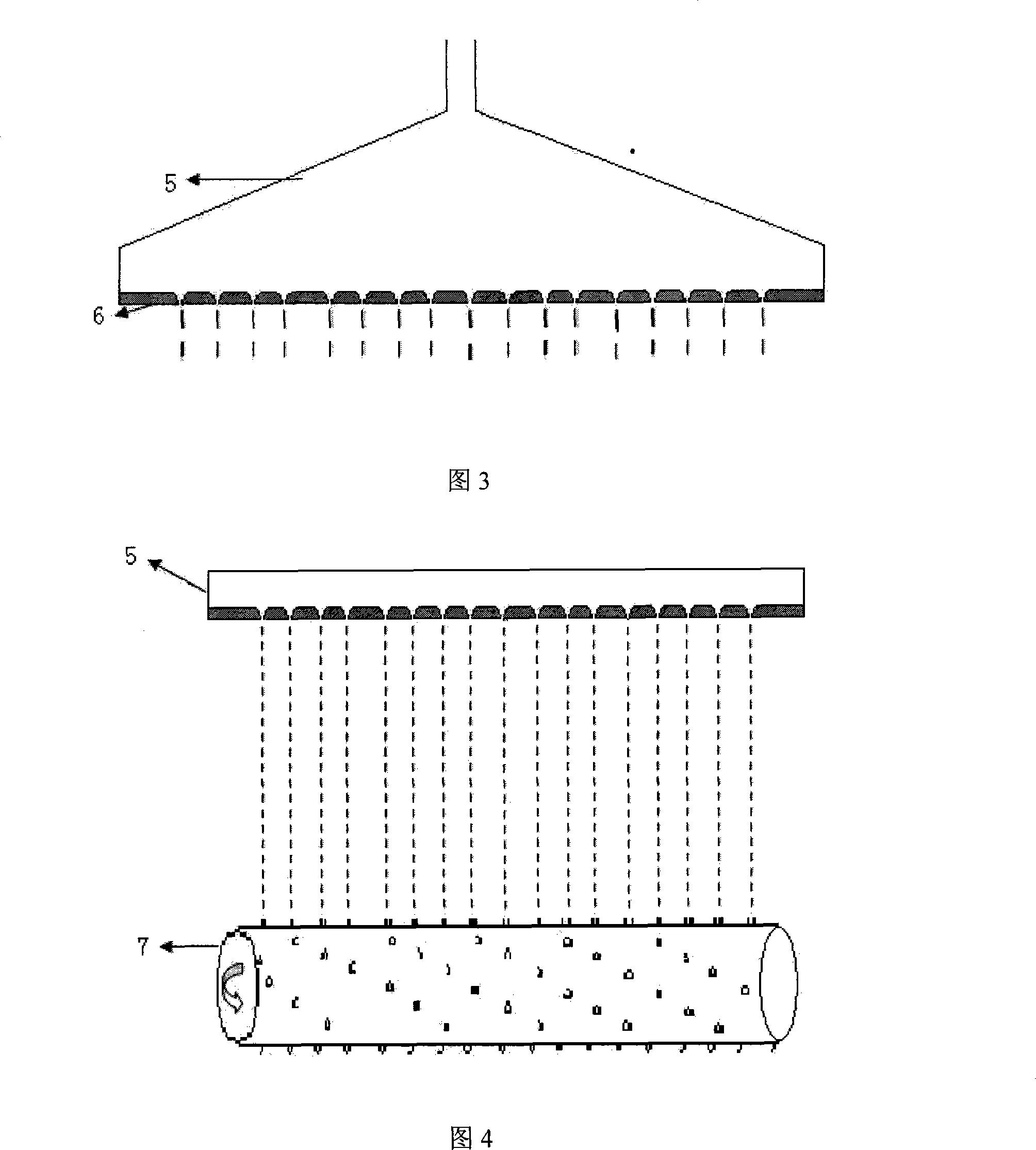

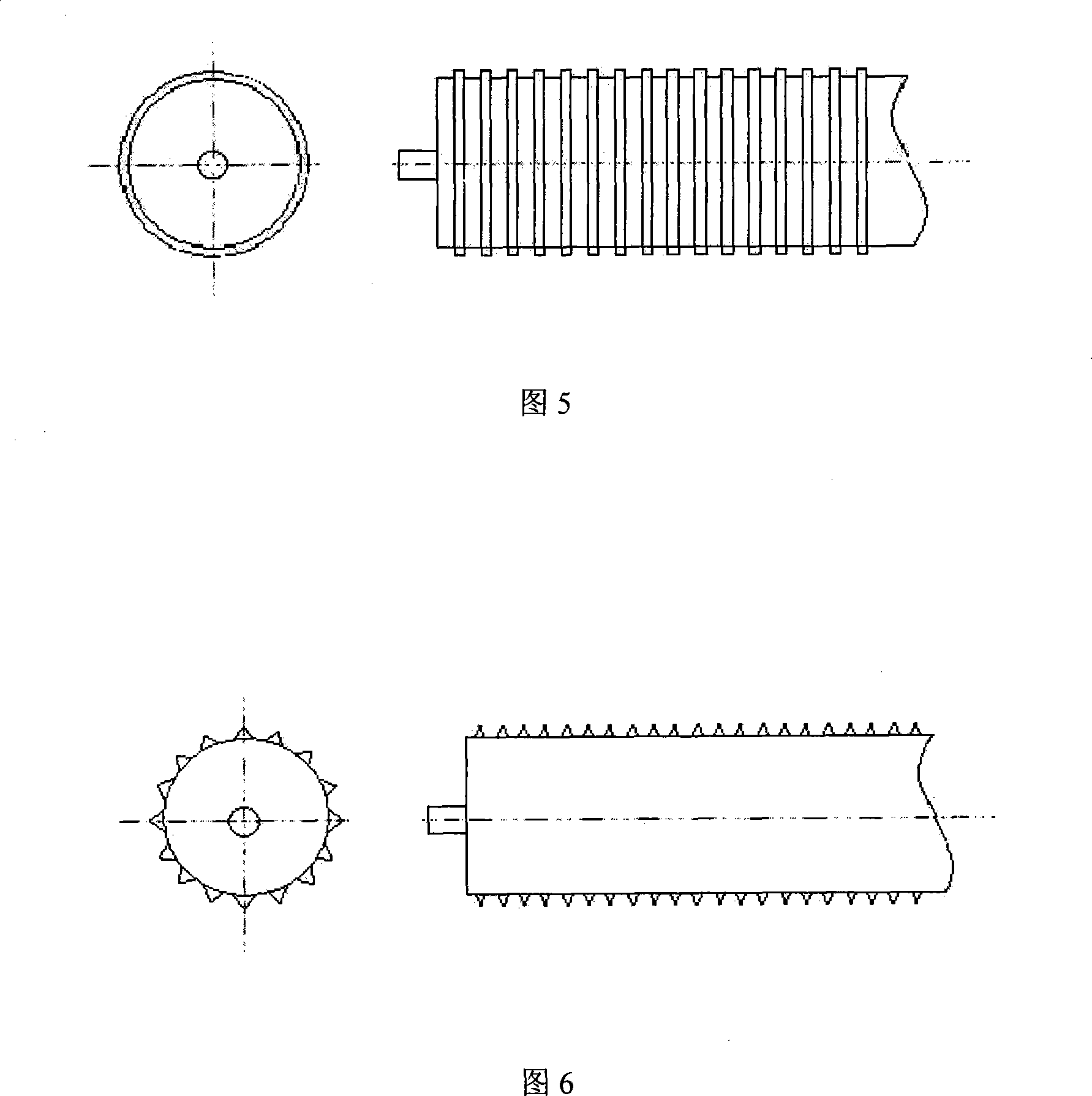

Device and method for preparing highly effective continuous electrostatic spinning nano fibre felt

InactiveCN101215762AGuaranteed continuous supplyEasily overcome surface tensionSpinning head liquid feederFilament/thread formingFiberLiquid storage tank

The invention relates to a preparing device of a high-effective continuous-type electro-spin nanometer fiber felt, the invention comprises a fluid supply system, a metal roller, a receiving device and a spinning fluid recycling groove. The process for preparing comprises firstly, preparing polymer spinning fluid with correct concentration in a dissolution kettle, temporarily storing in a liquid storage tank after passing through a filter, secondly, connecting the metal roller and the positive electrode of a high-pressure electrostatic generator, applying correct electrostatic