Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

69 results about "Streptococcus zooepidemicus" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Streptococcus zooepidemicus is a Lancefield group C streptococcus that was first isolated in 1934 by P. R. Edwards, and named Animal pyogens A. It’s a mucosal commensal and opportunistic pathogen that infects several animals and humans, but most commonly isolated from the uterus of Mares. It’s a subspecies of Streptococcus equi, a contagious upper respiratory tract infection of horses, and shares greater than 98% DNA homology, as well as many of the same virulence factors.

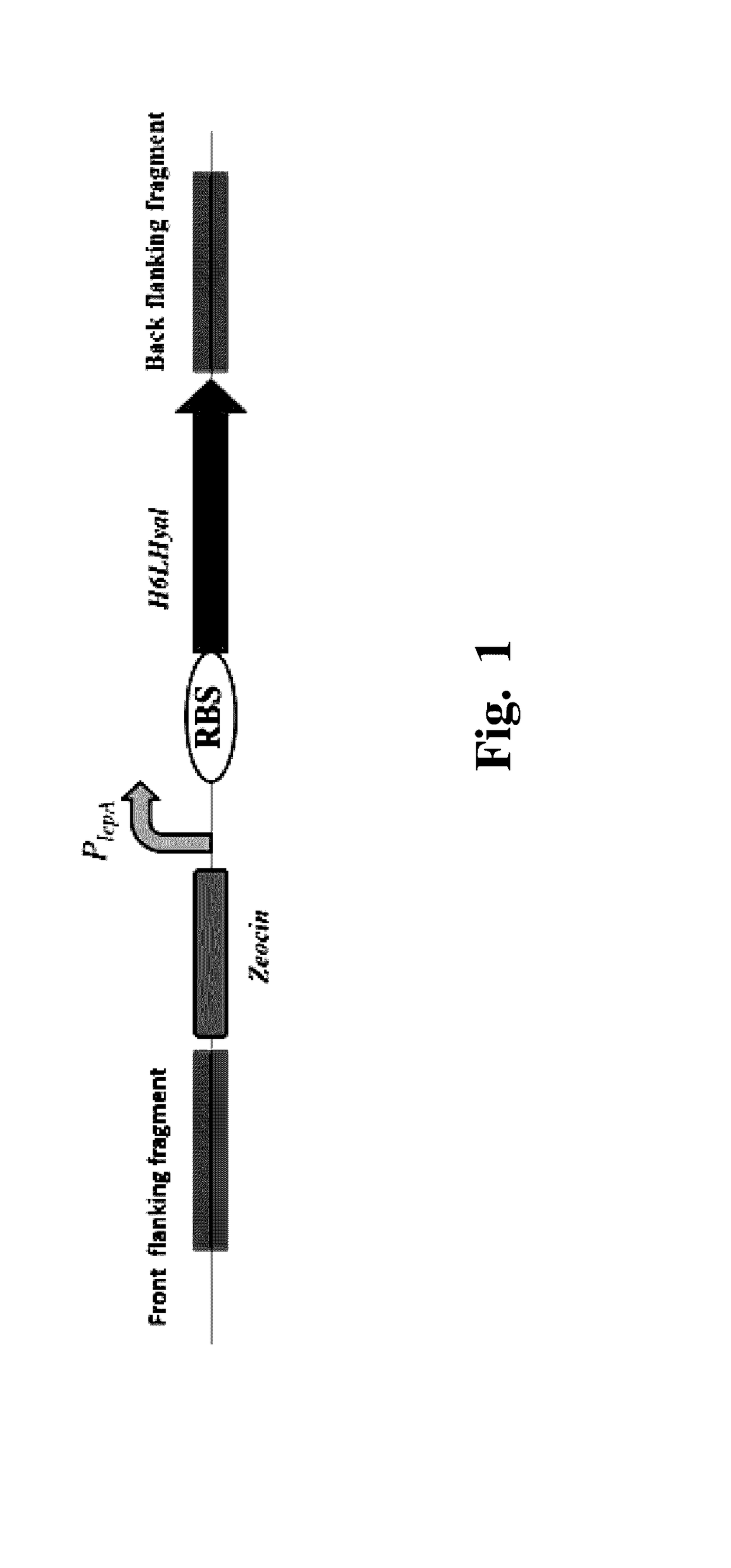

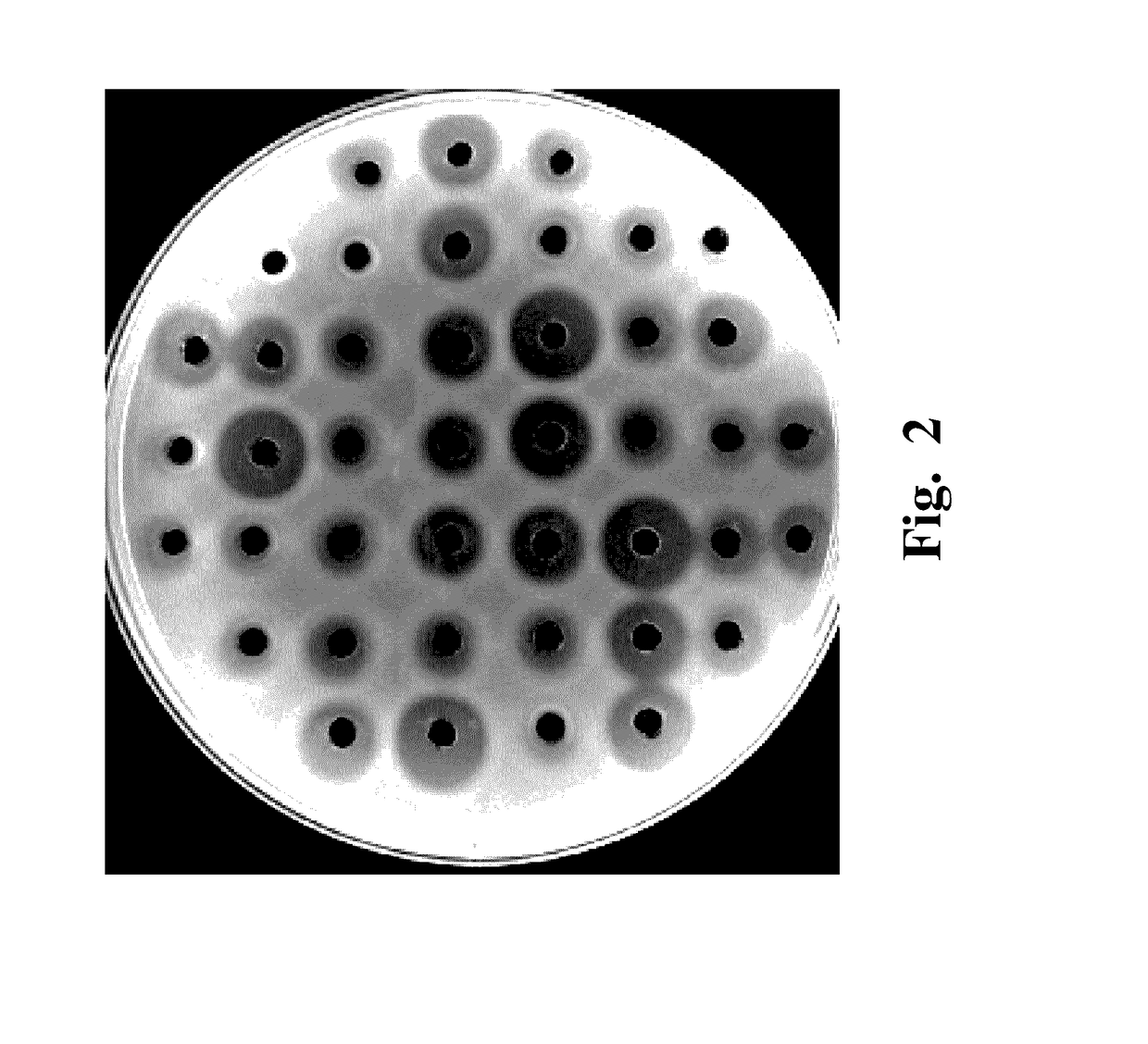

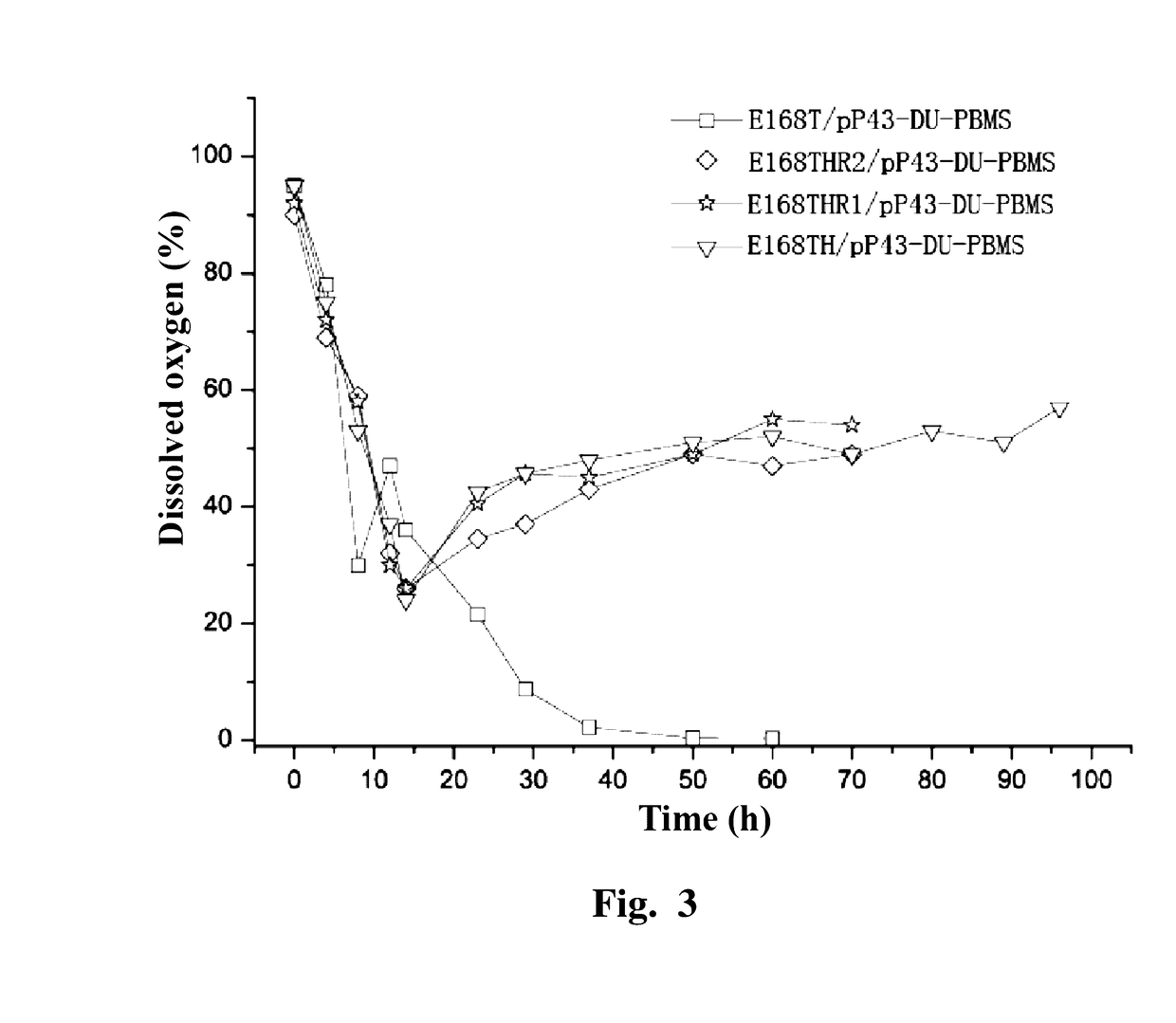

Construction method of recombinant bacillus subtilis capable of generating hyaluronic acid with specific molecular weight

ActiveCN105087456AIncrease productionReduce viscosityBacteriaTransferasesStreptococcus zooepidemicusHigh-Throughput Screening Methods

