Porous hollow carbon nanofiber as well as preparation method and application thereof

A carbon nanofiber and nanocomposite fiber technology, applied in the field of carbon fiber materials, can solve the problems of unstable fiber structure and excessively wide distribution of porous pore sizes, and achieve the effects of narrow pore size distribution, simple pore-forming methods, and increased specific surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] (1) At 20°C, stir 1.0g of cobalt acetate until it is completely dissolved in 20ml of DMF, then add 2.5g of PAN to it, and stir evenly to obtain a wine-red transparent liquid as the outer layer fluid; take pure dimethyl silicone oil as Inner fluid.

[0035] (2) At 20°C, input the prepared PAN / cobalt acetate solution and pure simethicone oil into the outer layer and inner layer of the coaxial electrospinning nozzle at flow rates of 0.6ml / h and 0.25ml / h, respectively, for Coaxial electrospinning, the spinning voltage is 14KV, the spun fiber is received by aluminum foil paper, and the receiving distance is 15cm, and the simethicone (core)-PAN / cobalt acetate (shell) nanocomposite fiber is obtained.

[0036] (3) The obtained core-shell nanocomposite fibers were placed in petroleum ether for ultrasonic washing (ultrasonic frequency: 100 W) to obtain PAN / cobalt acetate hollow nanocomposite fibers.

[0037](4) Pre-oxidize the obtained hollow nanocomposite fiber in air, the pre-...