pressure, leading an aluminium screen cloth to connect ground, thirdly, leading the metal roller to rotate in correct rotary speed, fourth, starting a measuring pump, feeding spinning liquid from the liquid storage tank to an even allotter, leading the spinning liquid to be evenly allocated to a spraying hole on the front end of the even allotter, sputtering from the spraying hole to the surface of a rotating metal roller to form Taylor awl, fifthly, leading a coiling drum to rotate to drive a fiber receiving net to move, and continuously receiving nanometer fiber felt. The process for preparation of the nanometer fiber felt of the invention has high production efficiency, which is suitable for scale production of electro-spinning.

Owner:DONGHUA UNIV

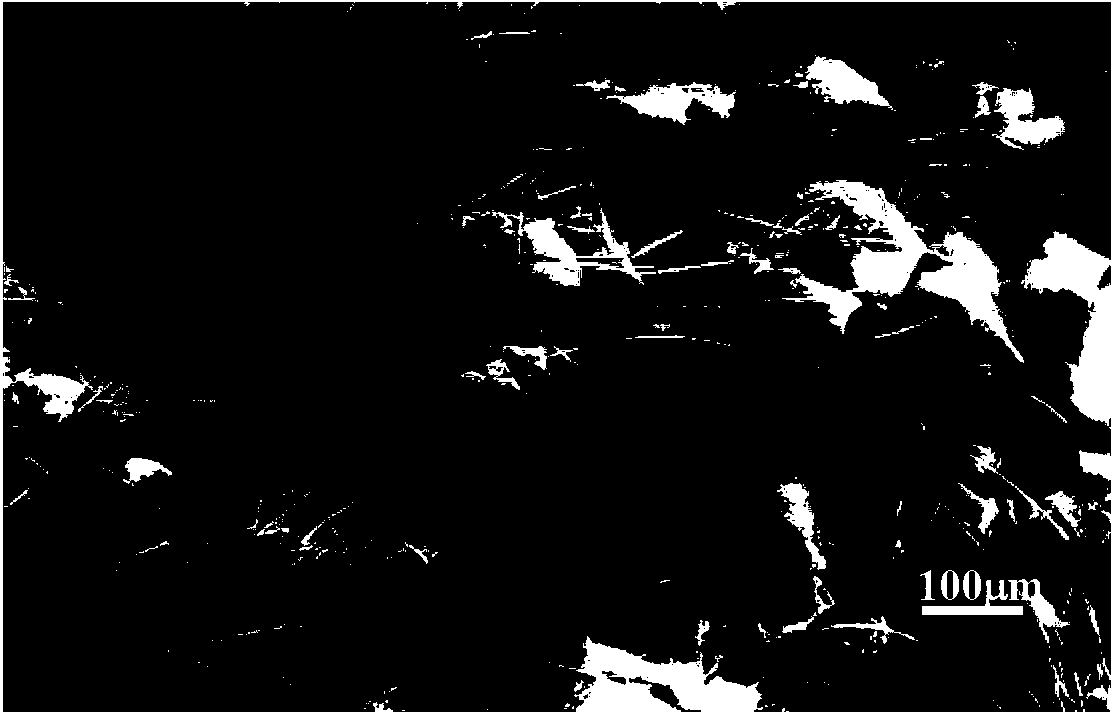

Method for preparing grapheme/ ceramic nanocrystalline particle composite material with electrospinning-hydrothemal method