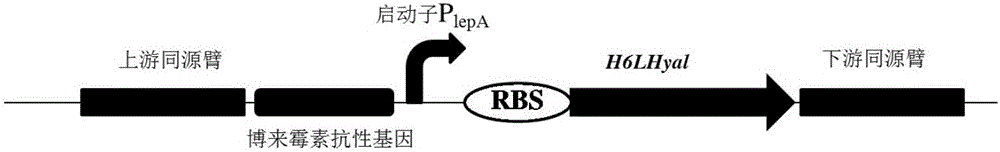

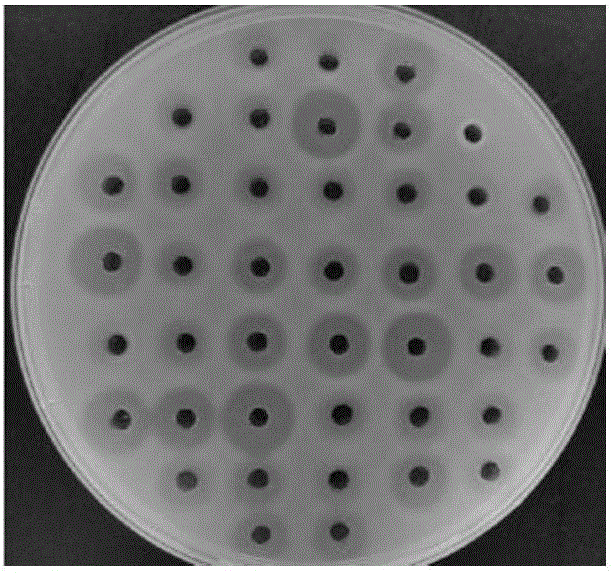

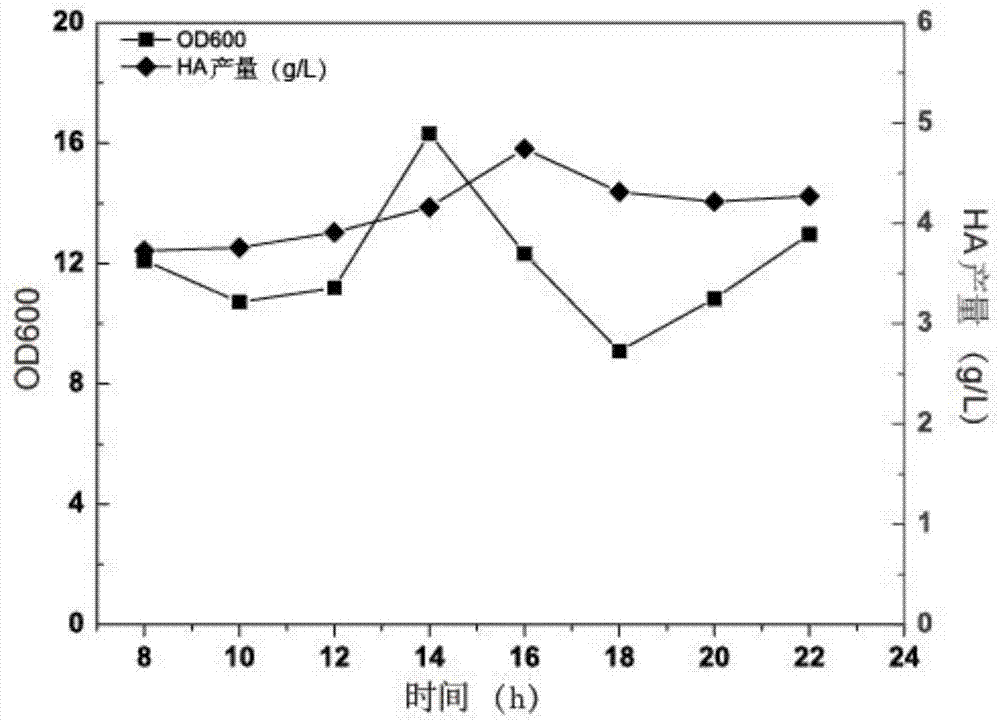

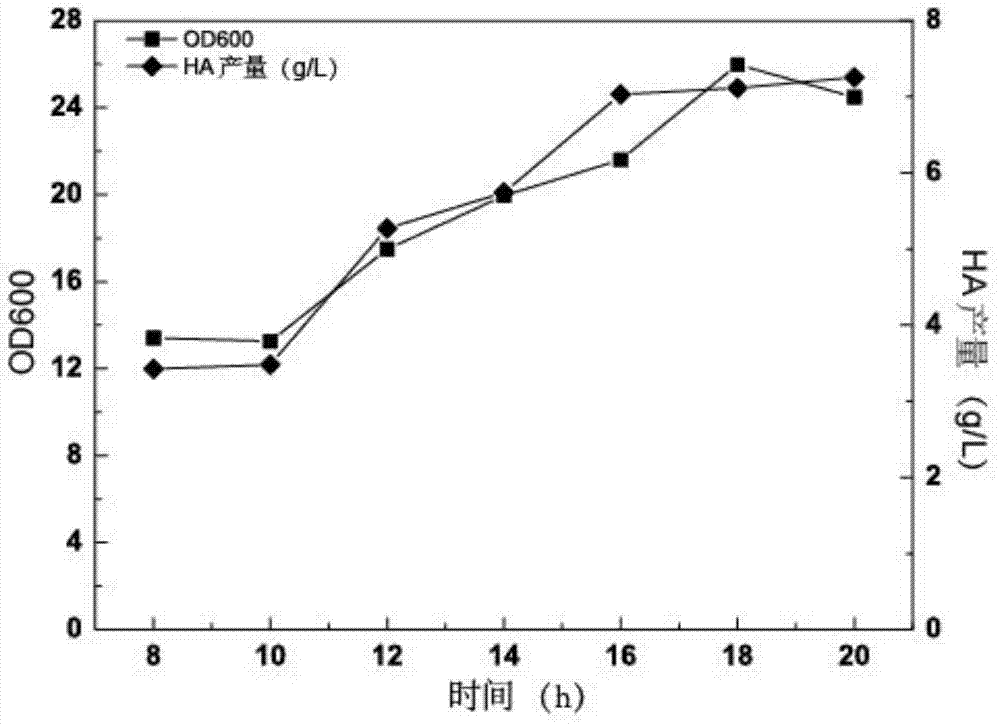

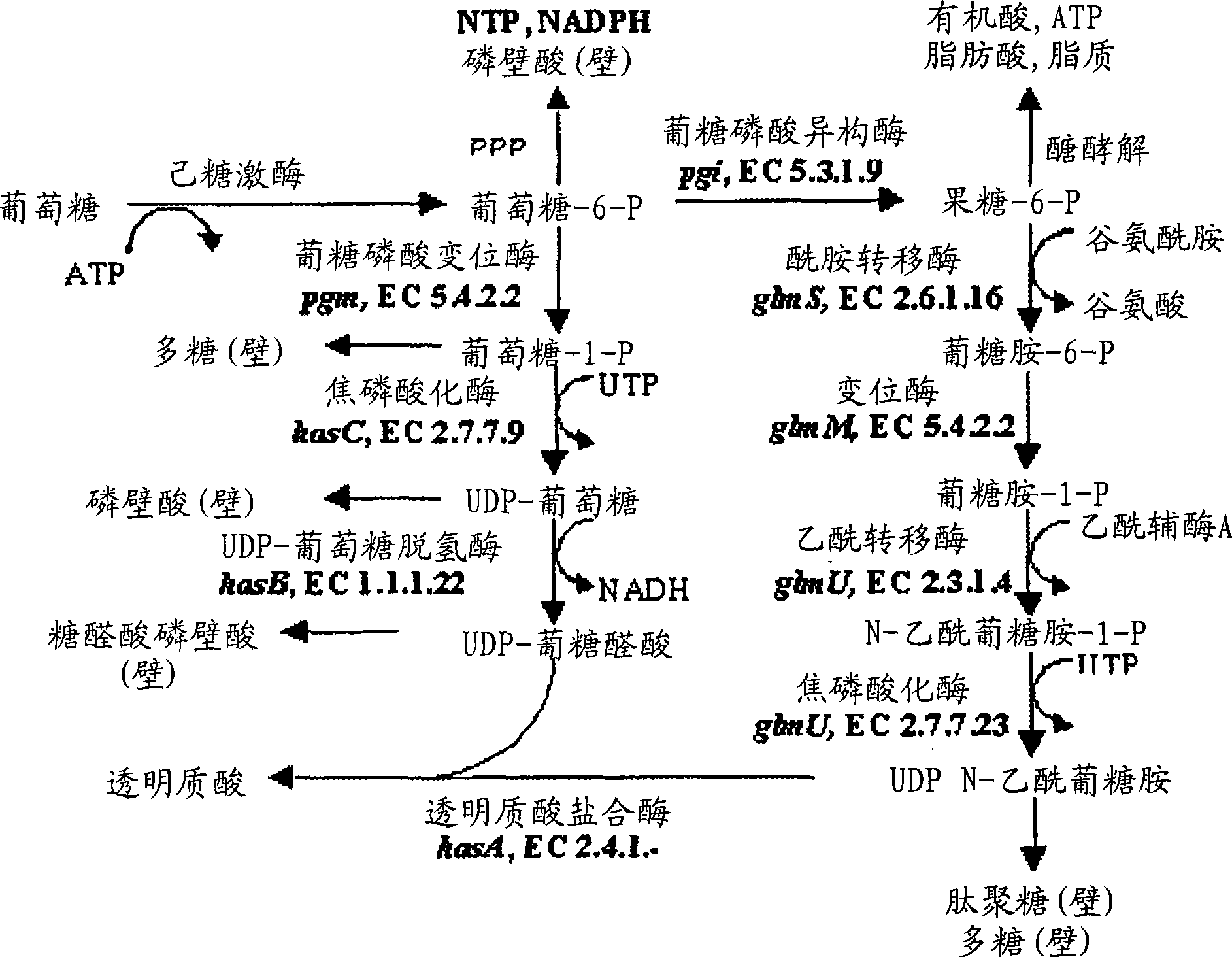

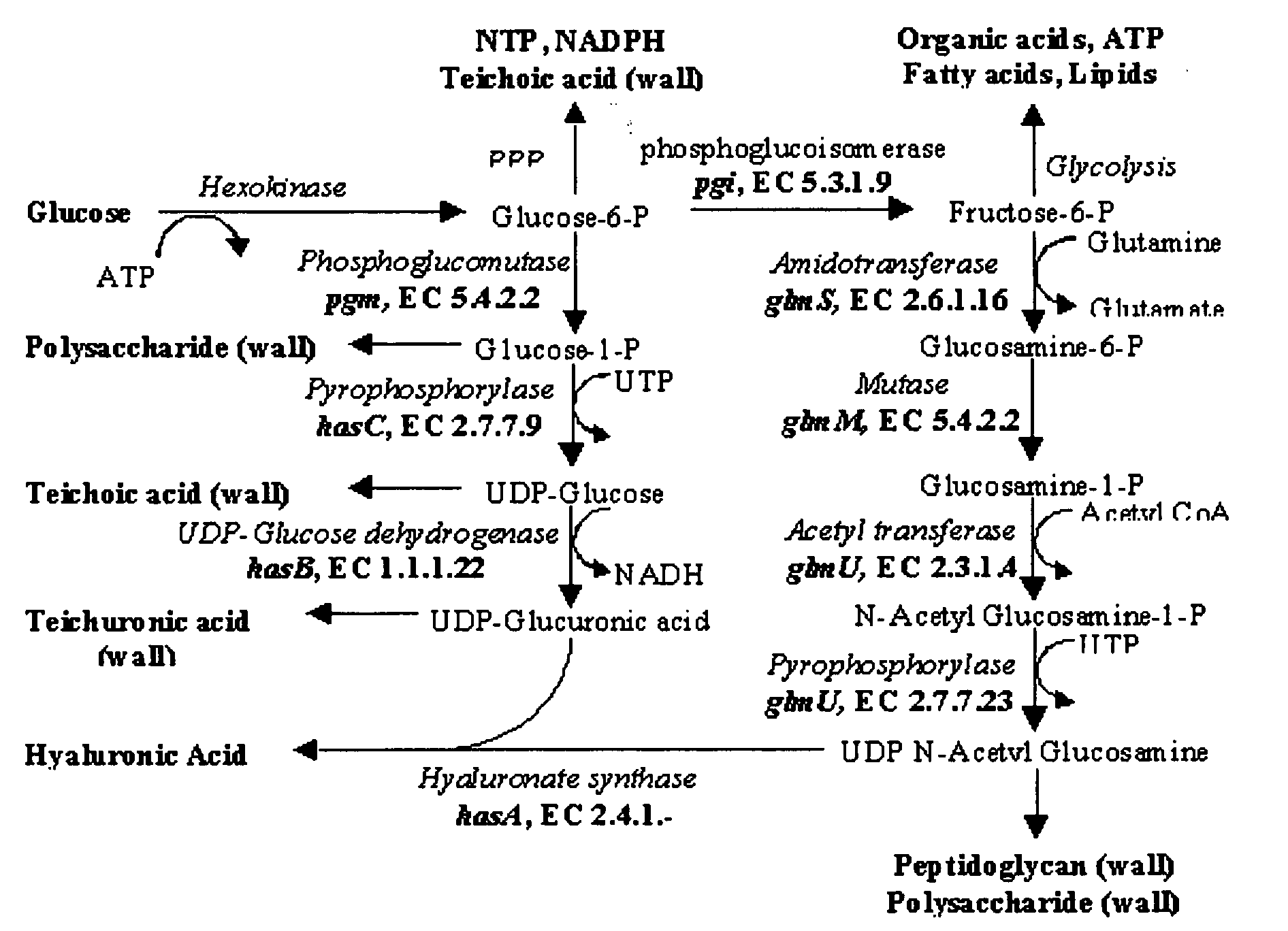

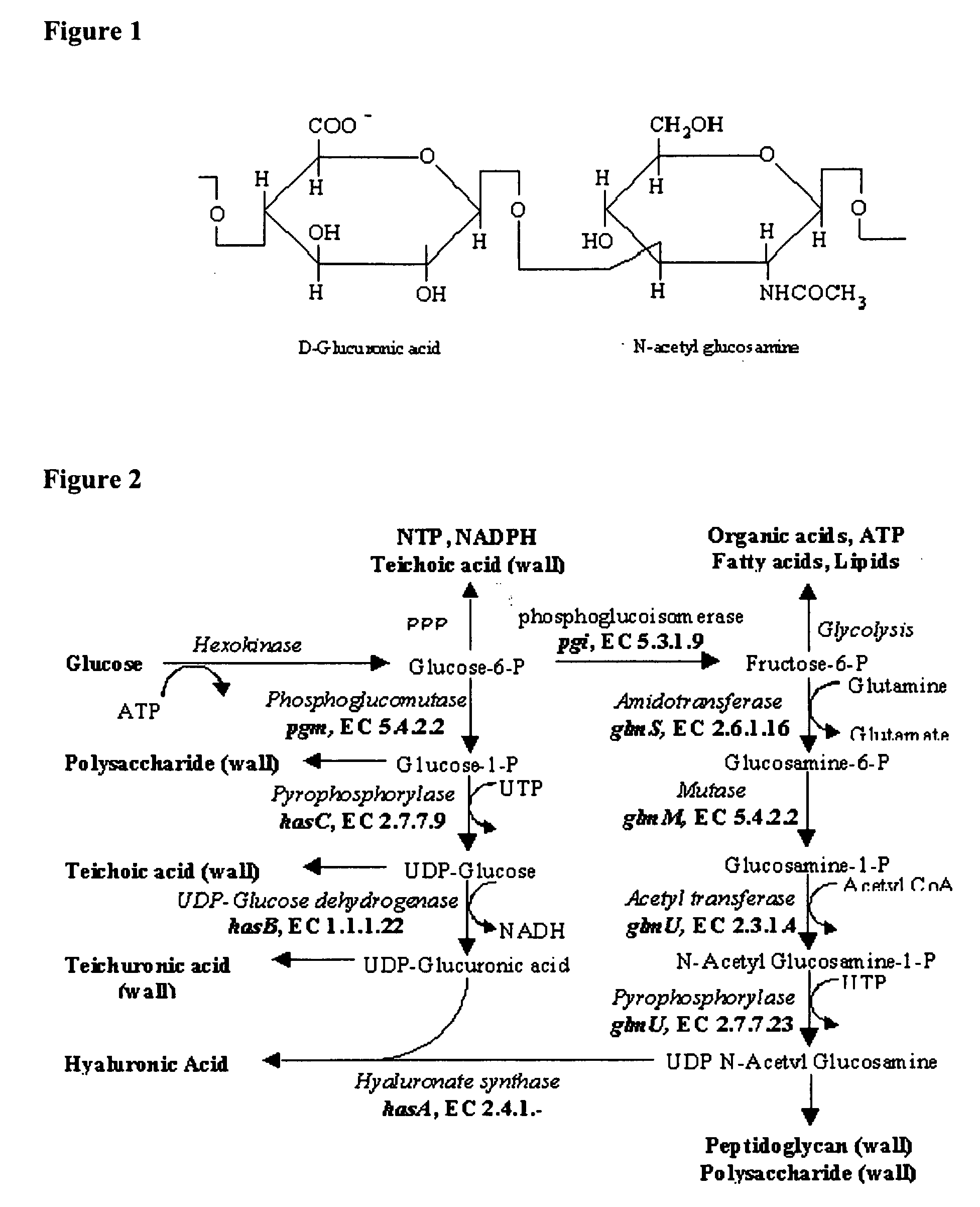

The invention discloses a construction method of recombinant bacillus subtilis capable of generating hyaluronic acid with specific molecular weight, belonging to the field of the bioengineering technology. According to the method, the production of hyaluronic acid is realized through integration of hyaluronic synthase (hasA) with streptococcus zooepidemicus source to bacillus subtilis; meanwhile, overexpression is realized on key genes of the synthetic route of HA, so that the high yield of bacillus subtilis is realized; on the basis, the hyaluronidase with the leech source is integrated to the genome of the bacillus subtilis, then mutant library construction is realized on ribosome bind sites (RBS) from the genetic expression translational level, and thus a series of mutants with different expression levels of hyaluronidases are obtained through high throughput screening; the yield of the hyaluronic acid achieves 19.38g / L, the molecular weight ranges from 103-106 Dalton, certain basis is laid for efficiently preparing micromolecule hyaluronic acids, and the construction method is suitable for industrial production and application.

Owner:JIANGNAN UNIV

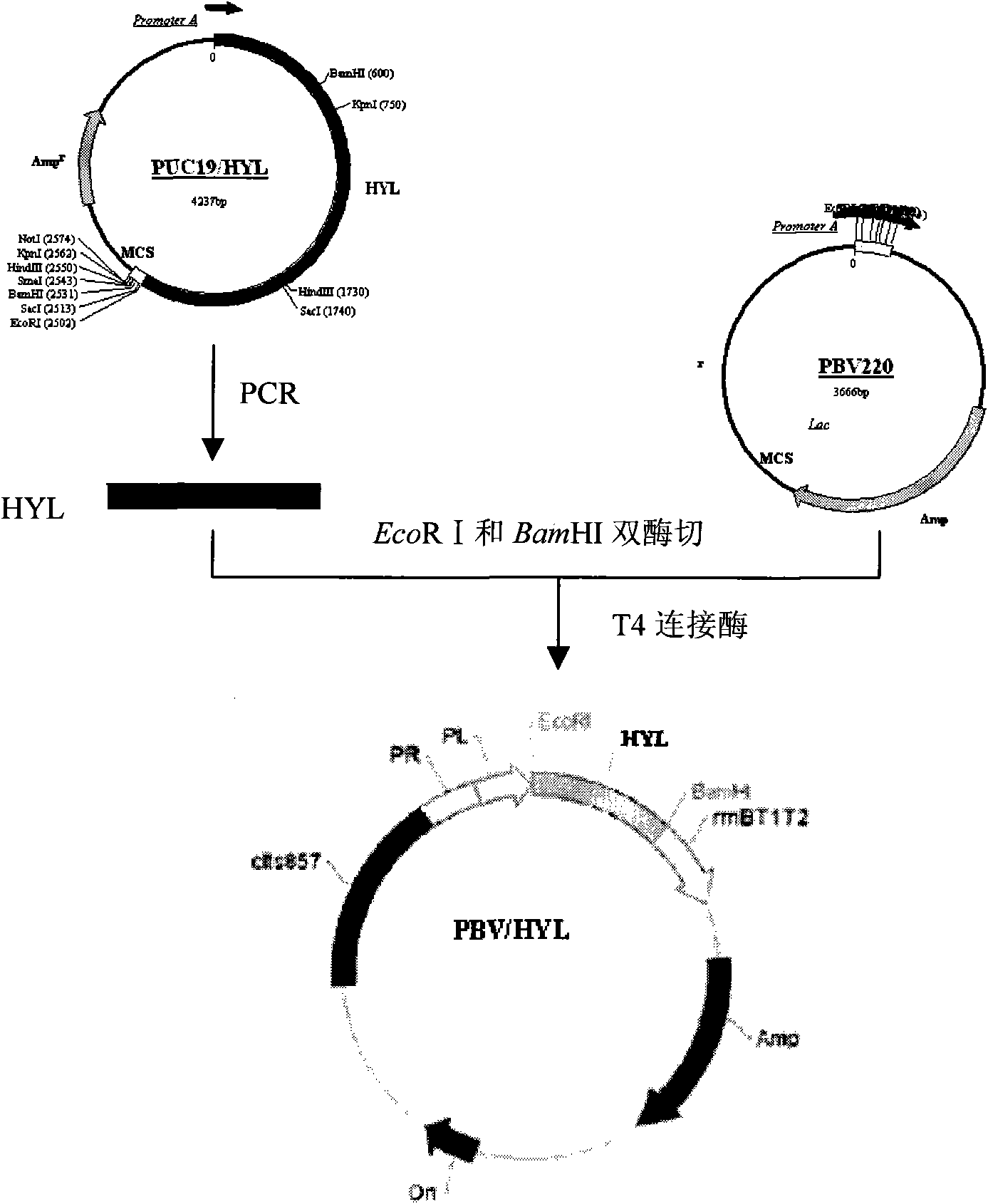

Hyaluronidase expression vector and application thereof

InactiveCN101633931AEasy to buildEasy to separate and purifyBacteriaMicroorganism based processesEscherichia coliStreptococcus zooepidemicus

The invention relates to an expression plasmid containing streptococcus zooepidemicus hyaluronidase genes and the application thereof and aims at providing a streptococcus zooepidemicus hyaluronidase expression vector, a recombinant Escherichia coil cell, a method for generating the hyaluronidase by using the cell and a method for preparing a hyaluronic acid oligose. By using a PCR method, the expression plasmid containing coding genes of the streptococcus zooepidemicus hyaluronidase is formed; a recombinant Escherichia coil strain is obtained by transforming the expression plasmid; and the hyaluronidase is generated by expressing the engineering bacterium. The hyaluronidase expression vector is an Escherichia coil expression vector containing streptococcus zooepidemicus hyaluronidase genes. The method for expressing the zooepidemicus hyaluronidase comprises the following steps of: culturing the recombinant Escherichia coil cells; expressing the hyaluronidase by controlling the temperature or IPTG induction; and using the hyaluronidase to prepare the HA oligose. The method for preparing the hyaluronidase has the characteristics of high expression level, easily expanded production and low cost. The hyaluronidase of the invention can be applied to degrading a hyaluronic acid.

Owner:INST OF BIOPHARM OF SHANDONG PROVINCE

Production method for extracting and purifying hyaluronic acid

The invention discloses a production method for extracting and purifying hyaluronic acid, for solving the problems such as long process route, long production period, high labor intensity, more human factors influencing product quality and relatively low product yield, existing in the purification of the traditional CPC (Cetyl Pyridinium Chloride) complexing ethanol sedimentation technology. The production method comprises the following steps of: fermentation liquor inactivation, primary alcohol precipitation, rough separation, redissolution, primary filtering decontamination, secondary filtering purification, alcohol precipitation crystallization, drying and smashing. The invention provides an industrial extraction and purification method of fermentation liquor for producing the hyaluronic acid through a streptococcus zooepidemicus fermentation method. The industrial extraction and purification method provided by the invention has the characteristics of short process route and production period, high adaptability, low production cost and good effect, can be concluded into a secondary filtering and secondary alcohol precipitation extraction process and is proved to be feasible through a small-scale test and a pilot scale test in a laboratory and verification in actual production and can meet the requirement for industrialized production.

Owner:SICHUAN HENGYI TECH

Method for producing high molecular weight sodium hyaluronate through fermentation and culture medium utilized by same

InactiveCN102242165AReduce contentReduce the process steps of extraction and purificationMicroorganism based processesFermentationBiotechnologyStreptococcus zooepidemicus

The invention discloses a novel method for producing high molecular weight sodium hyaluronate (HA-Na) with amino acid complex liquid as a nitrogen source through fermentation. In the method for producing the high molecular weight sodium hyaluronate, provided by the invention, yeast cream or yeast powder is replaced with the amino acid complex liquid as a fermentation nitrogen source of streptococcus zooepidemicus. The HA-Na with molecular weight of 2.2*10<6>D is obtained through control of a fermentation process. When the method is applied to industrial production, on the one hand, contents of hetero-protein and pigment in fermentation liquid can be effectively reduced, the step of subsequent HA-Na extraction is decreased, and the physical damage of the molecular weight of HA-Na in the fermentation liquid in the extraction process is reduced; on the other hand, the HA-Na production cost can be lowered, and the novel method has higher industrial application value. The HA-Na produced by the method has the molecular weight of 2.0-2.2*10<6>D, the alduronic acid content of 42.4-43.5%, the intrinsic viscosity of 3,064-3,115 and the protein content of 0.1%.

