Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

32 results about "Thermal dissociation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Thermal Dissociation. a chemical reaction in which a substance decomposes reversibly when the temperature is raised. A substance undergoing thermal dissociation may form several substances (2H2 O ⇄ 2H 2 + O 2, CaCO3 ⇄ CaO + CO 2) or a single, simpler substance (N 2 O 4 ⇄ 2NO2, Cl 2 ⇄ 2C1). In thermal dissociation,...

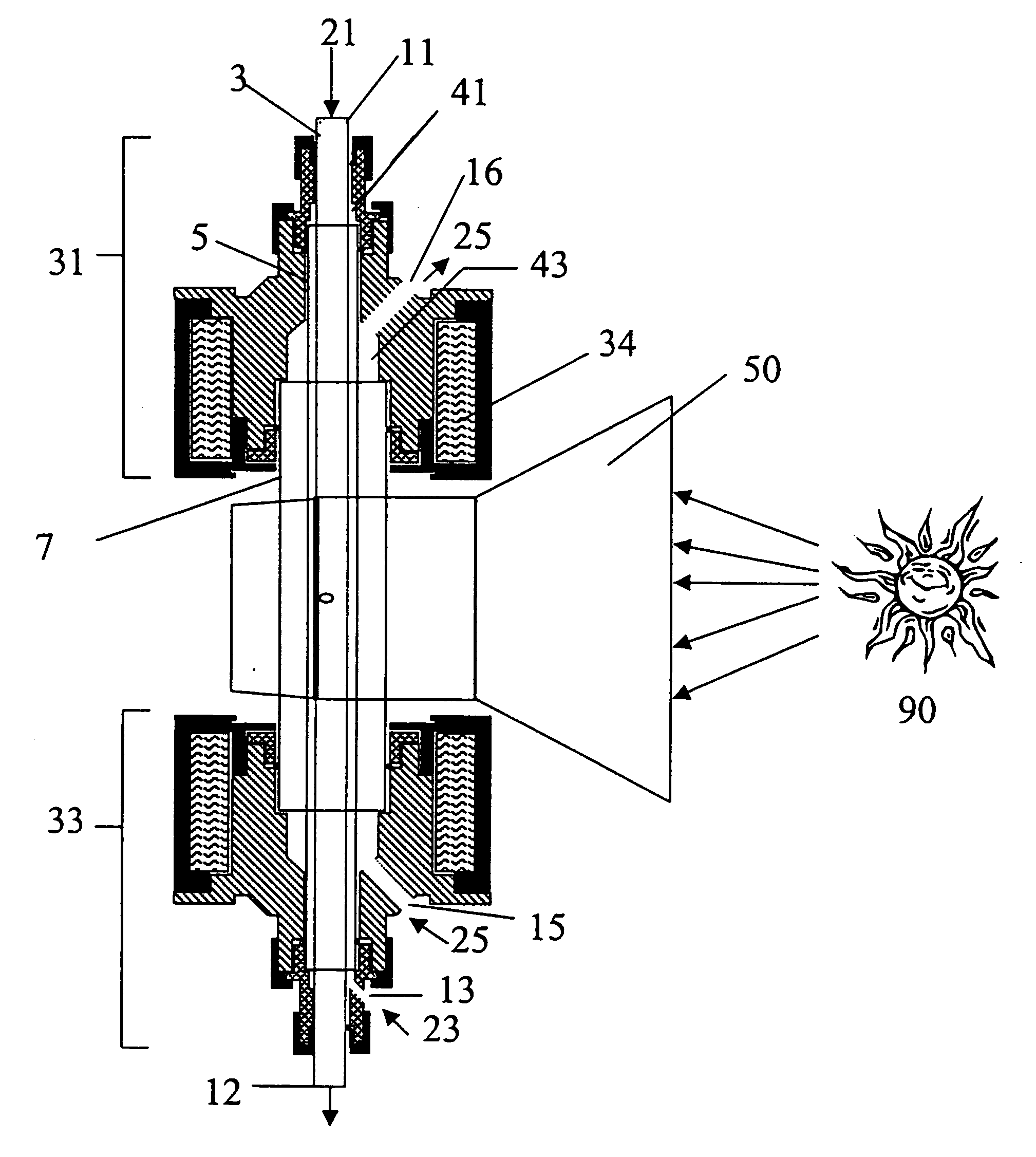

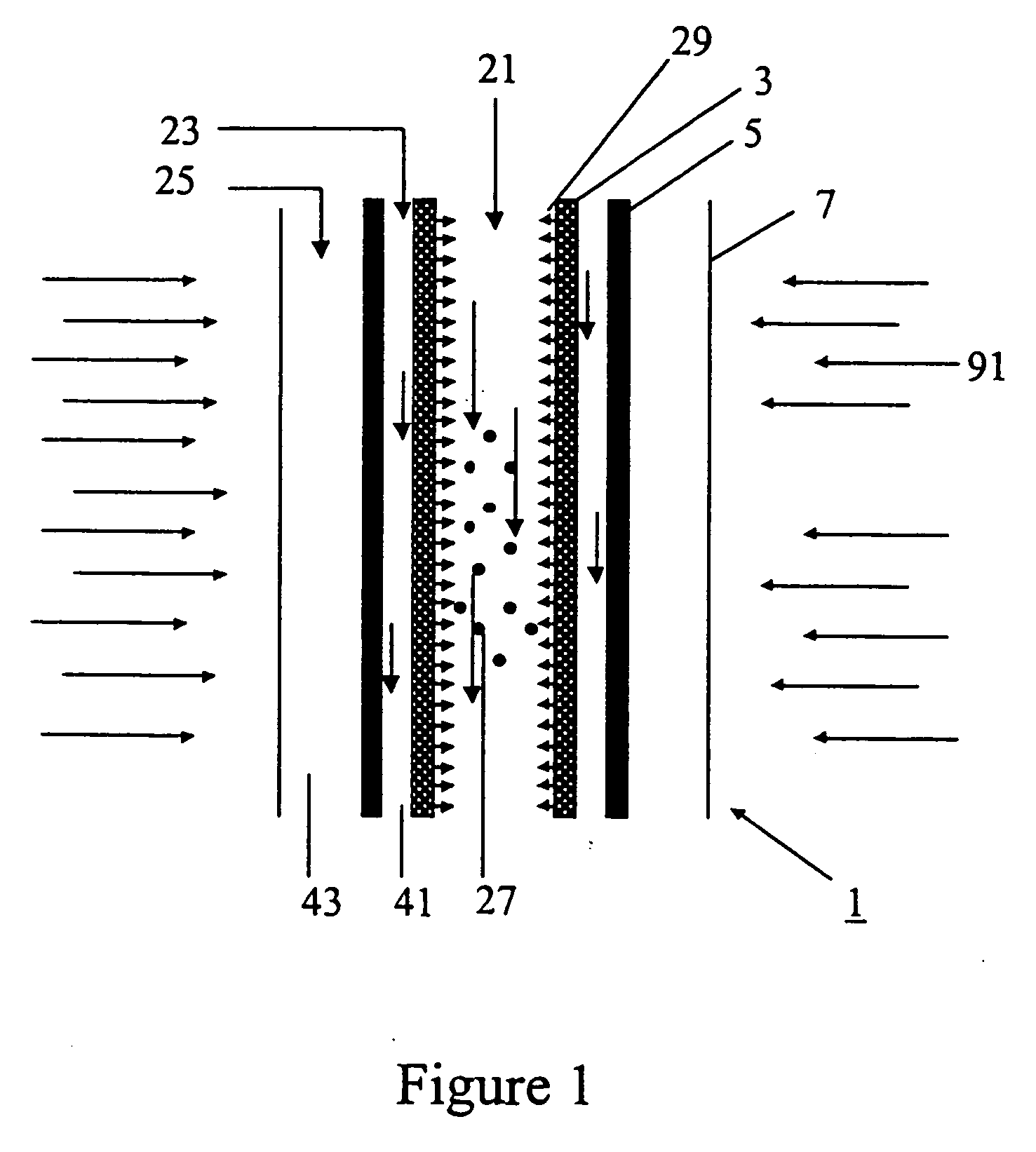

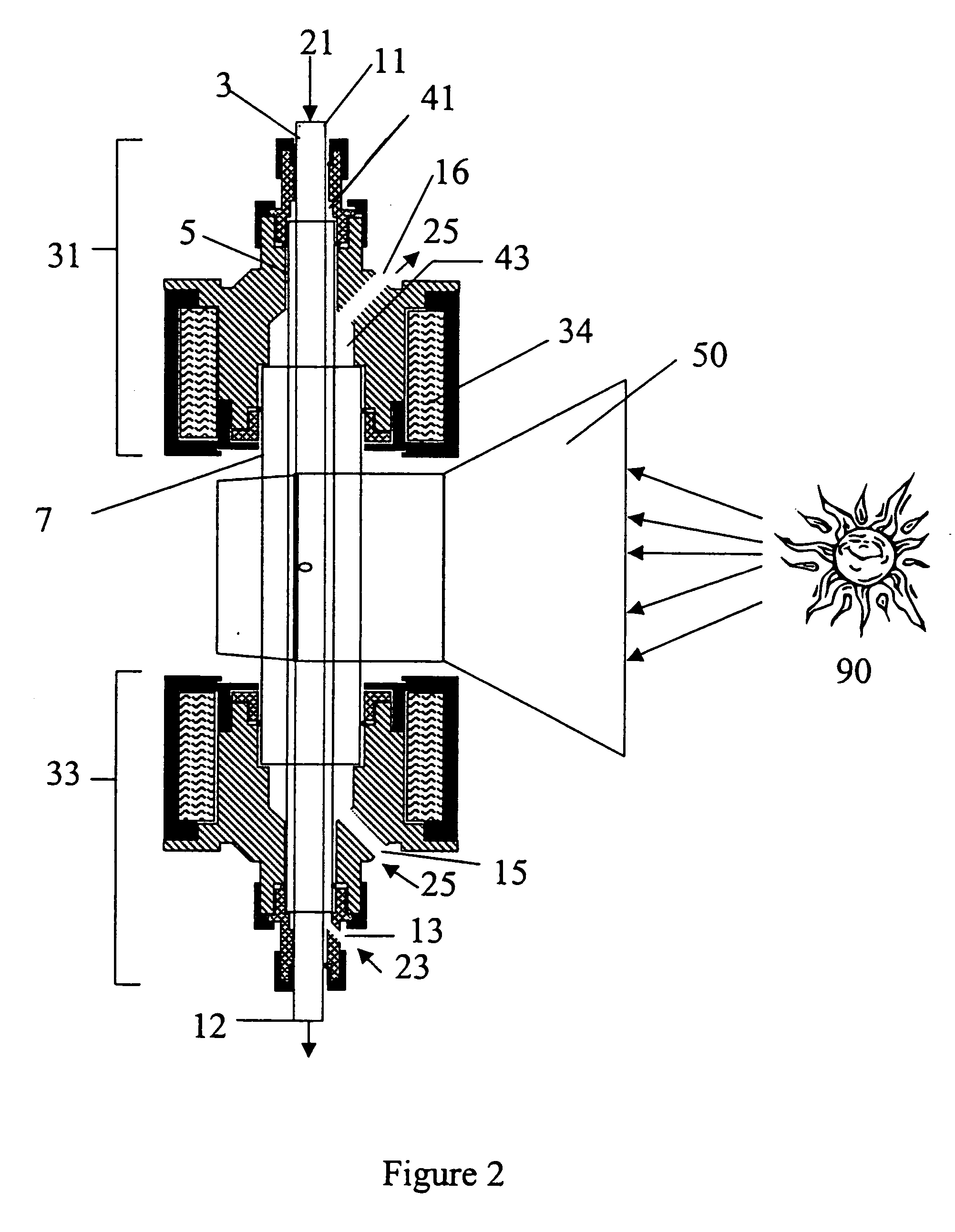

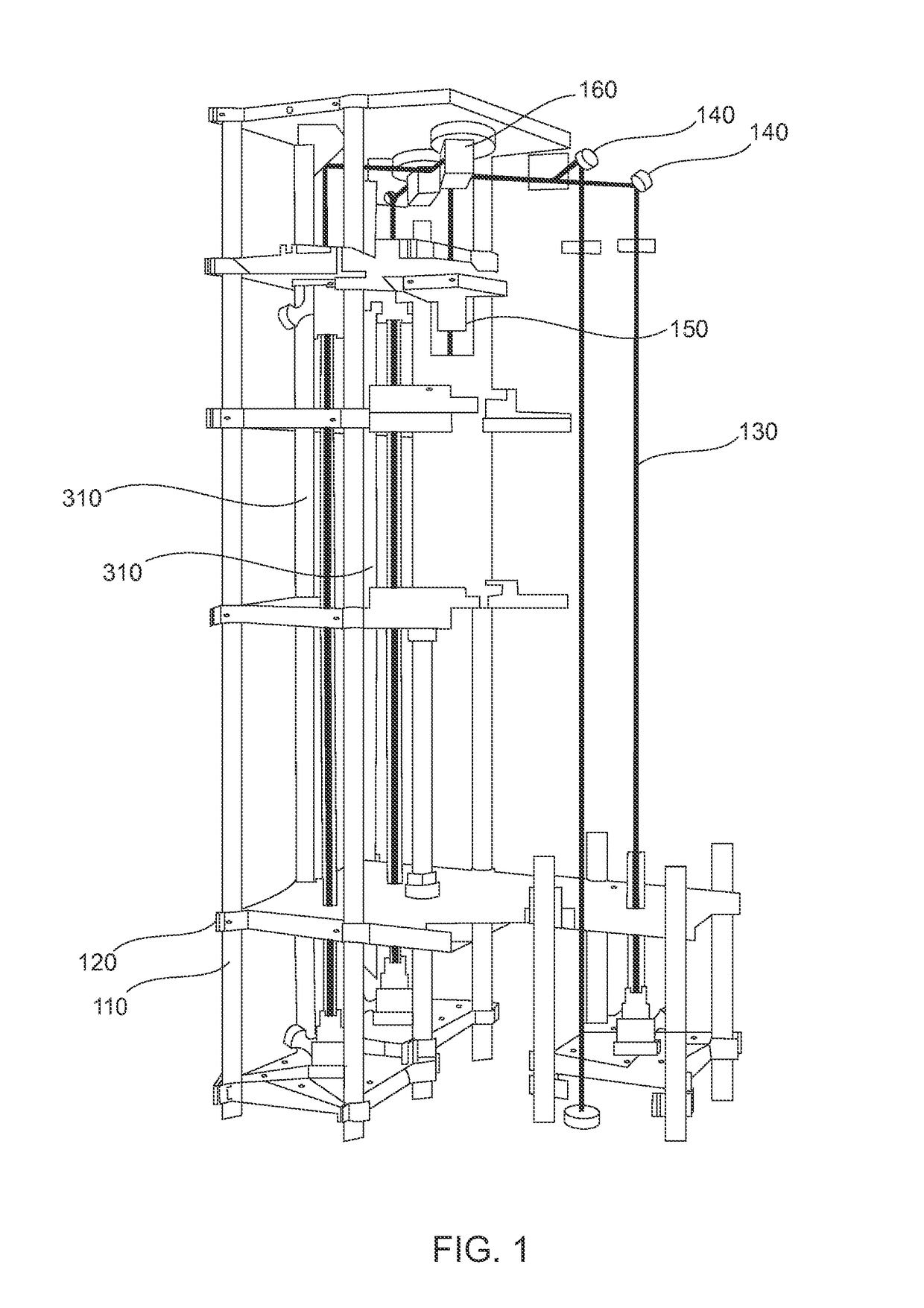

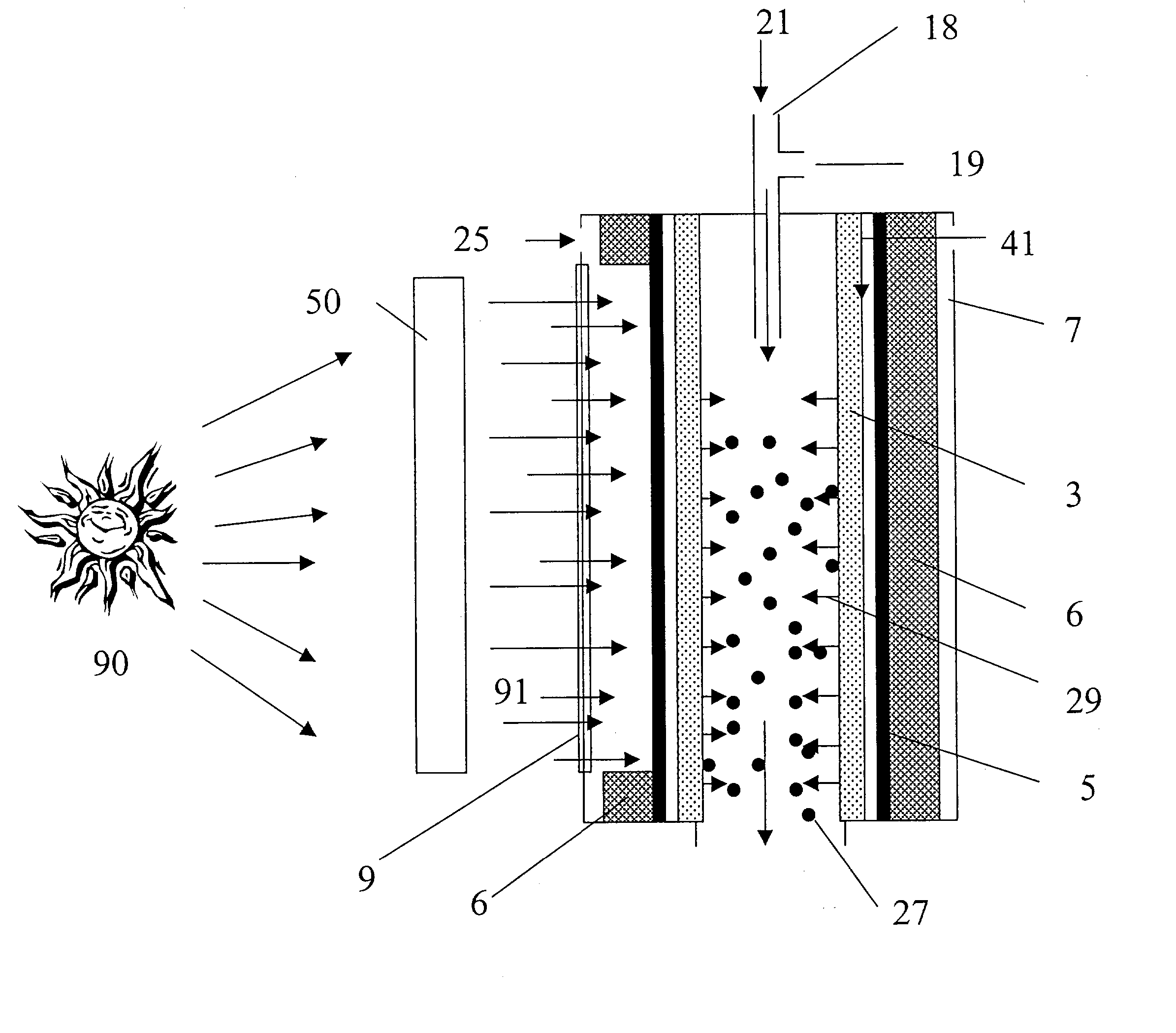

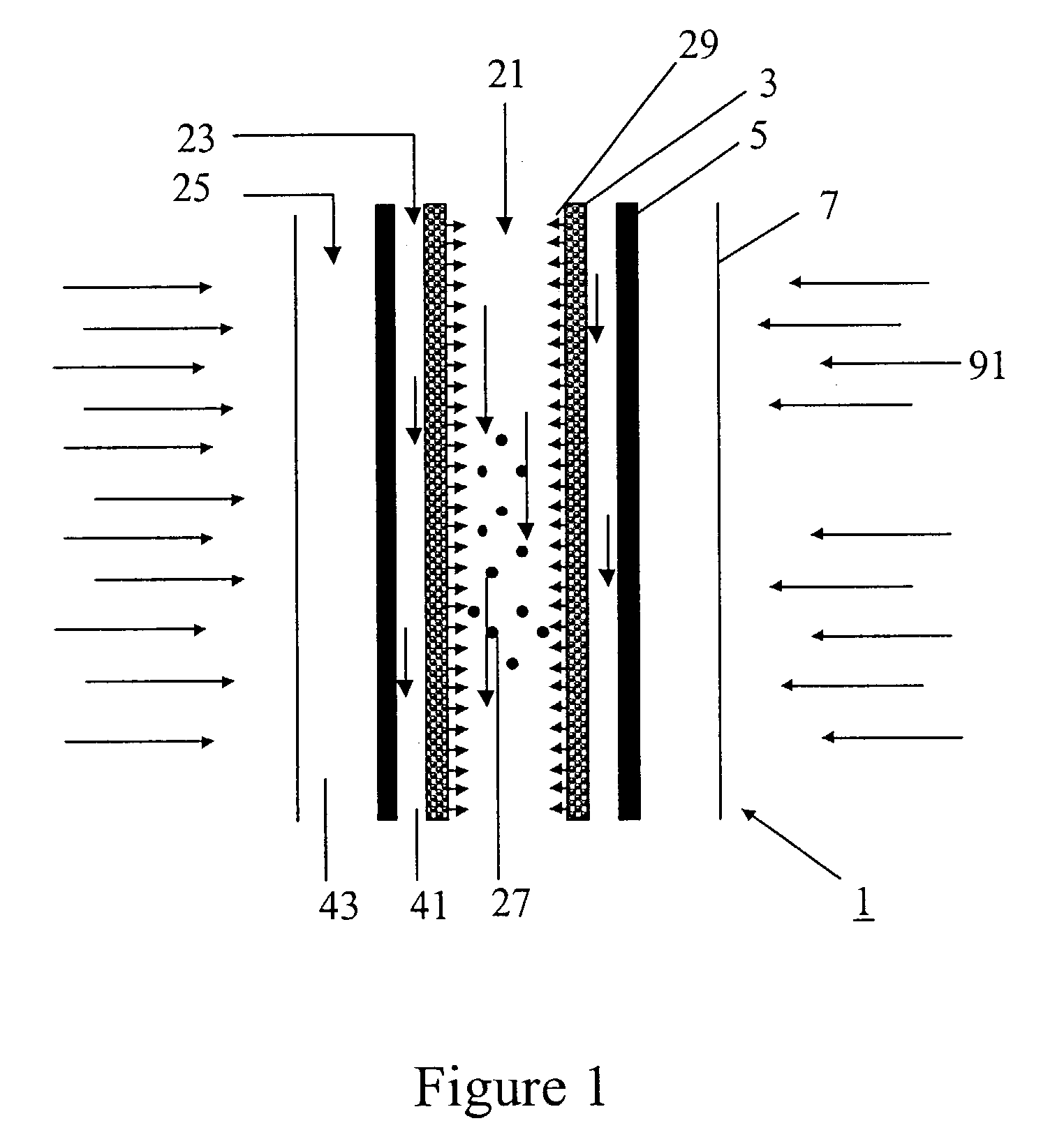

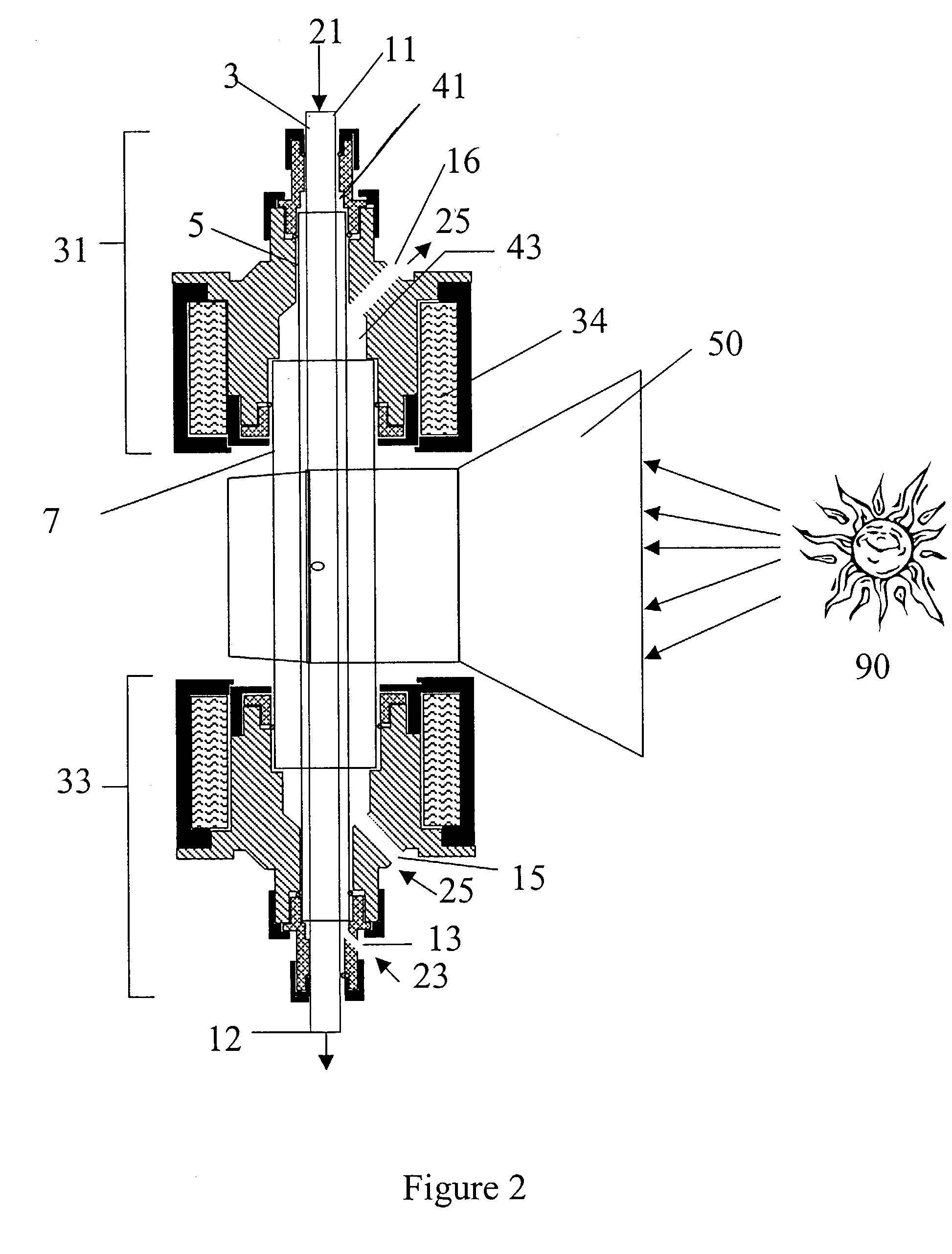

Solar-thermal fluid-wall reaction processing

InactiveUS7033570B2Reduce and preventShort stayThermal non-catalytic crackingSolar heating energyHydrogenReactor system

The present invention provides a method for carrying out high temperature thermal dissociation reactions requiring rapid-heating and short residence times using solar energy. In particular, the present invention provides a method for carrying out high temperature thermal reactions such as dissociation of hydrocarbon containing gases and hydrogen sulfide to produce hydrogen and dry reforming of hydrocarbon containing gases with carbon dioxide. In the methods of the invention where hydrocarbon containing gases are dissociated, fine carbon black particles are also produced. The present invention also provides solar-thermal reactors and solar-thermal reactor systems.

