Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

37results about How to "Raw material requirements are low" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

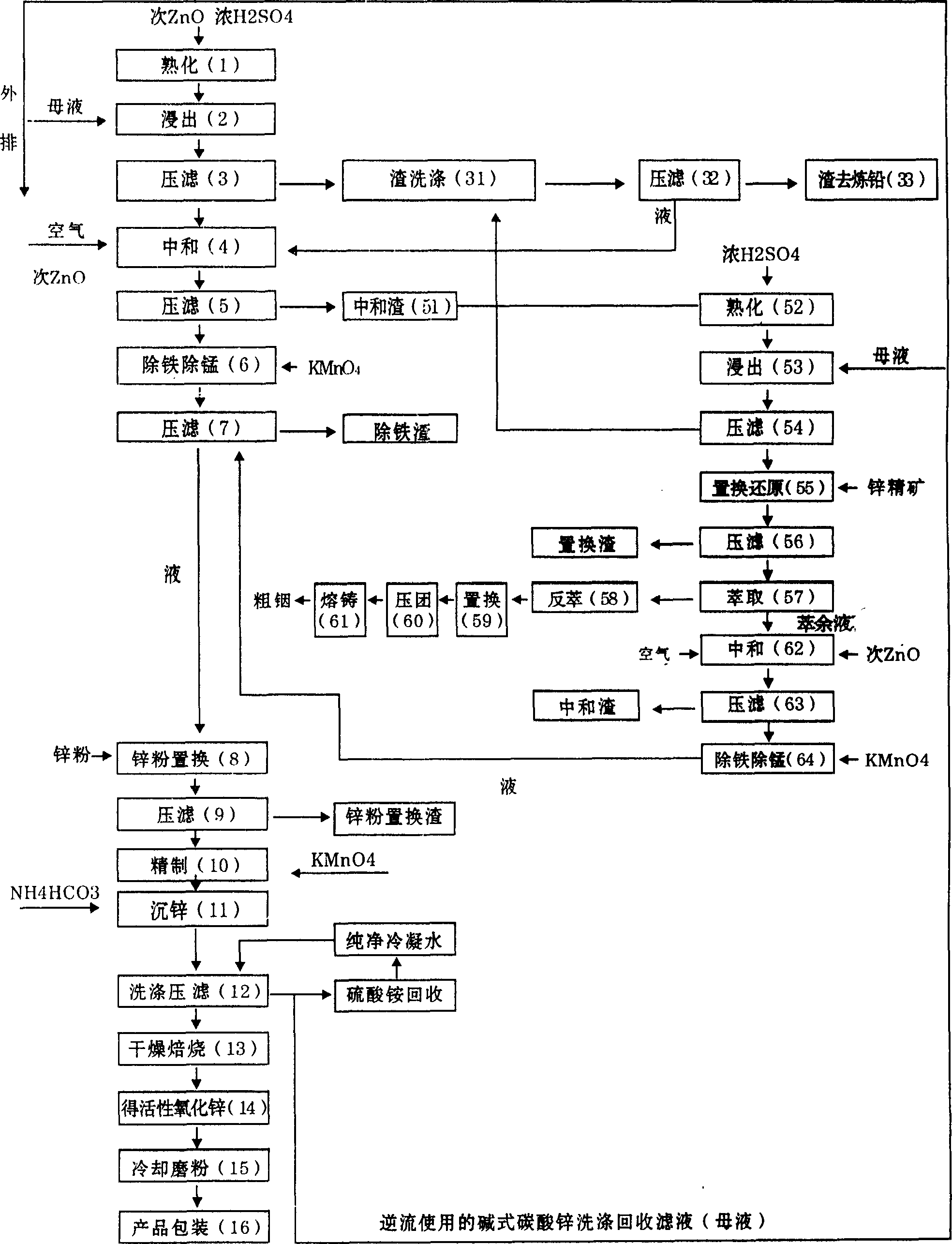

Crude indium and active zinc oxide co-production process

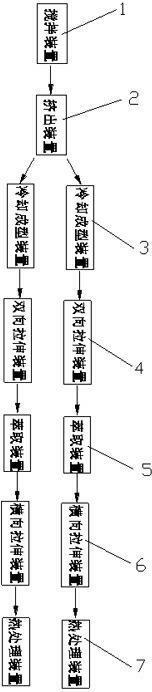

The coproduction technique for coarse indium and active ZnO comprises: (1) curing In-contained hypo-ZnO or material contained both Zn and In; (2) leaching out with mother liquor; (3) filter pressing; (4) neutralizing; (5) filter pressing; (51) extracting neutralized slag; (52) cuing; (53) leaching out; (54) filter pressing; (55) displacing and reducing with Zinc concentrate; (56) filter pressing; (57) extracting; (58) back extracting; (59) displacing; (60) agglomerating; (61) fusing and casting; then, obtaining the coarse IN element; meanwhile, (4) neutralizing; (5) filter pressing; (6) removing Fe and Mn elements with KMnO4; (64) mixing reffinate; (7) filter pressing; (8) displacing with Zn powder; (9) filter pressing; (10) refining with KMnO4; (11) depositing with NH4HCO3; (12) cleaning, filter pressing; (13) drying and baking; (14) obtaining the active ZnO. Compared with the independent prior art, this invention produces little pollution, has small loss to valuable metal, makes full use to the source with low request, and needs low cost and investment.

Owner:黄有余

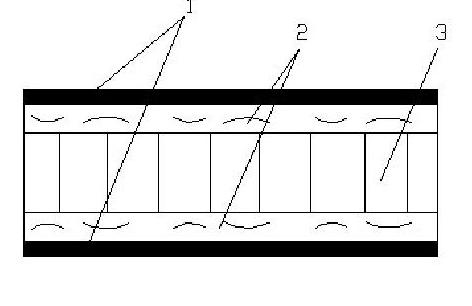

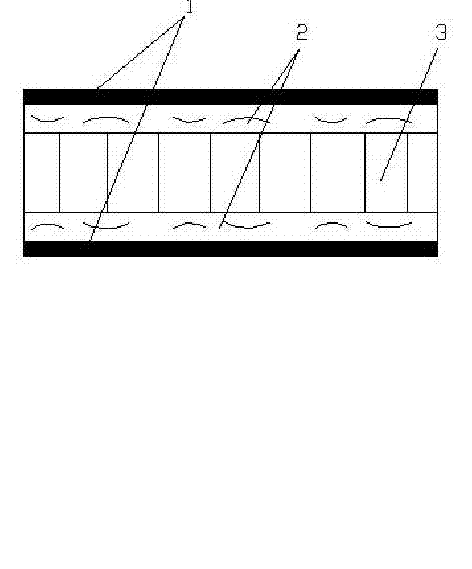

Novel laminated wood and manufacturing method thereof

ActiveCN101863058AKeep textureLight textureOther plywood/veneer working apparatusPlywood pressesWood veneerPulp and paper industry

The invention relates to a novel laminated wood. The novel laminated wood comprises a fir core veneer layer positioned at a central position, two cotton wood veneer layers which are respectively adhered on both upper and lower surfaces of the fir core veneer layer and two laminated wood layers which are adhered on the other surface of the two cotton wood veneer layers respectively, wherein the directions of wood grains of every two adjacent two veneer layers are vertical to each other. The invention also relates to a method for preparing the laminated wood. The method comprises the steps of producing the laminated wood layers, producing the cotton wood veneer layers, producing the fir core veneer layer, sizing, laminating, molding and the like. The novel laminated wood has the advantages of good stability, low cost and environment protection and can be widely used for preparing indoor decoration, such as furnitures, floors, door panels, ceilings and the like.

Owner:DEHUA TB NEW DECORATION MATERIAL CO LTD

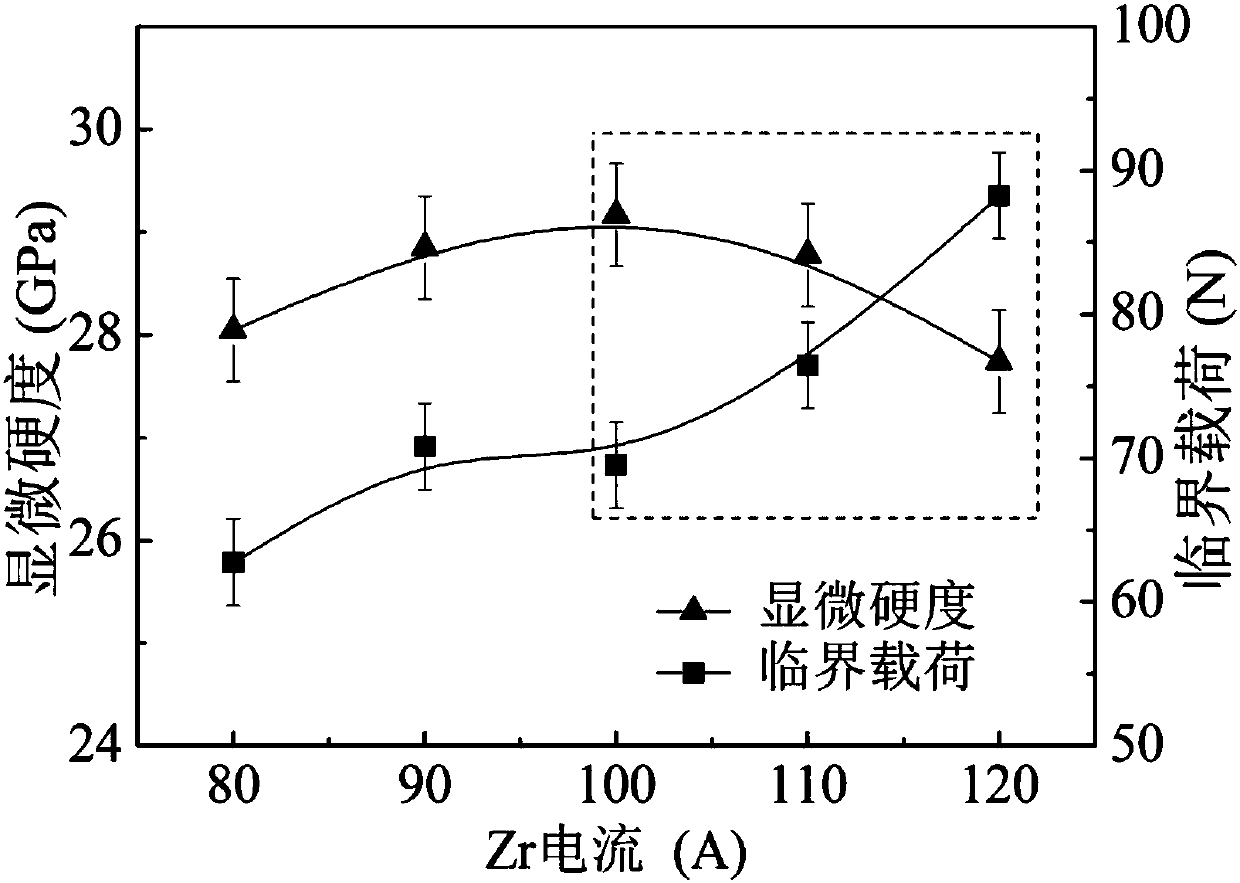

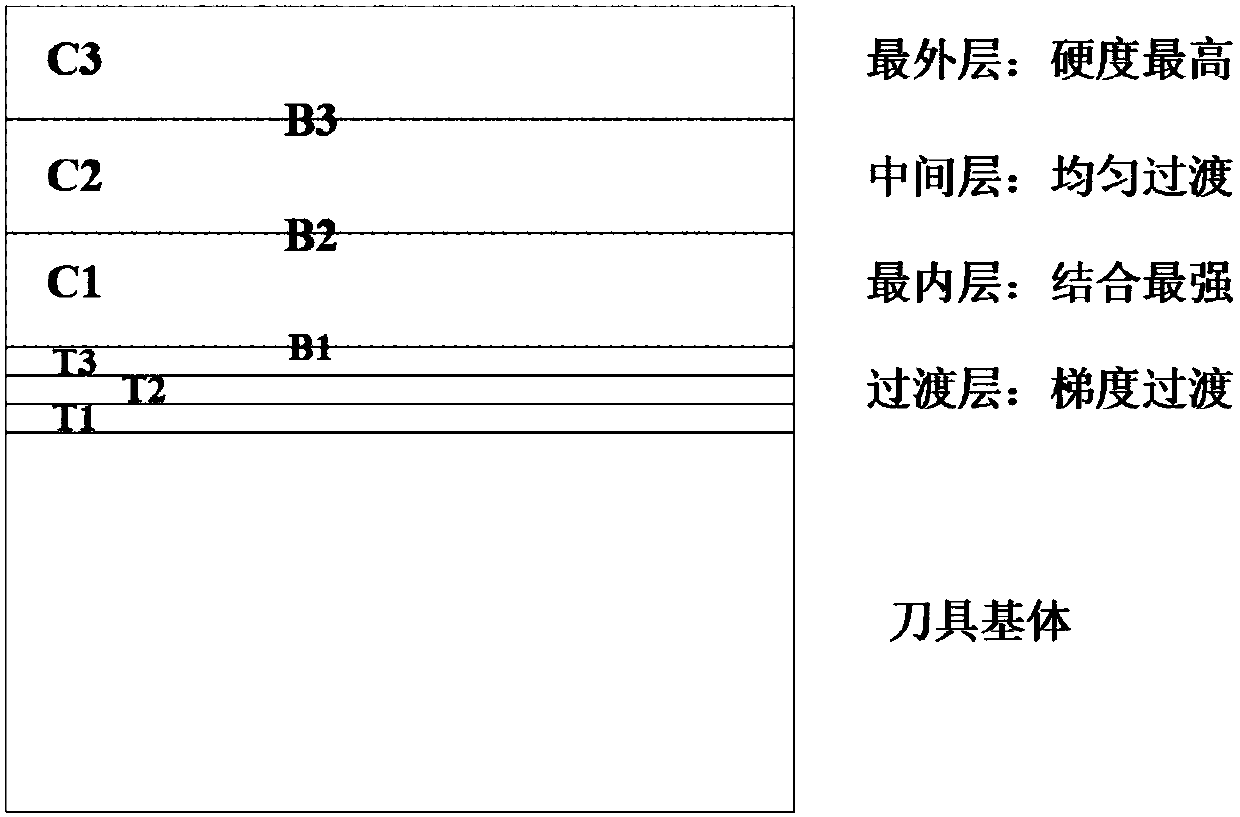

Preparation method of multi-dimensional gradient coating layer on surface of cutter