Owner:SHANGHAI INST OF TECH +1

Production technology for fermentatively producing sodium hyaluronate by utilizing bacterium

InactiveCN103173507ATo satisfy the market's needsImprove mutagenesis efficiencyMicroorganism based processesFermentationStreptococcus zooepidemicusHydrogen

The invention relates to a production technology for fermentatively producing sodium hyaluronate by utilizing bacterium. The production technology comprises the following steps of: using streptococcus equi subsp. zooepidemicus (Streptococcus Zooepidemicus) as an original strain; mutagenizing by virtue of nitrosoguanidine, and also mutagenizing by virtue of a protoplast in the presence of ultraviolet rays; introducing a special culture medium; carrying out submerged fermentation to produce high-output hyaluronic acid; and then carrying out a relative separation and purification technology to obtain a high-purity sodium hyaluronate product. According to the production technology for fermentatively producing the sodium hyaluronate by utilizing the bacterium, under the culture conditions that the culture temperature is 32 to 38 DEG C, the pH (Potential Of Hydrogen) of fermentation liquor is maintained within the range of 5.0 to 9.0, and a fermentation tank is at speed of stirring of 150 to 600rev / min, the output of the hyaluronic acid is greatly increased; and the production technology is suitable for being applied to industrial production.

Owner:宁波林叶生物科技有限公司

Method for producing hyaluronic acids with different molecular weights through reasonable regulation

InactiveCN104371965AIncrease valueGreat application advantageBacteriaMicroorganism based processesStreptococcus zooepidemicusBio engineering

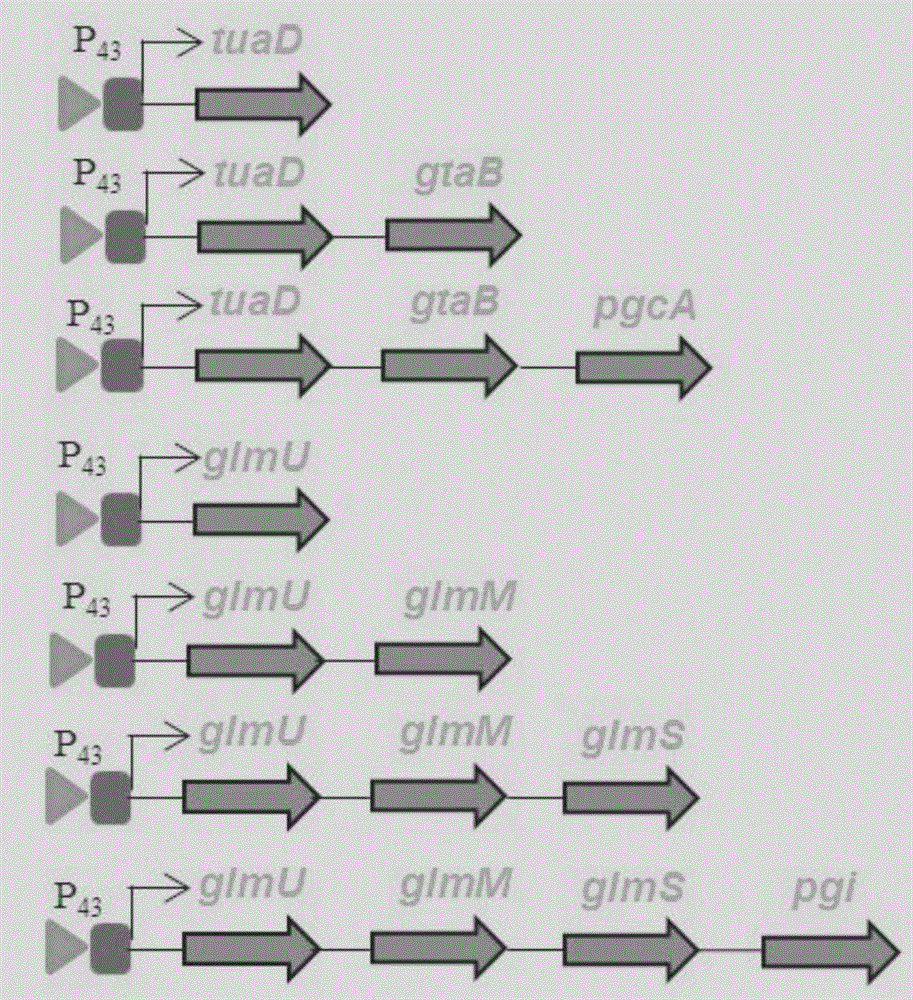

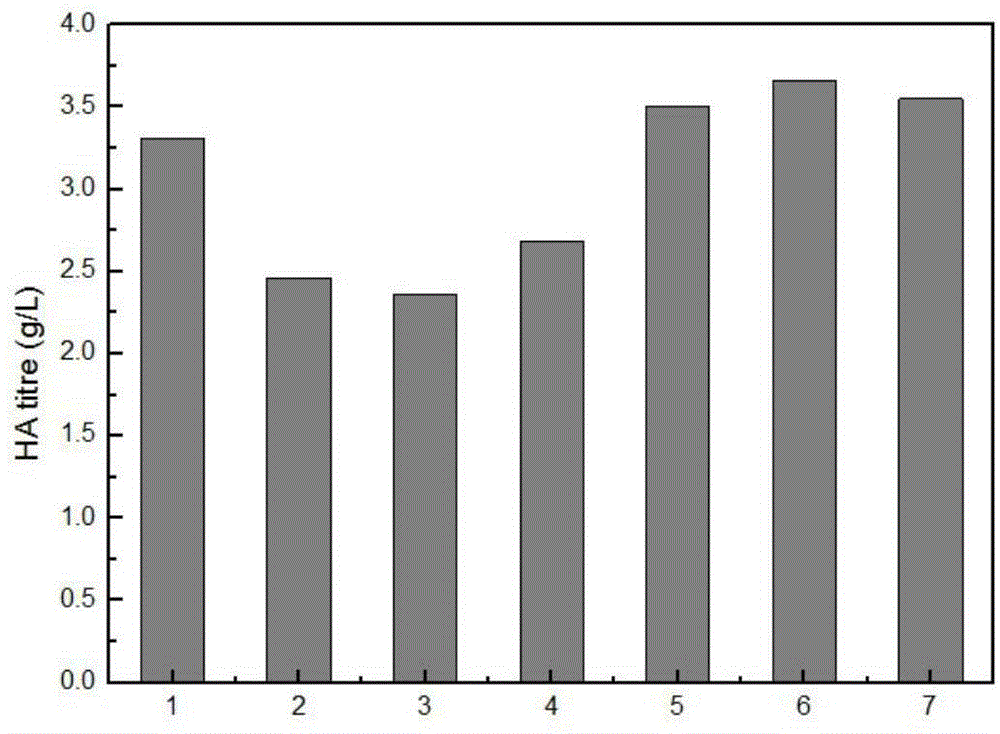

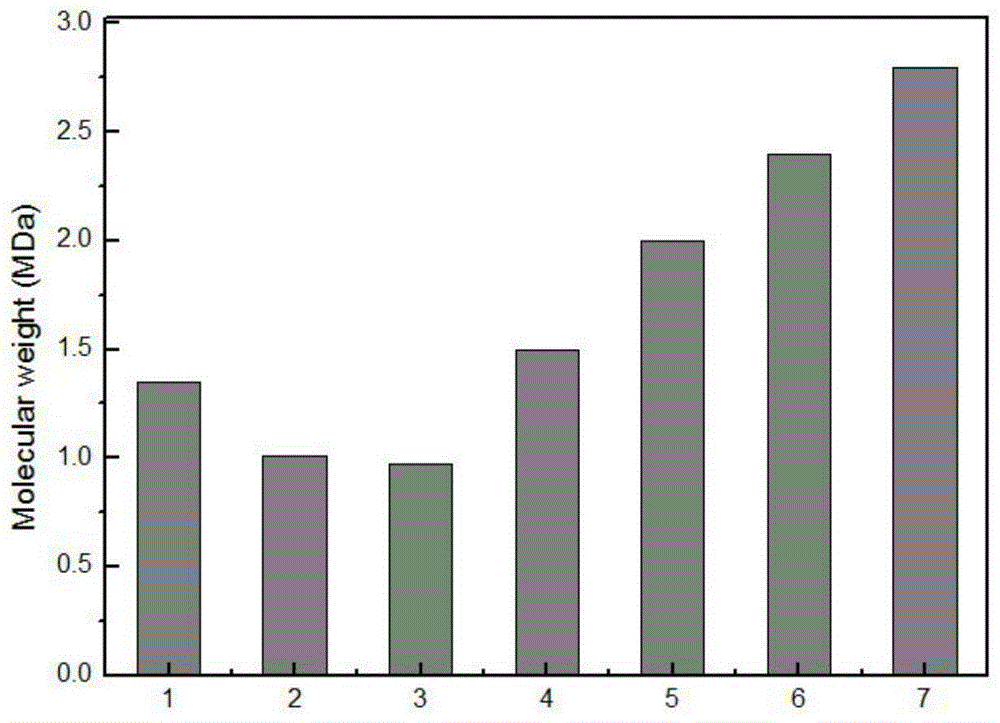

The invention discloses a method for producing hyaluronic acid with different molecular weights through reasonable regulation, belonging to the technical field of bioengineering. The method comprises the following steps: integrating hyaluronic synthase hasA from streptococcus zooepidemicus on a bacillus subtilis genome; performing modularized assembly and expression analysis on genes of UDP-GlcA and UDP-GlcNAc synthetic routes in bacillus subtilis, and producing hyaluronic acids with different molecular weights from the bacillus subtilis by controlling different UDP-GlcA and UDO-GlcNAc concentrations. The method disclosed by the invention can be used for laying a certain foundation for efficiently preparing the hyaluronic acids within a specified molecular weight range and is suitable for industrial production and application.

Owner:JIANGNAN UNIV

Method for improving fermentation yield of low-molecular hyaluronic acid (HA) by adding hyaluronidase

InactiveCN104120158AReduce viscosityImprove conversion yieldFermentationStreptococcus zooepidemicusMicroorganism

The invention discloses a method for preparing a low-molecular hyaluronic acid (HA) by adding a hyaluronidase liquid during microbial fermentation for production of the HA, and belongs to the technical field of bioengineering. The method comprises the following steps: adding the recombinant hyaluronidase obtained from leeches in fermentation of streptococcus zooepidemicus, and carrying out fed-batch fermentation so as to prepare the low-molecular HA and oligosaccharide (the molecular weight is lower than 105 Daltons) via a fermentation coupling enzymolysis method and improve the yield of the low-molecular HA at the same time. The method provides a certain foundation for the efficient preparation of the low-molecular HA and is suitable for industrial production.

Owner:JIANGNAN UNIV

Efficient process for purification of high molecular weight hyaluronic acid

Owner:RELIANCE LIFE SCI PVT

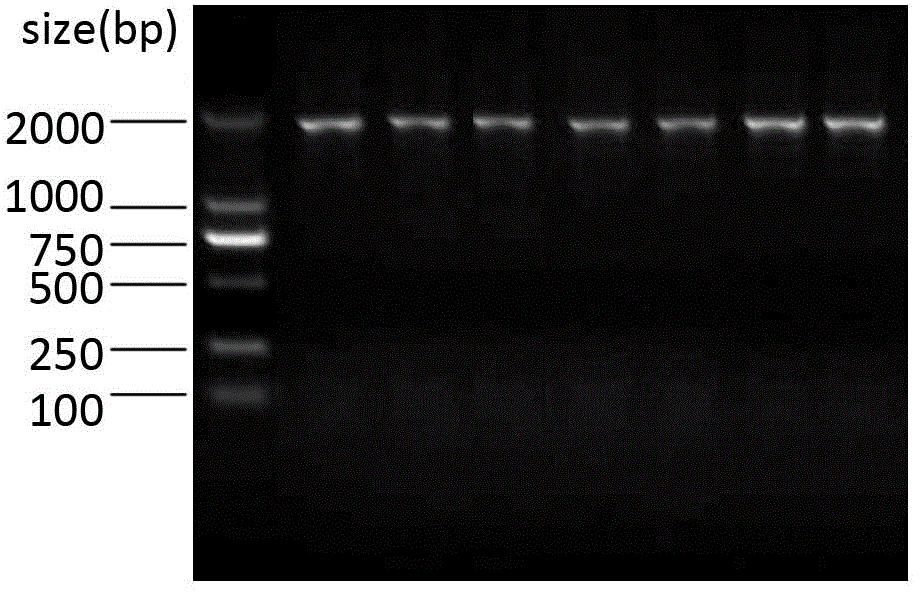

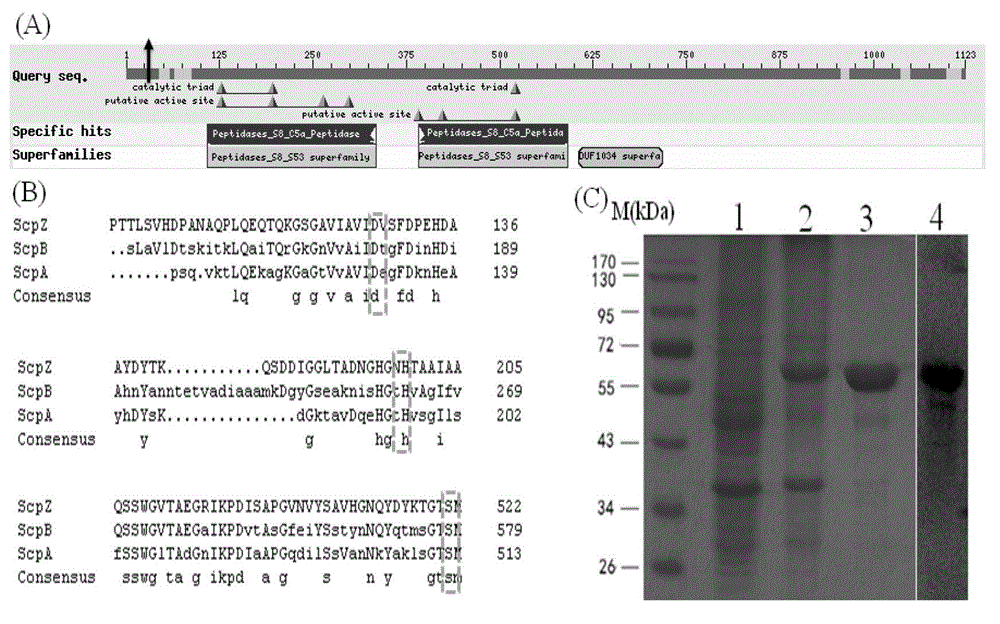

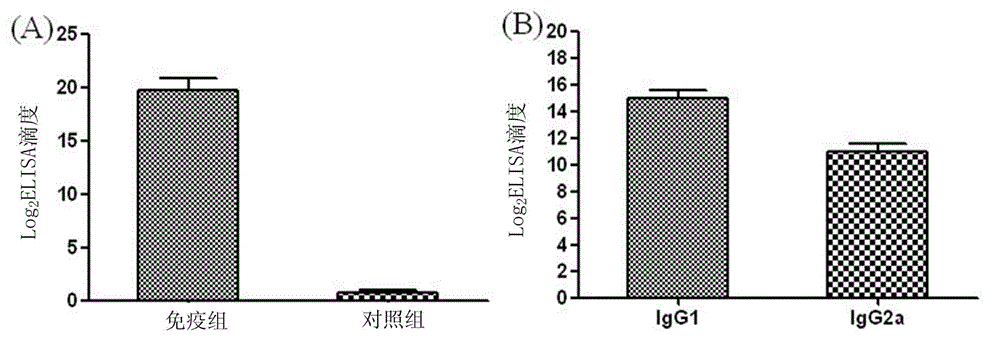

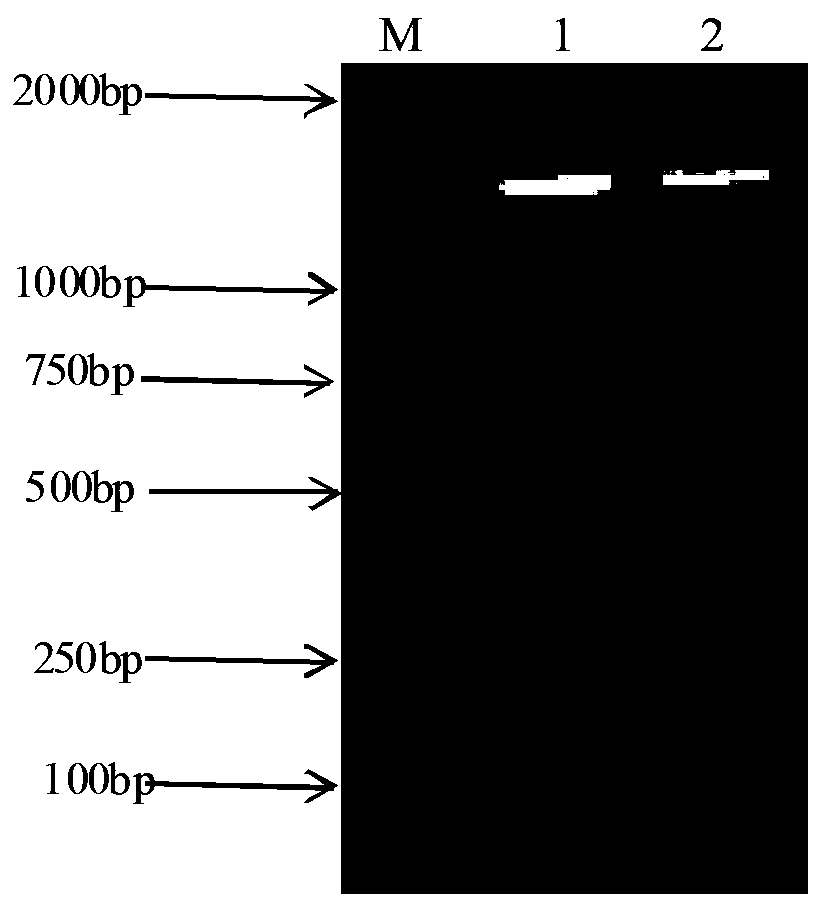

Streptococcus protective antigen C5a and preparation method thereof

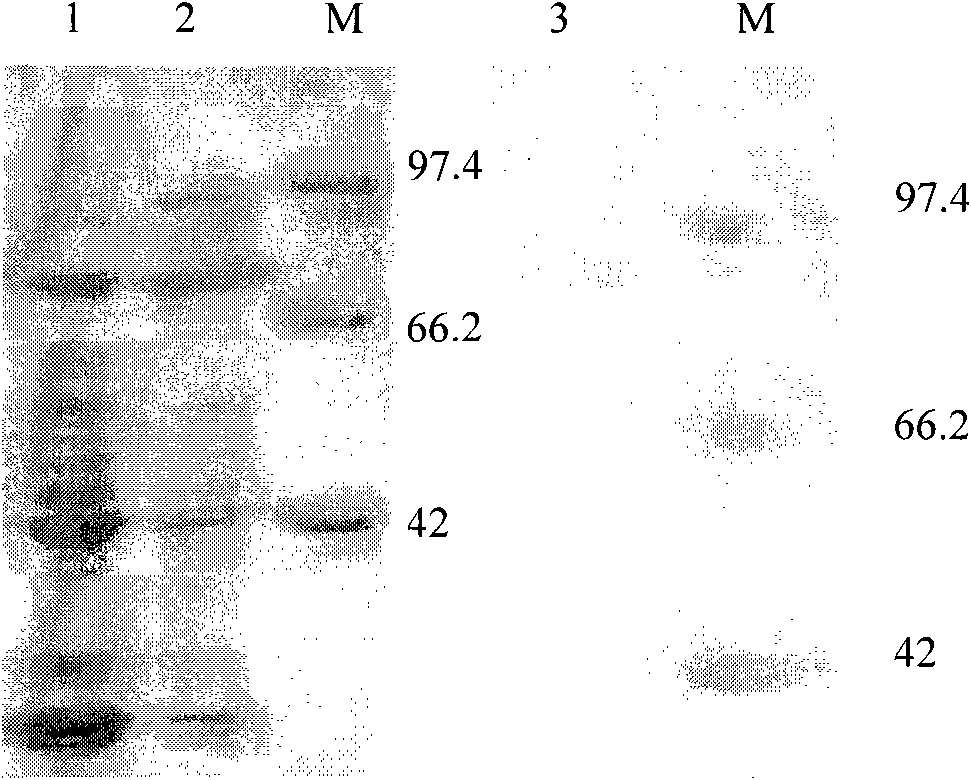

InactiveCN102746388AStrong immune responseSignificant passive immune protectionAntibacterial agentsBacterial antigen ingredientsForward primerProtective antigen

The present invention relates to a streptococcus antigen C5a and a preparation method thereof. The streptococcus protective antigen C5a is an SEZC5a recombinant protein, which consists of 571 amino acids and has a molecular weight of 60.3kDa; a forward primer has one BamHI restriction enzyme cutting site, and a reverse primer has one EcoRI restriction enzyme cutting site. According to the preparation method of the streptococcus protective antigen C5a, the SEZ C5a recombinant protein is treated with cloning, expression and purification; and a series of biological engineering technologies and experiments on mice are applied to conduct system analysis on an rSCPZ. After vaccination, the rSCPZ can provide high protective efficacy; an anti-rSCPZ mice double-immunized serum has significant passive immune protection on mice; and the mice immunized by the rSCPZ show high level of antibody titer in serum. The anti-rSCPZ antibody can induce high level of bactericidal capability; an scpZ gene has a transcription level in SEZ (Streptococcus zooepidemicus) infected mice higher than that of culture in vitro; and the rSCPZ can adhere to hep-2 cells and inhibit cell infection ability of SEZ.