The invention discloses a method for preparing grapheme / ceramic nanocrystalline particle composite material with an electrospinning-hydrothemal method. The method comprises the following steps: firstly, preparing ceramic / polymer composite fiber by electrospinning; then, dissolving the composite fiber into a solvent for dissolving polymers; dismembering the fiber into tiny ceramic nanocrystalline seeds while the polymers in the composite fiber are dissolved; then, adding graphene oxide; carrying out hydrothermal or solvothermal reaction; and after reaction ends, adding a reducing agent to reduce the graphene oxide into grapheme. The ceramic / polymer composite fiber is weaved by the electrospinning, and the hydrolysis speed of the metallorganics of a ceramic material precursor is controlled by controlling the moisture, electrospinning flow rate and the like in the electrospinning environment. The electrospinning method and the hydrothemal method are both simple and easy to implement and can be used for industrially producing and preparing nanofiber materials. The combination of the electrospinning method and the hydrothemal method creates convenience for industrial production of materials.

Owner:SOUTHEAST UNIV

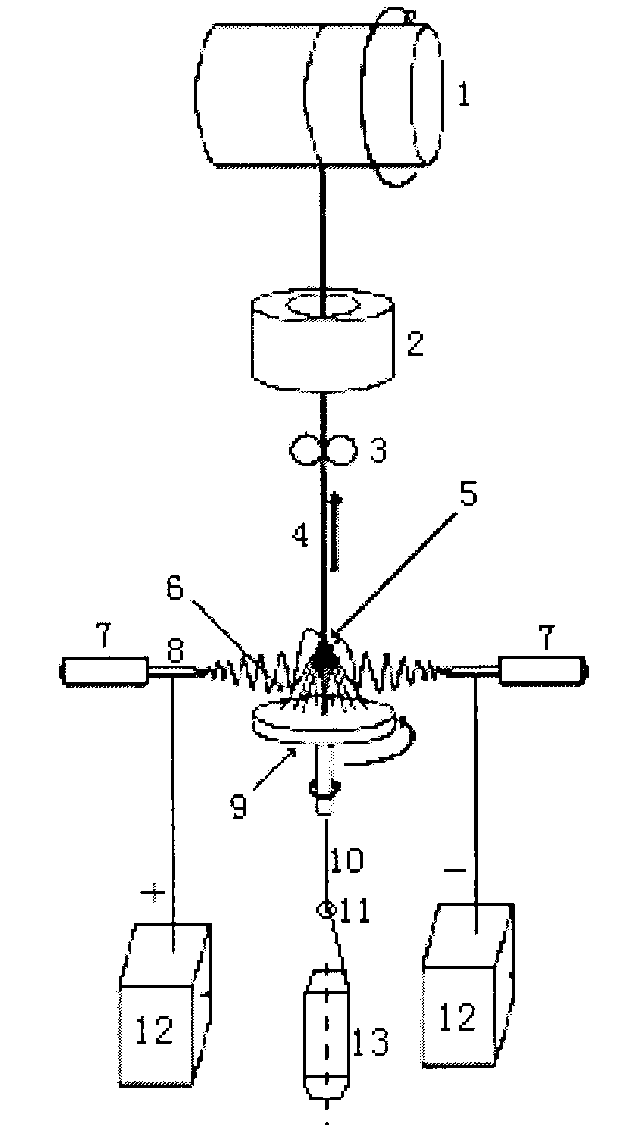

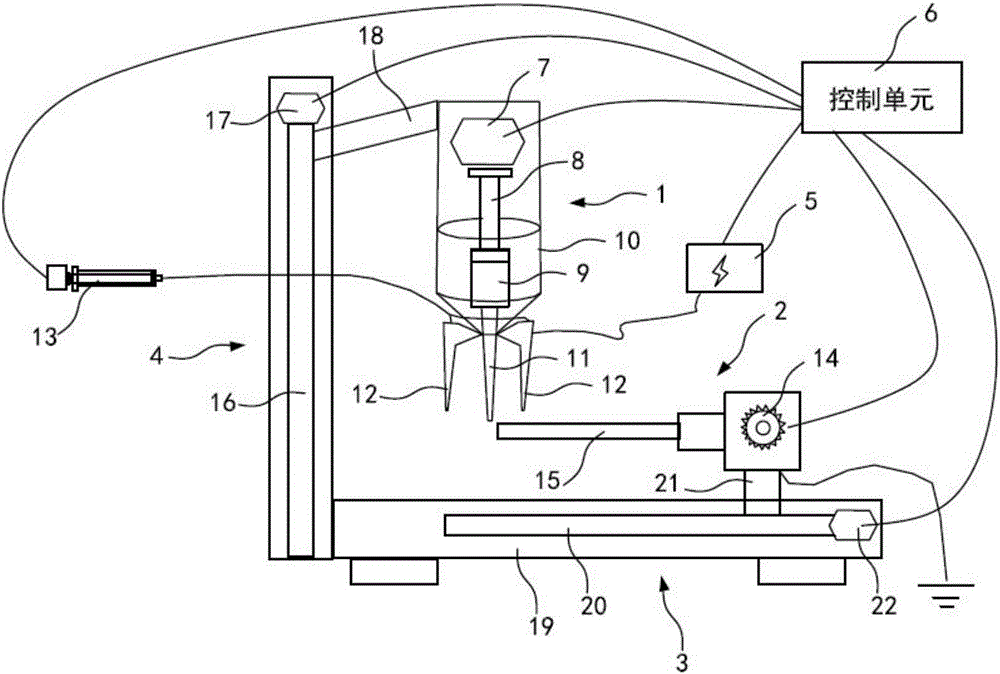

Device for manufacturing artificial blood vessel through combination of bio-printing and electro-spinning technologies

