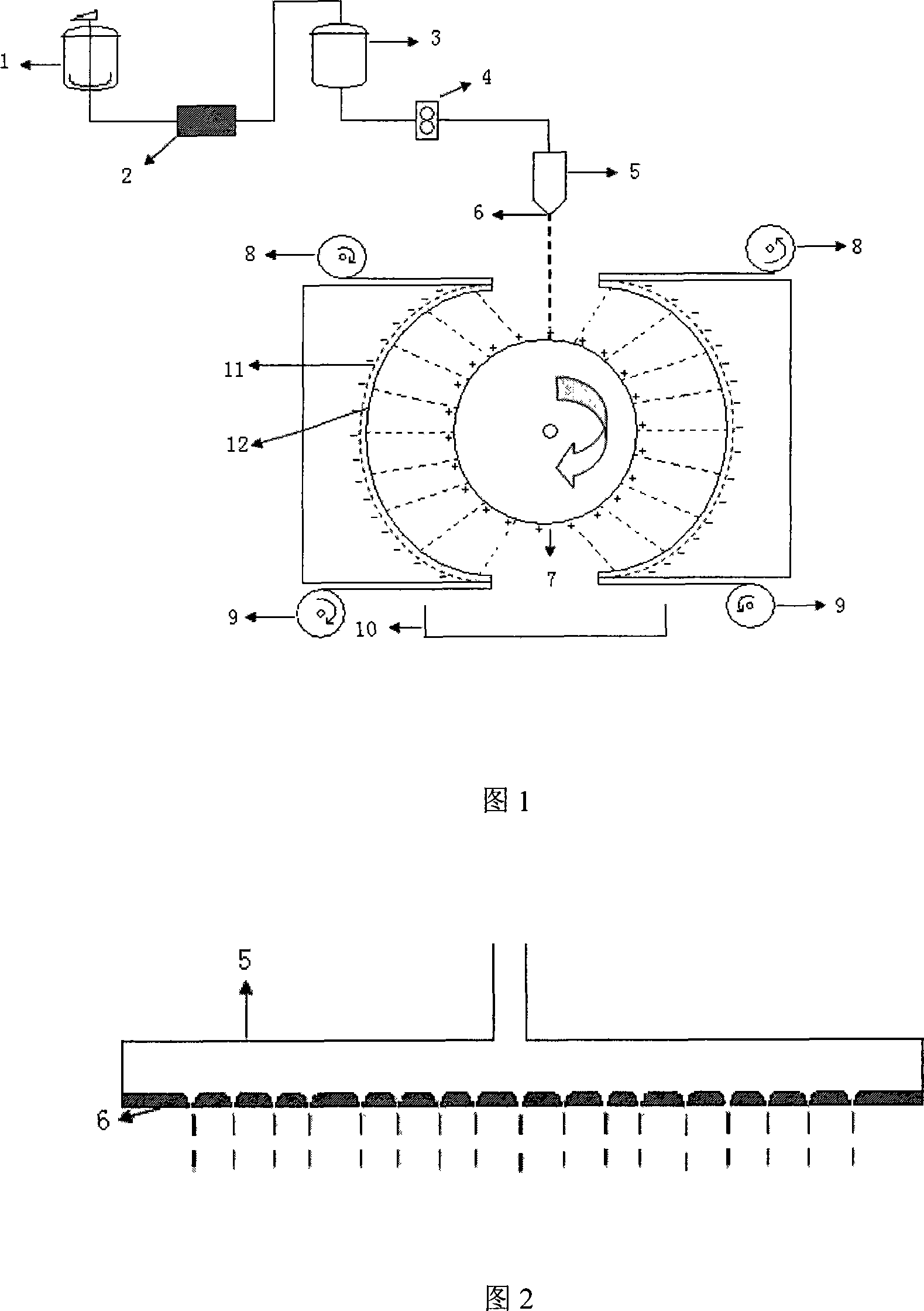

Device and method for preparing highly effective continuous electrostatic spinning nano fibre felt

A nanofiber and preparation device technology, applied in fiber processing, textiles and papermaking, filament/wire forming, etc., can solve the problems of not being able to form Taylor cones, thicker polymer films, and demanding settings, and achieve electrospinning The silk is smooth, the uniformity is improved, and the output is improved