Owner:ALLIANCE FOR SUSTAINABLE ENERGY +1

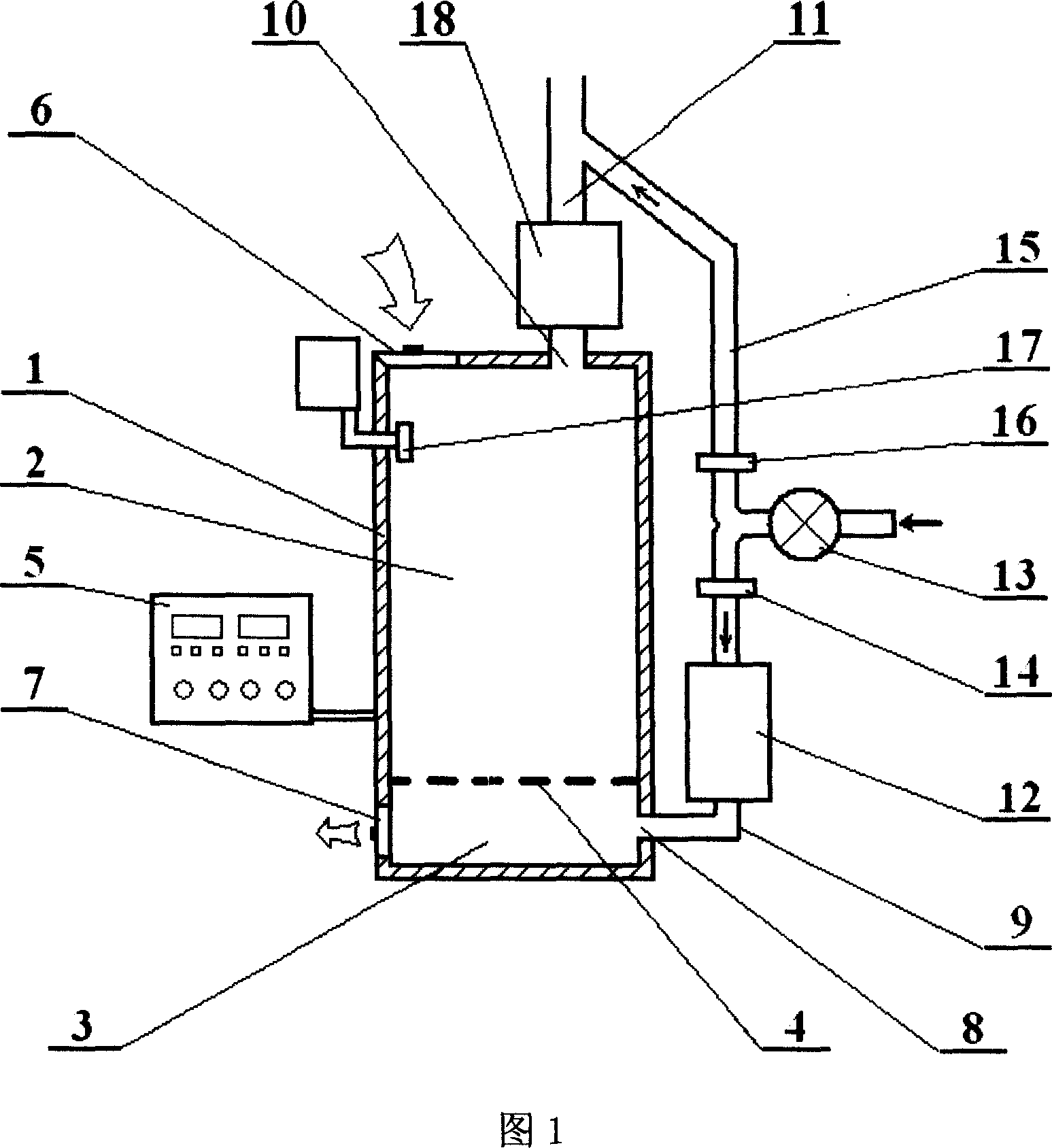

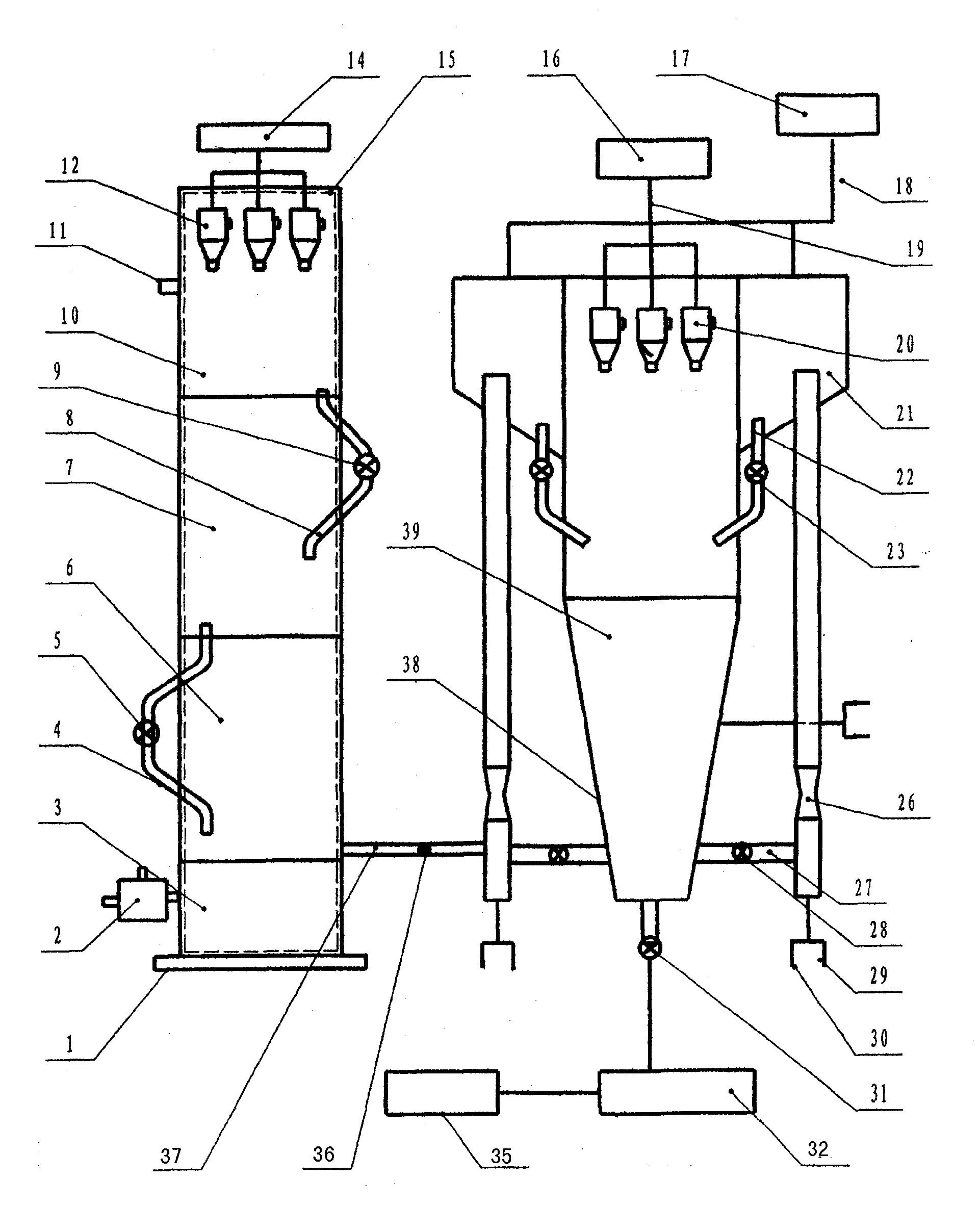

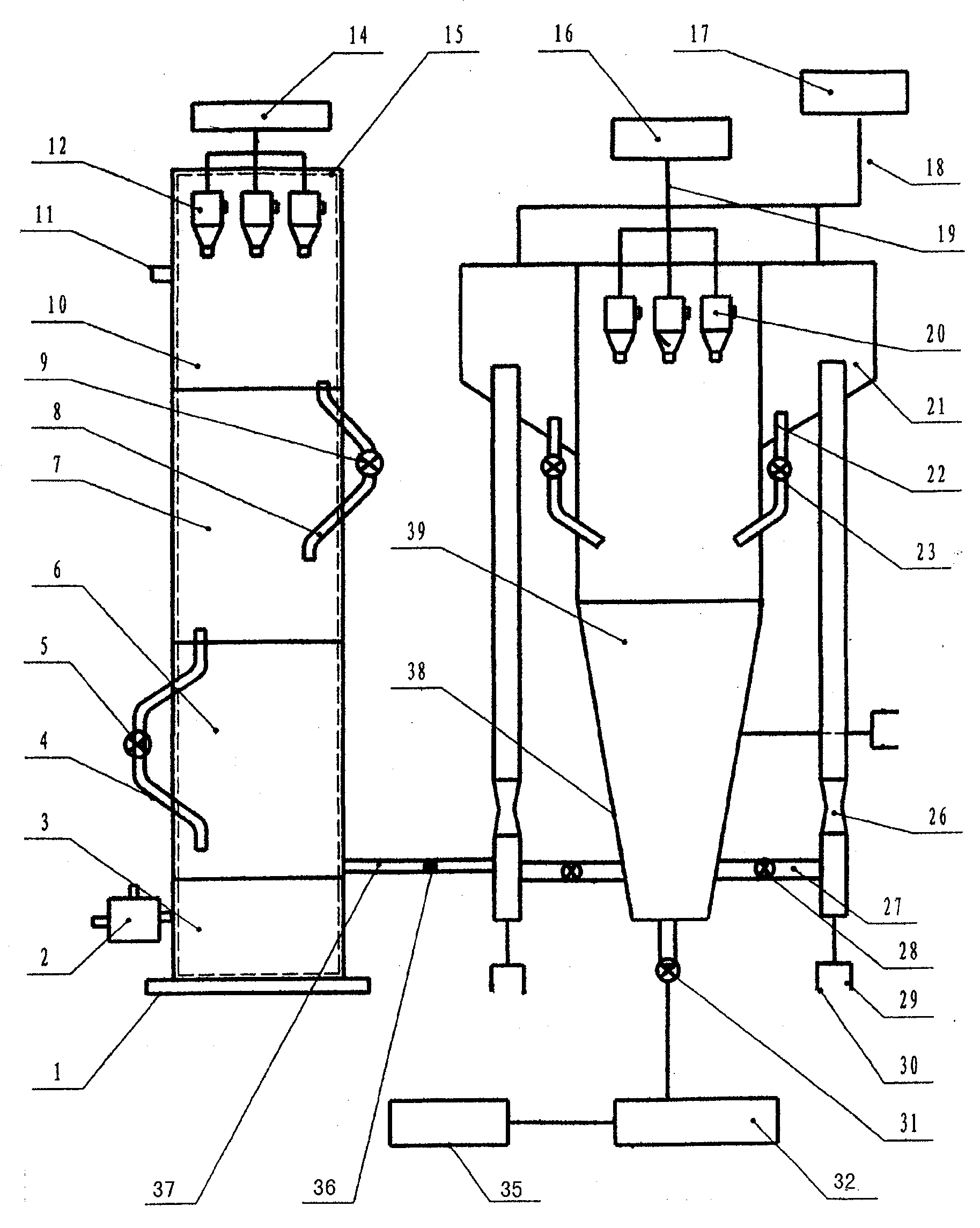