InactiveCN107675133AHigh hardnessHigh bonding strengthVacuum evaporation coatingSputtering coatingStress concentrationTreatment field

The invention relates to a preparation method of a multi-dimensional gradient coating layer on a surface of a cutter, and belongs to the technical field of metal cutting and cutter coating. The multi-dimensional gradient coating layer adopts the same coating material system; and components and performances of each deposition layer are controlled through controlling process parameters of the deposition process, so that the components and the mechanical performances of each deposition layer can realize continuous transition from inner layer to outer layer, the mutation of interface element components, physical performances and mechanical performances is prevented, the stress concentration caused by mismatch on interfaces is effectively relieved, and the coating reliability in the use processis improved. The outermost layer of the multi-dimensional gradient coating layer prepared by the method is high in hardness, so that the surface wear resistance can be effectively improved; the interfaces of internal deposition layers are high in bonding strength to effectively improve the coating capacity of resisting such destructions and failures as stripping / layered stripping; and the methodcan be widely applied to the coating treatment field of cutting tools and wear resisting surfaces.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

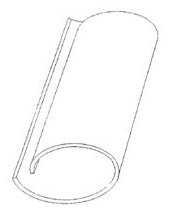

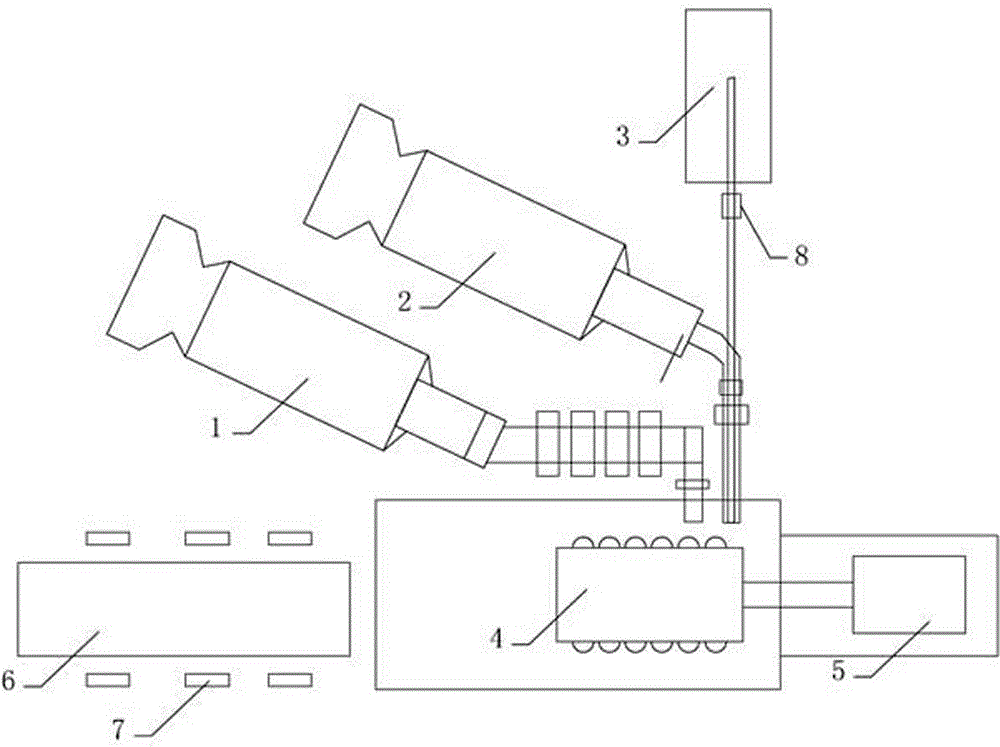

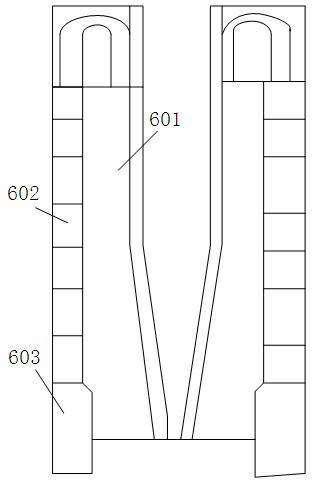

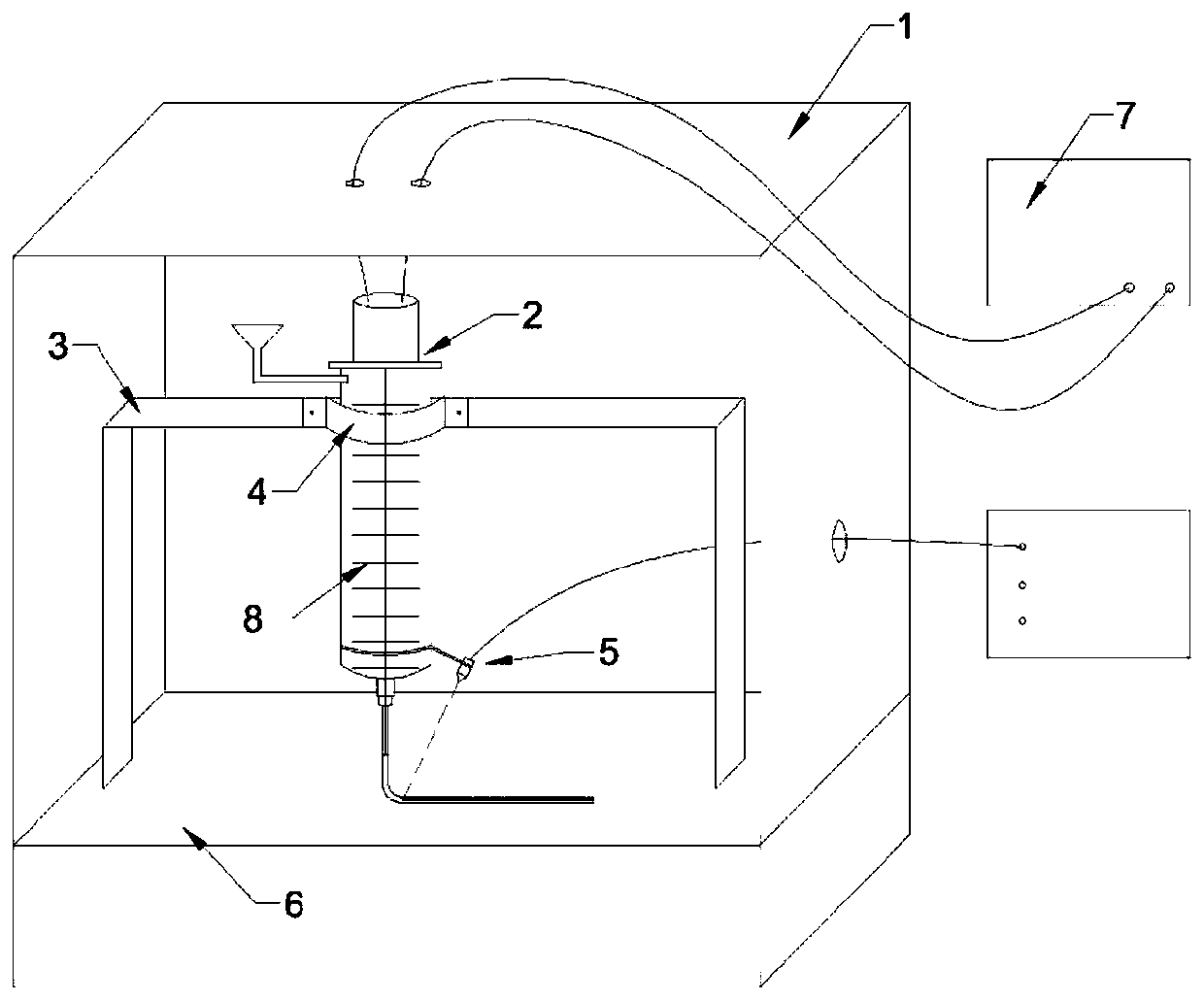

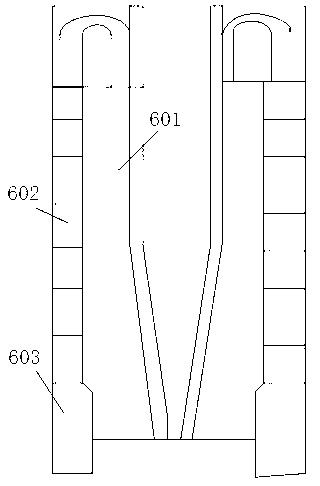

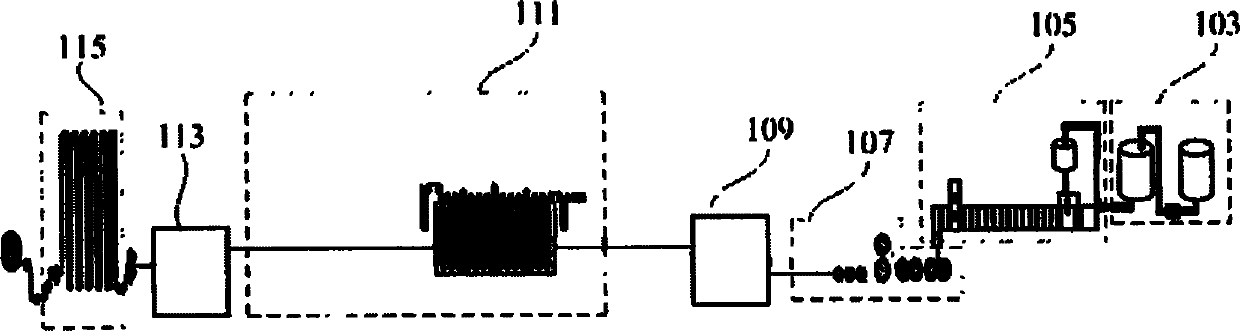

Novel spiral wound krah pipe continuous production technology and device

The invention relates to a novel spiral wound krah pipe continuous production technology and device. The novel spiral wound krah pipe continuous production technology comprises the following technological steps of material stirring operation, heating extrusion, extrusion of circular pipes, extrusion of flat strips, winding of the flat strips, winding of the circular pipes, winding of bells and spigots, cooling, cutting, shape modification of the bells and the spigots, inspection and storage. The impact resistance of spiral wound krah pipes produced through the novel spiral wound krah pipe continuous production technology and device is improved, and continuous production is achieved.