Owner:广东艾佩克科技有限公司

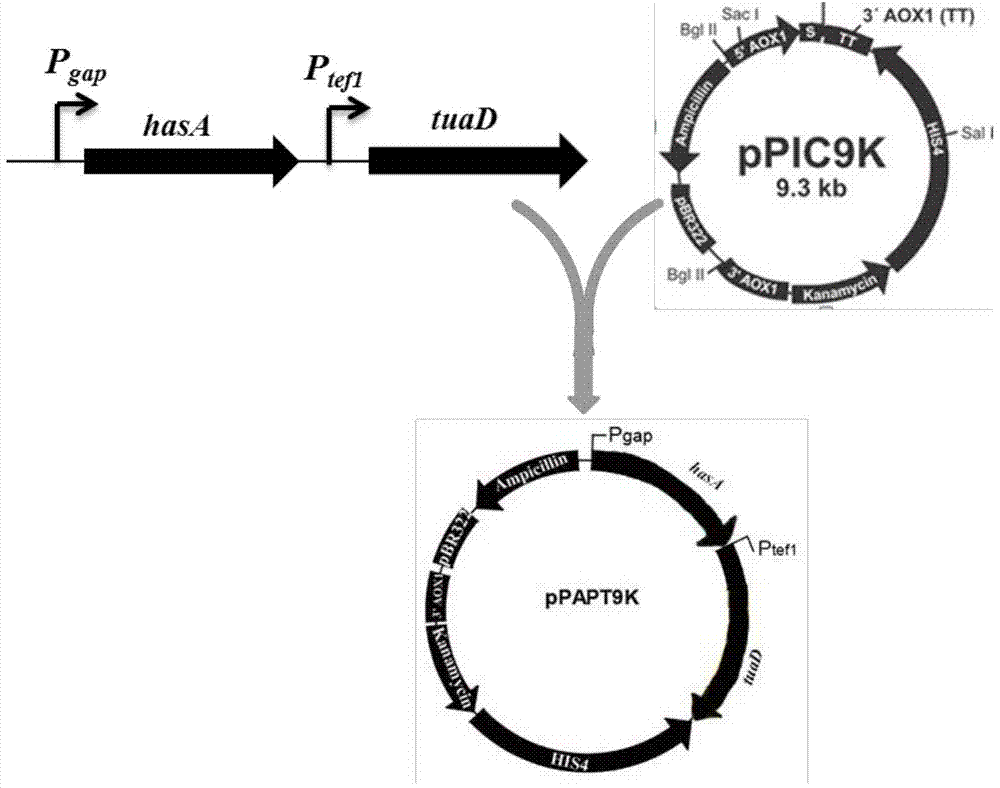

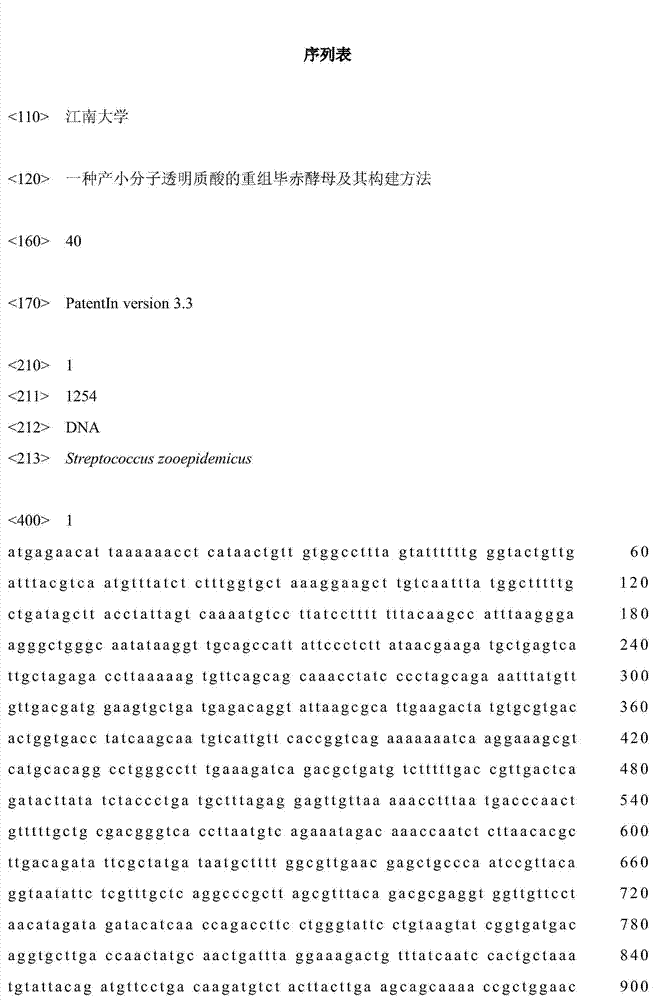

Recombinant Pichia pastoris for producing small-molecular hyaluronic acids and construction method thereof

ActiveCN104263666AImprove conversion yieldIncrease productionFungiMicroorganism based processesBiotechnologyStreptococcus zooepidemicus

The invention discloses a recombinant Pichia pastoris for producing small-molecular hyaluronic acids and a construction method thereof, belonging to the technical field of bioengineering. Hyaluronic acid synthase hasA derived from Streptococcus zooepidemicus and UDP-glucose dehydrogenase tuaD derived from Bacillus subtilis are expressed in recombinant Pichia pastoris GS115 host to implement production of hyaluronic acids. Meanwhile, hyaluronidase derived from hirudo is integrated to the Pichia pastoris genome and subjected to secretion expression by constitutive promoters with different intensities; the secretion expression level of the hyaluronidase is controlled to prepare small-molecular hyaluronic acid products with different molecular weights; and the prepared products have different ranges of molecular weight, and have instruction and reference meanings for directly producing small-molecular hyaluronic acids within a specified range from microbes. The recombinant Pichia pastoris lays certain foundation for high-efficiency preparation of small-molecular hyaluronic acids, and is suitable for industrial production.

Owner:JIANGNAN UNIV

Method of improving byaluronic acid yield and molecular weight by fermentation process

InactiveCN1786180AIncrease productionHigh molecular weightFermentationYeastStreptococcus zooepidemicus

The invention relates to a method of improving fermentation method producing hyaluronic acid yields and molecular weight. It belongs to hyaluronic acid fermentation technique field. Its steps is as follows: adopting streptococcus zooepidemicus H23 as start strain; producing hyaluronic acid by liquid fermentation; fermenting culture medium and using yeast powder as single nitrogen source; the yields and molecular weight of the hyaluronic acid is greatly increased at 180-220rpm rotate speed. It is applied to hyaluronic acid industrialization production. The invention can increase fermentation method producing hyaluronic acid yields and molecular weight, economize energy consumption, reduce production cost, and improve hyaluronic acid production quality.

Owner:JIANGNAN UNIV

Streptococcus zooepidemicus and production process for preparing hyaluronic acid by using same

ActiveCN104059865AEasy to separate and purifyShorten the production cycleBacteriaMicroorganism based processesBiotechnologyStreptococcus zooepidemicus

The invention discloses streptococcus zooepidemicus and a production process for preparing hyaluronic acid by using the same. The compound mutation technology is adopted to screen out strains with high hyaluronic acid yields and is combined with the fermentation technology. The yield of the hyaluronic acid product is as high as 7-9g / L. The hyaluronic acid obtained through fermentation is easy to separate and purify and is short in production period. Production is easy to control. The production process is suitable for large-scale industrial production, is high in yield and has the effect of greatly reducing the production cost.

Owner:SHANDONG AWA BIOPHARM

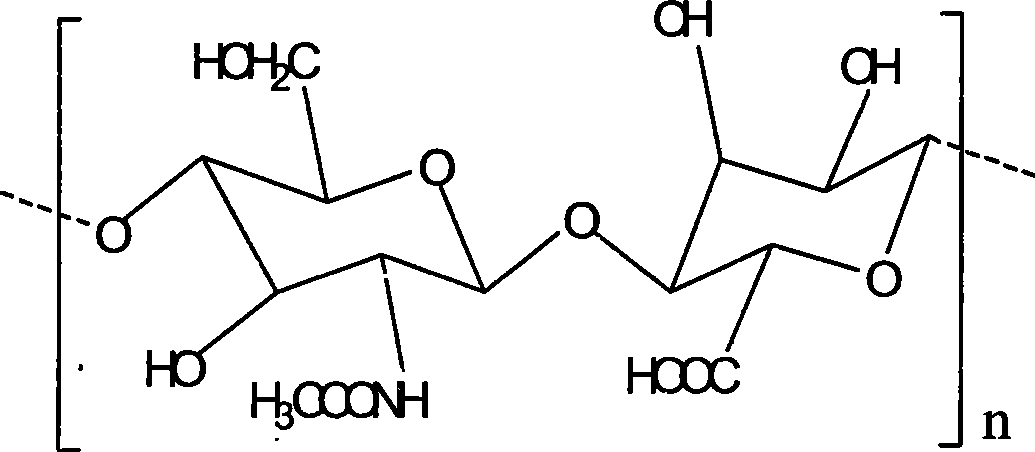

Biological polysaccharide, and production and use thereof

InactiveCN101503722AGood moisturizing effectOrganic active ingredientsCosmetic preparationsStreptococcus zooepidemicusBiological materials

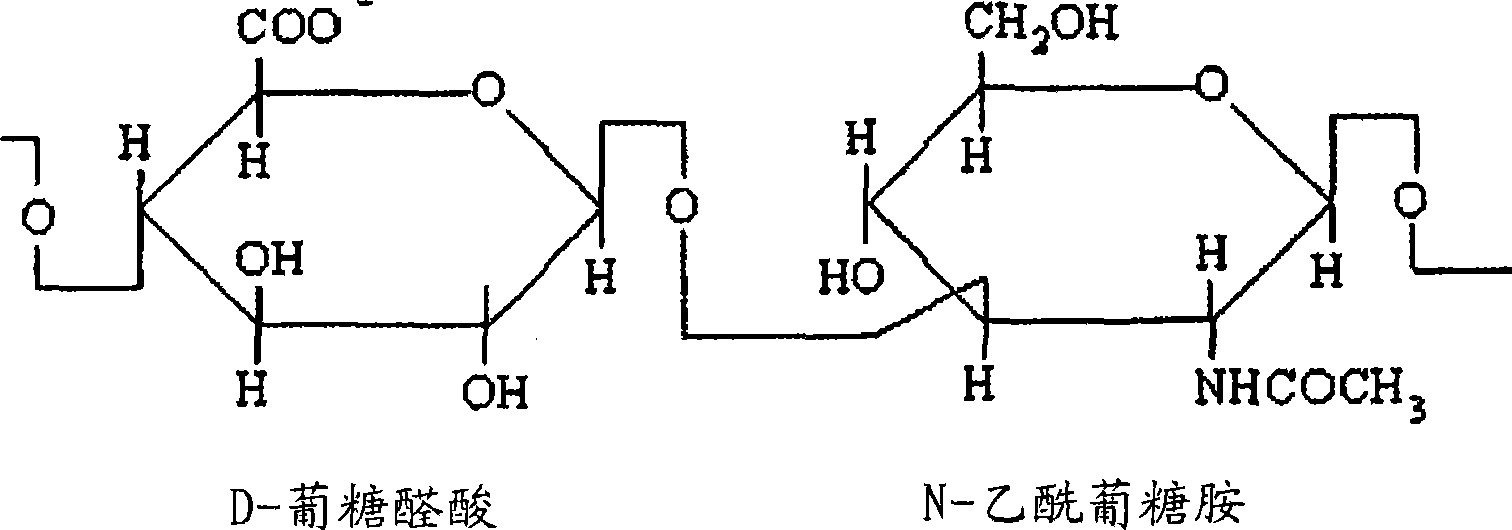

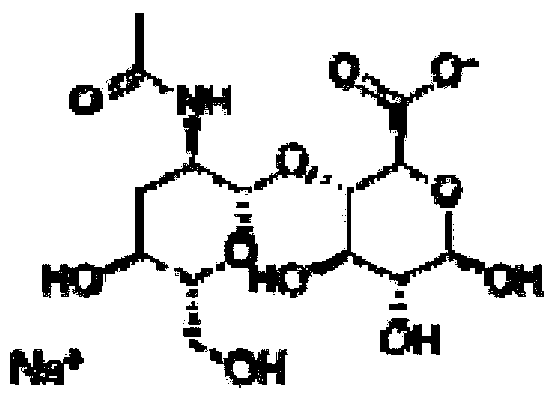

The invention relates a novel biological polysaccharide, a method for producing the same and application of the same. The biological polysaccharide is prepared by fermenting Streptococcus zooepidemicus CGMCC No. 1988. The preparation method comprises the following process steps of preparation of an inclined plane seed, preparation of seed solution, optimization of fermentation condition, separation purification of products and the like. The biological polysaccharide produced by the method has the advantages of high yield, simple process step, low production cost and the like; and in a liter of fermentation liquid, the content of the polysaccharide is between 20 and 50g, and the whole yield reaches between 70 and 90 percent. The research on the structure and the physical property of the biological polysaccharide shows that the biological polysaccharide comprises a plurality of disaccharide folding structures adopting a connection mode shown in the figure 1, has the characteristics of the macro molecular net structure biological polysaccharide, can be widely applied in various fields such as medical treatment, foods, cosmetics, oil extraction, biological materials and the like, and has important realistic significance.

Owner:张鹏 +1

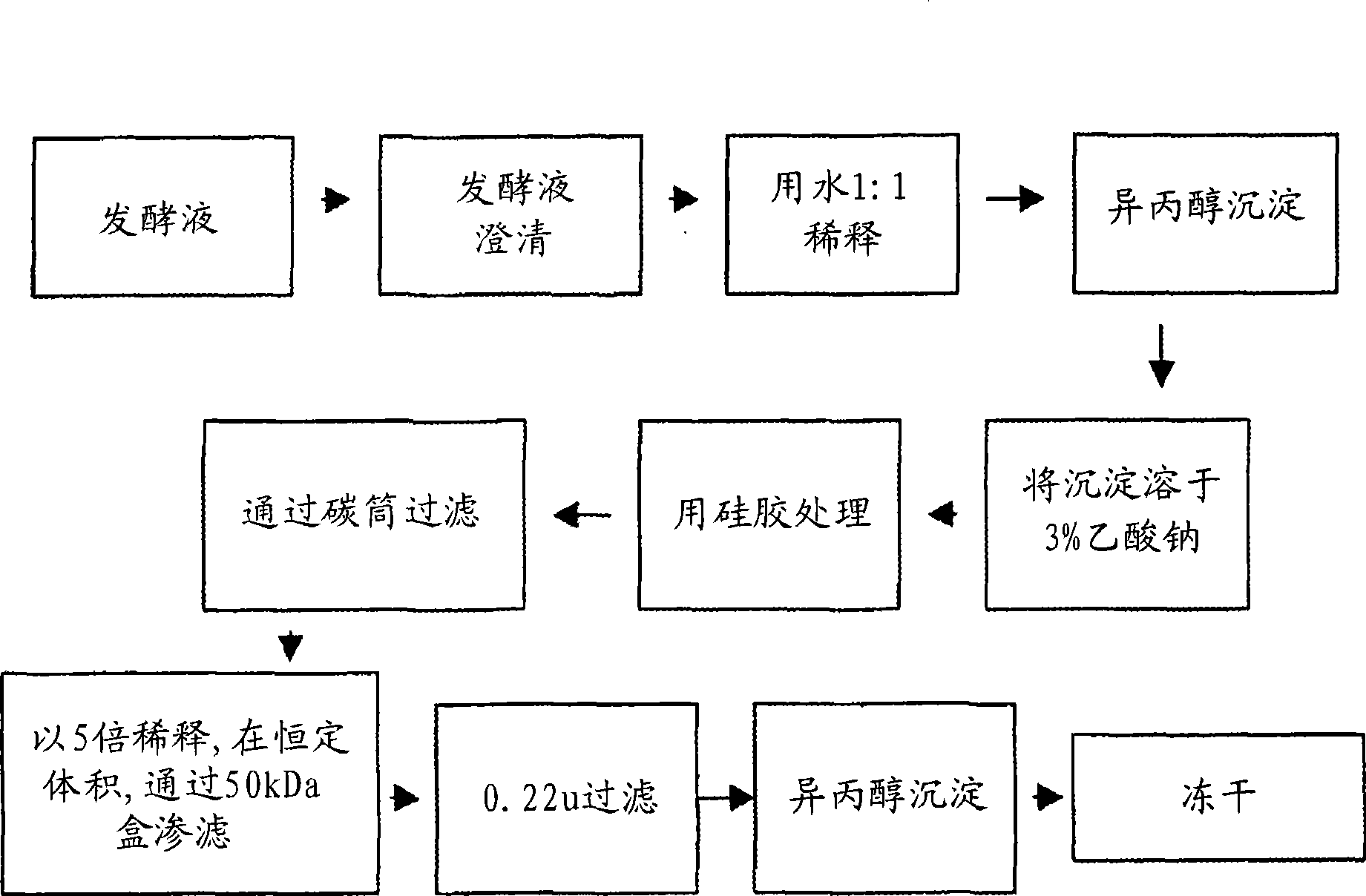

Optimisation of culture conditions for production and process of purification of high molecular weight hyaluronic acid

