Method and system for preparing dynamic lithium ion battery diaphragm

A technology of lithium-ion batteries and diaphragms, which is applied to battery components, circuits, electrical components, etc., can solve the problems of high production requirements, high equipment costs, and large equipment usage, and achieve the requirements of reducing production technology and improving technology. Level, energy saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

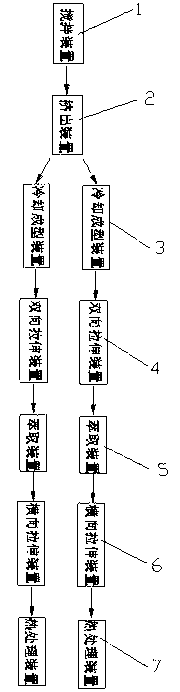

[0055] The utility model provides a preparation method of a power lithium-ion battery diaphragm, which comprises the following steps:

[0056] 1. Add ultra-high molecular polyethylene, antioxidant and mineral oil into the mixer in a certain proportion to fully stir the raw materials;

[0057] 2. Put the mixture stirred in step 1 into a twin-screw extruder to heat and extrude continuously to form a substrate;

[0058] 3. The substrate extruded from the twin-screw extruder is divided into the first processing line and the second processing line for simultaneous processing;

[0059] 4. Processing of substrates entering the first processing line:

[0060] (1) The substrate entering the first processing line is cooled and formed by a set of cooling rollers;

[0061] (2) Stretch the cooled and formed substrate in both horizontal and vertical directions simultaneously through biaxial stretching equipment, so that the substrate can be stretched into a diaphragm;

[0062] (3) Use an a...

Embodiment 1

[0072] Embodiment 1, the steps of a lithium-ion battery diaphragm preparation method in this embodiment are as follows:

[0073] 1. Add ultra-high molecular weight polyethylene, antioxidant and mineral oil into the mixer in a certain proportion to fully stir the raw materials. Among them, the mass ratio of mineral oil to antioxidant is 1000~2000:1, mineral oil and The mass ratio of UHMWPE is 2~10:1.

[0074] The ultrahigh molecular weight polyethylene in this example has a molecular weight of 1 million or more.

[0075] 2. Put the mixture stirred in step 1 into a twin-screw extruder to heat and extrude continuously to form a substrate.

[0076] Here, the screw diameter of the twin-screw extruder is 10-150 mm, and its extrusion capacity is greater than 200 kg per hour.

[0077] 3. The substrate extruded from the twin-screw extruder is divided into the first processing line and the second processing line for simultaneous processing.

[0078] 4. Processing of substrates enteri...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com