Owner:HUBEI TONGSU PIPELINE CO LTD

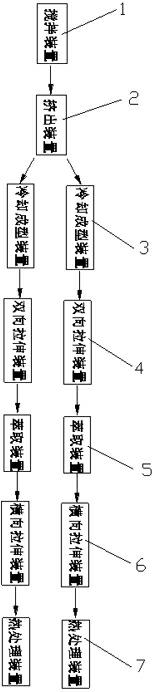

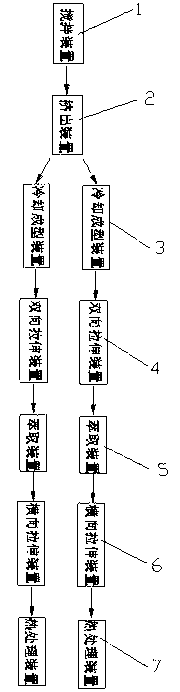

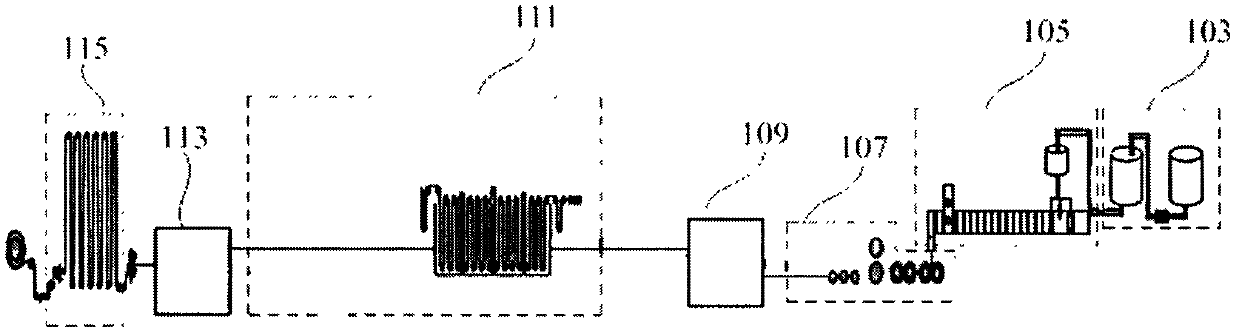

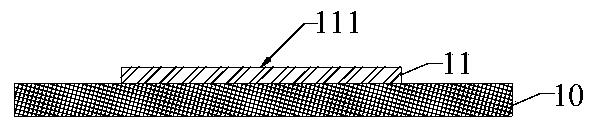

Method and system for preparing dynamic lithium ion battery diaphragm

The invention provides a method for preparing a dynamic lithium ion battery diaphragm. The method comprises the following steps: firstly, adding raw materials in a blender, and abundantly stirring; next feeding the stirred materials into a twin-screw extruder, and heating while continuously extrusion, so as to base sheet; thirdly, shunting the base sheet extruded from the extruder and then feeding the shunted base sheet into two same processing lines and simultaneously and respectively processing, wherein the respective processing line is as follows: 1, cooling and forming; 2, transversely and longitudinally stretching the cooled and formed base sheets through a two-way stretch device at the same time, so that the base sheet is stretched to form a diaphragm; 3, extracting out ore oil fromthe diaphragm with an alkane extractant by virtue of an extraction groove; 4, through a transverse stretch device, shaping, stretching and rectifying the diaphragm subjected to extraction, and ensuring the volatilization of the residual extract on the diaphragm; and 5, thermally treating the diaphragm. According to the invention, the defects that when the battery diaphragm is produced in the prior art, the equipment usage amount is large, the equipment cost is high, and the inferior-quality product incidence and production requirement of the prepared lithium ion battery diaphragm are high aresolved.

Owner:SHANGHAI QIANCHENG TOY TECH

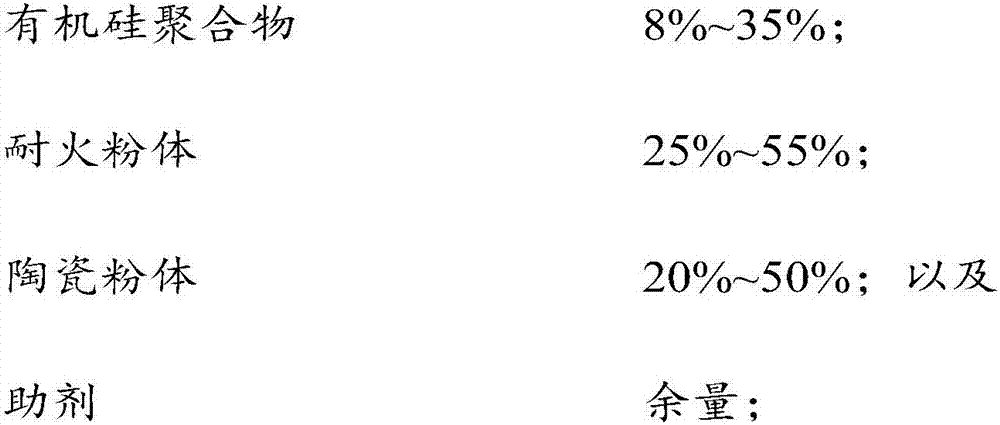

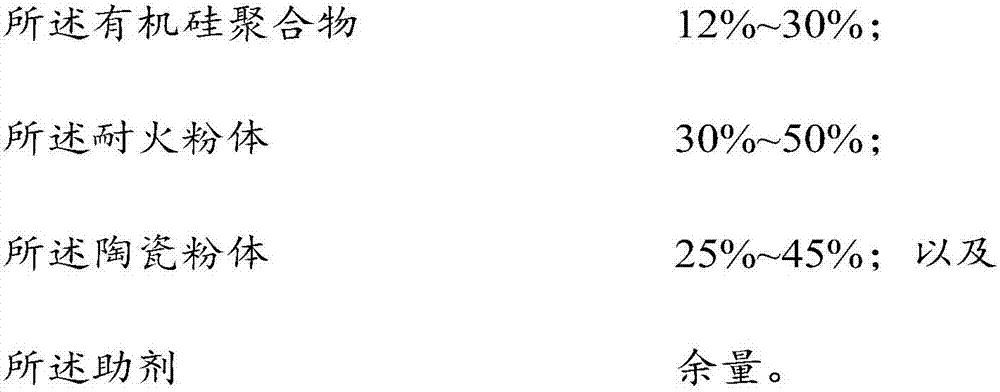

Superhard amorphous state ceramic silica gel and preparation method thereof as well as composition used for preparing superhard amorphous state ceramic silica gel

The invention relates to a superhard amorphous ceramic silica gel, a preparation method thereof and a composition for preparing superhard amorphous ceramic silica gel, and relates to the technical field of high temperature resistant materials. The composition comprises 8%-35% of organosilicon polymer, 25%-55% of refractory powder, 20%-50% of ceramic powder and the rest of additives in weight percent. The silicone polymer includes at least one of vinyl polysiloxane, styryl polysiloxane, methacrylate siloxane, and polymethylhydrogen siloxane. Auxiliaries include coupling agents. It is readily available and inexpensive. The preparation method includes heating and molding the mixture of refractory powder, ceramic powder, organosilicon polymer and additives. The process is simplified and the production is convenient. The superhard amorphous ceramic silica gel is prepared from the above composition through the above preparation method. The high-temperature resistance performance is good, the production is convenient, and the cost is low, which is helpful for the large-scale industrial production and popularization of the fire-resistant cable.

Owner:KUSN ZHONGDI MATERIALS TECH

Novel laminated wood and manufacturing method thereof

ActiveCN101863058BKeep textureLight textureOther plywood/veneer working apparatusPlywood pressesWood veneerEnvironmental resistance

The invention relates to a novel laminated wood. The novel laminated wood comprises a fir core veneer layer positioned at a central position, two cotton wood veneer layers which are respectively adhered on both upper and lower surfaces of the fir core veneer layer and two laminated wood layers which are adhered on the other surface of the two cotton wood veneer layers respectively, wherein the directions of wood grains of every two adjacent two veneer layers are vertical to each other. The invention also relates to a method for preparing the laminated wood. The method comprises the steps of producing the laminated wood layers, producing the cotton wood veneer layers, producing the fir core veneer layer, sizing, laminating, molding and the like. The novel laminated wood has the advantages of good stability, low cost and environment protection and can be widely used for preparing indoor decoration, such as furnitures, floors, door panels, ceilings and the like.