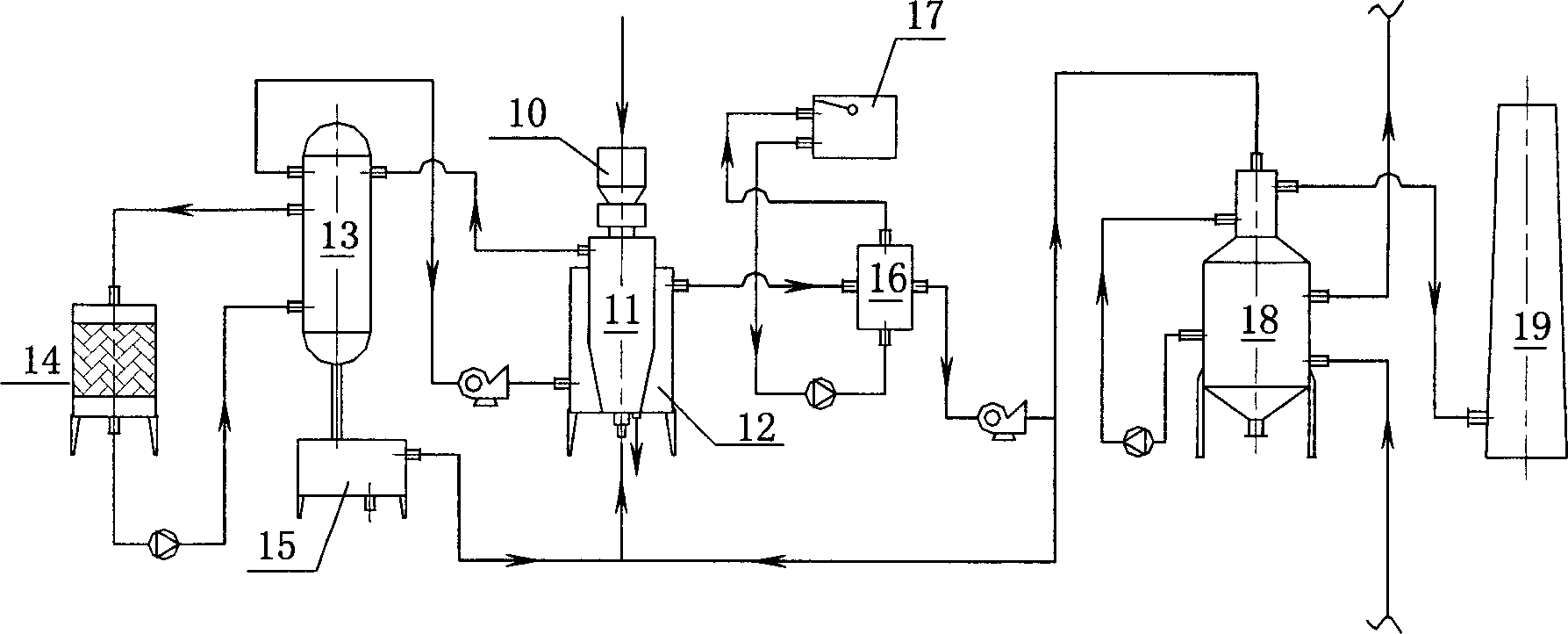

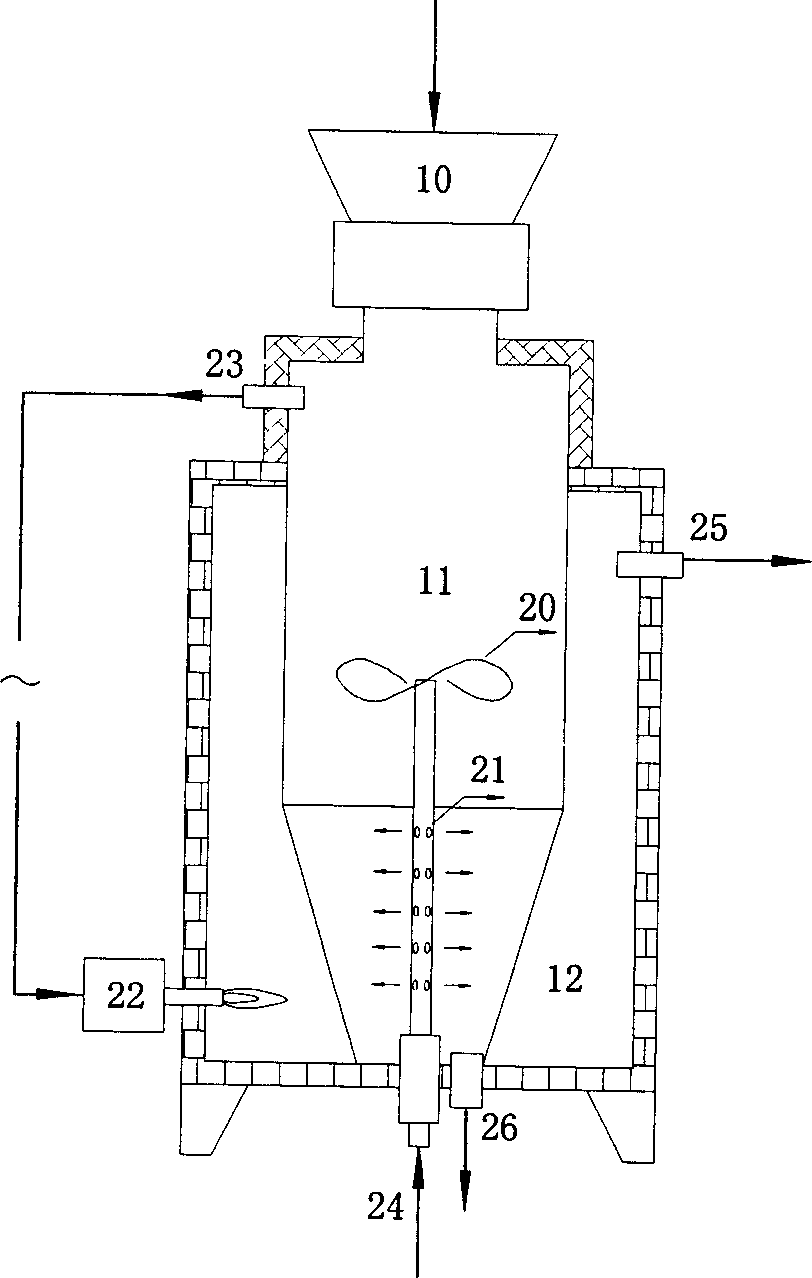

Device and method for suppressing refuse end gas injurant using pyrolysis and aerification technology