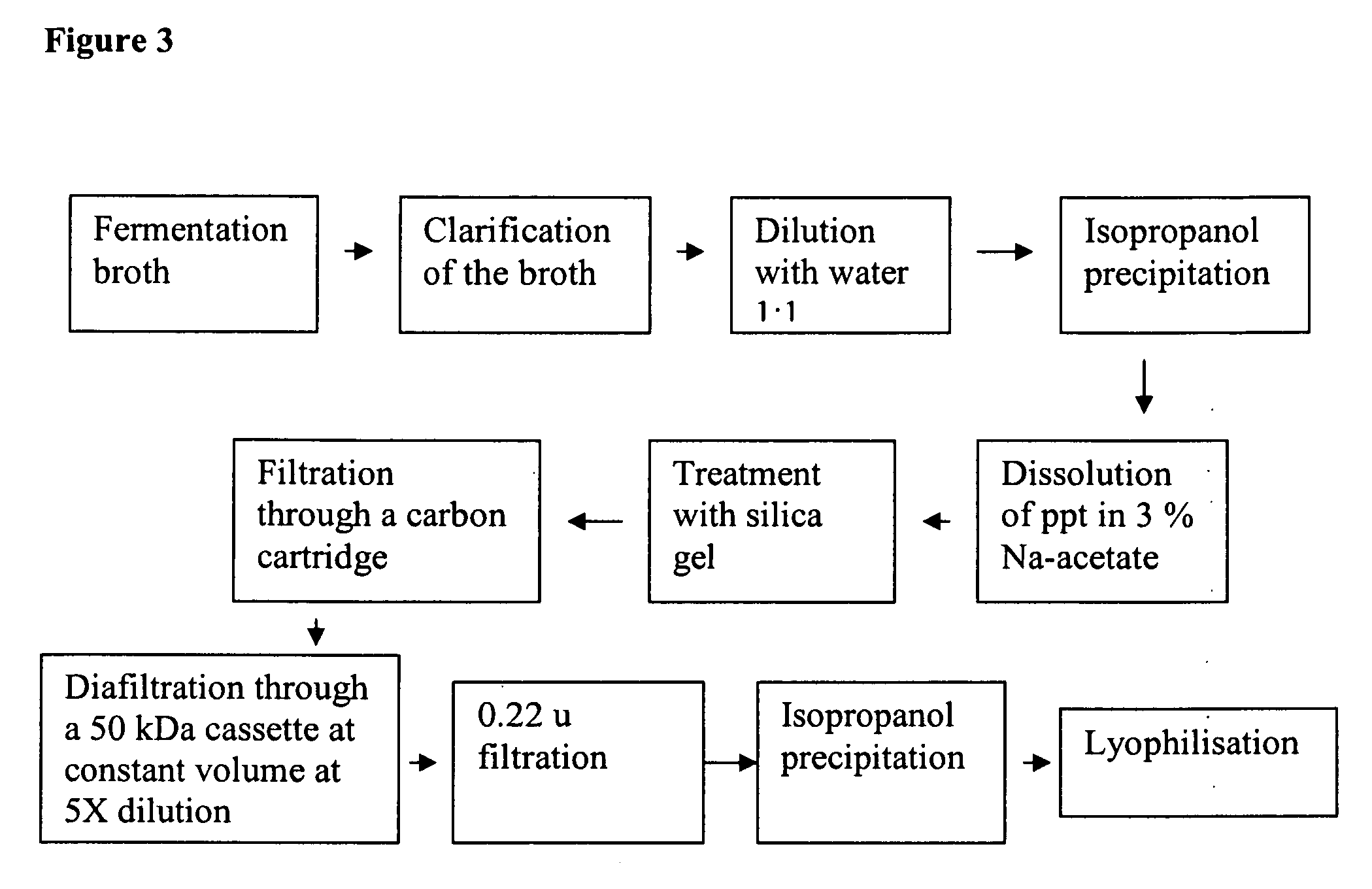

The present invention provides an efficient and improved process for the production and purification of high molecular weight hyaluronic acid (HA). One embodiment relates to providing growth conditions for production of high molecular weight HA in Streptococcus zooepidemicus. For example, growth in medium comprising a lower protein concentration, e.g., 1% casein hydrolyzate, and a higher sugar concentration, e.g., 5% sucrose, gave 5-6 g / L of high molecular weight HA in the range of 3.5-4.0×106 Da. The present invention also provides an efficient process for the purification of HA comprising treatment with silica gel then active carbon, and subsequent diafiltration with less volume of solvent.

Owner:RELIANCE LIFE SCI PVT

Method for producing hyaluronic acid (HA) by streptococcus zooepidemicus fermentation

InactiveCN101619331AMicroorganism based processesFermentationStreptococcus zooepidemicusFermentation broth

The invention discloses a method for producing hyaluronic acid (HA) by streptococcus zooepidemicus fermentation. In the method, normal hexane is added in the fermenting process of streptococcus zooepidemicus so that the content of the HA in a fermenting product is greatly improved. When the normal hexane accounting for 0.50 percent of total volume of fermentation liquor is added, the HA yield reaches a maximal value of 0.406 g / L and is improved by 33.56 percent compared with a comparison.

Owner:SICHUAN UNIVERSITY OF SCIENCE AND ENGINEERING

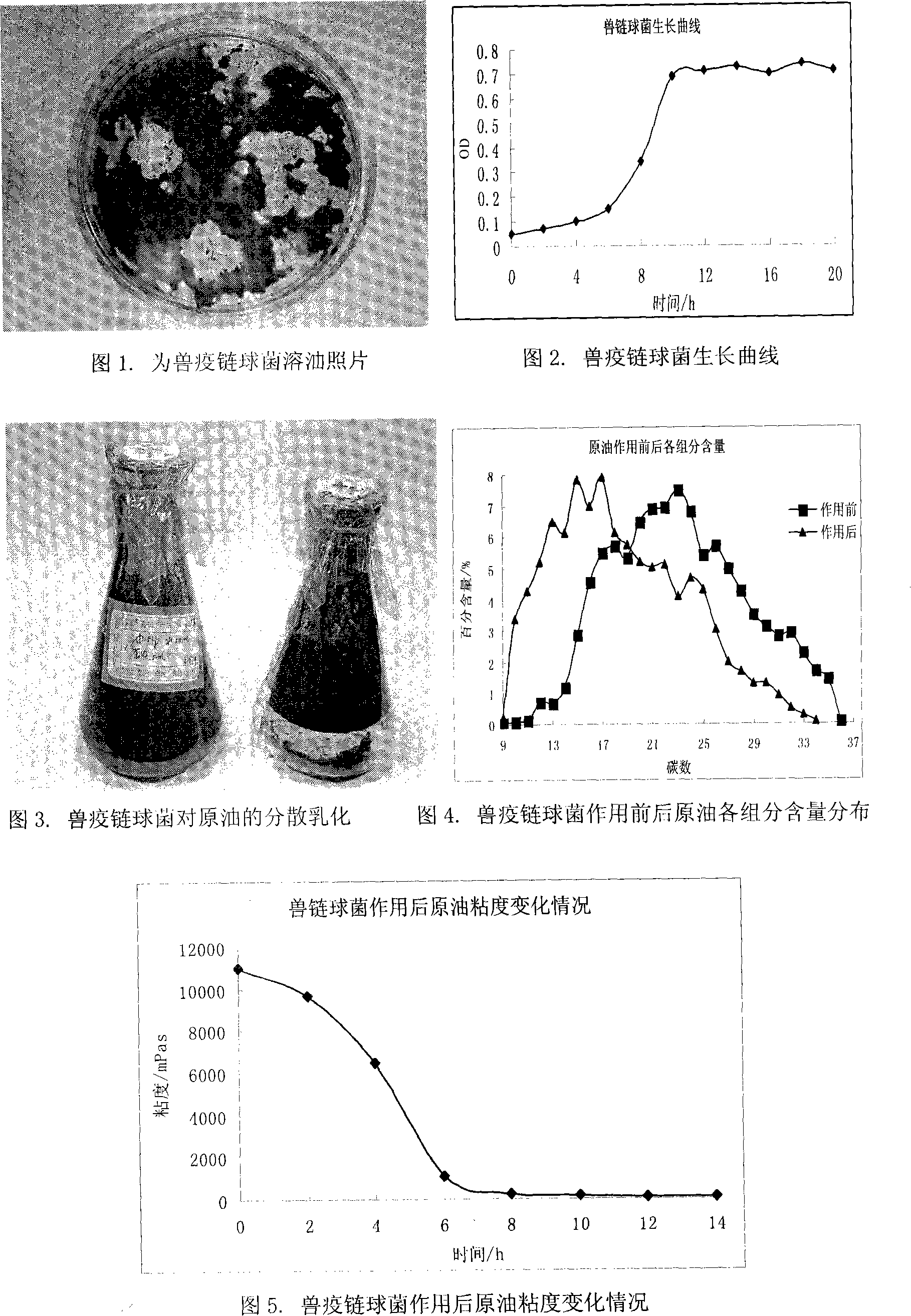

Viscosity reduction bacteria for increasing recovery ratio of petroleum, and application

InactiveCN101092602AIncrease vitalityReduce oil production costsBacteriaMicroorganism based processesStreptococcus zooepidemicusOil production

This invention discloses Streptococcus zooepidemicus (CGMCC No.1988) for reducing petroleum viacosity and increasing petroleum yield, and its application. Streptococcus zooepidemicus is applied by: inoculating in petroleum, and fermenting at 20-60 deg.C for 8-72 h. Streptococcus zooepidemicus can reduce petroleum viacosity from 8000-15000 mPa.s to 50-250mPa.s, increase petroleum acid value by 8-15 times and light component contents, reduce wax and glue contents by 50-95%, improve rheological property of petroleum, reduce interfacial tension between water and oil, increase organic acid contents in fermented petroleum, and increase oil layer pressure and petroleum fluidity. Besides, CO2, biogas and hyaluronic acid are generated during the fermentation process, thus fermented petroleum is easy to emulsify, moisten and disperse. Streptococcus zooepidemicus can be used in oil production, especially microbe-enhanced oil production and petroleum transportation.

Owner:厦门绿启源生物科技有限公司

Streptococcus adhesion antigen GAPDH and preparation method thereof

InactiveCN102746389AImpairs the ability of adherent cellsSignificant passive immune protectionAntibacterial agentsBacterial antigen ingredientsForward primerAntigen

The present invention relates to a streptococcus adhesion antigen GAPDH and a preparation method thereof. The GAPDH is an rGAPDH, which has high conservative property and sequence homology, consists of 319 amino acid residues, and has a molecular weight of 32.4kDa. The rGAPDH is encoded by a gapdh gene; and a forward primer and a reverse primer of the gapdh gene respectively have one restriction enzyme cutting site at 5' and 3'. The preparation method of the GAPDH comprises the following steps of: PCR amplification, connection to a carrier, transformation and induction, and purification. The rGAPDH and an SEZ (Streptococcus zooepidemicus) rehabilitation pig serum show good immune responses; the rGAPDH can protect SEZ infected mice with limitation; and the mice immunized by the rGAPDH show high level of antibody titer in serum. An anti-GAPDH antibody can induce high level of bactericidal capability; a gapdh gene has a transcription level in SEZ infected mice much higher than that of culture in vitro; and the rGAPDH can significantly weaken cell adhesion ability of the SEZ, and greatly reduce cell infection ability of the SEZ.

Owner:SUN YAT SEN UNIV +1

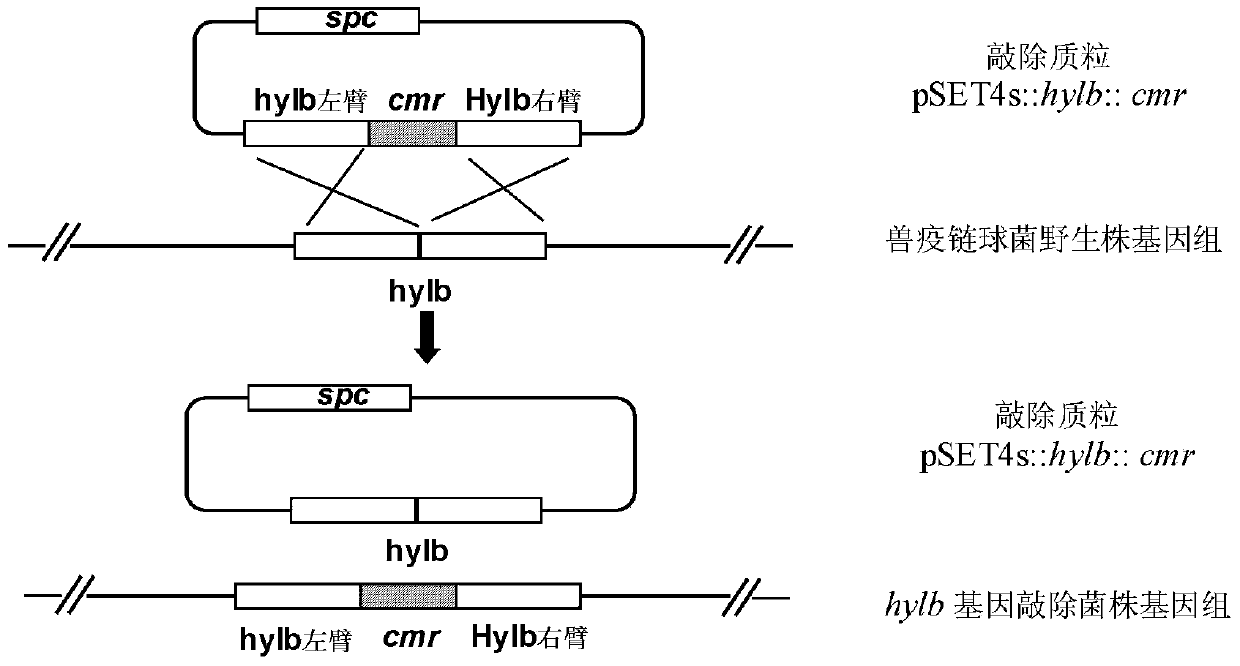

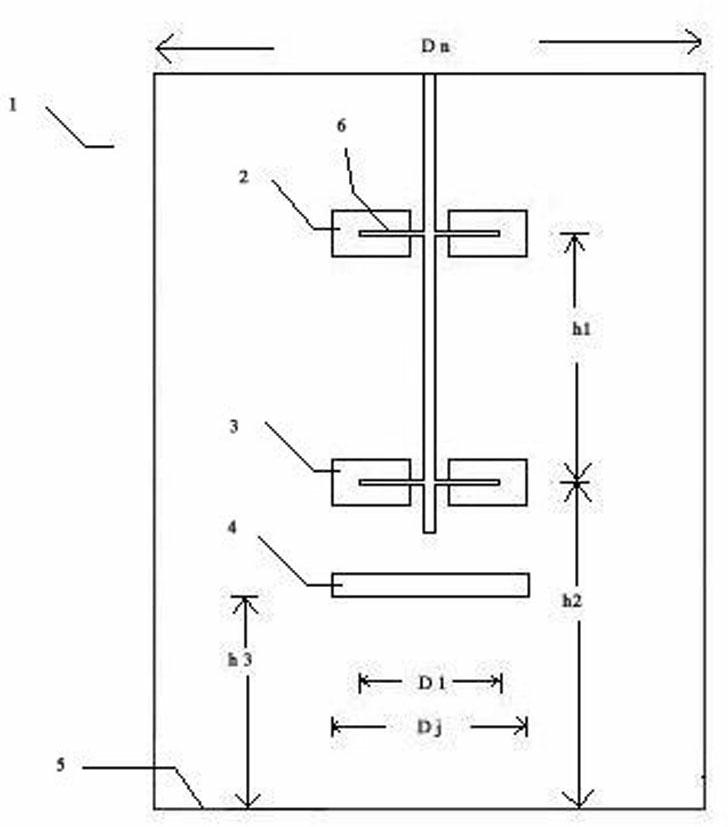

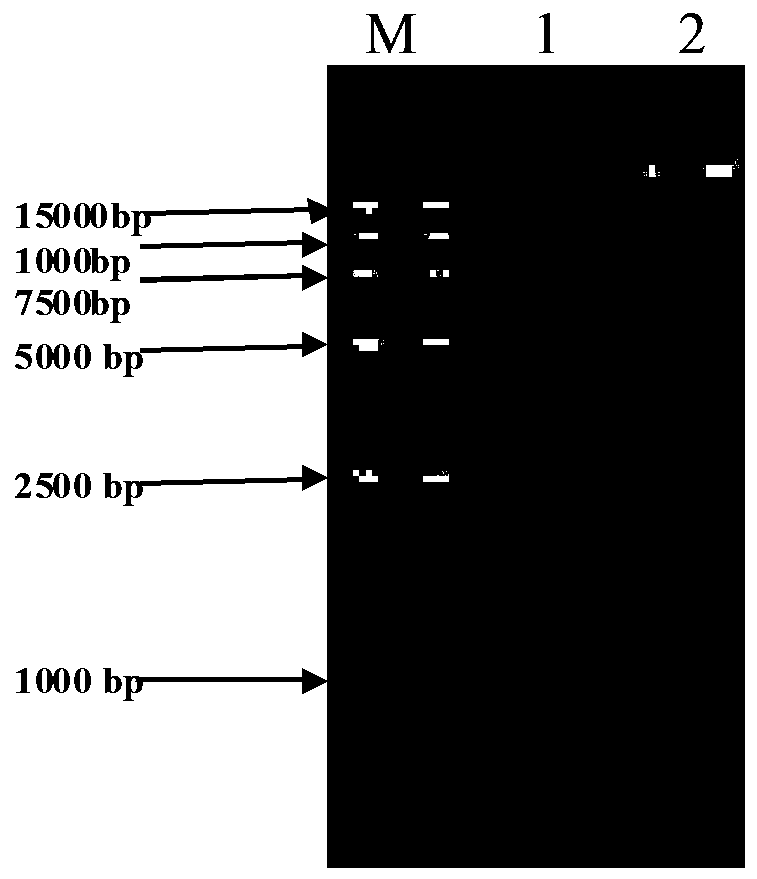

Preparation method for high-molecular-weight hyaluronic acid (HA), and engineering bacterium

ActiveCN103993031APrecise positioningDoes not affect functionBacteriaMicroorganism based processesStreptococcus zooepidemicusIntrinsic viscosity

The invention relates to a preparation method for high-molecular-weight HA and an engineering bacterium. According to the method, a coding hyaluronic acid lyase gene (hylb) in the genome of Streptococcus zooepidemicus ATCC39920 is knocked out, and a hyaluronic acid lyase gene (hylb)-knocked out vector pSET4s:: hylb:: cmr is constructed. The method provided by the invention subjects a recombinant bacterium in which the hylb gene is knocked out to fermentation and analysis, the molecular weight of HA is measured by using an intrinsic viscosity process, and HA with a molecular weight of 3.9 * 10<6> Da is obtained.