Owner:DEHUA TB NEW DECORATION MATERIAL CO LTD

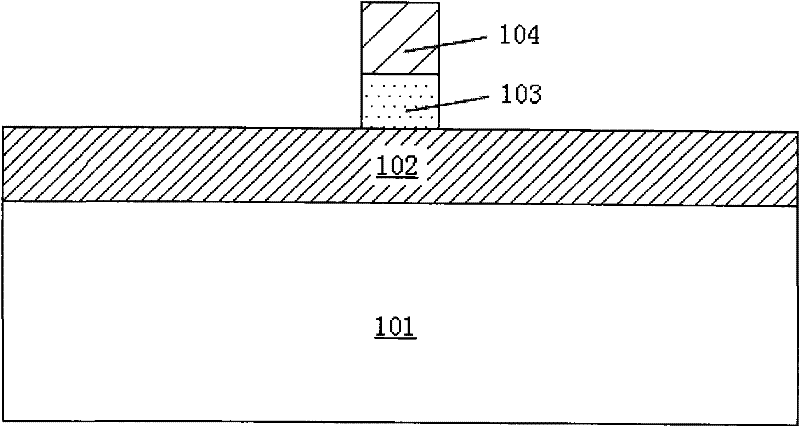

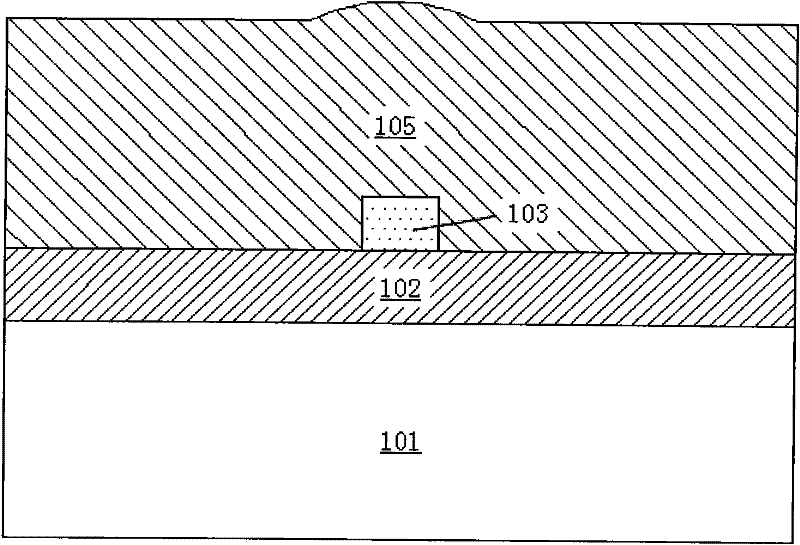

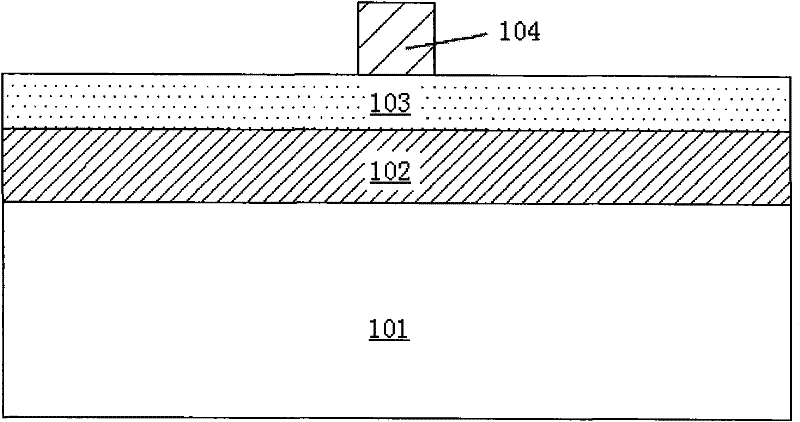

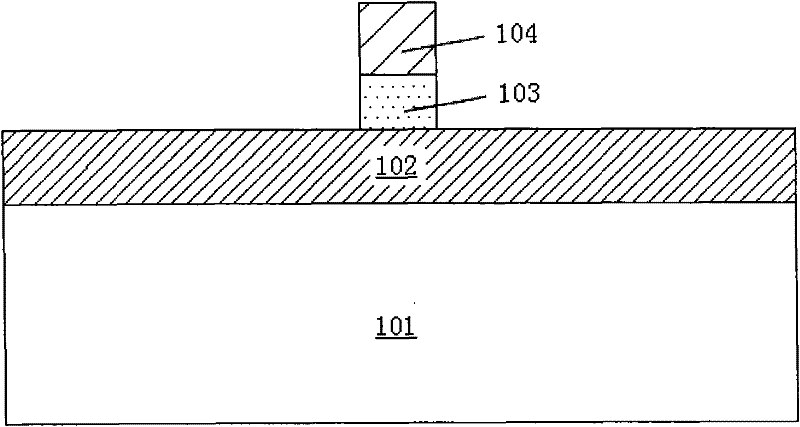

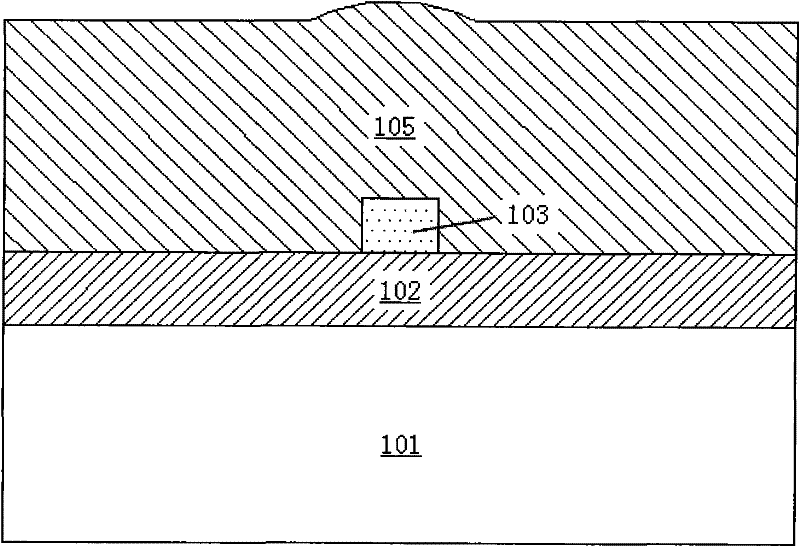

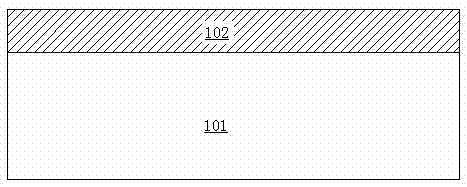

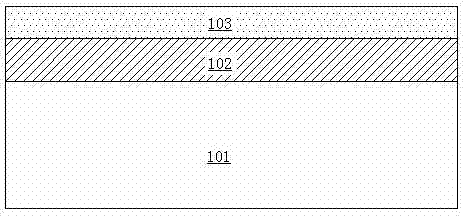

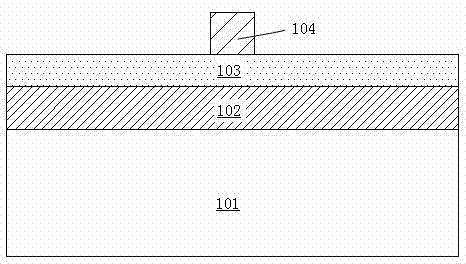

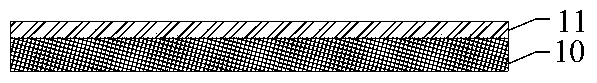

Manufacture method for planar lightwave circuit (PLC) light device

InactiveCN102540336AThe process is simpleReduce technical difficultyOptical light guidesPhotoresistLight wave

The invention belongs to the technical field of planar lightwave circuit (PLC) splitters, particularly relates to a manufacture method for a lightwave guide, and comprises the steps of enabling a layer of silicon dioxide to grow on a silicon wafer; performing deposition of photoresist; performing photoetching to form a pattern; forming an optical waveguide core layer with a high refractive index in a groove between the photoresist; stripping the photoresist; and forming a film wrapping layer with a low refractive index. The manufacture method for the lightwave guide is simple in process, low in technical difficulty and requirements of raw materials and production devices, reduces production cost, and easily achieves industrialized mass production.

Owner:SUZHOU ORIENTAL SEMICONDUCTOR CO LTD

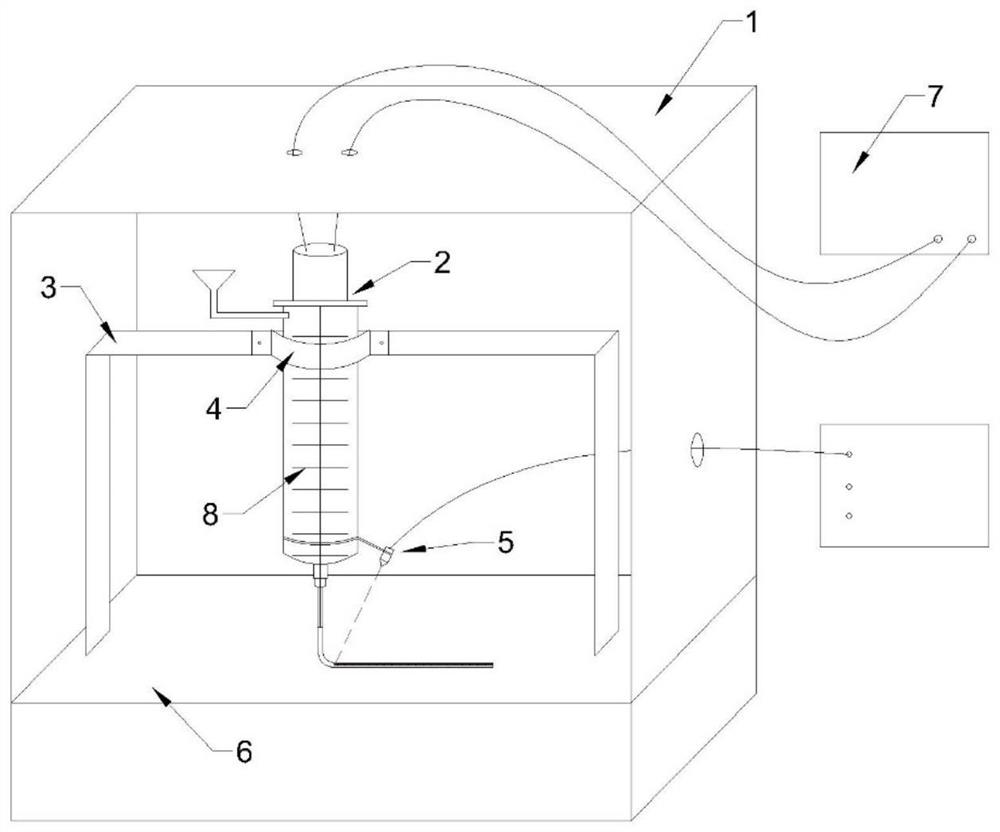

3D printing method for selective laser curing metal

ActiveCN110842204ASolve the accuracy problemSolve efficiency problemsAdditive manufacturing apparatusIncreasing energy efficiencyHigh densityWorking environment

The invention provides a 3D printing method for selective laser curing metal, and belongs to the technical field of 3D printing forming. The 3D printing method comprises the following steps that firstly, metal powder is mixed with liquid photosensitive resin, then a dispersing agent is added in the slurry to adjust the rheological property of the slurry, and photosensitive paste with proper solid-phase volume fraction and good rheological property is prepared. A 3D printing device is used for extruding the slurry out of a nozzle with a certain diameter; meanwhile, in the process of extruding and dispersing accumulation of a slurry flow line, a fine laser beam selection area is adopted to synchronously scan to the plane of the slurry flow line, so that the slurry flow line is locally and rapidly solidified and formed, and forming of a metal part with a certain shape can be achieved. According to the 3D printing method for selective laser curing metal, the high-precision metal part can be directly formed, the forming speed is high, the part strength is high, the density is uniform, the cost is low, and no special requirements are required for the working environment.

Owner:UNIV OF SCI & TECH BEIJING

Manufacture method for planar lightwave circuit (PLC) optical device

InactiveCN102540335AThe process is simpleReduce technical difficultyOptical light guidesPhotoresistRefractive index

The invention belongs to the technical field of planar lightwave circuit splitters (PLC splitters), in particular relates to a manufacture method for optical waveguide, and comprises the steps of depositing a layer of photoresist on a glass substrate; performing photoetching to form an image; forming optical waveguide core layers with high reflection rate in a groove between the photoresist; curing the photoresist; and forming a wrapping layer on a membrane with a the high reflection rate. The manufacture method for the optical waveguide is simple in technology process and low in technical difficulty. Requirements for raw materials and production equipment are low, production cost is reduced, and industrialized mass production is easy to achieve.

Owner:SUZHOU ORIENTAL SEMICONDUCTOR CO LTD

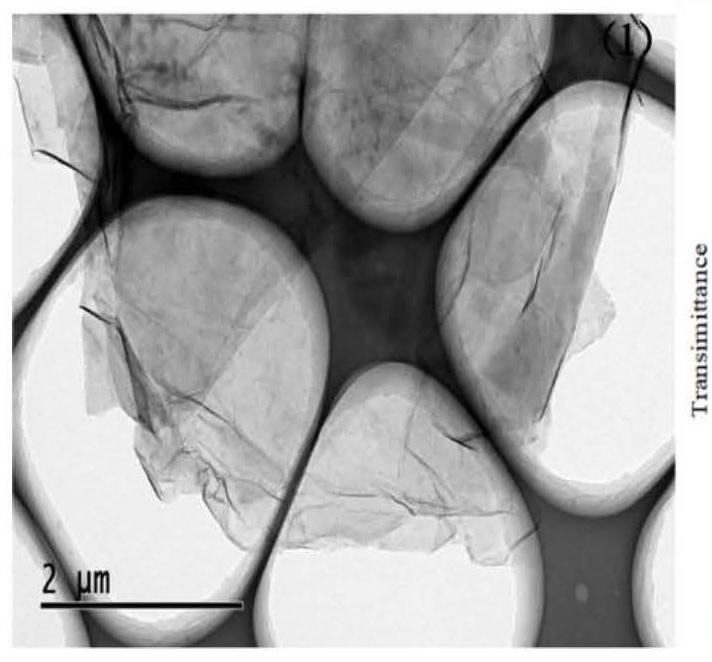

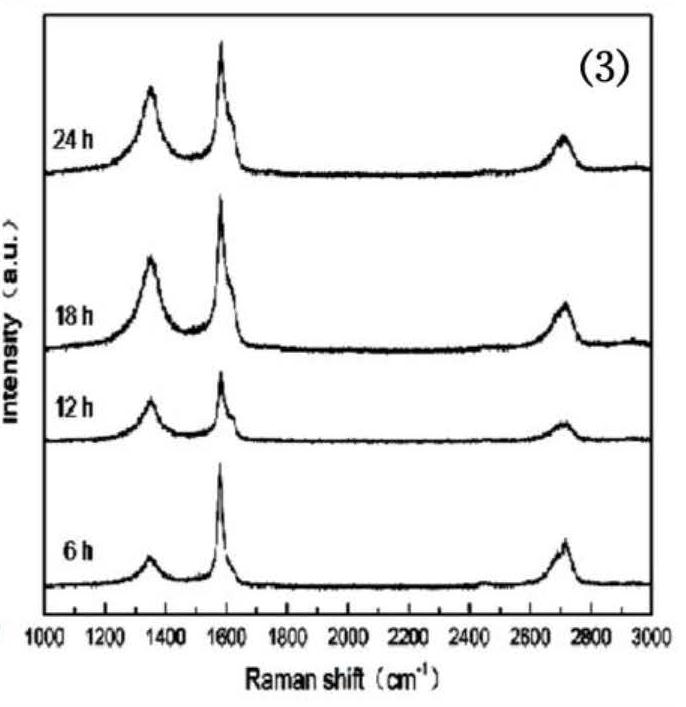

Ultralow-oxygen-content three-dimensional nitrogen-doped graphene aerogel and preparation method thereof

ActiveCN113387346AReduce oxygen contentLow nitrogen dopingGrapheneDoped grapheneNitrogen doped graphene

The invention discloses an ultralow-oxygen-content three-dimensional nitrogen-doped graphene aerogel and a preparation method thereof, belonging to the technical field of graphene aerogel. According to the method, a graphene oxide precursor is adopted for preparation of low-carboxyl highly-hydroxylated graphene oxide through an electrolytic method; and then one-step hydrothermal reduction nitrogen-doped in-situ self-assembling and high-temperature sintering are conducted to obtain the ultralow-oxygen-content three-dimensional nitrogen-doped graphene aerogel with a light three-dimensional grid structure, wherein an oxygen content is less than 0.1 at.%, a nitrogen doping amount is 4-12%, and pyridine type nitrogen accounts for 30-80%.

