Method for manufacturing PLC (Programmable Logic Controller) device

A manufacturing method and device technology, applied to optical elements, light guides, optics, etc., can solve the problems of high raw material requirements, difficult manufacturing, high maintenance costs, etc., and achieve the effect of low production equipment requirements, low raw material efficiency, and reduced production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

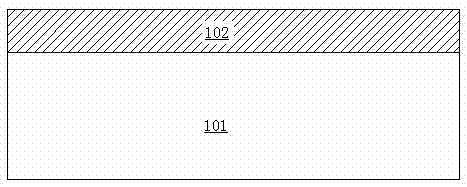

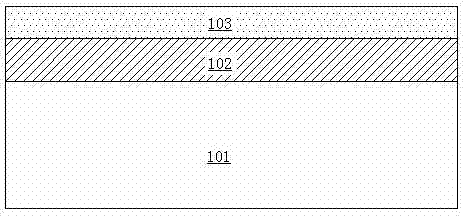

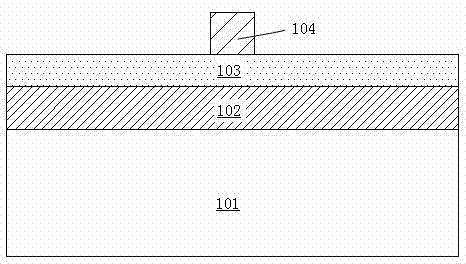

[0026] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments. In the drawings, for the convenience of illustration, the thicknesses of layers and regions are enlarged or reduced, and the sizes shown do not represent actual sizes. Although these figures do not fully reflect the actual size of the device, they still completely reflect the mutual positions between the regions and the constituent structures, especially the upper-lower and adjacent relationships between the constituent structures. Meanwhile, in the following description, the term substrate used can be understood to include the semiconductor substrate being processed, possibly including other thin film layers prepared thereon.

[0027] Figure 6 It is a schematic diagram of an embodiment of the optical waveguide provided by the present invention, and the direction indicated by CD is the light propagation direction in the silica optical ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com