InactiveCN106012052AAdjustable positionStentsAdditive manufacturing apparatusRelative displacementMotor control

The invention discloses a device for manufacturing an artificial blood vessel through combination of bio-printing and electro-spinning technologies. The device comprises a material release unit, a rotary receiving unit, a horizontal moving platform, a vertical moving platform, a high-voltage power supply and a control unit, wherein the rotary receiving unit is located below the material release unit and comprises a rotary motor and a receiving rod; the rotary motor can drive the receiving rod to conduct rotary operation. The device has the following benefits: during operation, when the material release unit uses a bio-printing nozzle, a first stepping motor controls an extrusion pump to extrude out a cell-containing hydrogel material in a storage tank, and the extrusion pump can realize setting and controlling of the material release speed and quantity by the control unit; the vertical moving platform controls relative displacement of the whole material release unit to the rotary receiving unit, and can conduct vertical up-and-down displacement (such as 0.1 mm, 0.5 mm, 5 mm and continuous displacement), the displacement can be adjusted according to the extrusion requirement, and the distance between the bio-printing nozzle and the rotary receiving unit is adjusted through the displacement; the bio-printing nozzle and electro-spinning nozzles can work simultaneously or alternately, which is adjusted by the control unit according to actual demands.

Owner:THE SECOND HOSPITAL AFFILIATED TO SUZHOU UNIV

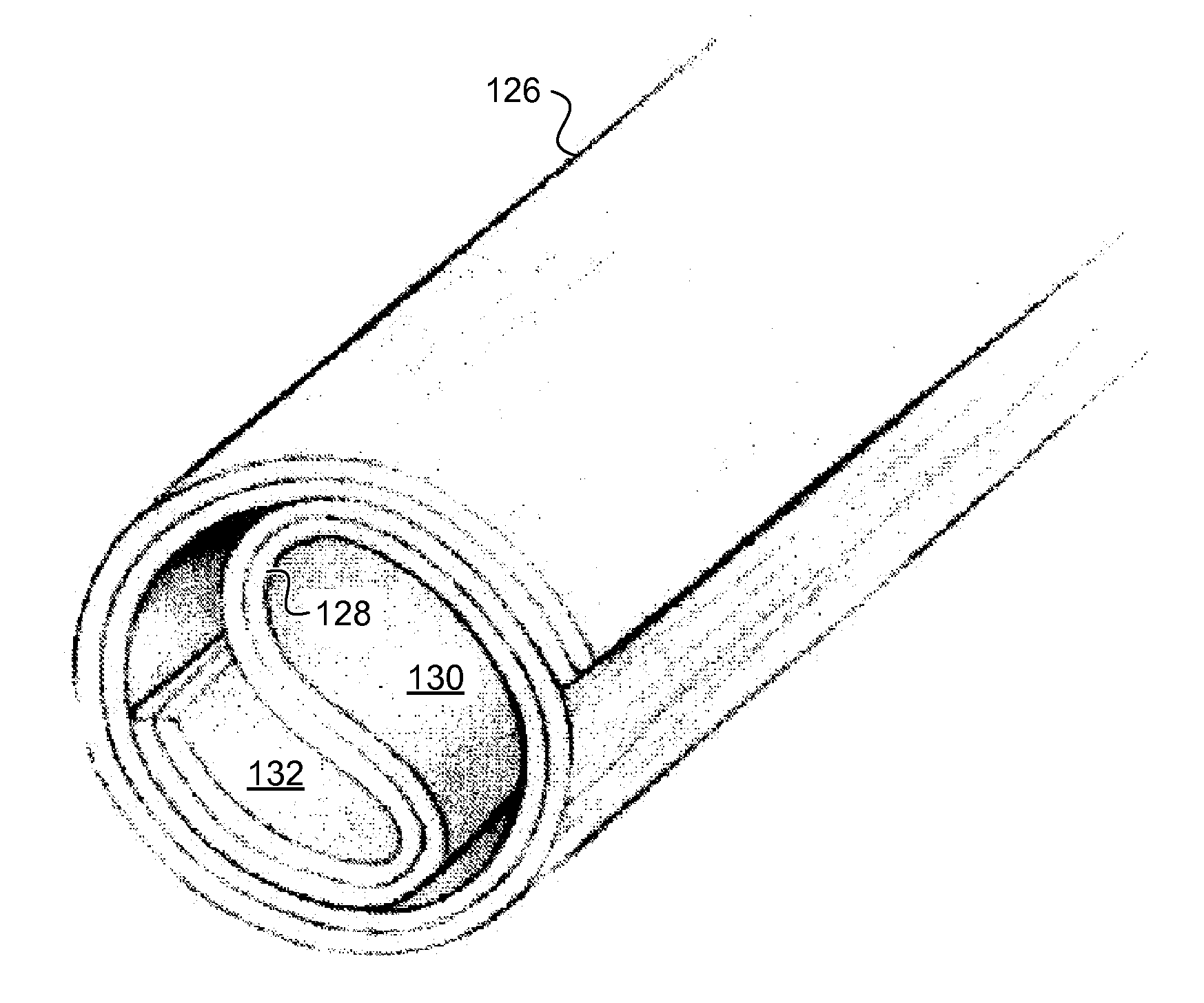

Method for preparing composite artificial blood vessel stent by combined electro-spinning with knitting technique

