Method for preparing grapheme/ ceramic nanocrystalline particle composite material with electrospinning-hydrothemal method

A composite material, graphene technology, applied in filament/thread forming, textile and papermaking, fiber processing and other directions, can solve the problem of product specific surface area reduction, etc., to achieve the effect of facilitating industrial production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

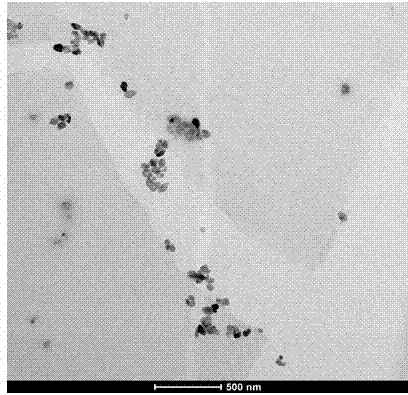

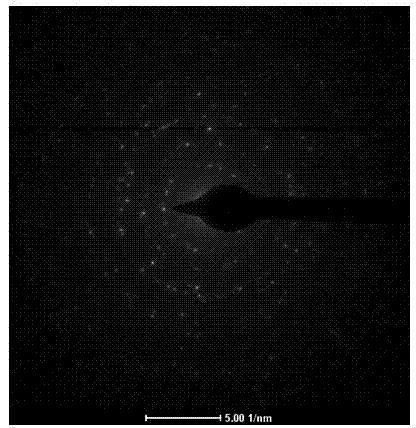

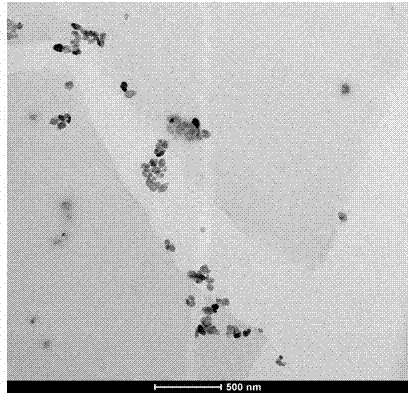

Image

Examples

Embodiment 1

[0018] a. Weigh 0.4 g of PVP and dissolve it in 7 mL of ethanol solvent, then add 2.0 g of glacial acetic acid and 1 mL of isopropyl titanate, stir magnetically at 20 °C for 1 h at a speed of 350 rpm / min, and obtain an electric spinning solution.

[0019] b. Electrospinning was carried out at 20 °C and a humidity of 45%. The flow rate of the electrospinning solution was 10 mL / h, the DC voltage was 15 kV, and the spinning receiving distance was 15 cm to obtain TiO 2 / PVP composite nanofibers.

[0020] c. Weigh 20 mg of electrospun composite nanofibers, immerse them in an aqueous solution of 75 vol % acetic acid, and configure a solution with a mass concentration of 1 mg / mL. At this time, PVP is dissolved in the solution, and at the same time, the nanofiber branches TiO 2 nanoparticles.

[0021] d, according to graphene oxide: TiO 2 The mass ratio of PVP / PVP composite nanofibers is 100:1. Add 2 g of graphene oxide into the above solution and stir evenly with a glass rod.

...

Embodiment 2

[0026] a. Weigh 0.3 g of PVP and dissolve it in 4 mL of ethanol, then add 1 mL of hydrochloric acid and 5 mL of tetraethyl orthosilicate, and stir magnetically at 20 °C for 12 h at a speed of 500 rpm / min to obtain an electrospinning solution .

[0027] b. Electrospinning was performed at 35 °C and a humidity of 80%. The flow rate of the electrospinning solution was 0.3 mL / h, the DC voltage was 35 kV, and the spinning receiving distance was 35 cm to obtain SiO 2 / PVP composite nanofibers.

[0028] c. Weigh 5 g of electrospun composite nanofibers, immerse them in water, and configure a solution with a mass concentration of 0.5 g / mL. At this time, PVP is dissolved in water, and at the same time, the nanofibers branch into fine SiO 2 nanoparticles.

[0029] d, according to graphene oxide: SiO 2 / PVP composite nanofiber mass ratio is 1:100, 0.1 g graphene oxide is added to the above solution, and stirred evenly with a glass rod.

[0030] e. Transfer the above solution to a hydr...

Embodiment 3

[0034] a. Weigh 0.3 g of PVA and dissolve in 8 mL of distilled water, then add 2.0 g of glacial acetic acid and 1 g of zinc acetate, and stir magnetically at 90 °C for 24 h at a speed of 50 rpm / min to obtain an electrospinning solution.

[0035] b. Electrospinning was carried out at 30 °C and a humidity of 10%. The flow rate of the electrospinning solution was 0.3 mL / h, the DC voltage was 35 kV, and the spinning receiving distance was 35 cm to obtain ZnO / PVA composite nanofibers.

[0036]c. Weigh 10 g of electrospun composite nanofibers, immerse them in water, and configure a solution with a mass concentration of 0.5 g / mL. At this time, PVA is dissolved in water, and at the same time, the nanofibers are branched into fine ZnO nanoparticles .

[0037] d. Add 0.1 g of graphene oxide into the above solution according to the mass ratio of graphene oxide:ZnO / PVA composite nanofibers of 1:100, and stir evenly with a glass rod.

[0038] e. Transfer the above solution to a hydrotherm...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com