InactiveCN1769397ANo emissionsPrevent gasificationThermal non-catalytic crackingSolid waste disposalThermal dissociationVaporization

Owner:TIANJIN UNIV

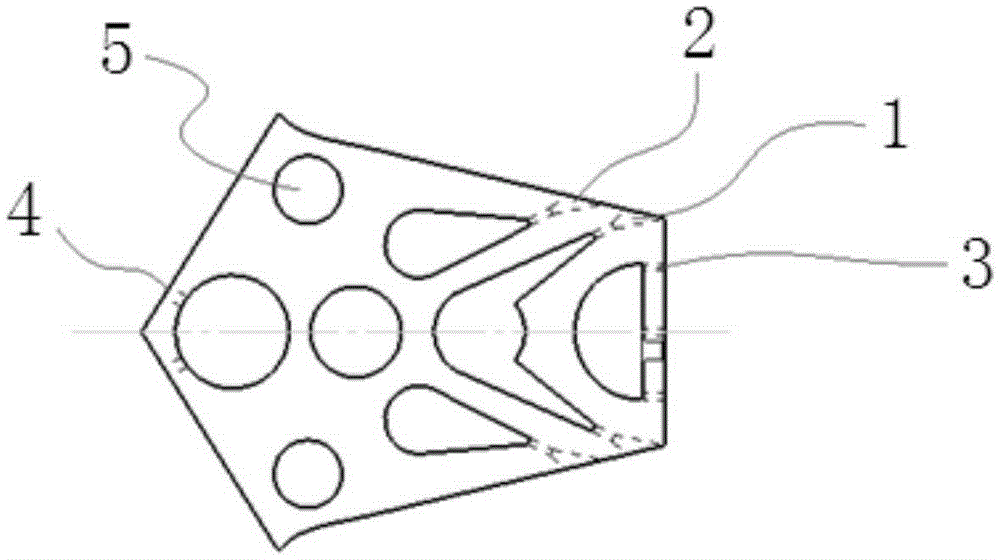

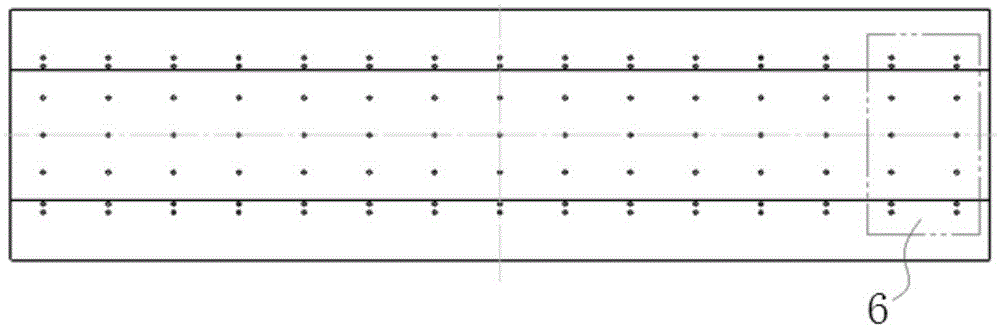

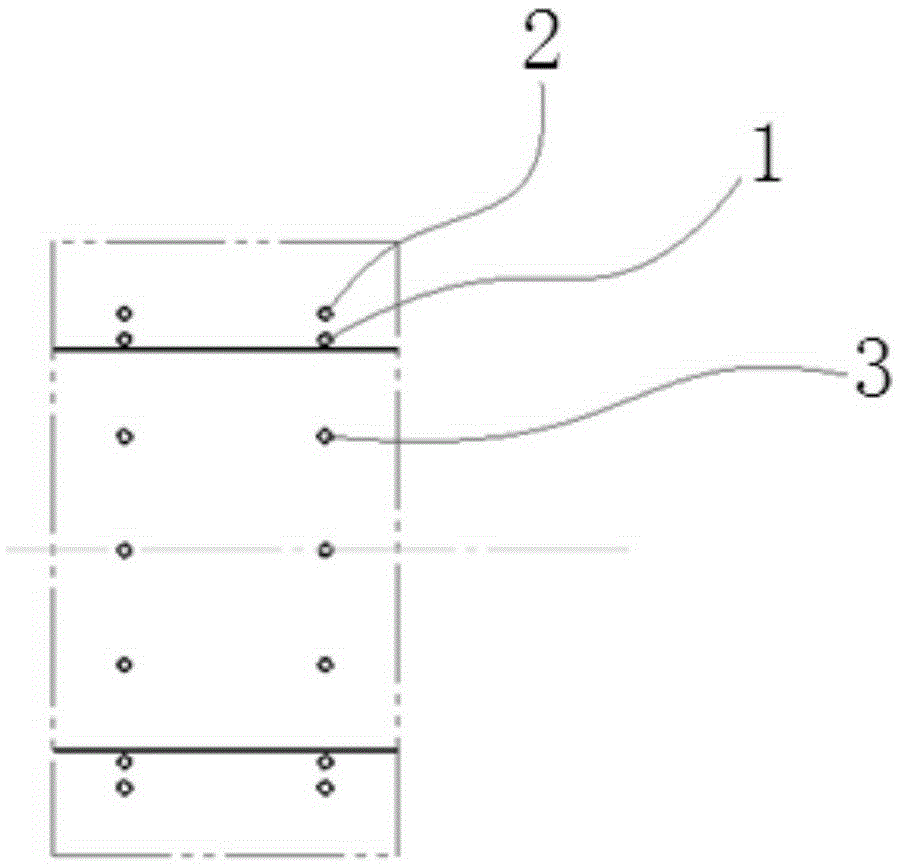

[non-volatile memory cell and fabrication thereof]

A non-volatile memory cell is described. The non-volatile memory cell comprises a substrate, a charge-trapping layer, a gate and a source / drain. The charge-trapping layer comprises an insulating layer and metal nano-particles contained therein, wherein the metal nano-particles are formed with thermal dissociation of an oxide of the same metal. The gate is disposed on the charge-trapping layer, and the source / drain is located in the substrate beside the gate.

Owner:MACRONIX INT CO LTD

F, Mn codoped deposit nano SnO2 transparent thermal-insulation film

The invention discloses an F, Mn co-doping deposition nano-SnO2 transparent heat insulating thin film, wherein the F, Mn element co-doping effect is utilized to increase the number charge carriers in the thin film material, thus increasing the index of thin film reflection to infrared rays. The invention can prevent the excess doping of one single element, it can be applied to chemical CVD or supersonic spraying thermal dissociation deposition.