InactiveCN101264349AIncrease growth activityNot easy to embolismStentsSurgeryTextile technologyHuman body

The invention relates to a preparation method of compound artificial blood vessel support by electrostatic textile and weave technology, which can be described as follows: 6% to 10% (g / ml) polymer spinning solution is prepared; under the control of electrostatic spinning parameter, the prepared solution is used to make nano fiber with electrostatic textile technology; the nano fiber is collected by a roller collecting device to be the inner layer of a tubular support; the fiber materials are woven into tubular form by making use of the textile equipment to be the outer layer of the tubular support; the electrostatically textile inner layer and the woven outer layer are compounded together with the method of hot shaping or coating; with the adoption of biocompatible implant technology, human endothelial cells are implanted on the inner layer of the support and human smooth muscle cells are implanted on the outer layer of the support; after cell culture, the blood support is completed. The preparation method of compound artificial blood vessel support through electrostatic textile and weave technology has the advantages of simplification and time-saving effect, fine growth activity of the prepared artificial blood vessel after being implanted into human body; besides, the smooth muscle can grow along and into the fiber, and adaptability adjustment can be made to the blood vessel according to the condition of the host, leaving less liability for embolization.

Owner:DONGHUA UNIV

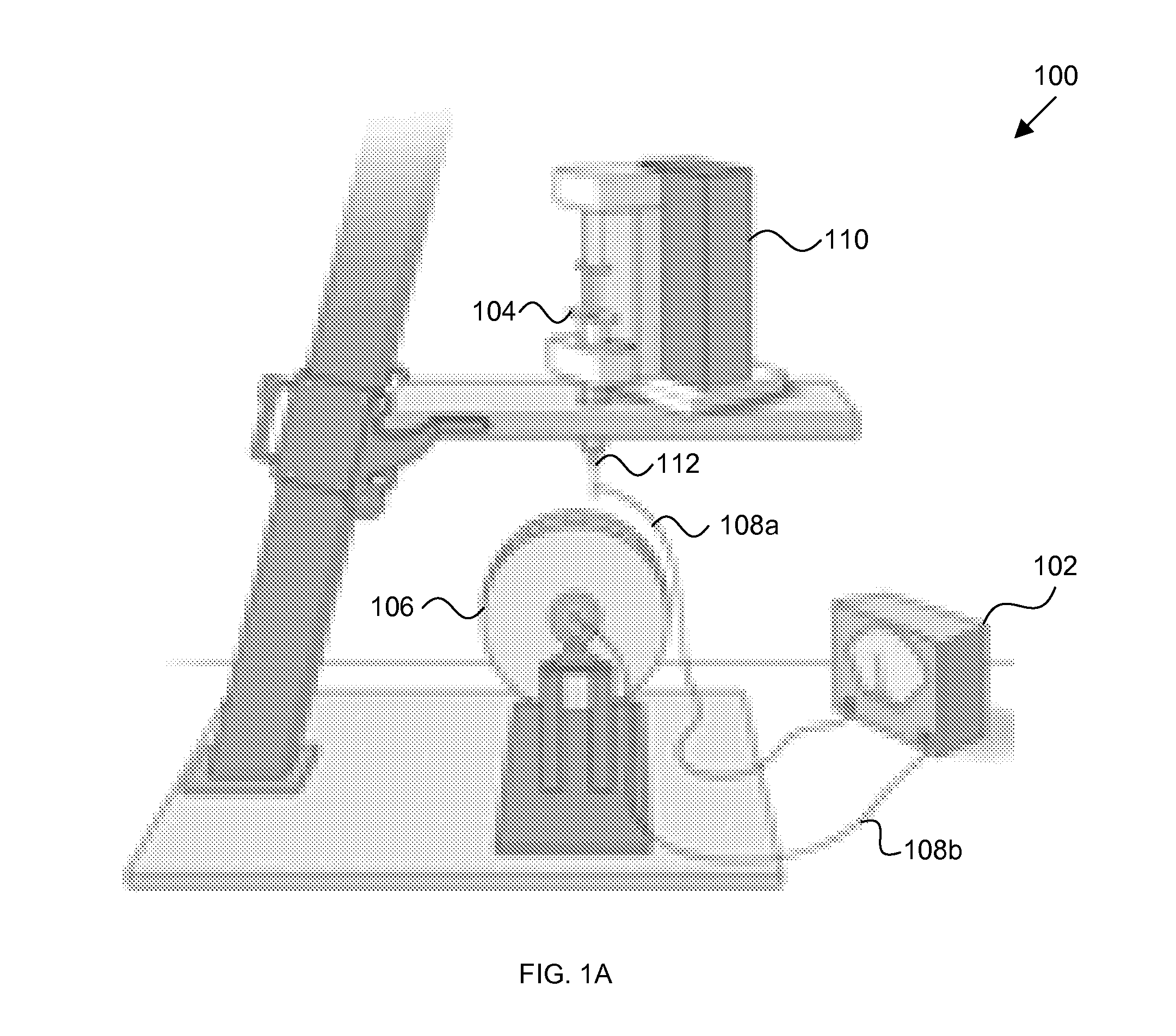

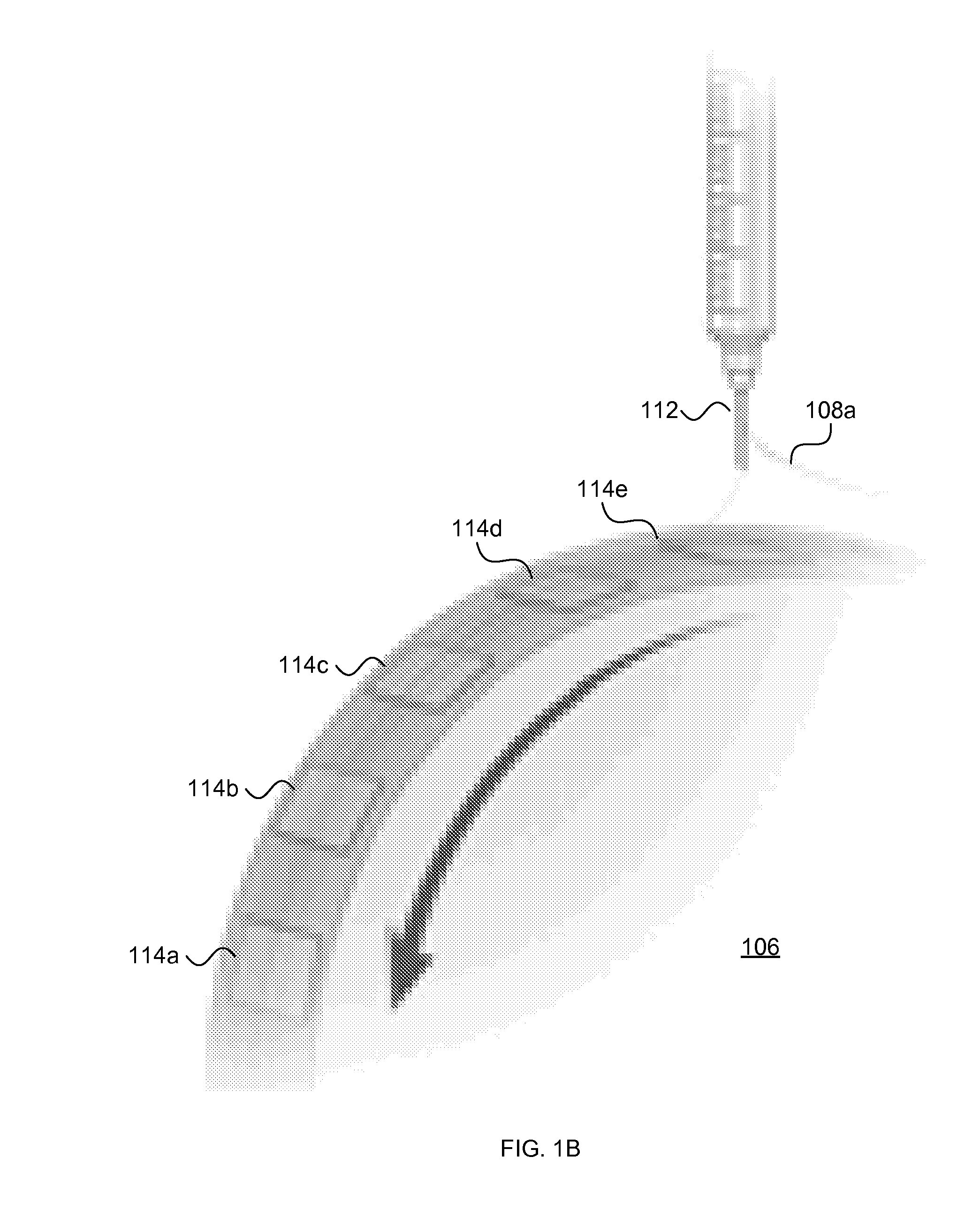

Three-dimensional scaffolds, methods for fabricating the same, and methods of treating a peripheral nerve or spinal cord injury

ActiveUS20130110138A1Promote extensive axonal regenerationRobust and long regenerationFilament/thread formingBiochemical treatment with enzymes/microorganismsFiberMedicine

One aspect of the invention provides a three-dimensional scaffold including at least one layer of highly-aligned fibers. The at least one layer of highly-aligned fibers is curved in a direction substantially perpendicular to a general direction of the fibers. Another aspect of the invention provides a method for fabricating a three-dimensional scaffold. The method includes: electro spinning a plurality of fibers to produce at least one layer of highly-aligned fibers and forming the at least one layer of highly-aligned fibers into a three-dimensional scaffold without disturbing the alignment of the highly-aligned polymer fibers. A further aspect of the invention provides methods for using a three-dimensional scaffold to treat nerve or spinal cord injury.

