Method for removing phosphorus and nickel in electroless nickel-plating wastewater and treatment system

An electroless nickel plating and waste water technology, which is applied in chemical instruments and methods, metallurgical waste water treatment, special compound water treatment, etc., can solve the problems of continuously and effectively meeting discharge standards, and achieve the effect of recycling and recycling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

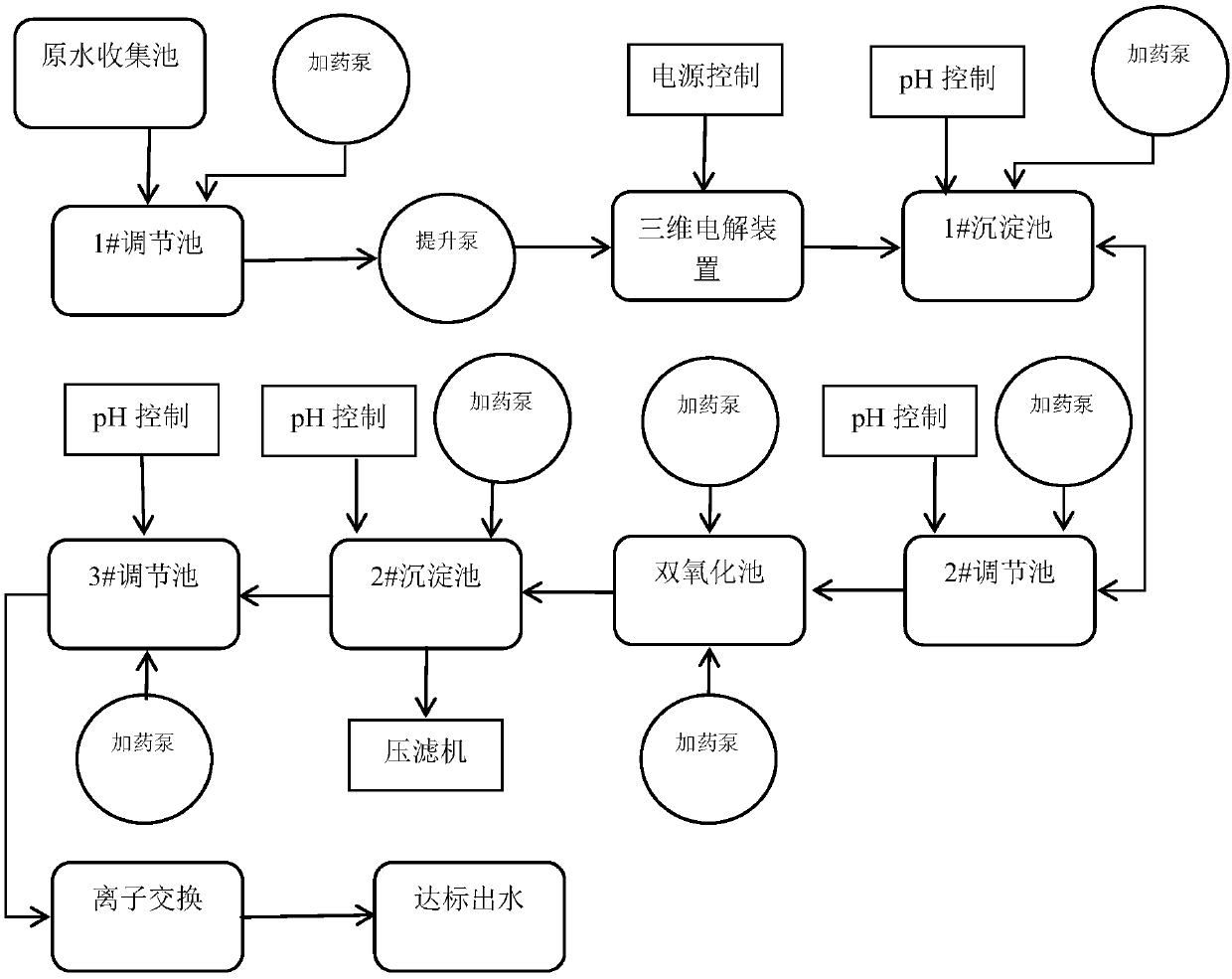

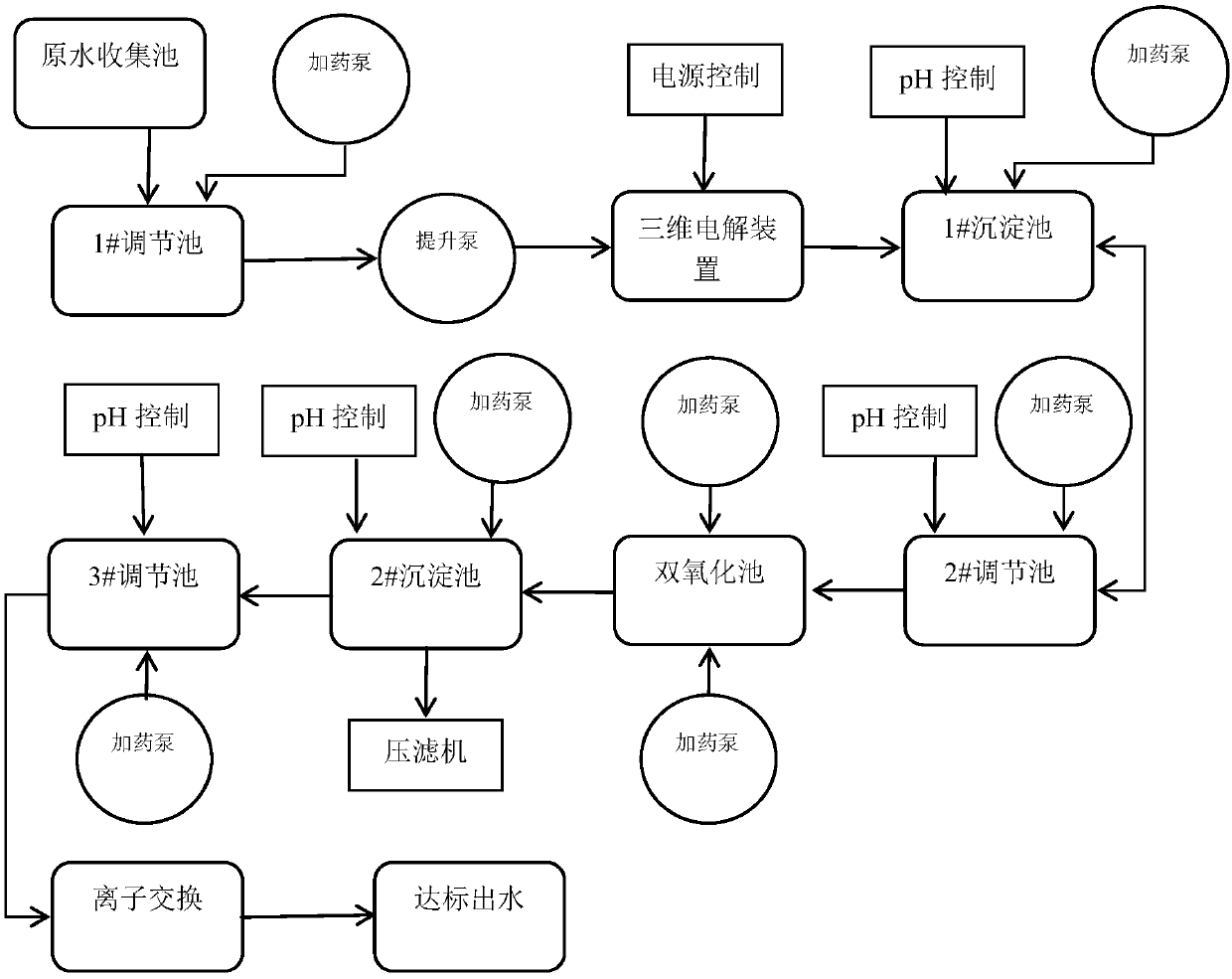

[0039] The method for removing phosphorus and nickel in the electroless nickel-plating wastewater of the present invention adopts the following steps to treat the total phosphorus concentration at 150mg / L-3000mg / L and the nickel concentration at 45mg / L-700mg / L nickel-plating wastewater until the total phosphorus concentration is Standard effluent with less than 0.5ppm and nickel concentration less than 0.1ppm:

[0040] Such as figure 1 As shown, in step 1, the nickel-plating wastewater is discharged into the 1# regulating tank and its pH value is adjusted to between 5-6. When it is in the weak acid state, it is difficult for the wastewater to produce cathodic hydrogen evolution during three-dimensional electrolysis. Phenomenon. Namely: when the pH value of the wastewater is too low, during three-dimensional electrolytic treatment, the cathodic hydrogen evolution reaction is serious, and the iron-carbon filler is consumed too quickly, which is not conducive to improving the ox...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com