New technology for salting, air drying and maturing weever

A mature and perch technology, applied in meat/fish preservation, meat/fish preservation with acid, food preservation, etc., can solve the problems of low air-drying and ripening temperature, poor product flavor quality, simple production method of wind fish, etc., to speed up The effect of reducing moisture content, ensuring safety and high quality, and improving flavor quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

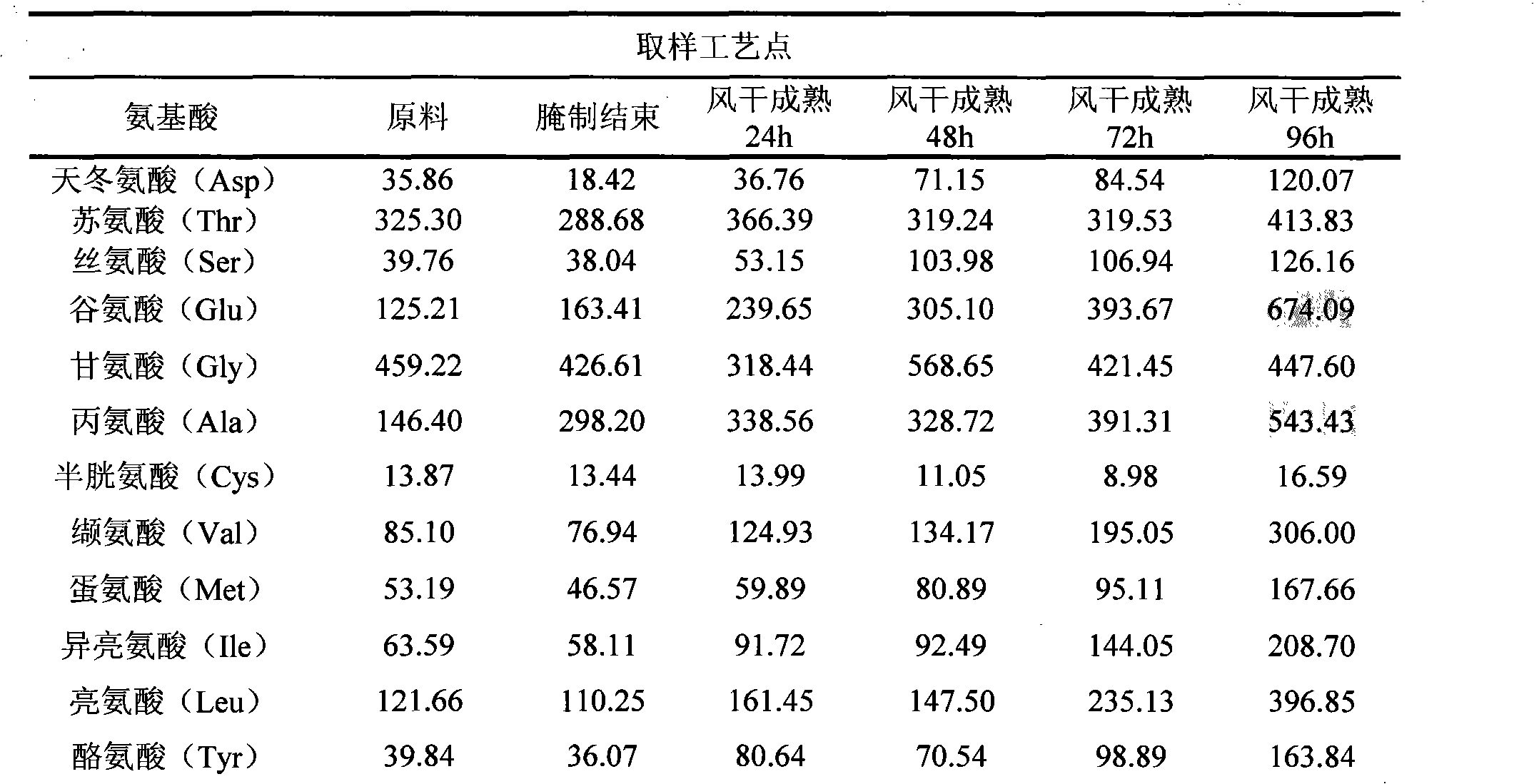

[0012] A new process of pickling and air-drying perch in the present invention, the process of pickling and ripening is as follows:

[0013] Fresh sea bass (gills and viscera removed) wash the remaining blood stains on the surface, drain the surface water, and apply 3.5-5.5% (W / W) evenly on the surface and inner cavity 鱼重 ) table salt, marinated for 45-50h at 0-8°C, (78±8)%RH. After pickling, under the conditions of humidity 65-85% RH and temperature 15-31°C, the temperature is gradually increased and air-dried for 80-108 hours to mature.

[0014] Sea bass air-drying maturation process: dehydration at low temperature for 28-38 hours under the conditions of wind speed 3-5 m / s, temperature 15-19 ℃, humidity 65-75% RH; then wind speed 2-4 m / s, temperature 20-25 ℃, humidity 75-80% RH conditions, medium temperature fermentation for 24-32 hours; then high-temperature ripening under the conditions of wind speed 1-3 m / s, temperature 26-31 ℃, humidity 75-85% RH conditions for 28-38 ho...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com