Owner:RENESSELAER POLYTECHNIC INST +1

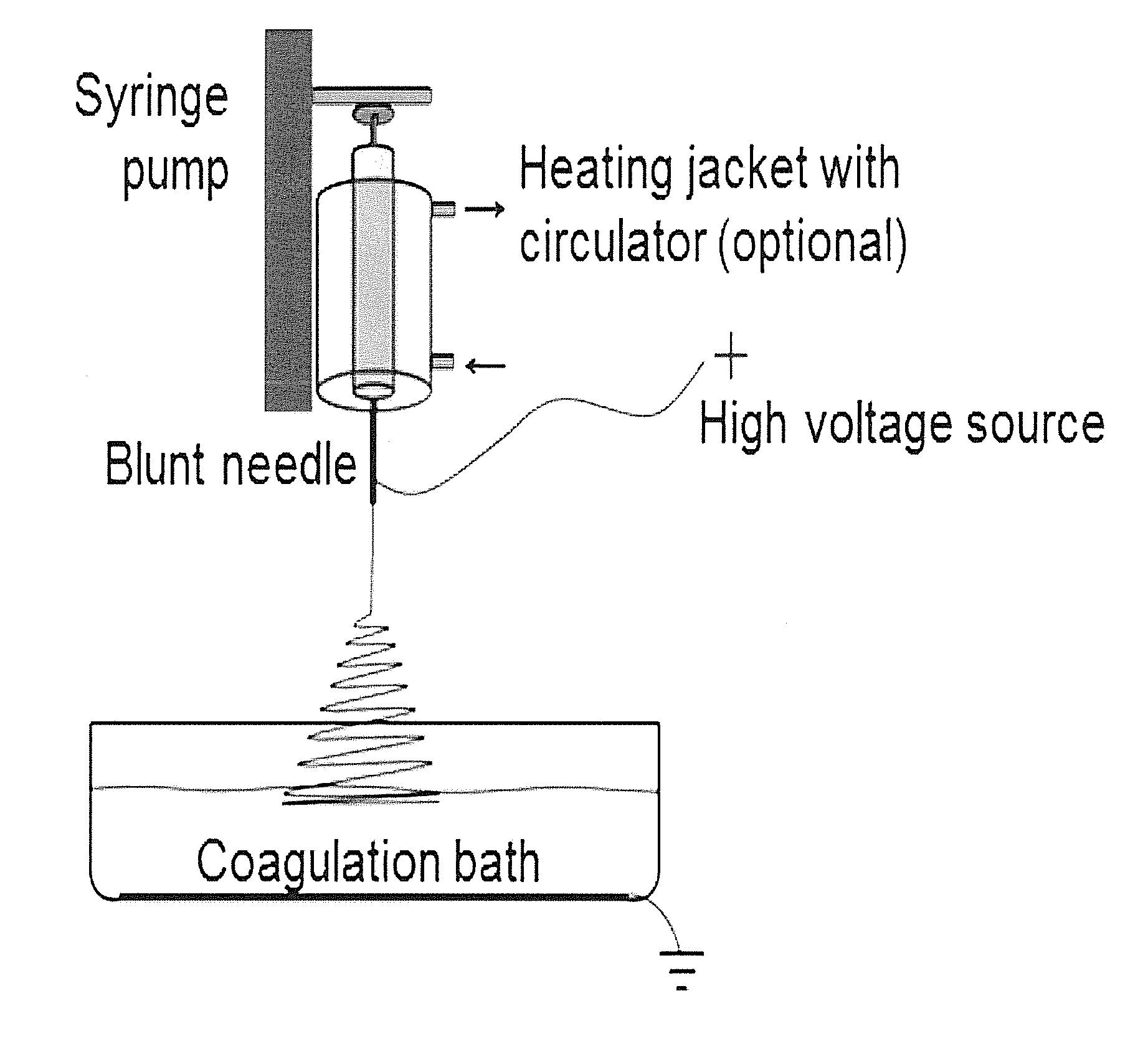

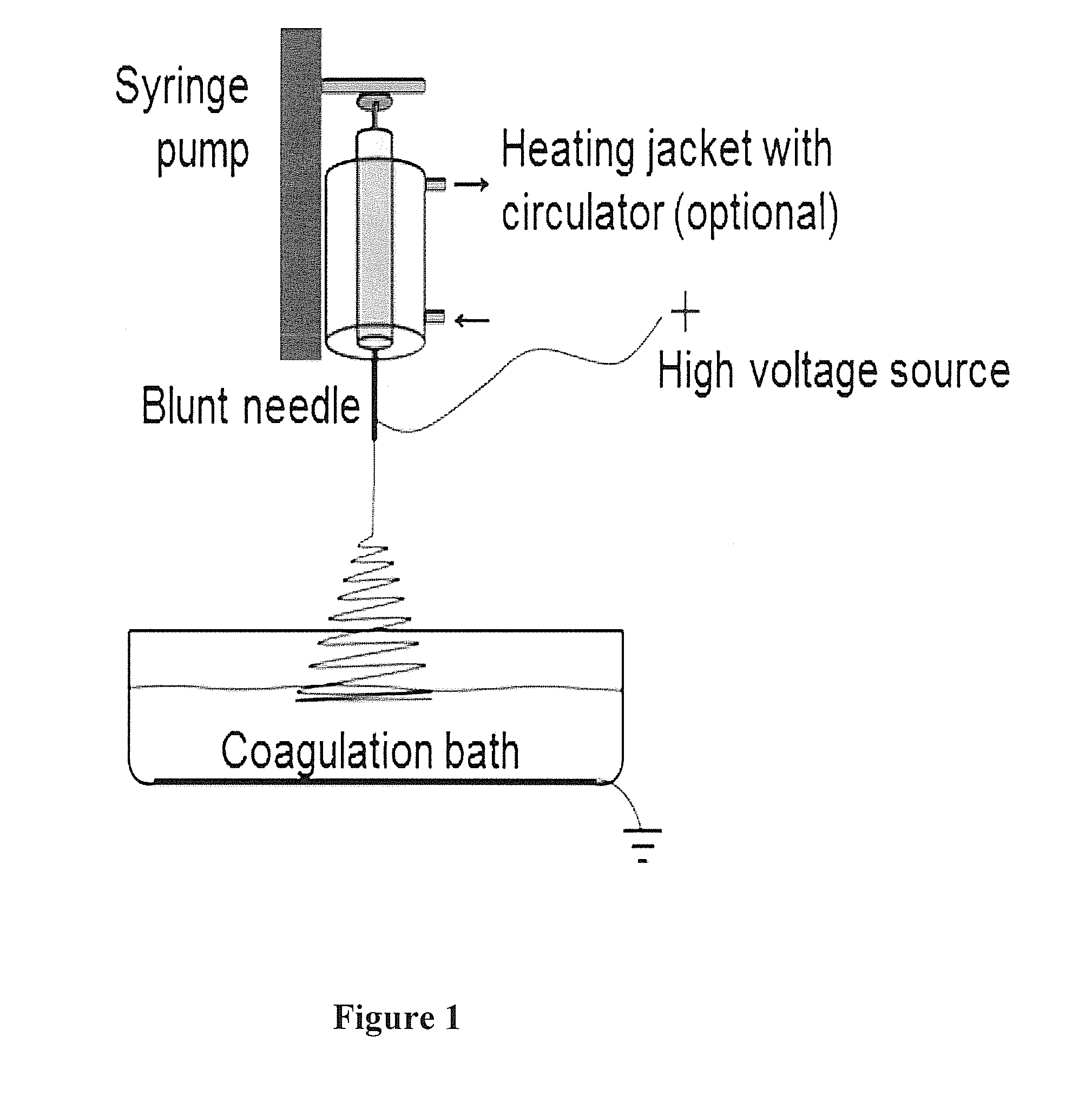

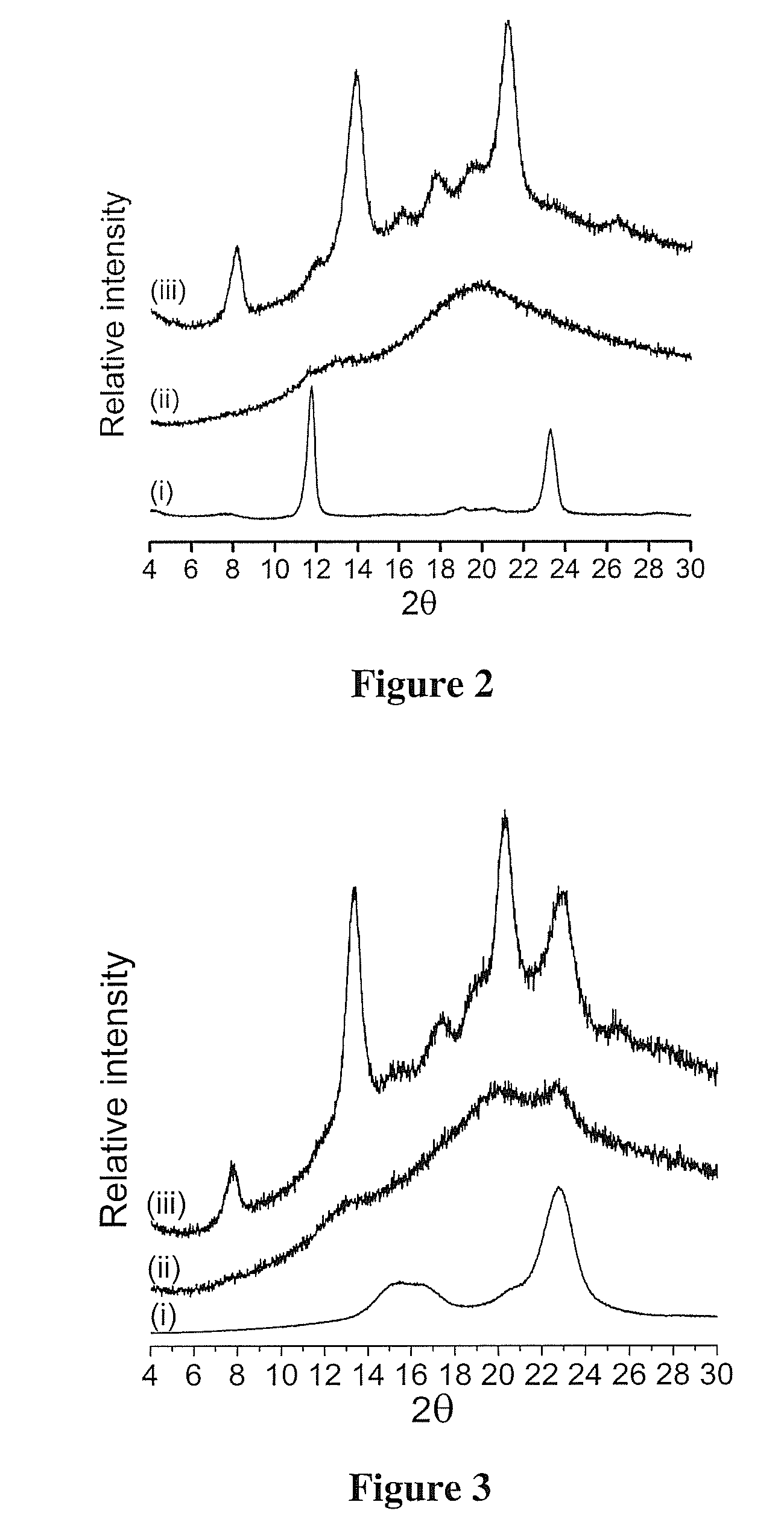

Methods and compositions relating to starch fibers

Methods are provided according to aspects of the present invention for making starch fiber or particle compositions by wet-electrospinning or wet-electrospraying including providing a solution or dispersion of starch in an aqueous or non-aqueous solvent or dispersant, where the starch is present at a concentration above the critical entanglement concentration, with the proviso that the aqueous or non-aqueous solvent or dispersant does not consist only of water; heating the solution or dispersion of starch to a temperature above the crystallization temperature of the starch; electro spinning or electro spraying the heated solution or dispersion of starch to produce starch fibers or starch particles, respectively; and contacting the starch fibers or starch particles with a coagulation bath fluid.

Owner:PENN STATE RES FOUND

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com