Method for preparing nano lithium manganese phosphate material with uniform size

A lithium manganese phosphate, size technology, applied in the direction of nanotechnology, nanotechnology, nanotechnology for materials and surface science, etc., can solve the problem of large particle size distribution range, and achieve simple equipment, environmental friendliness, and low energy consumption Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0017] 0.08mol of H 3 PO4 is dissolved in a mixed solvent of PEG-400 and distilled water, the volume of PEG-400 is 80mL, the volume ratio of organic solvent to water is 1, H 3 PO 4 The concentration of oleic acid is 0.5mol / L, add LiOH until the pH value of the solution is 9.5, then add 0.032mol oleic acid and stir evenly, the concentration of oleic acid is 0.2mol / L, then add 0.08mol of MnSO 4 , MnSO 4 The concentration of the above solution is 0.5mol / L, transfer the above solution to the reaction kettle, conduct hydrothermal crystallization reaction at 210°C for 5h, open the kettle after cooling at room temperature, centrifuge, wash with deionized water and alcohol for 3 times respectively, at 50 The product was obtained by drying at ℃, and the prepared nano-LiMnPO 4 The scanning electron microscope photograph of the material is as figure 1 As shown, it shows that the prepared product has a uniform size smaller than 40nm.

Embodiment 2

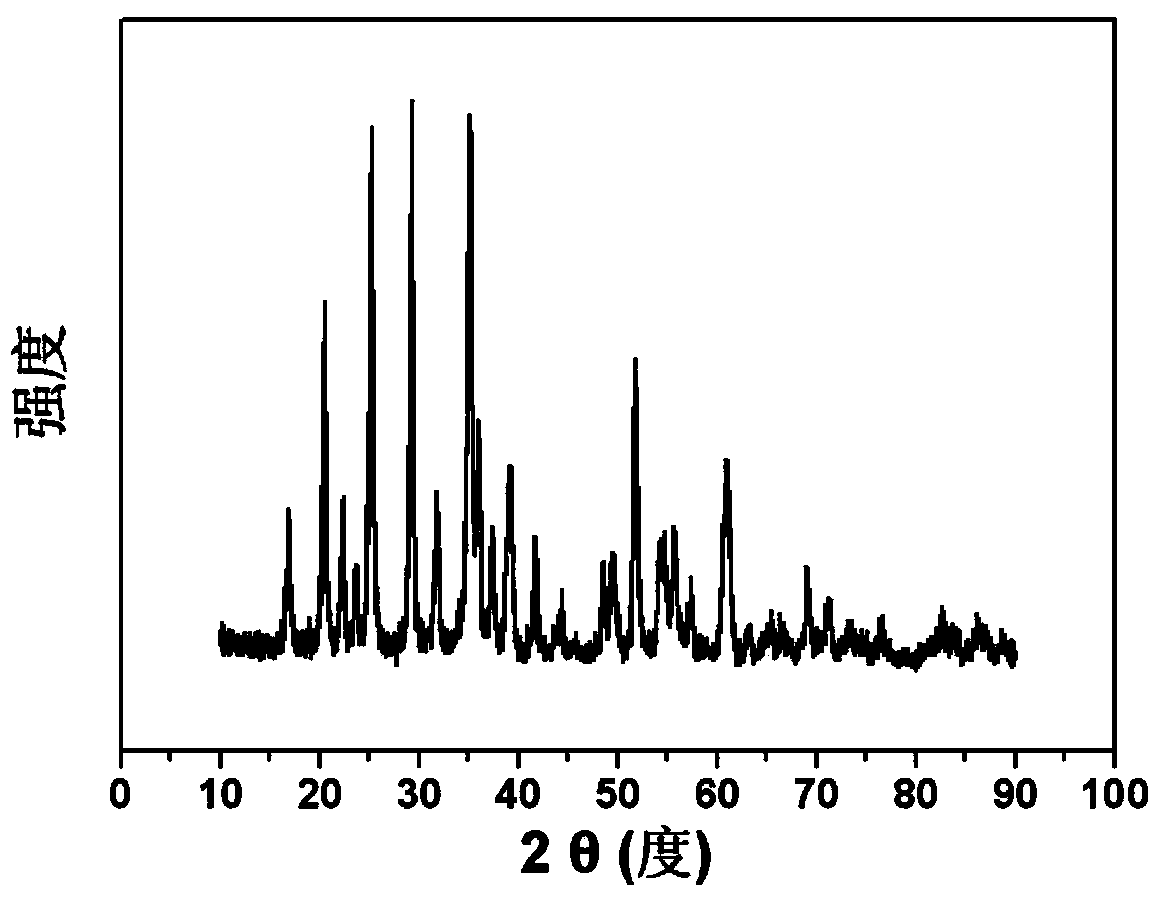

[0019] 0.015mol of H 3 PO4 is dissolved in a mixed solvent of PEG-400 and distilled water, the volume of PEG-400 is 60mL, the volume ratio of organic solvent to water is 0.5, H 3 PO 4 The concentration of oleic acid is 0.08mol / L, add LiOH until the pH value of the solution is 12.5, then add 0.0075mol oleic acid and stir evenly, the concentration of oleic acid is 0.04mol / L, then add 0.015mol of MnSO 4 , MnSO 4 The concentration of the solution is 0.08mol / L, the above solution is transferred to the reaction kettle, and the hydrothermal crystallization reaction is carried out at 140°C for 12 hours. After cooling at room temperature, the kettle is opened, centrifuged, washed with deionized water and alcohol for 3 times, and at 70 The product was obtained by drying at ℃, and the prepared nano-LiMnPO 4 The X-ray diffraction pattern of the material is as figure 2 As shown, the description has a pure composition and a small particle size.

Embodiment 3

[0021] 0.018mol of H 3 PO4 is dissolved in a mixed solvent of PEG-400 and distilled water, the volume of PEG-400 is 100mL, the volume ratio of organic solvent to water is 0.2, H 3 PO 4 The concentration of oleic acid is 0.03mol / L, add LiOH until the pH value of the solution is 13, then add 0.012mol oleic acid and stir evenly, the concentration of oleic acid is 0.02mol / L, then add 0.018mol of MnSO 4 , MnSO 4 The concentration of the above solution is 0.03mol / L, the above solution is transferred to the reaction kettle, and the hydrothermal crystallization reaction is carried out at 90 ℃ for 30 hours. The product was obtained by drying at ℃, and the prepared nano-LiMnPO 4 The transmission electron microscope photographs of the material are as image 3 As shown, it shows that the prepared product has a uniform size smaller than 40nm.

[0022] It can also be clearly seen from the accompanying drawings of the above embodiments that the product prepared by the present invention ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com