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

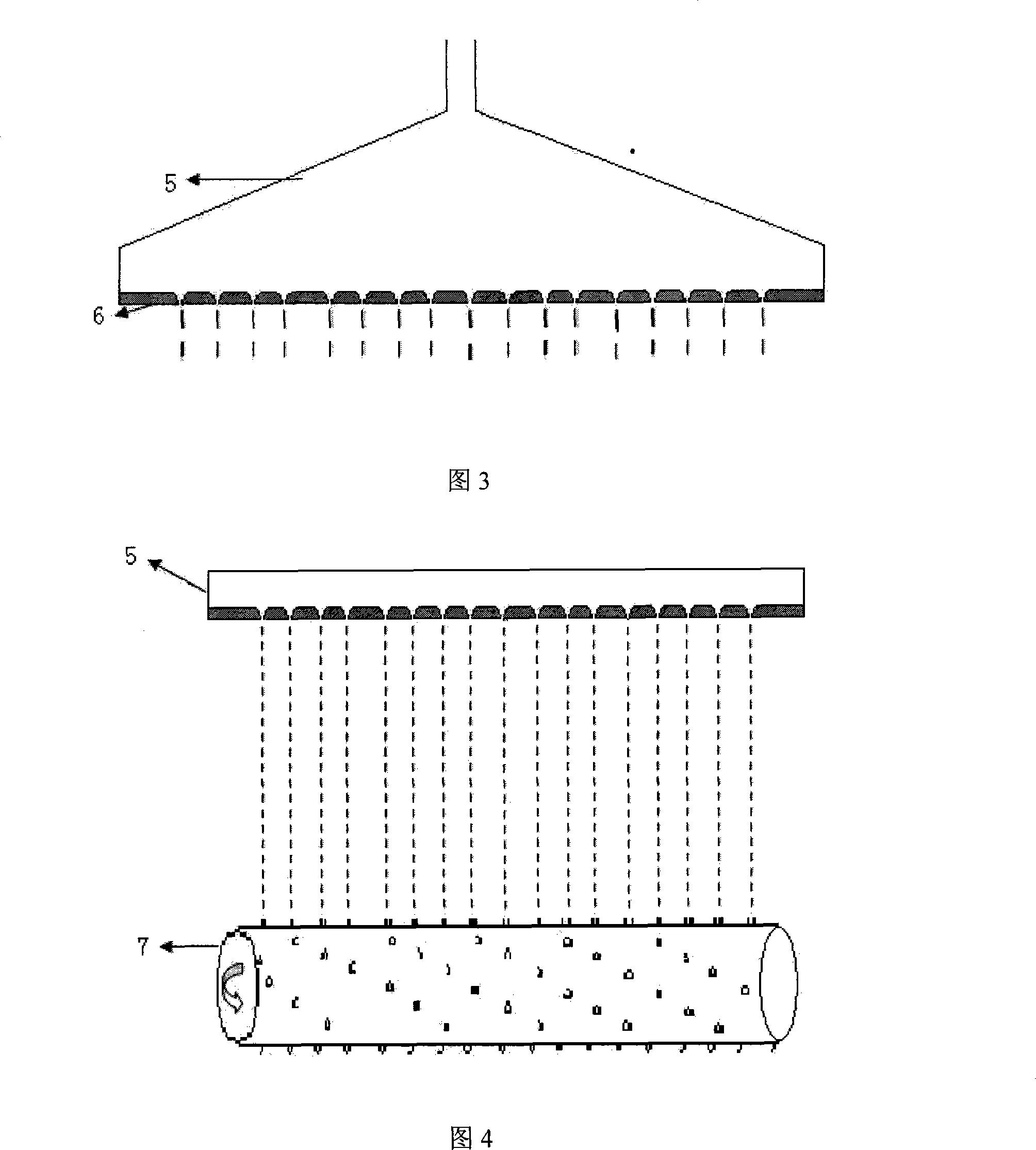

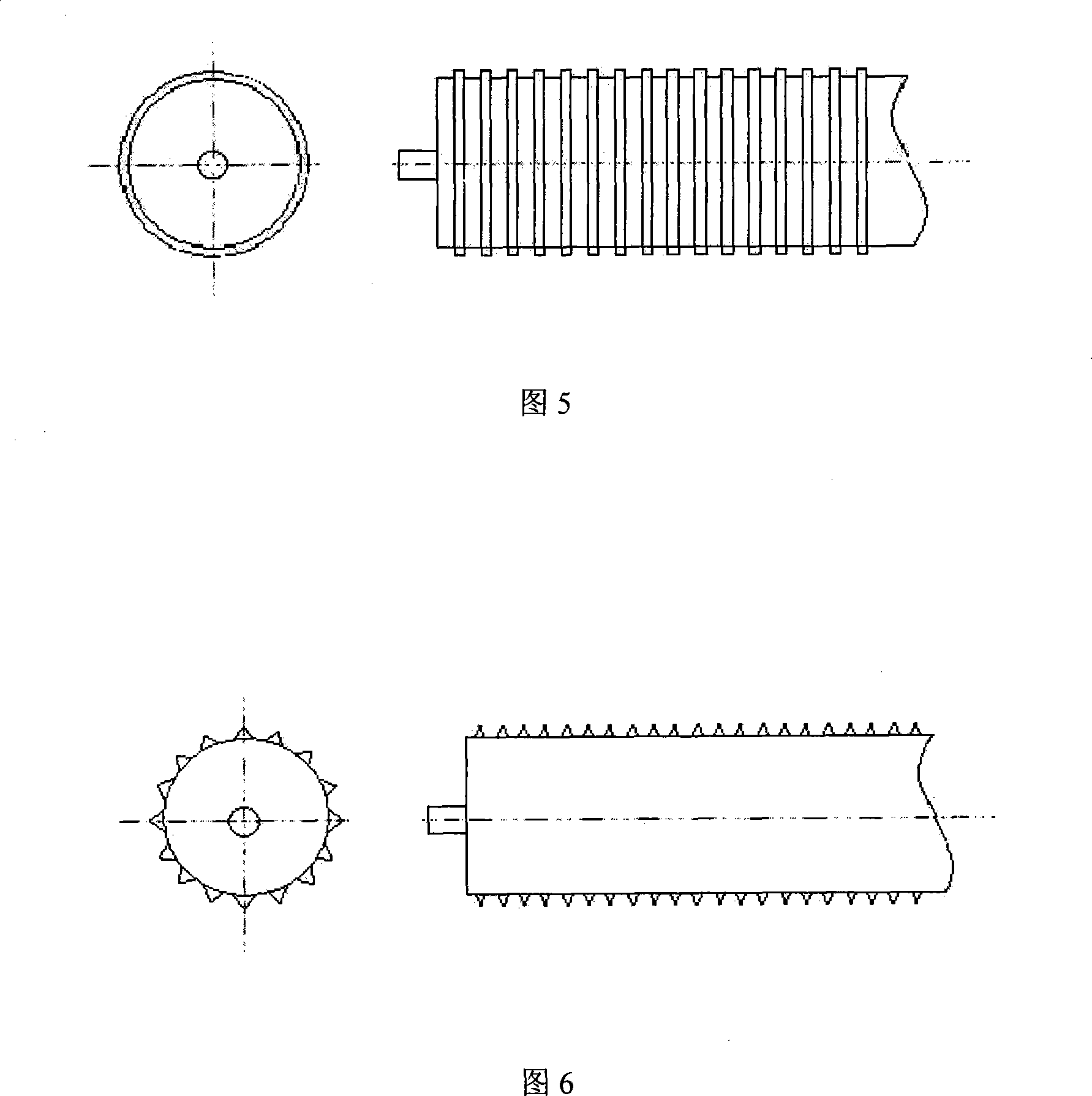

[0038] Dissolve 87 g of polyvinyl alcohol 1750 (molecular weight 1700, degree of alcoholysis 50%) in 1000 ml deionized water, add appropriate amount of sodium chloride and citric acid to make a transparent non-precipitating PVA spinning solution with a concentration of 8%. Adopt "T" type uniform distributor, the nozzle diameter is 2mm, and the density is 2 nozzle holes / cm. A grooved metal roller is used, the length is 50cm, the diameter is 5cm, the rotation speed is 4r / min, and the applied static voltage is +50kV. The receiving distance between the metal drum surface and the fiber receiving web was 35 cm. According to the above implementation steps, a nanofiber mat is prepared, the fiber diameter distribution is between 300-600nm, and the average output is 20g / h.

Embodiment 2

[0040] Dissolve 52.6 g of polyethylene oxide (molecular weight: 1,000,000) in 1,000 ml of deionized water, and add an appropriate amount of sodium chloride to prepare a transparent non-precipitating PEO spinning solution with a concentration of 5%. Adopt "T" type uniform distributor, the nozzle diameter is 1.5mm, and the density is 2 nozzle holes / cm. A grooved metal roller is used, the length is 50cm, the diameter is 5cm, the rotation speed is 4r / min, and the applied static voltage is +50kV. The receiving distance between the metal drum surface and the fiber receiving web was 35 cm. According to the above implementation steps, a nanofiber mat is prepared, the fiber diameter distribution is between 200-500nm, and the average output is 18g / h.

Embodiment 3

[0042] Dissolve 87 g of polyvinyl alcohol 1750 (molecular weight 1700, degree of alcoholysis 50%) in 1000 ml deionized water, add appropriate amount of sodium chloride and citric acid to make a transparent non-precipitating PVA spinning solution with a concentration of 8%. A hanger-type uniform distributor is used, the diameter of the spray hole is 2mm, and the density is 2 spray holes / cm. A brad nail type metal drum is used, the length is 50cm, the diameter is 5cm, the rotation speed is 4r / min, and the applied static voltage is +50kV. The receiving distance between the metal drum surface and the fiber receiving web was 35 cm. According to the above implementation steps, a nanofiber mat is prepared, the fiber diameter distribution is between 300-500nm, and the average output is 23g / h.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com