Method for improving fermentation yield of low-molecular hyaluronic acid (HA) by adding hyaluronidase

A technology of hyaluronidase and hyaluronic acid, applied in the field of bioengineering, can solve the problems of high price and unsuitable for small molecule HA, and achieve the effect of reducing viscosity and easy purification and recovery

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

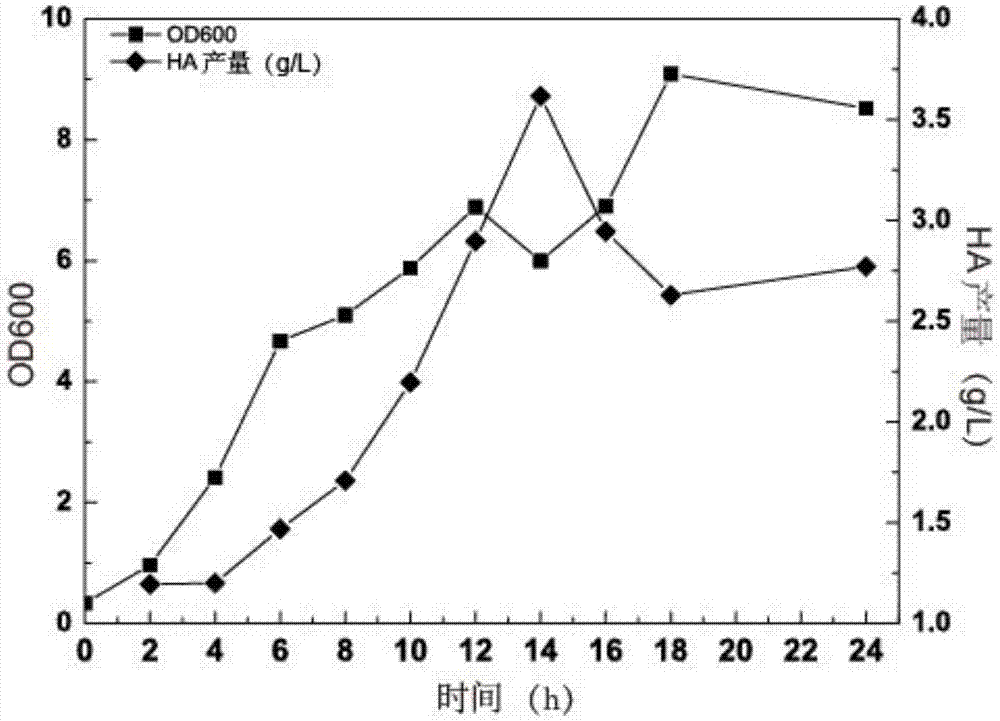

[0022] Embodiment 1 Streptococcus zooepidemicus batch fermentation (control group)

[0023] The bacterial strain used in the present invention is Streptococcus zooepidemicus WSH-24 (screened by this laboratory), the bacterial strain is first streaked on the M17 medium plate, then transferred to 50ml seed medium, cultivated at 37°C for 16h, and press 10% The inoculum was transferred to a 3L fermenter (1.5L liquid volume) and cultured for 16 hours. Fermentation conditions: rotation speed 200rpm, ventilation rate 1.0vvm, temperature 37°C, pH 7.0. Seed medium (g / L): sucrose 20, yeast powder 20, magnesium sulfate heptahydrate 2.0, manganese sulfate tetrahydrate 0.1, potassium dihydrogen phosphate 2.0, calcium carbonate 20, trace elements 1ml / L, buffer 40ml / L, pH7.0. Trace elements (g / L): calcium chloride 2.0, zinc chloride 0.046, copper sulfate pentahydrate 0.019. Buffer (g / L): disodium hydrogen phosphate 36.76, sodium dihydrogen phosphate 15.98, sodium bicarbonate 12.5. Fermen...