Owner:GRIMAT ENG INST CO LTD

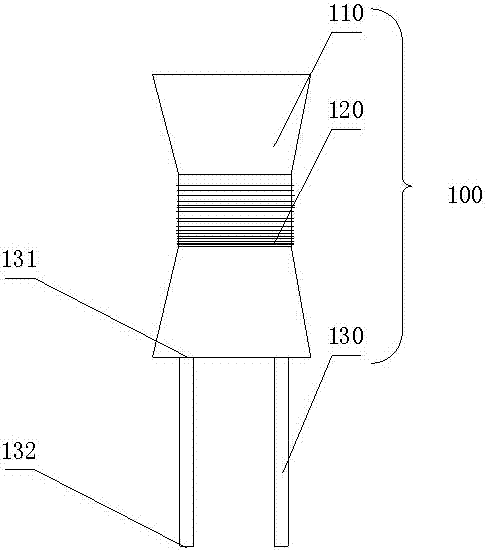

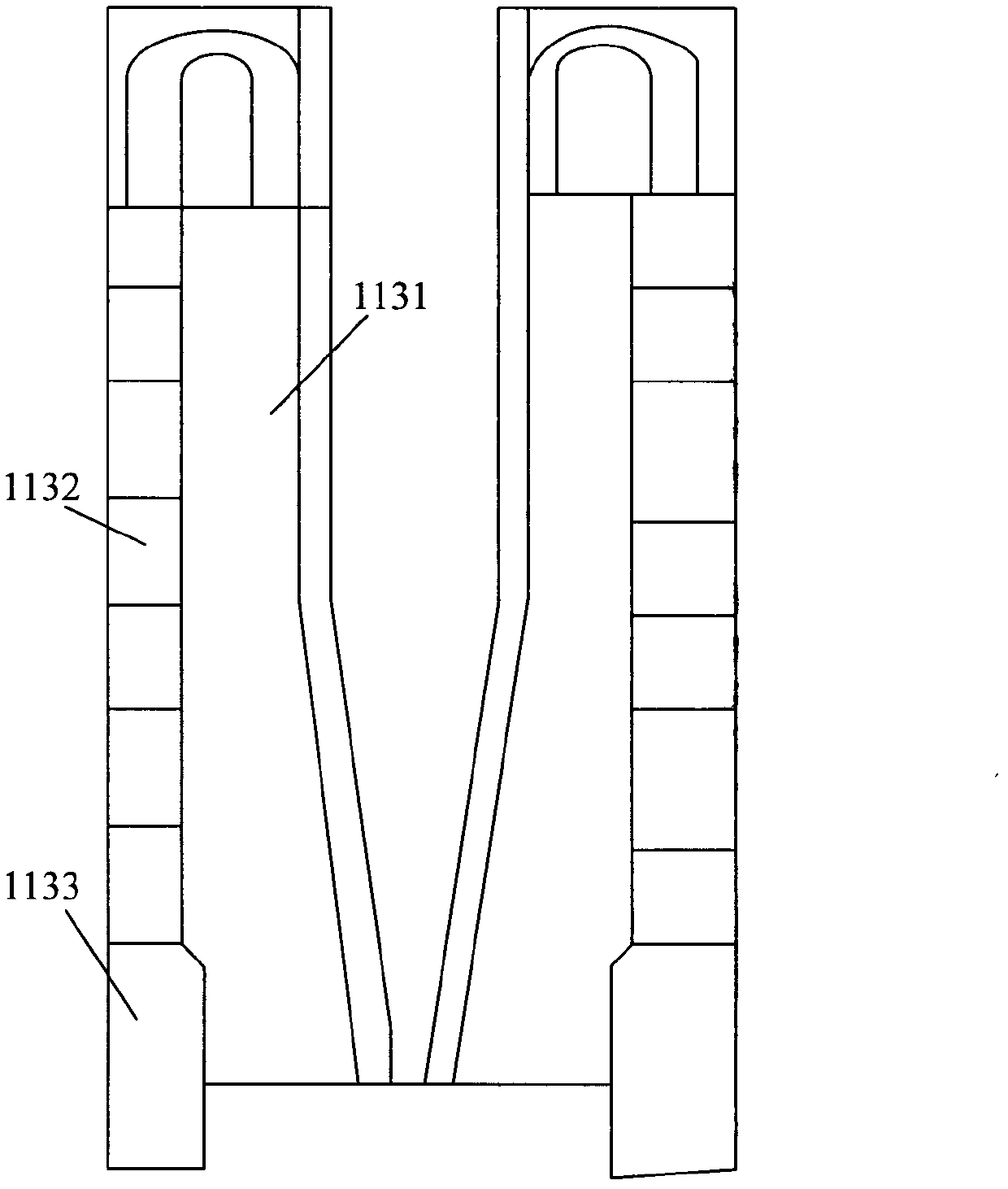

Inductance element and its preparation process

ActiveCN104465021BSolve the problem of disconnection and senseless volumeReduce pressure requirementsTransformers/inductances coils/windings/connectionsInductances/transformers/magnets manufactureInductorEngineering

The invention provides an inductance element and its preparation process, comprising an inner layer main body and an outer layer protective layer, the outer layer protective layer is combined with the inner layer main body by overmolding; the inner layer main body It includes a magnetic core, a coil and a pin; the magnetic core and the coil are completely wrapped in the outer protective layer, and the connection end of the pin and the magnetic core is wrapped in the outer protective layer In the layer, the free ends of the pins protrude from the outer protective layer. In the inductance element of the present invention, the magnetic core and the coil are all wrapped in the outer protective layer, which is safe to use and simultaneously solves the problem of inductive disconnection without inductance; moreover, the outer protective layer of the inductive element of the present invention is composed of multiple layers Composition, high voltage resistance, more suitable for the needs of modern LED development.

Owner:CHANGXING HEXING ELECTRONICS

Manufacturing method for PLC (planar lightwave circuit) optical device

InactiveCN102540337ASimple processReduce technical difficultyOptical light guidesResistRefractive index

The invention belongs to the technical field of planar lightwave circuit (PLC) splitters and specifically relates to a manufacturing method for optical waveguides, the manufacturing method comprises the following steps of: forming a layer of silicon dioxide on a silicon wafer; depositing photo resists; photo-etching to form patterns; forming an optical waveguide core layer with a high refractive index in a groove among the photo resists; curing the photo resists; and forming an upper film coating layer with low refractive index. The manufacturing method for the optical waveguides is simple in technological process, low in technical difficulty, low in raw material and production equipment requirement, low in production cost and easy to realize the industrialization scale production.

Owner:SUZHOU ORIENTAL SEMICONDUCTOR CO LTD

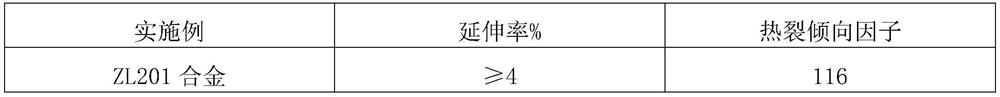

Thermal cracking resistant Al-Cu series cast aluminum alloy and preparation method thereof

The invention provides a thermal cracking resistant Al-Cu series cast aluminum alloy and a preparation method thereof. To solve the problem of thermal cracking of Al-Cu series cast aluminum alloys with high copper content, a plurality of strengthening elements and inhibition elements are added, thus the elongation of materials is increased, the solidification temperature interval in the pouring process is reduced, and meanwhile the grain boundary dragging effect is improved. The Al-Cu series cast aluminum alloy comprises the following components in percentage by weight: 4-6% of Cu, 0.7-1.5% ofMn, 0.1-0.4% of Ti, 0.005-0.06% of B, 0.005-0.030% of V, and the balance Al. Through increase of the content ratio of Mn in the Al-Cu series cast aluminum alloy, MnAl16 chemical combination dispersion particles are formed to distribute along the grain boundary to stop growth of recrystallized grains; and meanwhile, iron impurities are molten to form (Fe, Mn) Al16 compounds to reduce harmful influence of iron. The thermal cracking resistance and the elongation of the Al-Cu series cast aluminum alloy are prominently improved.

Owner:LANZHOU FLIGHT CONTROL

Manufacturing method for archaistic embossment wood floor

InactiveCN102555006AIncrease productivityQuality improvementWood working apparatusSolid woodPulp and paper industry

The invention relates to a manufacturing method for an archaistic embossment wood floor, which comprises the following steps: selecting a hot roll heated by conduction oil; carving selected archaistic wood grain patterns on the surface of the hot roll in a manual or mechanical or electrochemical method, wherein the carving depth is 0.1-4mm; selecting the processed solid wood to wait for embossing; installing a prepared hot roll on an embossing machine; heating the hot roll by the conduction oil; heating the surface of the hot roll to 100-320 DEG C; causing the wood floor to pass through the hot roll at the speed being 1-20m / min, wherein the linear pressure of the hot roll on the wood floor is 2-200kg / cm; and according to the material of the wood floor, hot roll surface heating temperature and hot roll revolving speed pressure, taking the situation that a concave part after the wood floor passes through the hot roll is burnt but a convex part is not burnt as a reference. The manufacturing method is convenient and has the advantages of high production efficiency and good product quality.

Owner:沈要勤

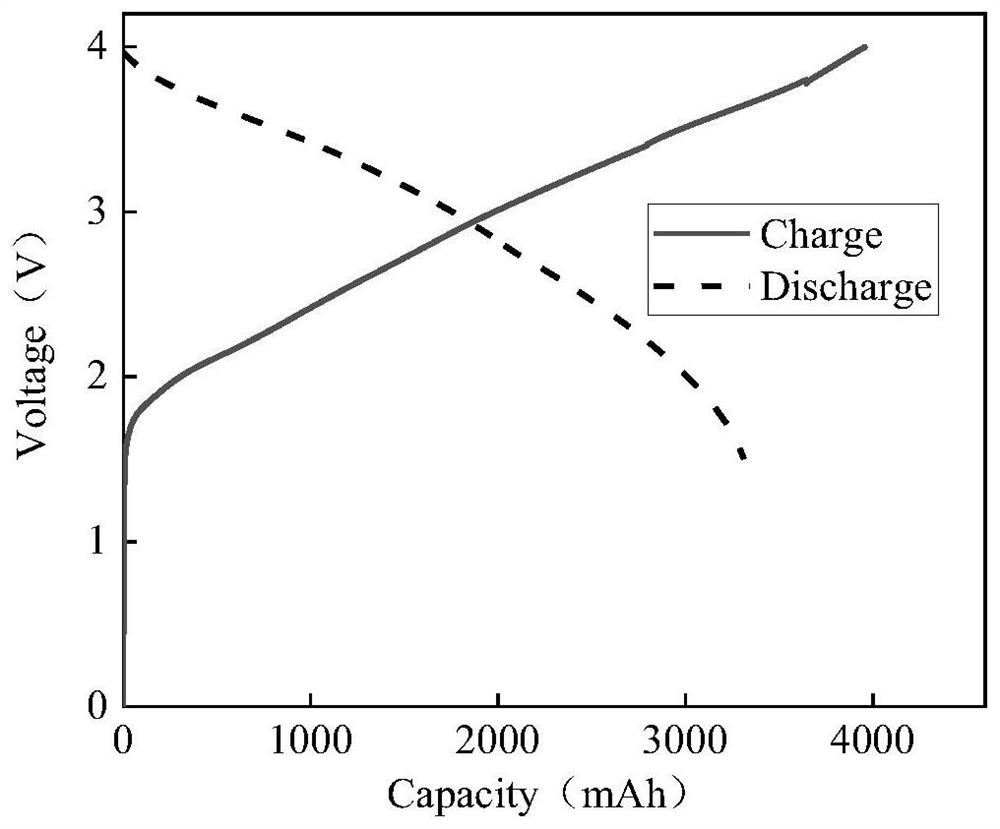

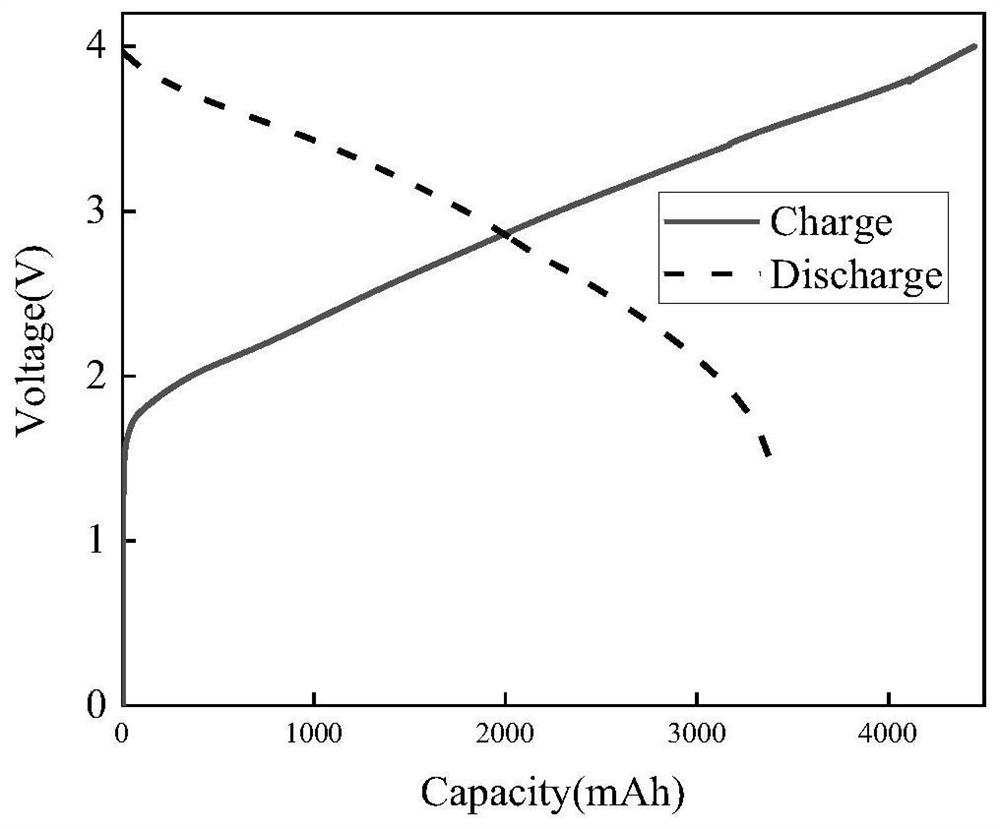

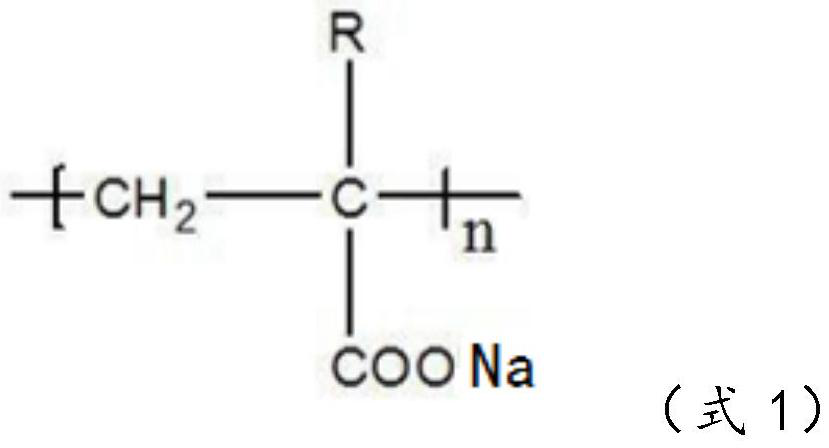

Hard carbon binder, negative plate containing hard carbon binder and sodium ion battery

