Superhard amorphous state ceramic silica gel and preparation method thereof as well as composition used for preparing superhard amorphous state ceramic silica gel

An amorphous and ceramic technology, applied in the field of high-temperature-resistant materials, can solve problems such as obstacles to the promotion and use of fire-resistant cables and large-scale production, unfavorable promotion and use of fire-resistant cables and large-scale production, and increased production costs and production cycles of fire-resistant cables. , to achieve the effects of large-scale production and popularization, convenient and low-cost preparation, and convenient production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

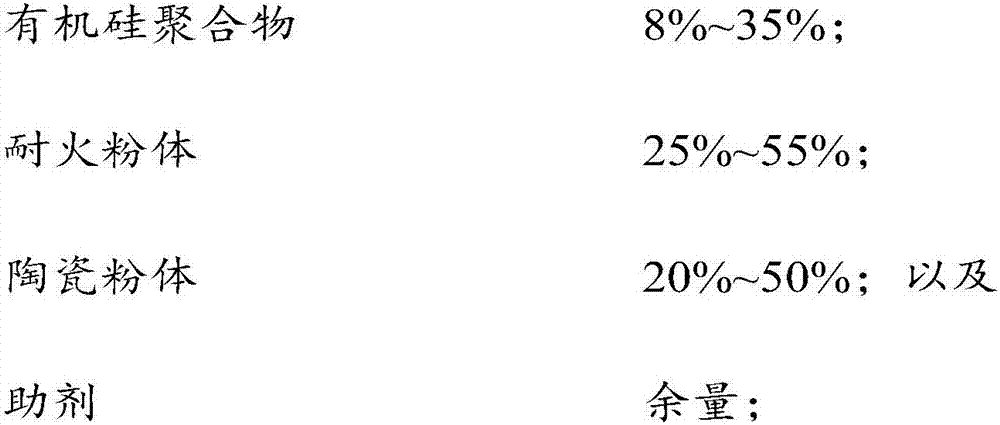

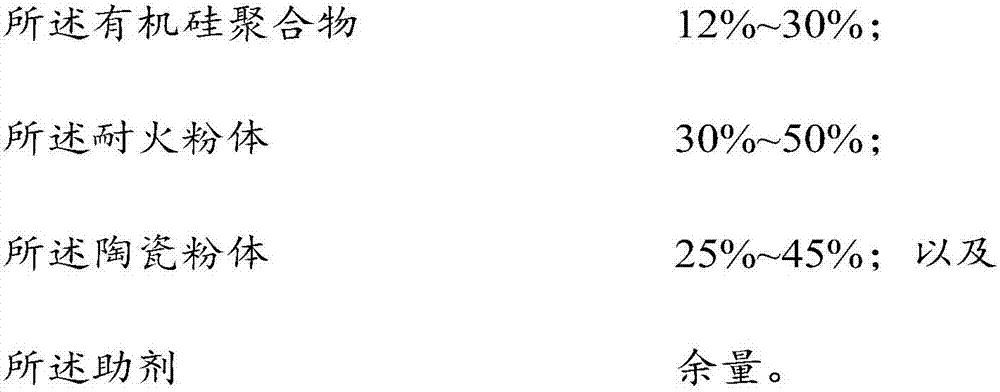

Method used

Image

Examples

preparation example Construction

[0030] The embodiment of the present invention also provides a method for preparing the above-mentioned superhard amorphous ceramicized silica gel, which comprises: heating and molding a mixture of refractory powder, ceramic powder, organic silicon polymer and auxiliary agent.

[0031] It should be noted that after heating and molding, in the state of a mixture of refractory powder, ceramic powder, organosilicon polymer and additives, the coupling agent couples the organosilicon polymer to form a spatial network structure. The refractory powder and ceramic powder are tightly connected together. After heating and forming, the reticulated silicone polymer is solidified and formed, so that the super-hard amorphous ceramized silica gel forms a stable and extremely strong spatial network skeleton, and each component is tightly connected and embedded in the spatial network 状架中。 In the framework. This makes the strength, high temperature resistance and high temperature stability of the ...

Embodiment 1

[0046] This embodiment provides a composition for preparing superhard amorphous ceramicized silica gel, which includes:

[0047] 20g vinyl polysiloxane;

[0048] 27g of alumina powder, 27g of aluminum hydroxide powder;

[0049] 9g of silica powder

[0050] 0.2g of coupling agent LD-70.

[0051] Among them, the average particle size of the alumina powder is 35 μm, the average particle size of the aluminum hydroxide powder is 4.7 μm, and the average particle size of the silica powder is 10 μm.

Embodiment 2

[0053] This embodiment provides a composition for preparing superhard amorphous ceramicized silica gel, which includes:

[0054] 20g vinyl polysiloxane, 0.08g polymethylhydrogensiloxane;

[0055] 15g of alumina powder, 30g of aluminum hydroxide powder;

[0056] 18g of silica powder;

[0057] 0.2g of coupling agent LD-70.

[0058] Among them, the average particle size of the alumina powder is 35 μm, the average particle size of the aluminum hydroxide powder is 4.7 μm, and the average particle size of the silica powder is 10 μm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Mohs hardness | aaaaa | aaaaa |

| Mohs hardness | aaaaa | aaaaa |

| Mohs hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com