Embodiment 2

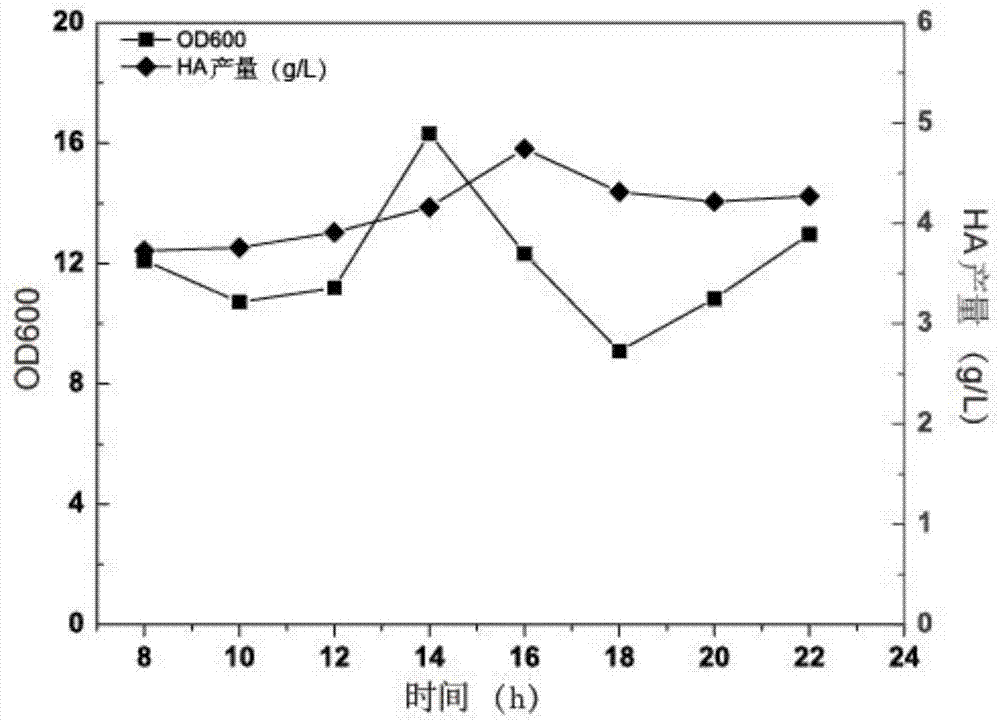

[0025] Example 2 Add hyaluronidase for batch fermentation in the 8th hour during the fermentation of Streptococcus zooepidemicus

[0026] All operating conditions are the same as embodiment 1, add hyaluronidase liquid 7.5ml (10 6 U / ml), the content of hyaluronidase in the fermenter is 5×10 3 U / ml. The highest output of HA reaches 4.78g / L in 14h, the result is attached figure 2 shown. After the fermentation broth is collected, boil it in boiling water for 2 minutes to inactivate the hyaluronidase.

Embodiment 3

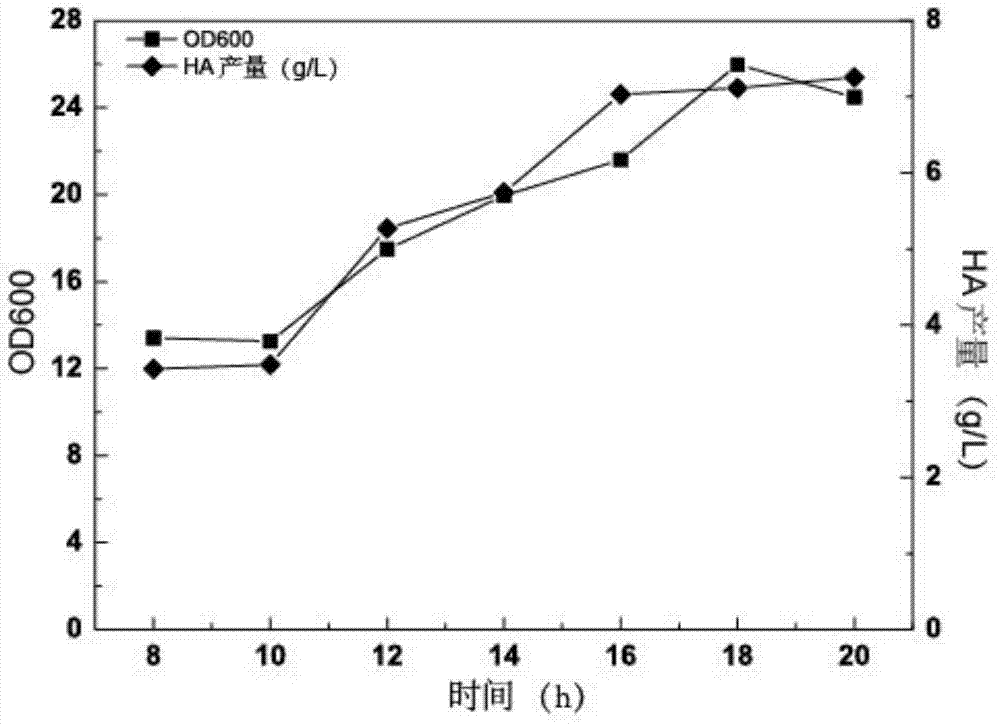

[0027] Example 3 Add hyaluronidase for fed-batch fermentation at the 8th hour during the fermentation of Streptococcus zooepidemicus

[0028] All operating conditions are the same as embodiment 1, add hyaluronidase liquid 7.5ml (10 6 U / ml), the content of hyaluronidase in the fermenter is 5×10 3 U / ml. At the same time, sucrose feeding was carried out at the 8th hour, and 50% sucrose was fed according to the following procedure:

[0029]

[0030]

[0031] After adding enzymes and supplementing sucrose in this fermentation process, the results are as attached image 3 As shown, the OD600 value of the thalline continued to increase, and the HA output reached 7.25g / L at 20h.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Average molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com