ActiveCN113054197ARaw material requirements are lowLow environmental requirementsSecondary cellsNon-aqueous electrolyte accumulator electrodesSodium-ion batteryPolypropylene

The invention relates to a hard carbon binder, a negative plate containing the hard carbon binder and a sodium ion battery. The hard carbon binder is chain-shaped sodium polyacrylate PAAS or a PAAS copolymer; and the hard carbon binder is used as a sodium ion battery negative electrode binder. The hard carbon binder provided by the invention does not have the problem that the traditional negative electrode dry binder polytetrafluoroethylene (PTFE) is easy to decompose under low pressure, and has the advantages of short process time and low environmental requirements; when the negative electrode material is used for preparing the dry-method sodium ion battery, the advantages of high surface density, simple process and low cost are achieved; and sodium ions in PAAS can migrate in the electrode, so that the electrode has the advantage of supplementing the sodium ions.

Owner:INST OF PHYSICS - CHINESE ACAD OF SCI

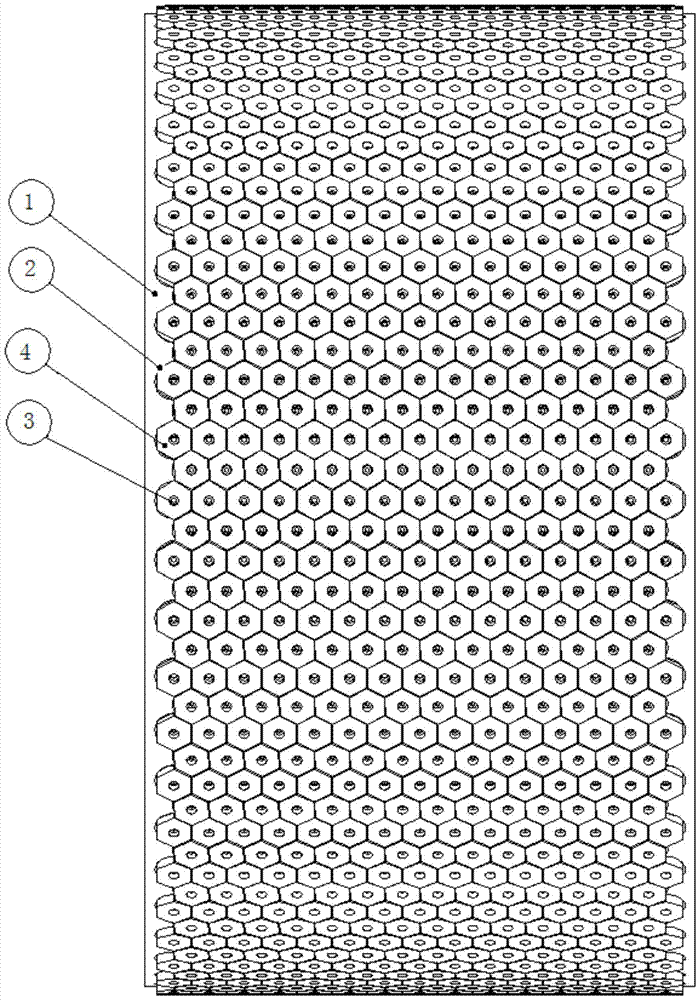

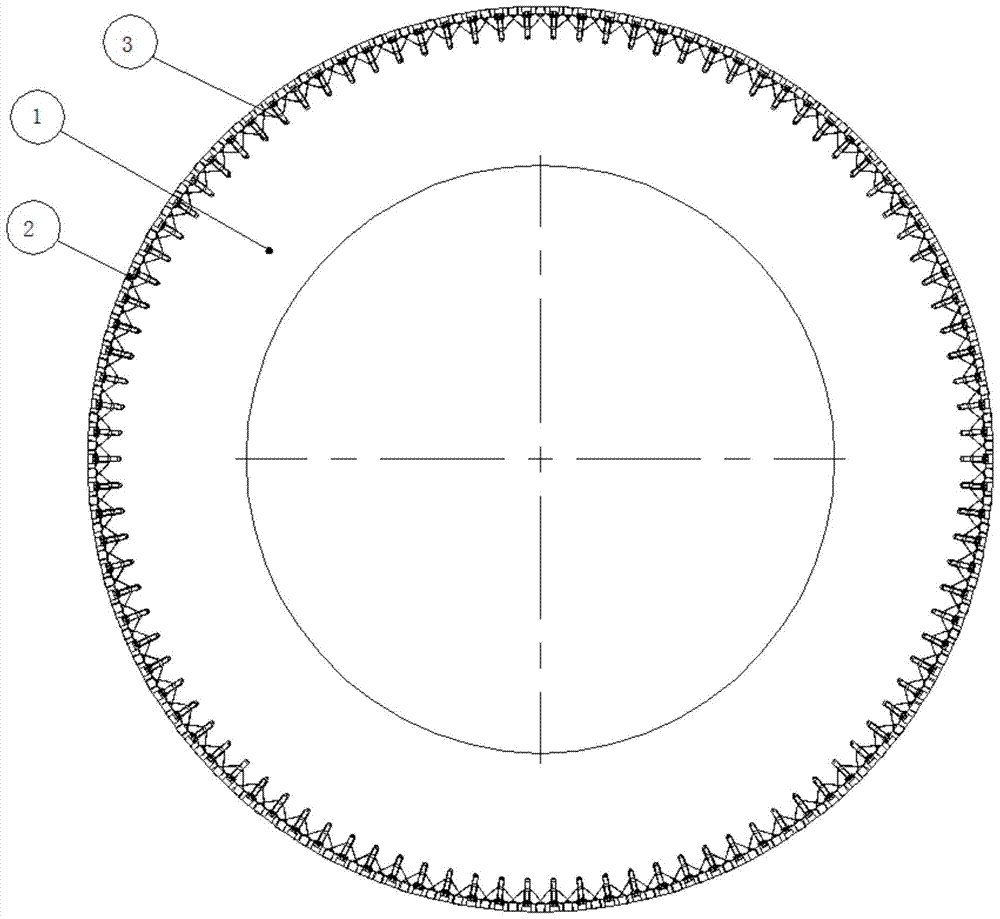

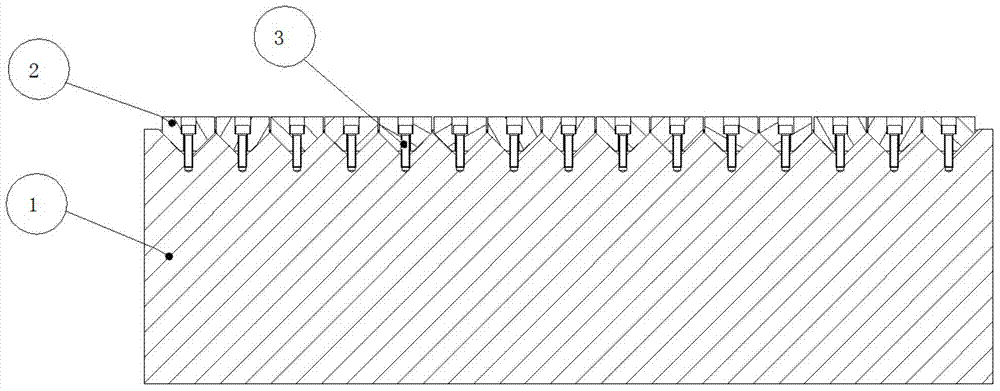

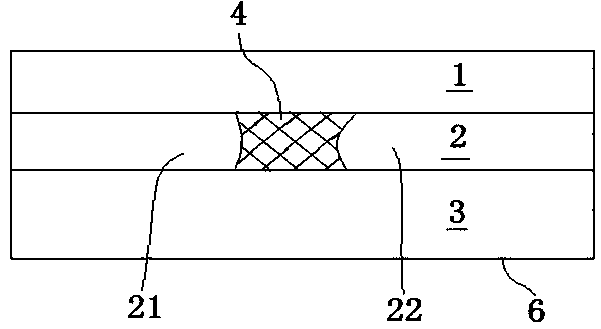

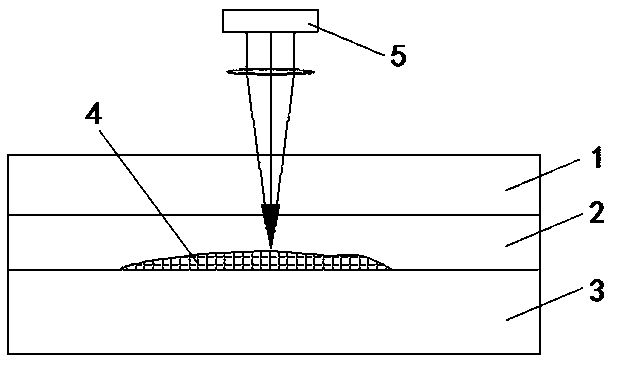

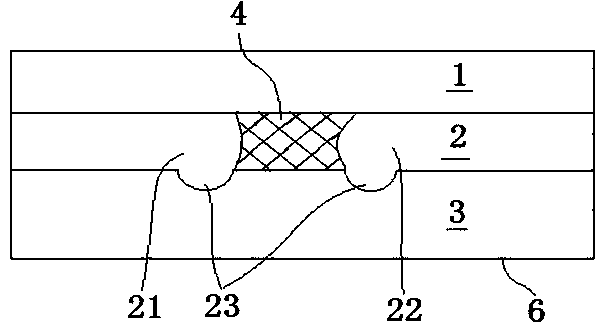

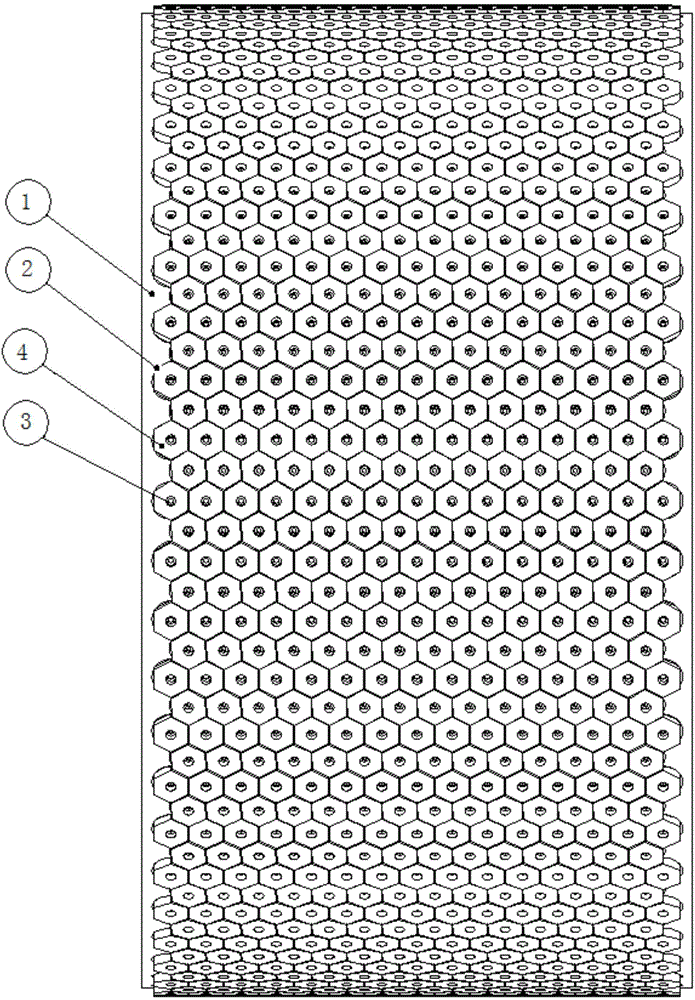

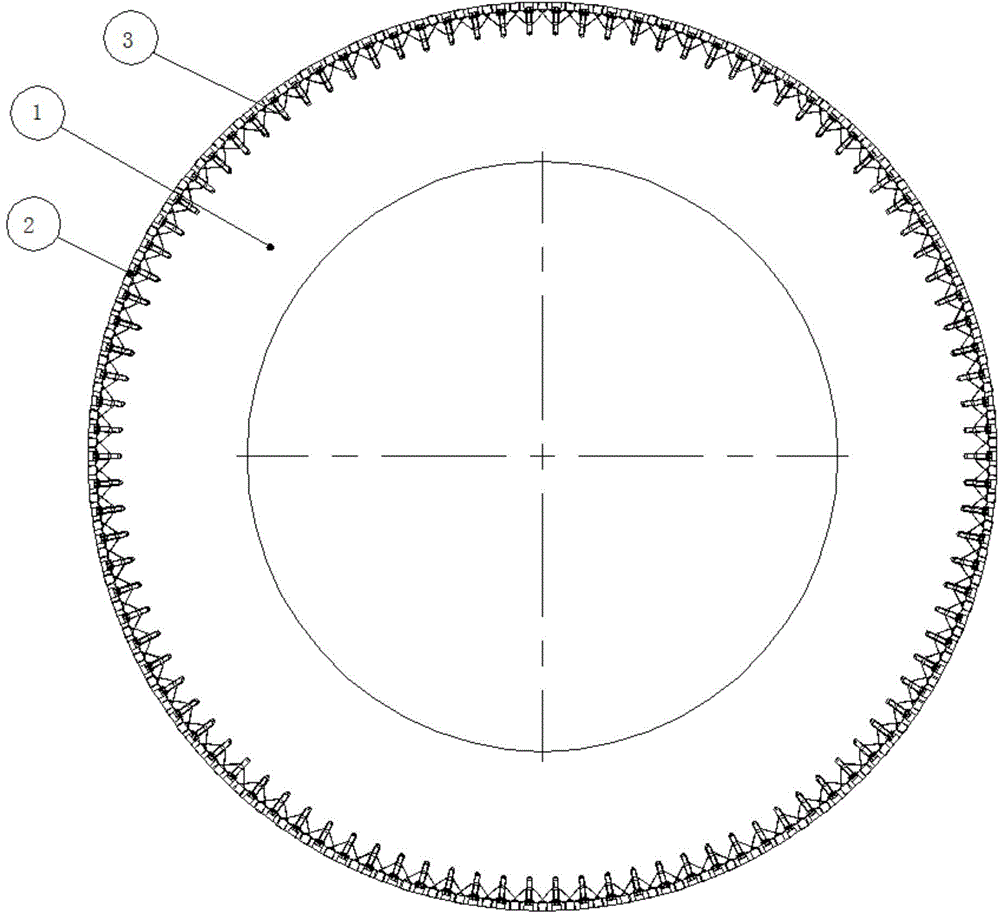

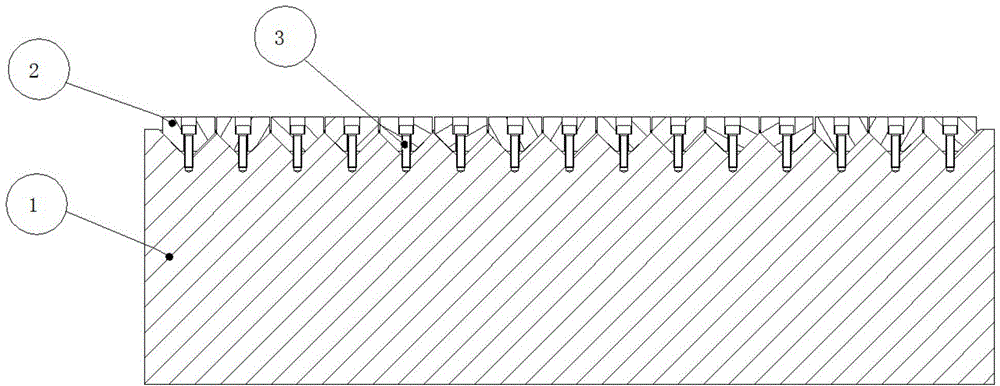

Wear-resistant close-packed armored roll surface

ActiveCN104525309BReduce hardness requirementsRaw material requirements are lowGrain treatmentsEngineeringHigh pressure

The invention discloses an antiwear close-packed armor roll surface, and belongs to the field of roller presses (high-pressure roller mills). The antiwear close-packed armor roll surface comprises a roll surface base body and an antiwear armor layer, wherein the antiwear armor layer is fixed on the roll surface base body and is composed of a plurality of armor units which are tightly arranged and are fixed on the roll surface base body through bolts; and each overall armor unit is a cone body and is composed of a regular hexagonal prism body on the upper part and a cone body on the lower part. The roll surface base body disclosed by the invention is not easy to wear; the demands on the materials and the processing equipments of the roll surface base body are reduced; the fabrication cost is reduced; the roll surface disclosed by the invention is good in wear resistance and long in service life; and a surface wear-resisting layer is not easy to wear, can be used at relatively high temperature and is easy to assemble and disassemble.

Owner:成都建筑材料工业设计研究院有限公司 +1

A kind of hot crack-resistant al-cu series cast aluminum alloy and preparation method thereof

The invention proposes a thermal-cracking-resistant Al-Cu series cast aluminum alloy and a preparation method thereof, aiming at the problem of hot cracking of Al-Cu-based cast aluminum alloys with high copper content, by adding various strengthening elements and inhibiting elements, the strength of the material is improved. Increase the elongation and reduce the solidification temperature range during the pouring process, while increasing the grain boundary dragging effect. The percentages of each component and weight in Al-Cu cast aluminum alloy are: Cu: 4%-6%, Mn: 0.7%-1.5%, Ti: 0.1%-0.4%, B: 0.005%-0.06%, V : 0.005% to 0.030%, the balance being Al. By increasing the content ratio of Mn element in Al-Cu-based casting alloy, the dispersed particles of MnAl16 compound are formed and distributed along the grain boundary, which hinders the growth of recrystallized grains; at the same time, iron impurities are melted to form (Fe, Mn)Al16 compound, reducing Harmful effects of small iron. Significantly improved the hot cracking resistance and elongation of Al-Cu series casting alloy.

Owner:LANZHOU FLIGHT CONTROL

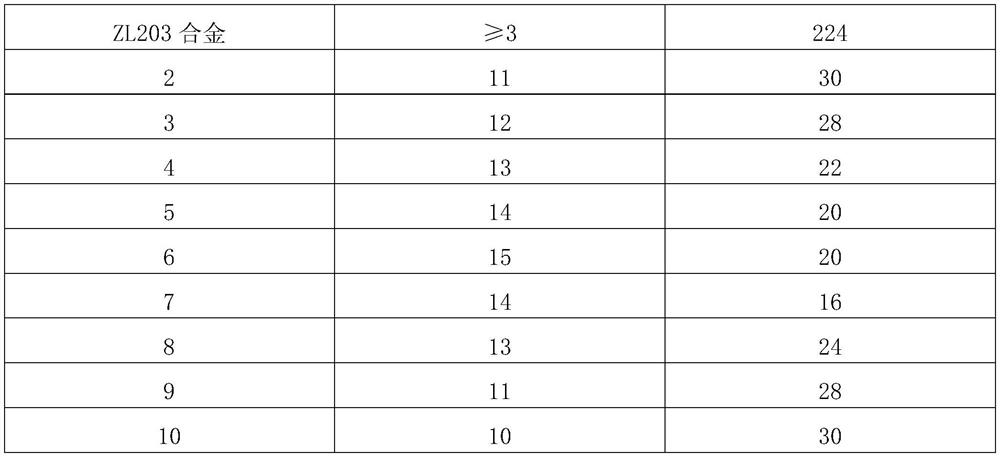

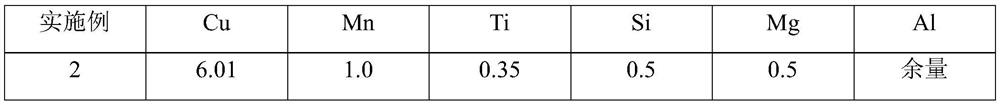

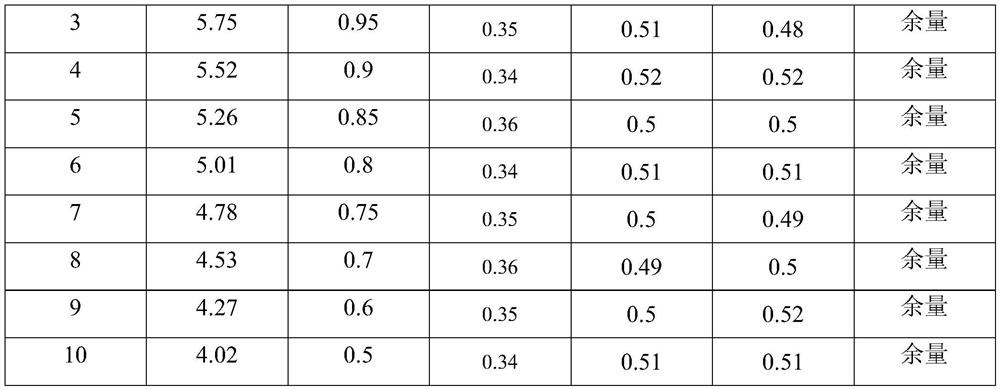

A kind of al-cu system casting alloy suitable for forging processing and preparation method thereof

ActiveCN111020321BStrong precipitation strengthening effectImprove mechanical propertiesCopperUltimate tensile strength