Owner:JIANGSU HEVI BIOTECH CO LTD

Method for preparing mask base materials

InactiveCN106214499AGood compatibilityEvenly distributedCosmetic preparationsToilet preparationsStreptococcus zooepidemicusRetention time

The invention provides a method for preparing mask base materials. The method includes steps of acquiring coconut water, adding xylan and pectin into the coconut water, carrying out pasteurization, then inoculating acetobacter xylinum into the coconut water, cultivating the acetobacter xylinum until fibrous membranes with the thicknesses of 0.1-0.5 cm are formed on the surface of fermentation liquor, adding cellulase into the fibrous membranes, treating the fibrous membranes, then carrying out ultrasonic treatment on the fibrous membranes in sodium hydroxide solution, washing the fibrous membranes by the aid of clear water until the fibrous membranes are neutral, slicing the fibrous membranes and then carrying out freeze drying on the fibrous membranes to obtain cellulose substrates; acquiring streptococcus zooepidemicus fermentation liquor containing hyaluronic acid, centrifugally removing precipitates, adding supernate into albumen powder, uniformly mixing the supernate and the albumen powder with each other to obtain mixtures, then adding the cellulose substrates into the mixtures, carrying out ultrasonic treatment, taking out the cellulose substrates after ultrasonic treatment is completely carried out, thorough flushing the mixtures by the aid of clear water, carrying out freeze drying on the mixtures and then packaging the mixtures under vacuum conditions to obtain the mask base materials. The method has the advantages that the mask base materials prepared by the aid of the method are excellent in human skin compatibility, free of skin irritation and suitable for various skin types; the mask base materials contain abundant hyaluronic acid, the hyaluronic acid is uniformly distributed, excellent slow-release effects can be realized, the mask base materials are long in skin retention time and are nutritional, and moisture can be preserved.

Owner:陈雄

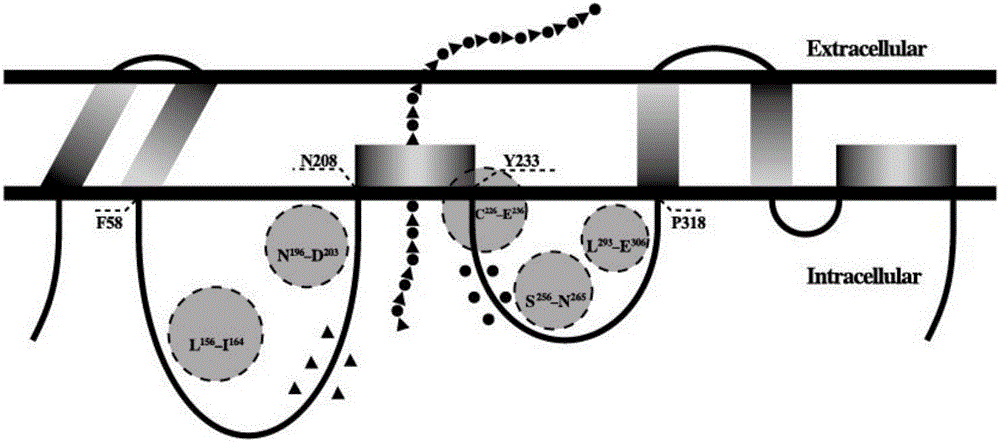

Hyaluronan synthase mutant and application thereof

ActiveCN105838688AIncrease productionIncrease valueBacteriaMicroorganism based processesBiotechnologyStreptococcus zooepidemicus

The invention discloses a hyaluronan synthase mutant and application thereof and belongs to the technical field of bioengineering. The mutant with positive effect in both yield and molecular weight is acquired by subjecting hyaluronan synthase of Streptococcus zooepidemicus origin to intracellular domain mutation in Bacillus subtilis; meanwhile, genes of UDP-GlcUA and UDP-GlcNAc synthetic routes in Bacillus subtilis are subjected to modular assembly expression analysis, and high yield of hyaluronan with wide molecular weight range from Bacillus subtilis is implemented by controlling different UDP-GlcA and UDP-GlcNAc concentrations and ratios. Certain basis is laid for the efficient preparation of hyaluronan from food-grade microorganisms, and this mutant is suitable for industrial production and application.

Owner:JIANGNAN UNIV

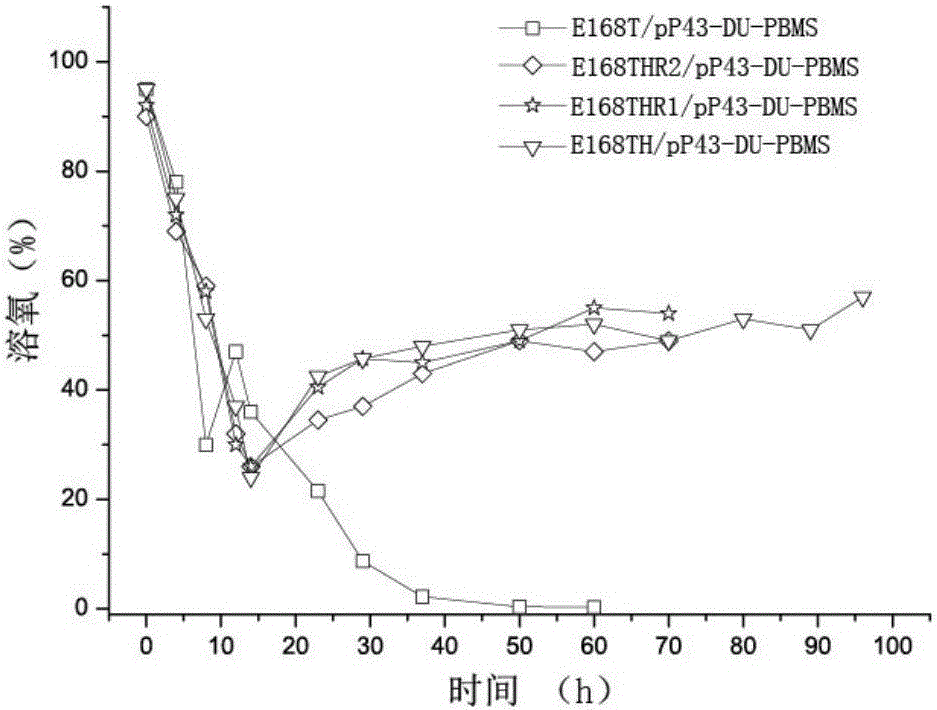

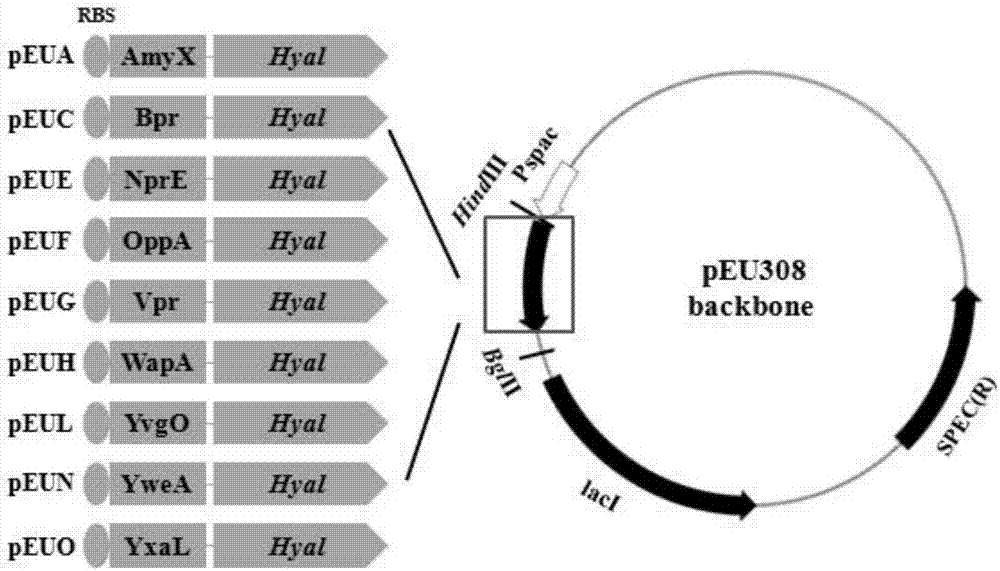

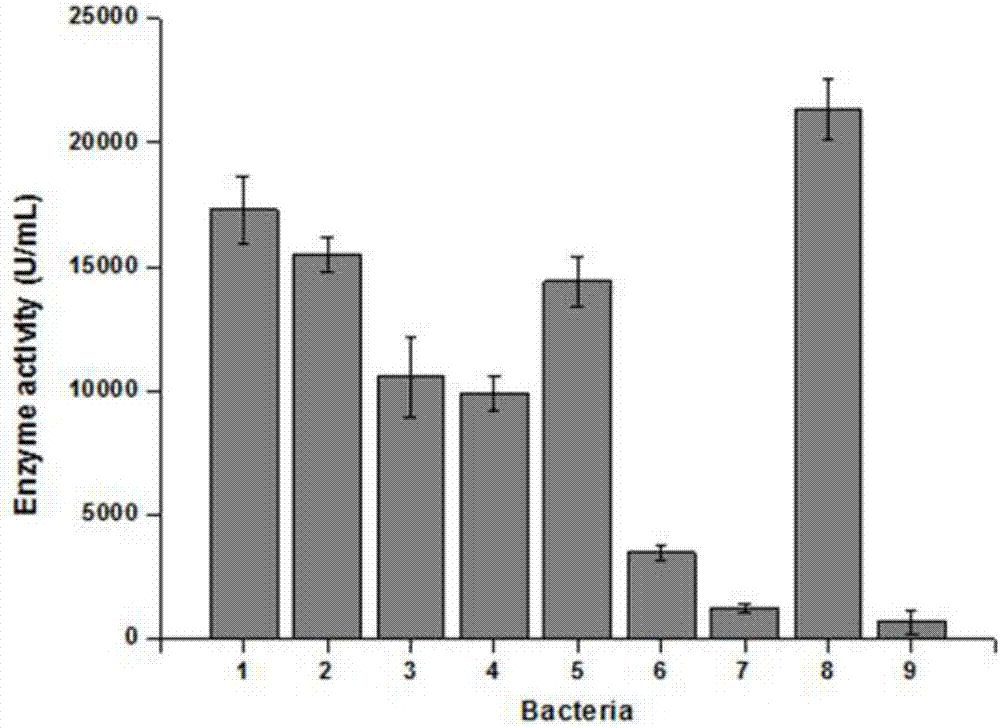

Recombinant Streptococcus zooepidemicus for fermentation of micromolecule hyaluronic acid

ActiveCN107227284AGood enzyme productionGreat application advantageBacteriaMicroorganism based processesSequence signalHeterologous

The invention discloses recombinant Streptococcus zooepidemicus for fermentation of micromolecule hyaluronic acid and belongs to the technical field of bioengineering. Hyaluronidase derived from leeches is heterologously expressed in Streptococcus zooepidemicus, nine kinds of signal peptides are selected and are fused with the terminal N of the hyaluronidase, and an appropriate signal peptide is selected through comparison of enzyme activity through a Pspac-induced promoter and Streptococcus RBS so that efficient secretion and expression of hyaluronidase in Streptococcus zooepidemicus is realized. Through degradation of macromolecule hyaluronic acid produced by the Streptococcus zooepidemicus, active micromolecule hyaluronic acid is obtained and a yield is improved. The recombinant Streptococcus zooepidemicus lays a foundation for the efficient fermentation preparation of micromolecule hyaluronic acid based on a microbial system and is suitable for industrial production and application.

Owner:JIANGNAN UNIV

Method for breeding fermentation high stability hyaluronic acid sodium bacterial

InactiveCN101451114AImprove stabilityEasy to useBacteriaMicroorganism based processesStreptococcus zooepidemicusAfter treatment

The invention discloses a method for culturing a high-stability sodium hyaluronate strain, which comprises the step of adoption of streptococcus zooepidemicus with a number of ATCC39920. The method is characterized in that the streptococcus zooepidemicus with the number of ATCC39920 is subjected to strain culture and fermentation culture; after repeating the steps and performing repeated tests for 200 times, a strain for fermentation is obtained; fermentation culture of sodium hyaluronate is performed in a fermentation medium; and the fermentation medium is subjected to slight sterilization for 20 minutes at the temperature of 121 DEG C, cooled and cultured at a temperature of between 36 and 37 DEG C and at a pH value of between 6.8 and 7.1, enters the after-treatment step after culturing the sodium hyaluronate for 30 hours without limiting the air flow, and the high-stability sodium hyaluronate is obtained. Under the same conditions, the prior strain which is not subjected to optimization treatment is used for fermentation and production of the sodium hyaluronate; and the stability of the sodium hyaluronate finished product is obviously higher than that of an external sodium hyaluronate sample by comparing and examining the stability of the two types of sodium hyaluronate.

Owner:TONGXIANG HENGJI BIOTECH

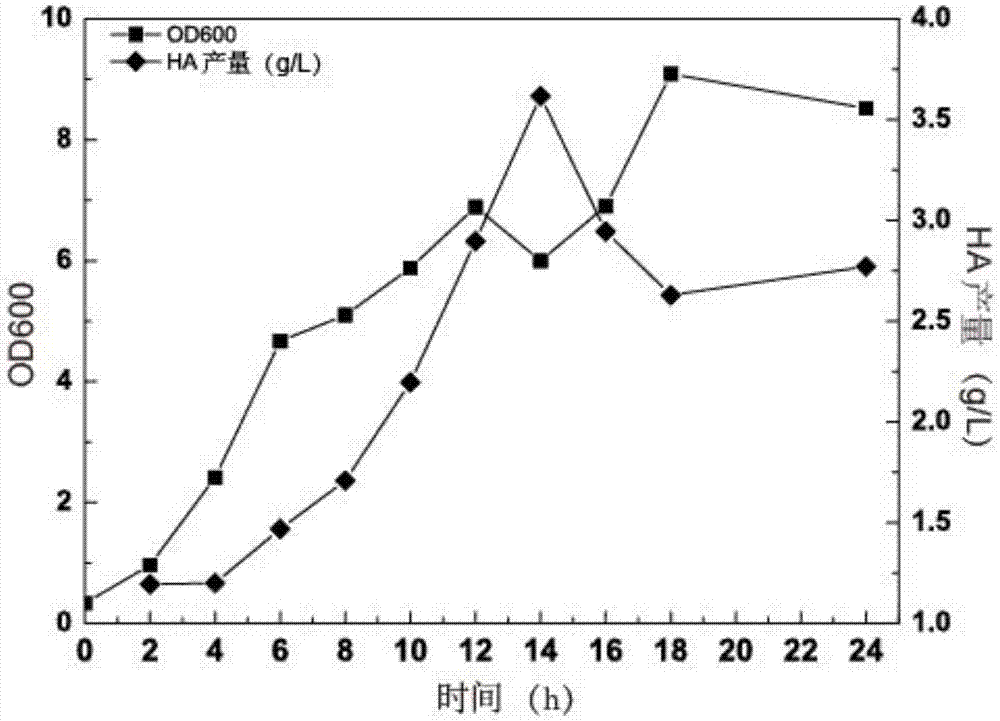

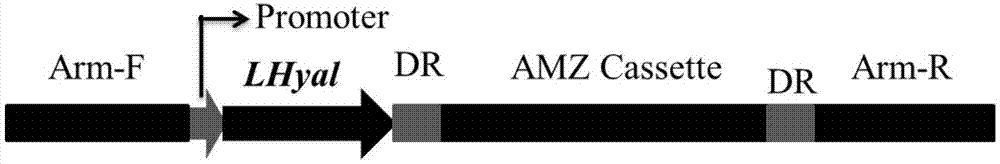

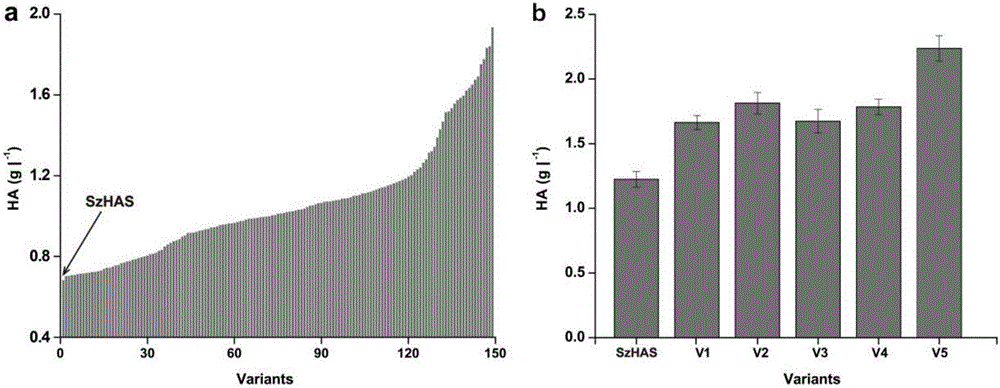

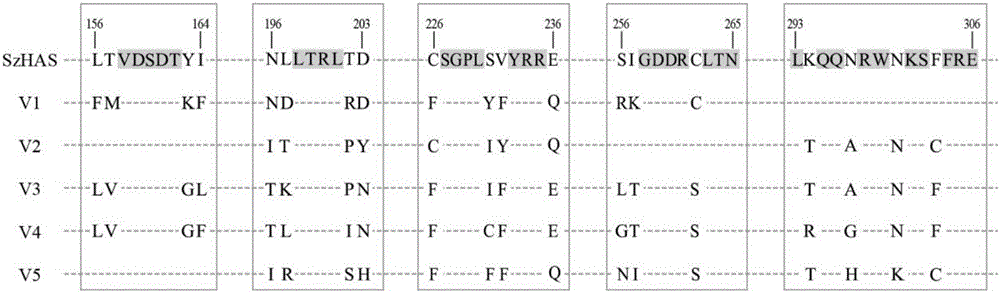

Method of constructing a recombinant Bacillus subtilis that can produce specific-molecular-weight hyaluronic acids

ActiveUS20170073719A1High strengthReduce molecular weightTransferasesOxidoreductasesBiotechnologyStreptococcus zooepidemicus

The present invention relates to the field of biotechnology engineering. It provides a method of constructing a recombinant Bacillus subtilis that can produce specific-molecular-weight hyaluronic acids. By integranted expression of hasA from Streptococcus zooepidemicus and overexpression of genes of HA synthetic pathway, tuaD, glmU and glmS, high yield HA production was achieved in the recombinant strain. Additionally, introduction and functional expression of the leech hyaluronidase in the recombinant strain substantially increased the yield of HA to 19.38 g·L−1. Moreover, HAs with a broad range of molecular weights (103 Da to 106 MDa) were efficiently produced by controlling the expression level of hyaluronidase using RBS mutants with different translational strengths. The method of the present invention can be used to produce low molecular weight HAs at large scale in industrial applications.