Embodiment 2

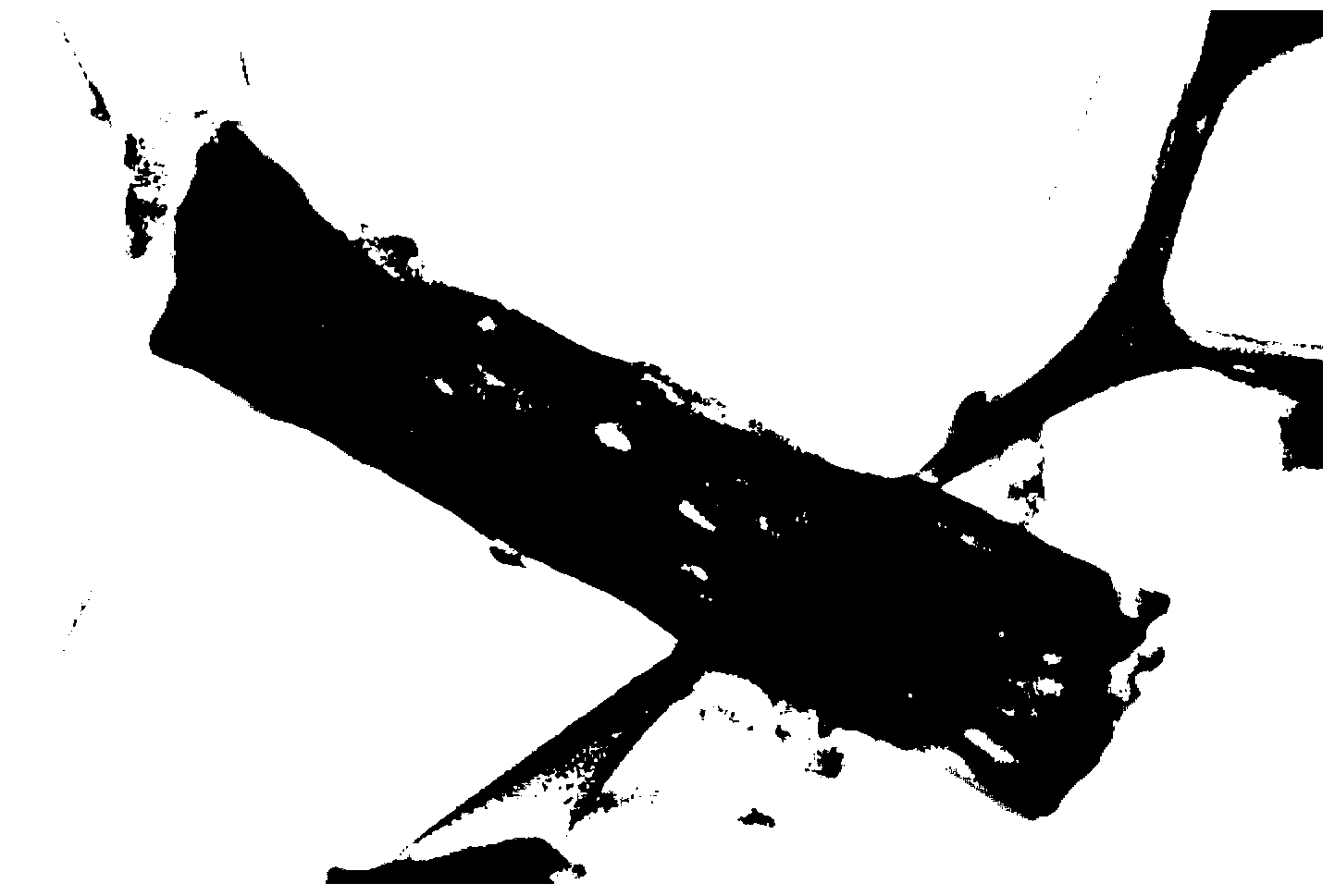

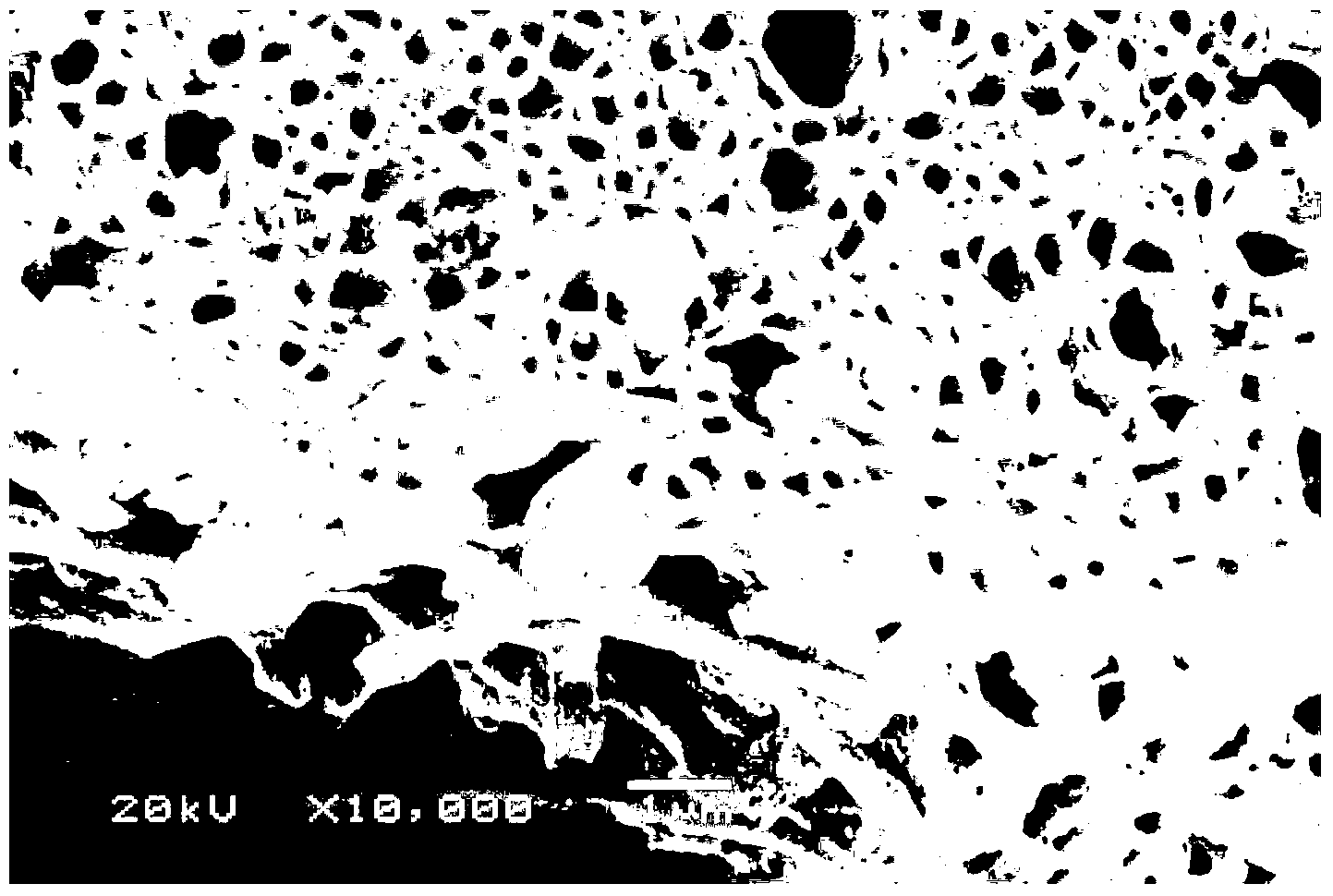

[0041] In addition to replacing the cobalt acetate used in step (1) with nickel acetate, the spinning voltage in step (2) was set to 13KV, the pre-oxidation time in step (4) was set to 1h, and the Except that the carbonization temperature was set to 900° C., the same procedure as in Example 1 was carried out to obtain porous hollow carbon nanofibers. The TEM and SEM pictures of the fiber are as follows image 3 , 4 As shown, the average diameter of the carbon fiber is 400nm, the porous diameter is 20nm, and the hollow diameter is 100nm.

Embodiment 3

[0043] In addition to replacing 1.0g of cobalt acetate used in step (1) with 1.5g of zinc acetate, setting the pre-oxidation time in step (4) to 1h, and setting the carbonization temperature in step (5) to 900°C, other In the same manner as in Example 1, porous hollow carbon nanofibers were obtained. The TEM and SEM pictures of the fiber are as follows Figure 5 , 6 As shown, the average diameter of the carbon fiber is 400nm, the porous diameter is 30nm, and the hollow diameter is 200nm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com