The present invention proposes an Al-Cu series casting alloy suitable for forging processing and a preparation method thereof. Aiming at the problem that the Al-Cu series casting alloy with high copper content is difficult to forge, the pouring process is shortened by adding various strengthening elements and inhibiting elements Medium solidification temperature range and increase the grain boundary dragging effect, reduce the generation of dendrites, etc., to achieve the effect of enhancing the forging performance of the material. The percentages of each component and weight in Al-Cu series casting alloy are: Cu: 4%~6%, Mn: 0.5%~1.0%, Si: 0.4%~0.8%, Mg: 0.3%~0.6%, Ti: 0.15% to 0.4%, the remaining impurities <0.5%, and the balance is aluminum. By increasing the content ratio of Mn element and Si element in Al-Cu-based casting alloys, the Si phase is refined and dispersed and the second phase particles (Al 2 Cu, ALCuFeMn compound equal) a large number of dispersed precipitation, the pinning effect is strengthened, which significantly improves the forging performance of Al-Cu series casting alloys. The mechanical properties after forging are tensile strength ≥ 500MPa, yield strength ≥ 350MPa, and elongation ≥ 15%.

Owner:LANZHOU FLIGHT CONTROL

Method for manufacturing PLC (Programmable Logic Controller) device

InactiveCN102116900BSimple processRaw material requirements are lowOptical light guidesProgrammable logic controllerRefractive index

The invention belongs to the technical field of planar optic splitters, and particularly relates to a method for manufacturing an optic waveguide. The method comprises the steps of: forming a layer of photoresist on a glass substrate; carrying out photoetching to form a graph; forming an optic waveguide core layer with high refractive index in a groove between the photoresist; stripping the photoresist; and forming an upper film coating layer with low refractive index. The method for manufacturing the optic waveguide is simple in technological process, low in requirements of raw materials andproduction equipment, low in production cost and easy for realizing industrialized scale production.

Owner:FUDAN UNIV

A kind of cationic polymer and preparation method thereof

The invention discloses a cationic polymer and a preparation method thereof, belonging to the technical field of water-soluble polymer preparation. The preparation method is as follows: add dimethyl diallyl ammonium chloride monomer into the reaction kettle, add viscosity regulator, metal ion chelating agent, chain transfer agent and deionized water under stirring to form a polymerization solution, and pass it into Nitrogen to drive out the air; raise the temperature to 75-95°C, start dropping the initiator and dimethyl diallyl ammonium chloride monomer at a predetermined rate for 2-4 hours; add the curing agent dropwise at 75-105°C, and mature for 1 After ~3 hours, dilute with water to obtain the target product. The invention adds a viscosity regulator to the reaction system to keep the product in a fluid state when polymerized to a relatively high molecular weight, which facilitates the dispersion of initiators and curing agents and the diffusion of free radicals, and improves the efficiency and effect of residue removal.

Owner:JIANGSU FEYMER TECH

Novel deep stretching process of curved surface

The invention relates to a novel deep stretching process of a curved surface. A structure of a stretching material of a product is cut by adopting special equipment; the stretching material is welded into a closed structure; after a welding seam is reshaped and a swaging is subjected to reversal pretreatment, a rudiment of the treated closed product is put in the curved surface or a cambered mould; and a required shape is pressed by utilizing the stamping press of the mould through one-time forming. The novel deep stretching process comprises the specific operating steps: cutting, closing, welding, the reshaping of the welding seam and the reversal pretreatment and the stretching of the swaging. The novel deep stretching process has the advantages of simple process, convenient operation, one-time stretch forming, time saving, improved efficiency, needlessness of repeatedly annealing and tempering treatment, high stretching quality, low requirement on raw materials, accurate shape of aformed product without the defects, of stretching pieces, such as surface dents, salient points, avulsion and the like, and low comprehensive cost.

