Portable automatic paper board cutting machine

A portable, cardboard machine technology, applied in metal processing and other directions, can solve the problems of inability to achieve design creativity sharing, unfavorable reuse of recycled cardboard, inconvenience for personal or family use, etc., to achieve convenient communication and sharing, high cutting efficiency, and simple structure. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

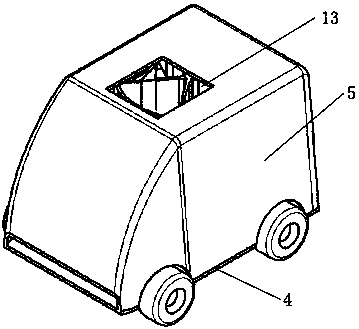

[0044] The invention is a portable automatic cardboard cutting machine, which is used for self-made cardboard works, such as figure 1 As shown, it includes a cardboard placement frame, a paper cutting vehicle 1 and a control system (not shown in the figure), the cardboard positioning frame is used for clamping the cardboard to be cut, and the paper cutting vehicle 1 is located under the cardboard positioning frame.

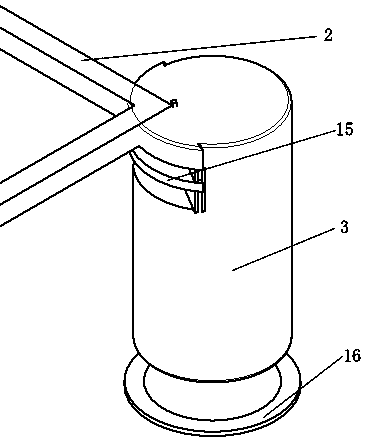

[0045] The paper cutting vehicle 1 can move below the cardboard placement frame to realize cutting of the cardboard. like figure 2 As shown, the paper cutting vehicle 1 includes a base plate 4 and a carriage 5 arranged on the base plate 4. The carriage 5 is a shell with a cavity as a whole and is fixed on the base plate 4. The carriage 5 can be arranged in the shape of a cuboid, or it can be placed close to The front w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com