Crude indium and active zinc oxide co-production process

A technology of activated zinc oxide and sub-zinc oxide, which is applied in the field of new technology for the production of crude indium and activated zinc oxide, can solve the problems of loss of valuable metals, high cost, and high production cost, and achieve low environmental pollution, low cost, and high requirements. low effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

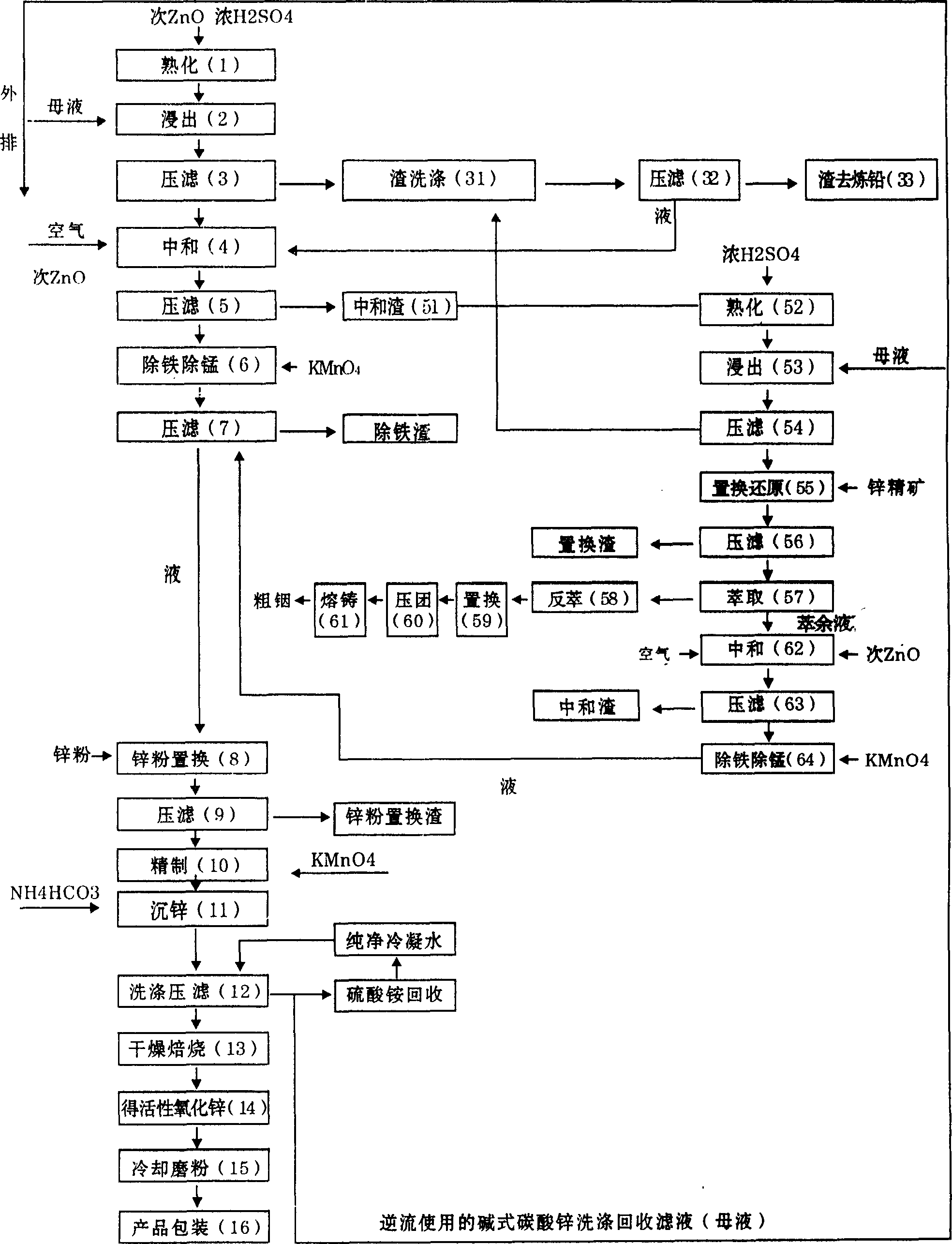

[0027] With reference to accompanying drawing, this technology comprises:

[0028] ①: Raw materials containing indium secondary zinc oxide are mixed with water in the aging tank, and concentrated sulfuric acid is used for high-temperature and high-acid aging as required (1), and the filtrate (mother liquor) recovered by washing with basic zinc carbonate is added for leaching (2), and press filtration After (3), its slag goes to lead smelting after washing (31) and pressure filtration (32) with mother liquor;

[0029] ②: The leaching solution (2) after pressure filtration (3) and the slag washing liquid (31) after pressure filtration (32) enter the neutralization tank and neutralize with secondary zinc oxide (4), and heat, blow air to oxidize, and hydrolyze to remove Miscellaneous, obtain neutralization slag (51) and neutralization liquid after pressure filtration (5);

[0030] ③: above-mentioned neutralization slag (51) adds concentrated sulfuric acid through maturing again (...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com