Owner:JIANGNAN UNIV

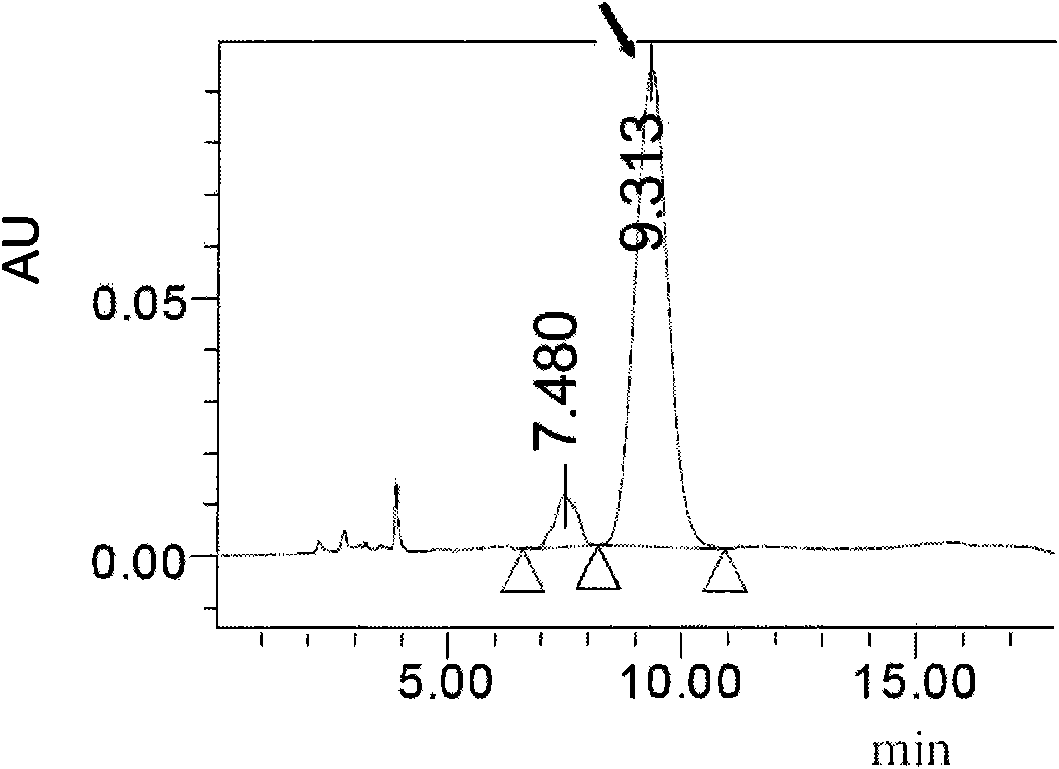

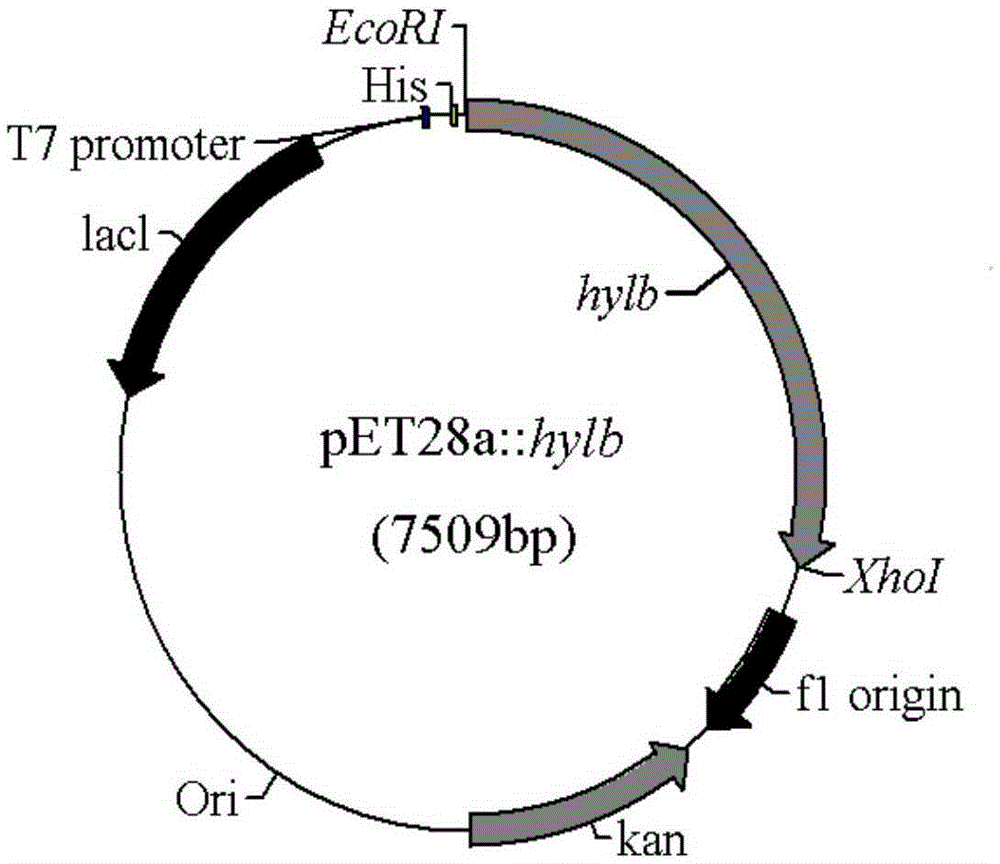

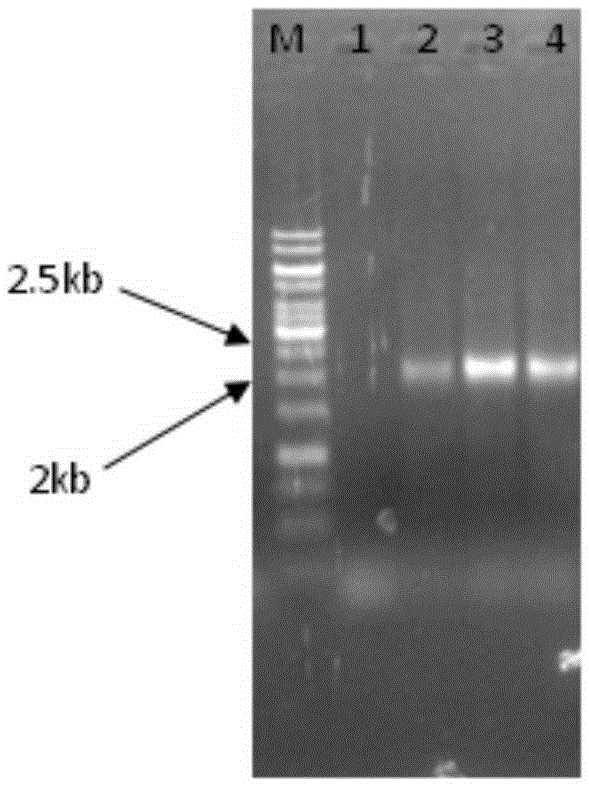

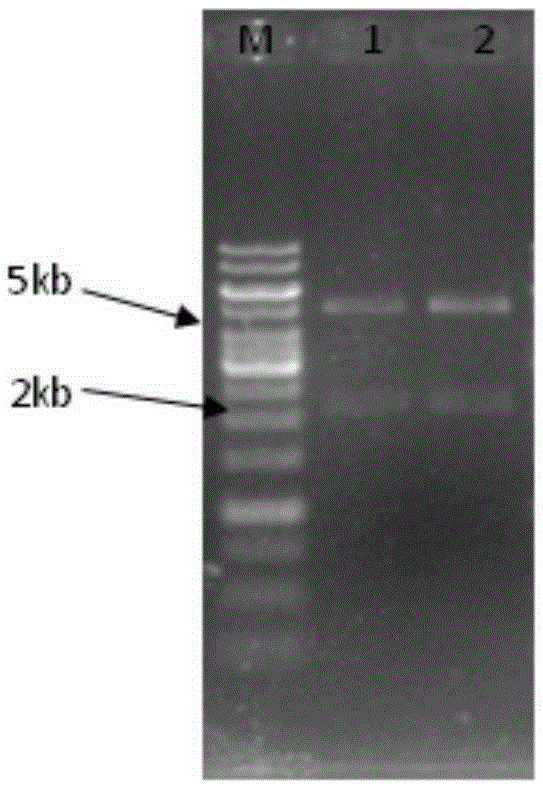

Preparation method and application of small molecular weight hyaluronic acid, and hyaluronate lyase genetic vector and engineering bacteria

InactiveCN105274127AIncrease enzyme activityMolecular weight controllableBacteriaMicroorganism based processesEscherichia coliStreptococcus zooepidemicus

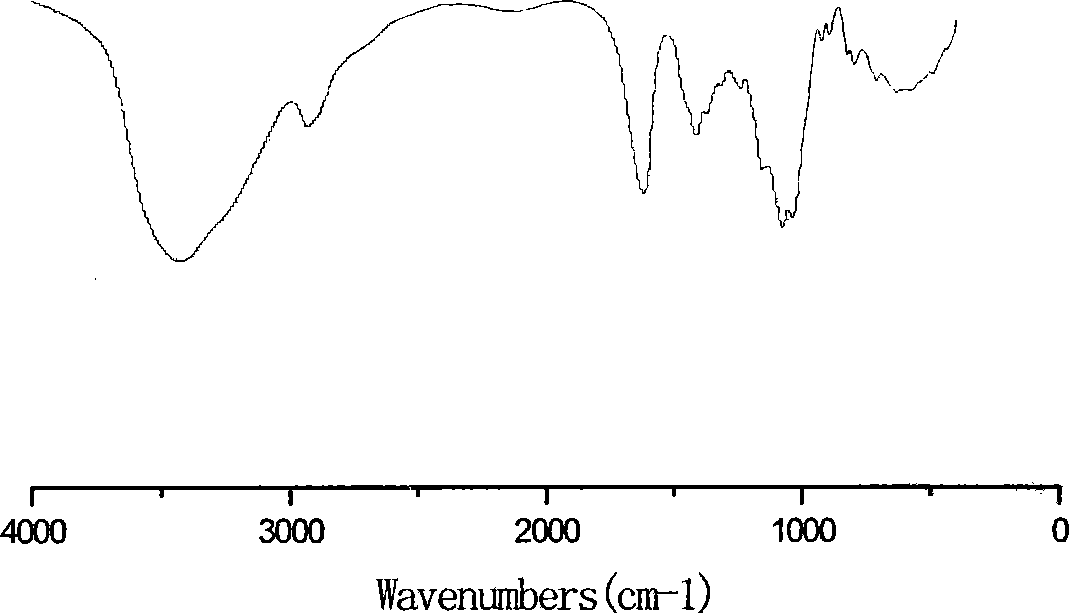

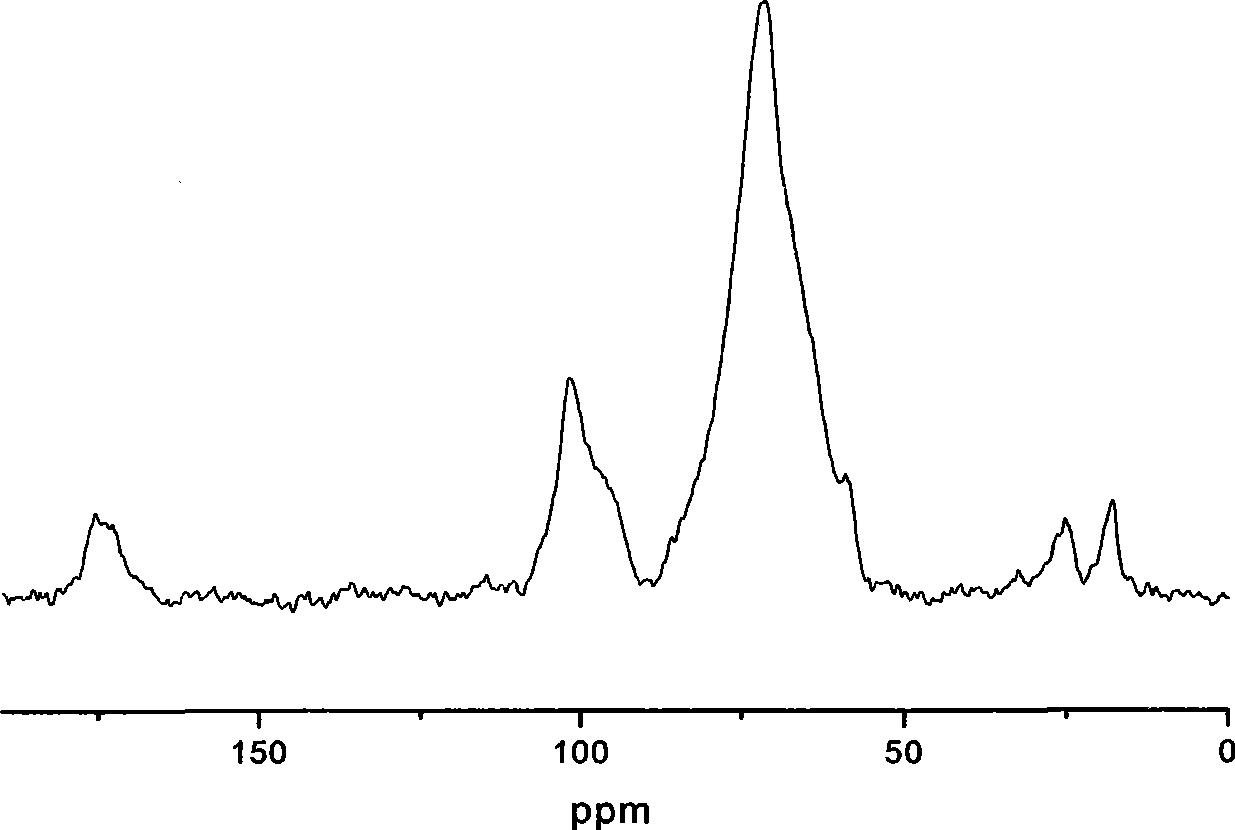

The invention provides a preparation method and application of small molecular weight hyaluronic acid, and a hyaluronate lyase genetic vector and engineering bacteria. An expression vector successfully constructed is converted to Escherichia coli BL21 (DE3) by: cloning part of fragments encoding hyaluronate lyase gene (hylb) in genome of Streptococcus zooepidemicus ATCC 39920 and constructing the expression carrier pET 28a:hylb, and high-activity soluble hyaluronate lyase is obtained by the induced expression of Escherichia coli. Specific enzyme activity of purified liquid of the lyase is 4655 U / mg (equivalently 4.655*107 IU / mg) that is measured by N-acetyl-glucosamine (NAG) measurement. The small molecular weight hyaluronic acid is prepared by controlling the enzyme content and reaction conditions to degrade large molecular weight hyaluronic acid, the molecular weight of the hyaluronic acid is measured by means of an intrinsic viscosity method and agarose gel electrophoresis, and the obtained molecular weight is that of small molecular weight hyaluronic acid of 6000Da level, an infrared spectrogram of which is consistent with standard atlas in national pharmacopoeia.

Owner:TIANJIN UNIVERSITY OF SCIENCE AND TECHNOLOGY

Culture medium for producing sodium hyaluronate and preparation method of culture medium

InactiveCN109161571AImprove stabilitySimplify complexityBacteriaMicroorganism based processesStreptococcus zooepidemicusArginine

The invention provides a culture medium for producing sodium hyaluronate and a preparation method of the culture medium. Each 100kg of culture medium comprises the following components: 28 to 35kg ofwhite granulated sugar, 8 to 12 kg of yeast extract powder, 0.8 to 1.1kg of MgSO4.7H2O, 1.2 to 1.4kg of NaH2PO4.2H2O, 0.5 to 1.0kg of K2SO4, 15 to 25kg of L-arginine and 15 to 30mL of a defoamer, andthe components are supplemented to be a total mass of 100kg with water. The culture medium provided by the invention simplifies the complexity of a formula, reduces impurities brought in, ensures thatthe yield of sodium hyaluronate can reach 7.5 to 8.5g / L when streptococcus zooepidemicus H23 is used for fermentation, and compared with the culture medium disclosed in the existing method, the culture medium provided by the invention is higher in fermentation yield in same conditions, facilitates industrial production, and improves the production efficiency.

Owner:SHANGHAI JINGFENG PHARMA

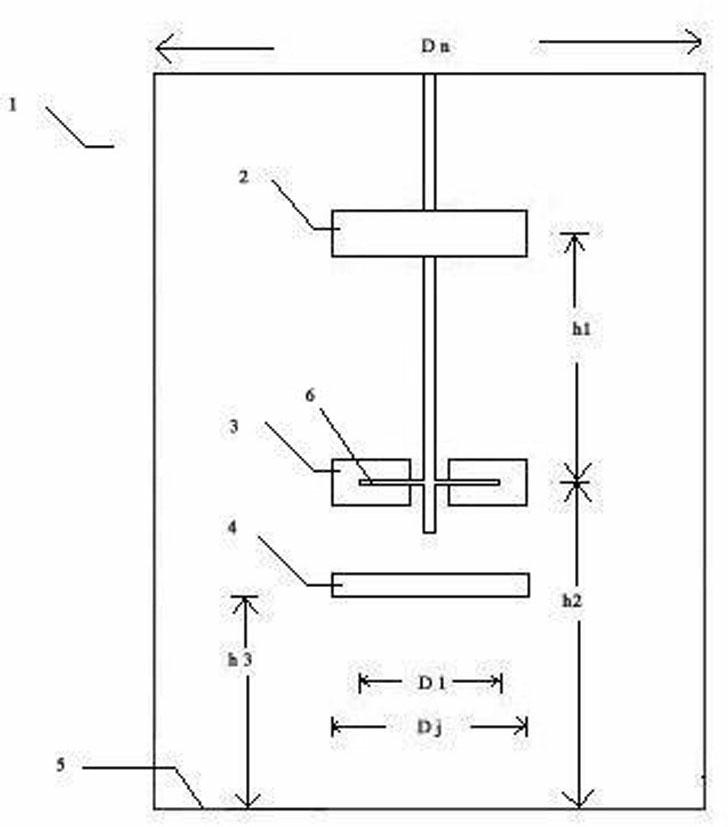

A microbial fermentation process amplification platform technology

InactiveCN102286369ASimple and fast operationHigh degree of automationBioreactor/fermenter combinationsBiological substance pretreatmentsBiotechnologyStreptococcus zooepidemicus

The invention provides a microorganism fermentation process scaling-up platform technique. In the process of fermentation, symbolic metabolites are chosen to reflect the growing state of microorganisms and the condition of fermentation medium, and by controlling the change of the symbolic metabolites, and combined with hydromechanics to calculate, design and improve the size and structure of a stirring reactor, the gas holdup is increased and the concentration of the symbolic metabolites is decreased; and fermentation conditions are optimized and the fermentation process is scaled up. The technique is applied in the production of glutathione and S-adenosine-L-methionine and the coproduction of glutathione and ergosterol by brewing yeast fermentation and the production of hyaluronic acid by streptococcus zooepidemicus fermentation. The symbolic metabolites are ethanol, glycerin, lactic acid and acetic acid. The technique ensures that the concentration of ethanol in the high-density aerobic fermentation of yeast is less than 0.5 percent and that the concentration of lactic acid as the symbolic metabolite in the production of hyaluronic acid by bacterial fermentation is less than 3 percent. The technique is easy to operate, and the automation degree is high; and the application range is wide, and the technique can be used in the yeast system as well as the bacteria system.