Owner:赵少峰

Method and system for preparing dynamic lithium ion battery diaphragm

The invention provides a method for preparing a dynamic lithium ion battery diaphragm. The method comprises the following steps: firstly, adding raw materials in a blender, and abundantly stirring; next feeding the stirred materials into a twin-screw extruder, and heating while continuously extrusion, so as to base sheet; thirdly, shunting the base sheet extruded from the extruder and then feeding the shunted base sheet into two same processing lines and simultaneously and respectively processing, wherein the respective processing line is as follows: 1, cooling and forming; 2, transversely and longitudinally stretching the cooled and formed base sheets through a two-way stretch device at the same time, so that the base sheet is stretched to form a diaphragm; 3, extracting out ore oil fromthe diaphragm with an alkane extractant by virtue of an extraction groove; 4, through a transverse stretch device, shaping, stretching and rectifying the diaphragm subjected to extraction, and ensuring the volatilization of the residual extract on the diaphragm; and 5, thermally treating the diaphragm. According to the invention, the defects that when the battery diaphragm is produced in the prior art, the equipment usage amount is large, the equipment cost is high, and the inferior-quality product incidence and production requirement of the prepared lithium ion battery diaphragm are high aresolved.

Owner:SHANGHAI QIANCHENG TOY TECH

Micro-flow control system, normally-closed micro-valve and control method

PendingCN108843855AThe production process is simpleReduce generation costValve arrangementsMicro valveEngineering

The invention discloses a micro-flow control system, a normally-closed micro-valve and a control method. The normally-closed micro-valve comprises a micro-flow pipeline which is formed inside a base body; a valve element is arranged inside the micro-flow pipeline and is used for dividing the micro-flow pipeline into a first pipeline and a second pipeline; when the valve element is molten or gasified, the first pipeline communicates with the second pipeline; the valve element and the wall of the micro-flow pipeline are made from the same material; and a transparent material is arranged betweenthe outer wall surface of the base body and the valve element. The micro-valve disclosed by the invention is simple in structure, can solve the problem of integration of the micro-valve and the micro-flow control system and greatly reduces the machining difficulty because the valve element and the wall of the micro-flow pipeline are made from the same material, so the production cost is lowered.

Owner:HUNAN LEGEND AI CHIP BIOTECH CO LTD

Antiwear close-packed armor roll surface

ActiveCN104525309AReduce hardness requirementsRaw material requirements are lowGrain treatmentsEngineeringHigh pressure

The invention discloses an antiwear close-packed armor roll surface, and belongs to the field of roller presses (high-pressure roller mills). The antiwear close-packed armor roll surface comprises a roll surface base body and an antiwear armor layer, wherein the antiwear armor layer is fixed on the roll surface base body and is composed of a plurality of armor units which are tightly arranged and are fixed on the roll surface base body through bolts; and each overall armor unit is a cone body and is composed of a regular hexagonal prism body on the upper part and a cone body on the lower part. The roll surface base body disclosed by the invention is not easy to wear; the demands on the materials and the processing equipments of the roll surface base body are reduced; the fabrication cost is reduced; the roll surface disclosed by the invention is good in wear resistance and long in service life; and a surface wear-resisting layer is not easy to wear, can be used at relatively high temperature and is easy to assemble and disassemble.

Owner:成都建筑材料工业设计研究院有限公司 +1

Preparation method for battery diaphragm

The invention provides a preparation method for a battery diaphragm. The preparation method for the battery diaphragm comprises the following steps in order: stirring, extruding, cooling and shaping, dual-direction stretching, extracting, transversely stretching and heat treating. A 6-micrometer ultra-thin battery diaphragm is prepared by the preparation method of the invention and has the advantages of high stability and long service life.

Owner:屠兆辉

Coating method, etching method and coating equipment for metal strip for etching

ActiveCN106283054BReduce the ratioLow environmental requirementsLaminationLamination apparatusEngineeringFilm-coated tablet

The invention relates to an etching technology and provides a film covering method of metal strip for etching, an etching method and film covering equipment. The film covering method comprises steps of film covering, first die cutting, first demoulding, second film covering, second die cutting, third film covering, fourth film covering and second demoulding. The film covering equipment comprises a first film covering device, a first die cutting device, a first demoulding device, a second film covering device, a second die cutting device, a third film covering device, a fourth film covering device and a second demoulding device sequentially arranged and enabling metal strip to continuously move. According to the invention, the following steps are finished in sequence: the metal strip is coated with an adhesive film, the adhesive film on an etching area of the metal strip can be mechanically removed, a non-etching area is protected, and the etching area is in direct contact with etching liquid, so that labor force is saved, the processing cycle is shortened, proportion of a chemical reagent is reduced, requirements for the environment and the raw material are lowered, reliability of the non-etching area is improved, and the production efficiency is greatly improved.

Owner:深圳臻金精密科技有限公司

A 3D printing method for laser selective solidification of metal

ActiveCN110842204BEasy to useIncrease profitAdditive manufacturing apparatusIncreasing energy efficiencyHigh densityPhysical chemistry

The invention provides a 3D printing method for selective laser solidification of metal, which belongs to the technical field of 3D printing forming. Firstly, the metal powder is mixed with the liquid photosensitive resin, and then a dispersant is added to the slurry to adjust the rheological properties of the slurry to prepare a photosensitive slurry with an appropriate solid phase volume fraction and good rheological properties. The 3D printing device is used to extrude the slurry from a nozzle with a certain diameter; at the same time, in the process of slurry streamline extrusion, dispersion and accumulation, a fine laser beam selection is used to scan synchronously on the slurry streamline plane, making it Partial rapid solidification forming, reciprocating, so that the forming of metal parts of a certain shape can be realized. The invention can directly form high-precision metal parts, has high forming speed, high part strength, uniform density, low cost and no special requirements on working environment.

Owner:UNIV OF SCI & TECH BEIJING

Robot flexible foot

ActiveCN114435505ASimple structureReduce processing costsVehiclesPhysical medicine and rehabilitationElectric machinery

The invention discloses a flexible foot of a robot, which solves the problem that the foot of the robot is in rigid contact with the ground, and comprises an ankle, a foot surface, a sole, a first connecting part, a second connecting part and a driving device, the ankle is provided with a foot kinematic pair and a driving part; the ankle, the foot surface, the first connecting part, the sole and the second connecting part are sequentially connected end to end, at least one of the foot surface, the first connecting part, the sole and the second connecting part is an elastic plate, and the elastic plate is fixedly connected with an adjacent component at one end of the elastic plate, so that the flexible foot forms a planar four-bar mechanism; the driving device acts on the driving part to drive the flexible foot to move around the foot kinematic pair, and the purpose that the foot of the robot makes elastic contact with the ground to reduce impact on an ankle motor is achieved.

Owner:ZHEJIANG LAB

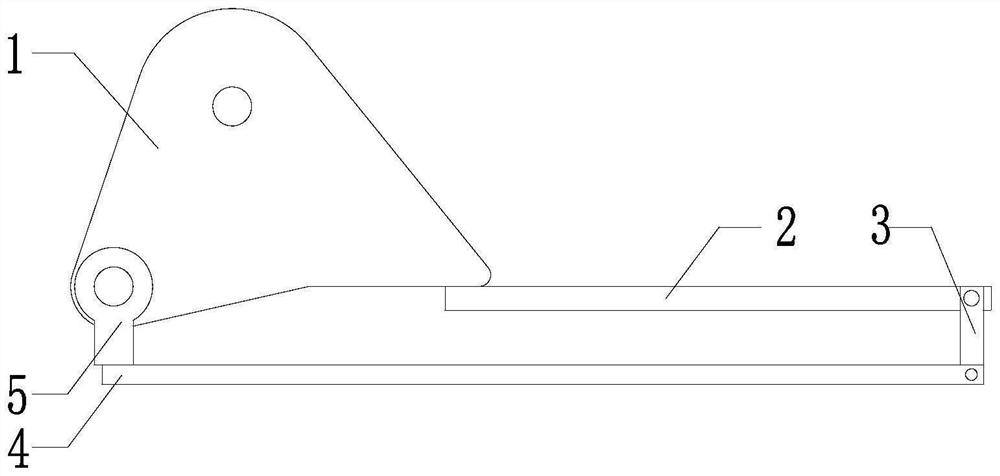

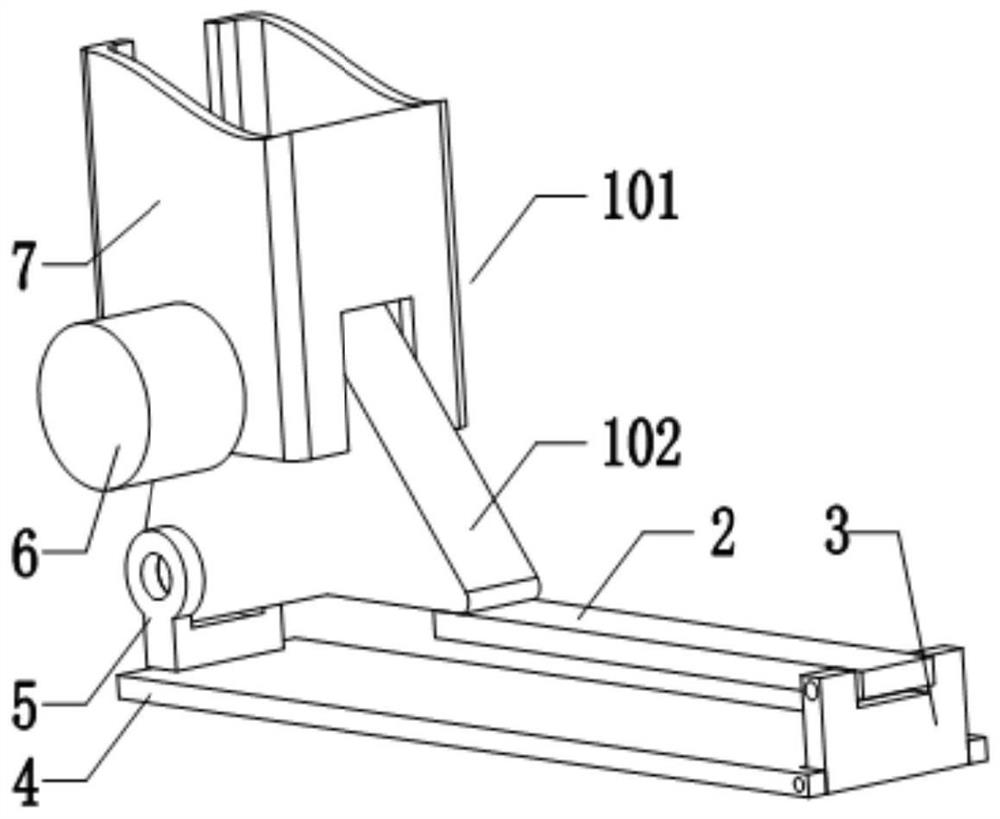

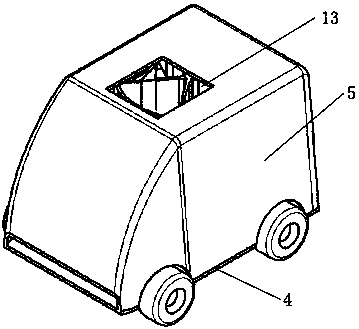

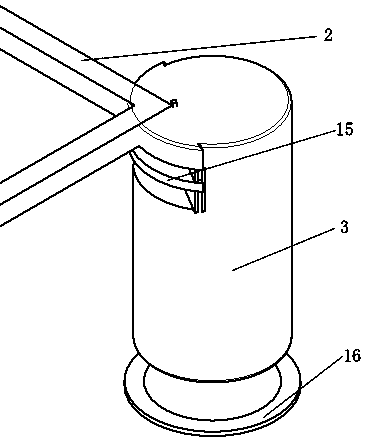

Portable automatic paper board cutting machine

The invention relates to a portable automatic paper board cutting machine. The portable automatic paper board cutting machine is composed of a paper cutting trolley and a paper board installing frame;a tool base is rotationally arranged on a bottom plate of the paper cutting trolley, and can rotate to switch a tool position, and up and down reciprocating movement of a tool is achieved due to camrotation; under control of a control system, cutting on a paper board can be automatically completed; the volume is small, the structure is simple, use in a family, a school, an office and other places is convenient, the cutting efficiency is high, and cutting types are diverse; the paper board installing frame can stretch out and draw back, so that adaptability to paper boards in different specifications is achieved; and requirements for a paper board raw material are low, no customized paper board is not needed, recycling and utilizing of the paper board are facilitated, and environment protecting and energy saving are achieved. According to the paper board cutting machine, due to connection of the control system, a network terminal and a database, resource sharing can be achieved, the information interactive capacity is high, and communication and sharing between users are facilitated.

Owner:HEFEI UNIV OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com