Owner:BEIJING UNIV OF CHEM TECH

Streptococcus equi strain XJMSY16-1 and application thereof in streptococcus equi vaccine

ActiveCN108220182AReduce manufacturing costEquine Streptococcus PreventionAntibacterial agentsBacterial antigen ingredientsDiseaseStreptococcus zooepidemicus

The invention relates to Streptococcus equi (also named as Streptococcus equi subsp.zooepidemicus) XJMSY16-1 with the preservation number of CGMCC No.12428. The strain has 16S rRNA gene sequences in asequence table 1. The stain is separated from sick horses suffering from Streptococcus equi and is a positive Gram bacterium, cells of the strain take the shapes of spheres and are arranged in pairs,or take the shapes of bent long chains, and are low in growth property in common meat soup and panels; beta-type hemolysis is caused on a panel with 5% fresh sheep blood, completely transparent hemolysis zones are formed around small dewdrop shaped bacterial colonies, and the width of the hemolysis zones can be up to 2.5-3.2 mm. The strain grows in a facultative anaerobic manner, the growth temperature is 26-40 DEG C, the most appropriate temperature is 37 DEG C, and the most appropriate growth pH value is 7.4-7.5. Glucose can be fermented to generate acids, and lactose, mannitol and sorbitolcannot be fermented with the strain. The strain can be used for preparing streptococcus equi deactivation vaccines. The vaccines prepared from the strain are high in disease specificity, low in cost,high in security and good in protection effect.

Owner:XINJIANG AGRI UNIV

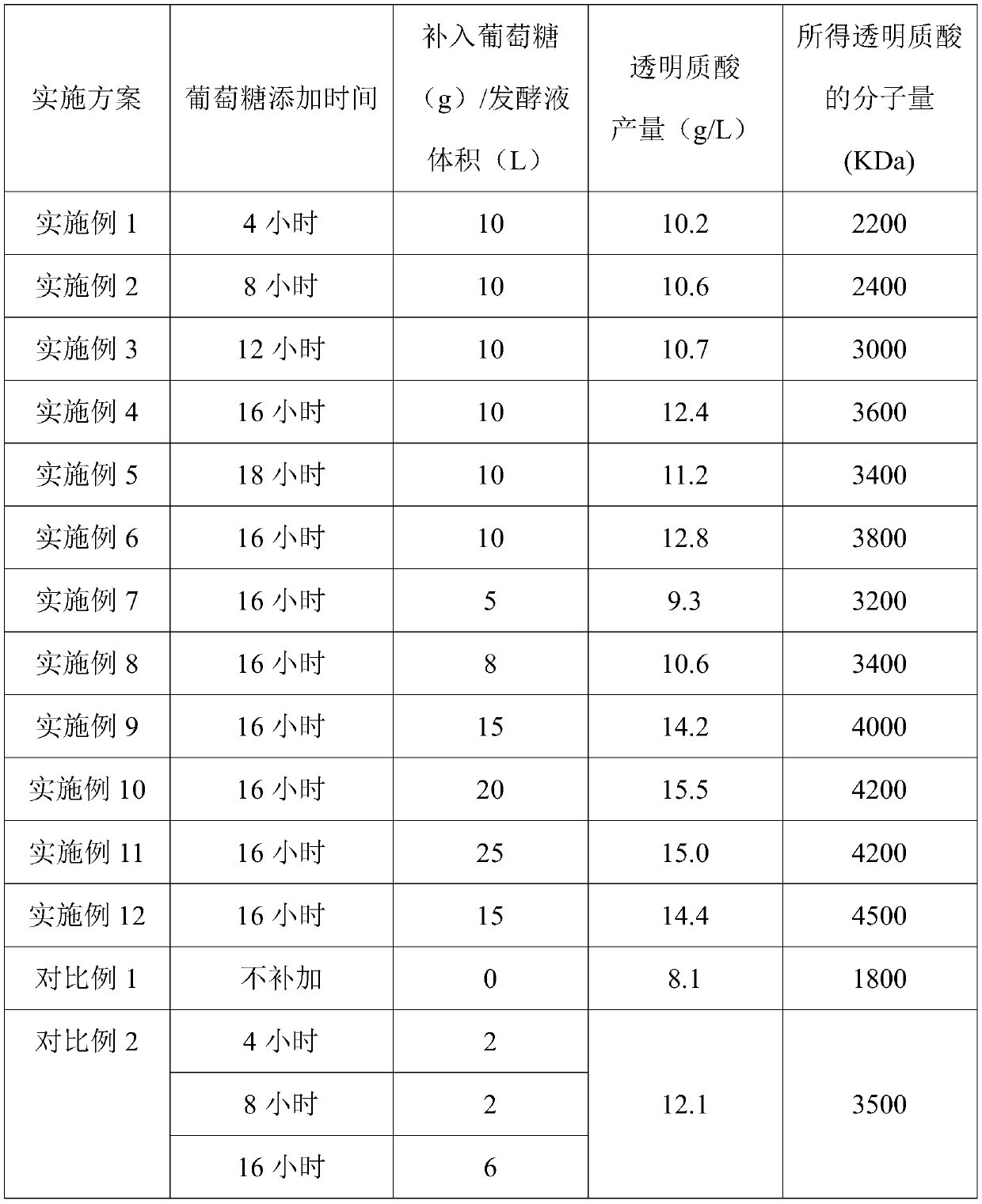

Method for producing hyaluronic acid by fermentation and application of method

PendingCN111172222ASolve outputShorten the fermentation cycleBacteriaMicroorganism based processesBiotechnologyStreptococcus zooepidemicus

The invention provides a method for producing hyaluronic acid by fermentation and an application of the method. The method comprises the following steps: performing activation and propagation on streptococcus zooepidemicus, then performing fermentation, supplementing a carbon source for once in the fermentation process to obtain a hyaluronic acid fermentation broth, and performing purifying to obtain hyaluronic acid. According to the fermentation method provided by the invention, the carbon source is added for once in the fermentation process, so that the glucose concentration in the fermentation broth can be maintained, the fermentation period is shortened, the contamination risk caused by adding the carbon source for a plurality of times is avoided, and normal growth and metabolism of thalli are facilitated. The invention solves the problem of unbalance between metabolism of streptococcus zooepidemicus and expression of products is solved, and the obtained hyaluronic acid has a highyield and a large molecular weight.

Owner:JIANGSU CHENGXIN PHARMA

Method for improving fermentation yield of hyaluronic acid

ActiveCN103397062AImprove fermentation yieldLow costMicroorganism based processesFermentationStreptococcus zooepidemicusCopper

The invention belongs to the technical field of hyaluronic acid preparation and particularly relates to a method for improving the fermentation yield of hyaluronic acid. Streptococcus zooepidemicus is taken as a hyaluronic acid fermentation strain; a reagent containing ferrous ions and copper ions is added to a culture medium used. The method provided by the invention is capable of improving the fermentation yield of hyaluronic acid by 30-34%, from 1.05 g / L to the range from 1.37 g / L to 1.41 g / L, and reducing the cost by 30%; meanwhile, the method provided by the invention has no influence on the molecular weight and quality of a product.

Owner:ANYANG JIUZHOU PHARMA

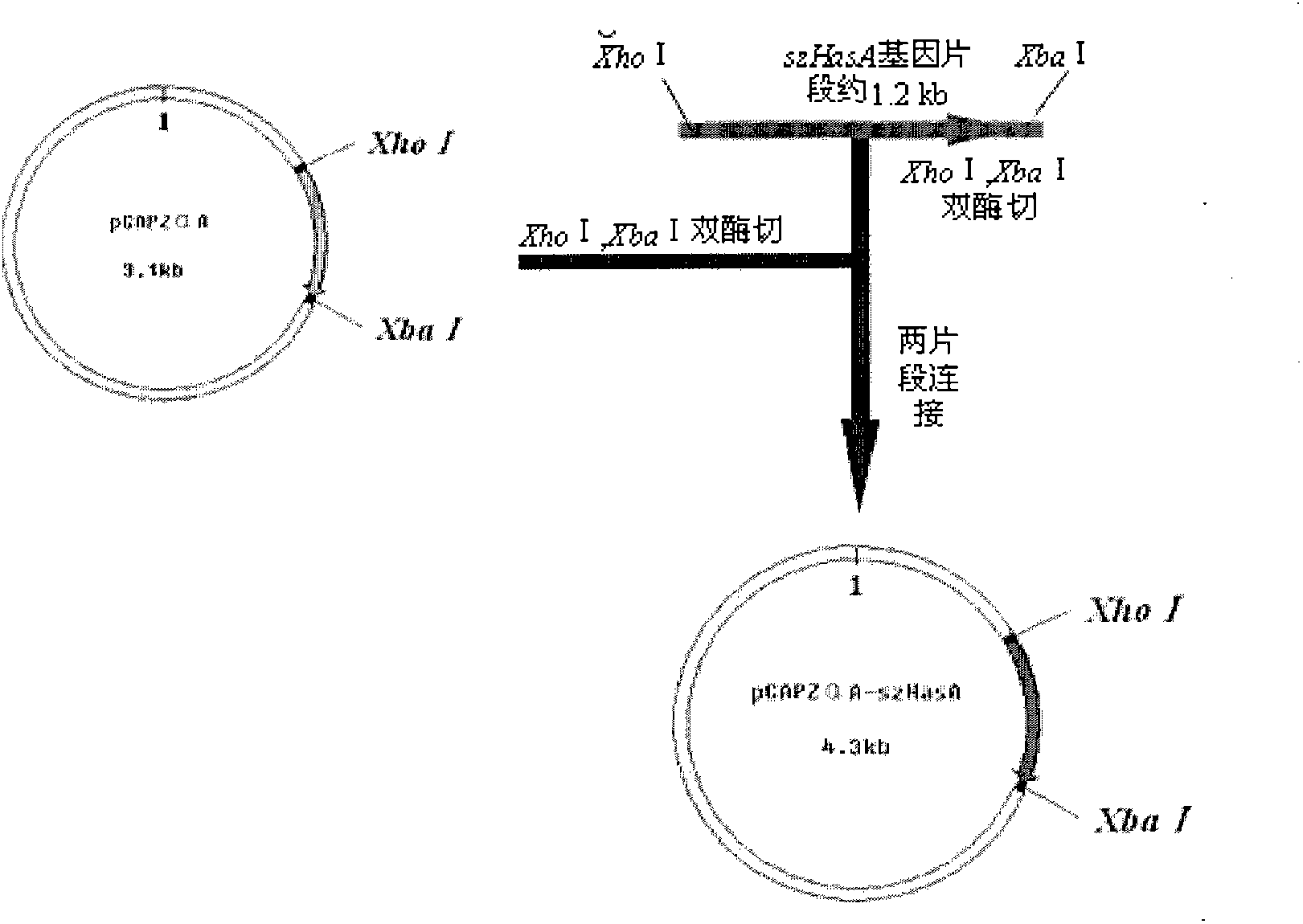

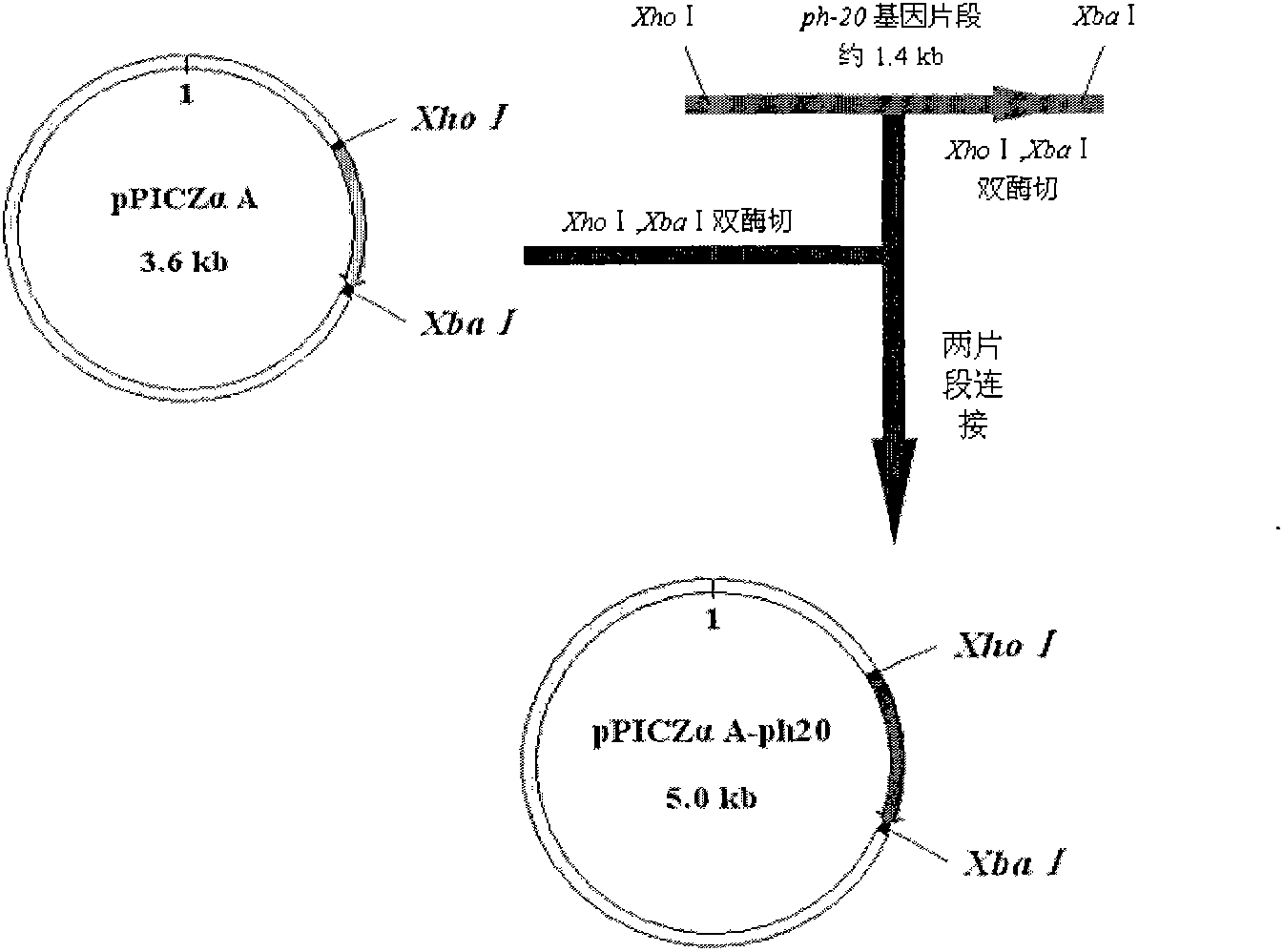

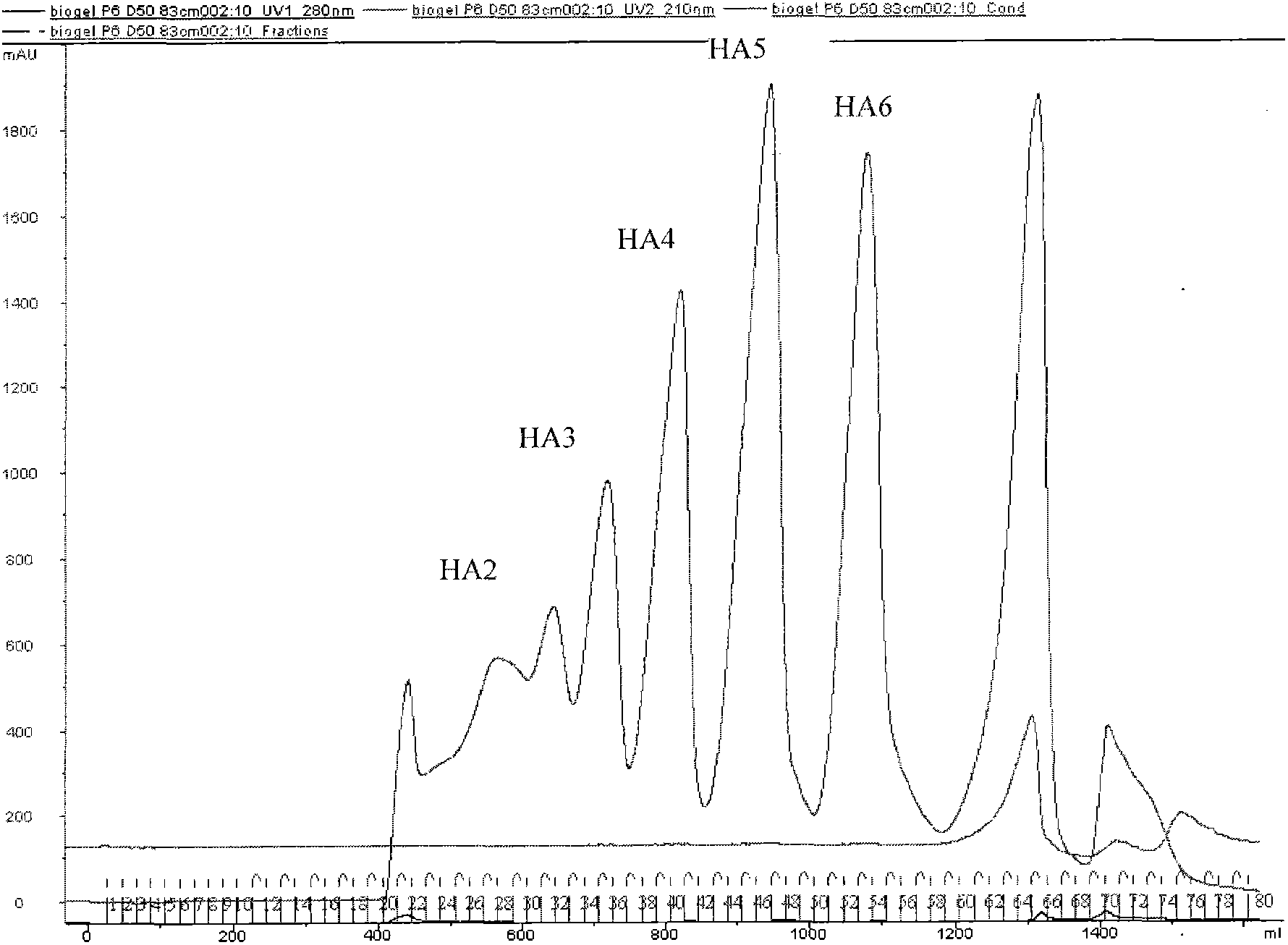

Method for producing hyaluronic acids with different molecular weights through pichia pastoris gene-regulation fermentation

InactiveCN102911887AAchieve couplingSolve the problem of difficult molecular weight fractionationFungiMicroorganism based processesBiotechnologyPichia pastoris

The invention relates to a novel method for producing hyaluronic acids (HA) with different molecular weights through pichia pastoris gene-regulation fermentation. The method comprises the steps that: recombinant plasmid pGAPZalphaA-szHasA constitutively expressing streptococcus zooepidemicus hyaluronic acid synthase and recombinant plasmid pPICZalphaA-ph20 inducibly expressing recombinant human hyaluronidase are used for converting yeast cells, such that a target strain HAS-PH20 is obtained. Through different gene regulation and induction methods, the yeast engineering strain HAS-PH20 directly produces various hyaluronic acids with different molecular weights through fermentation processes. With the method, the coupling of hyaluronic acid molecular weights and gene regulation methods is realized, and hyaluronic acids with specific molecular weights can be prepared according to requirements.

Owner:INST OF BIOPHARM OF SHANDONG PROVINCE

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com