Owner:雷智 +1

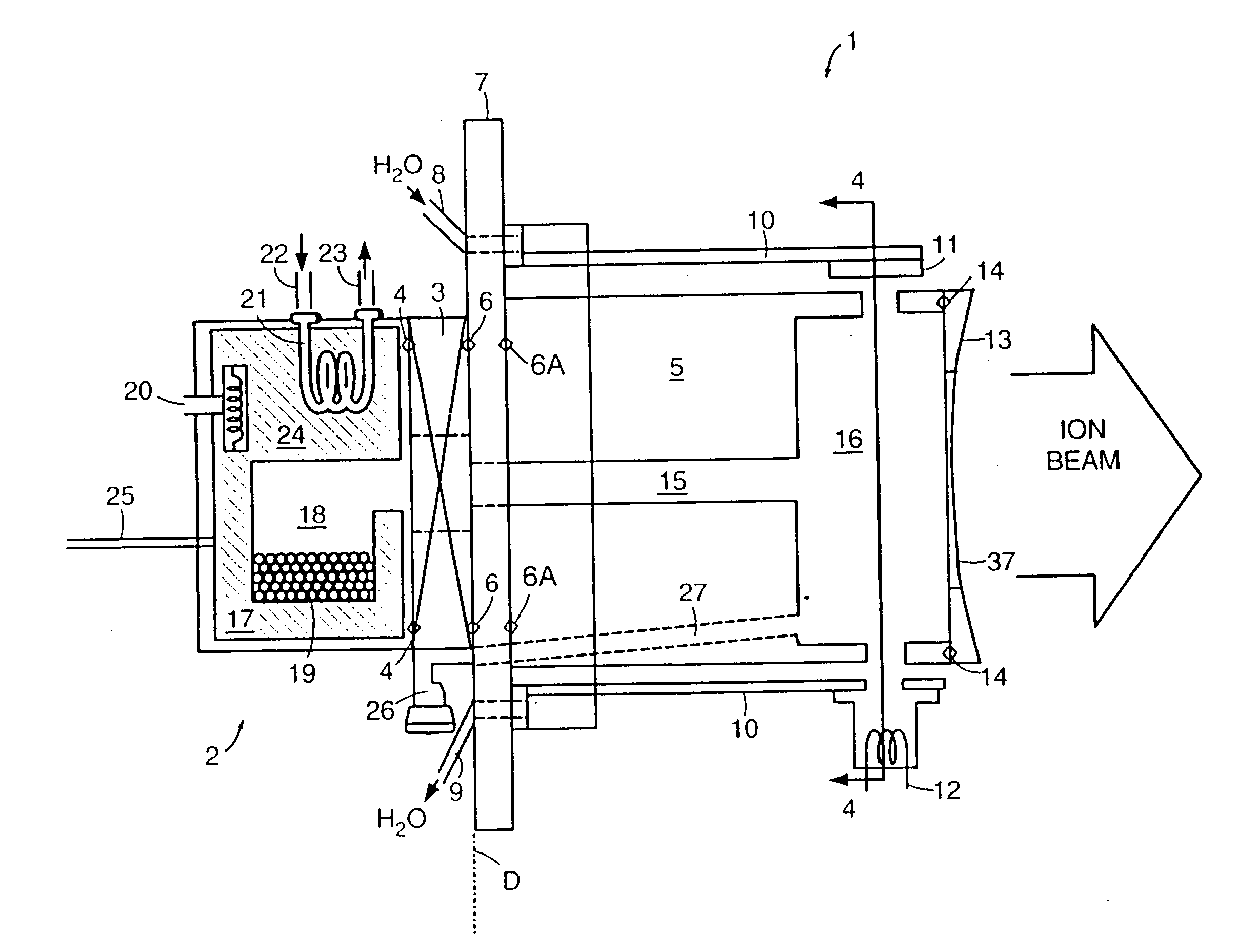

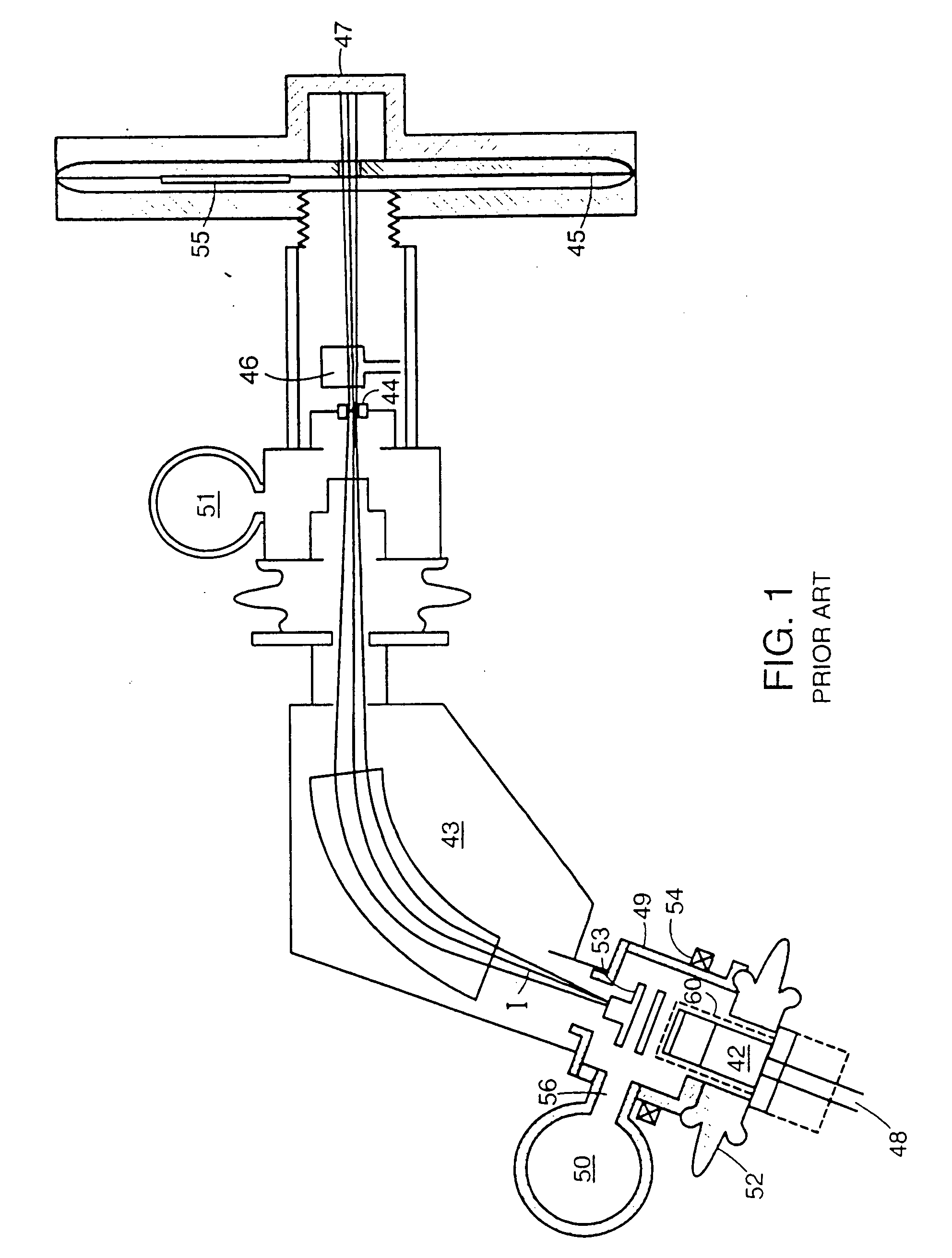

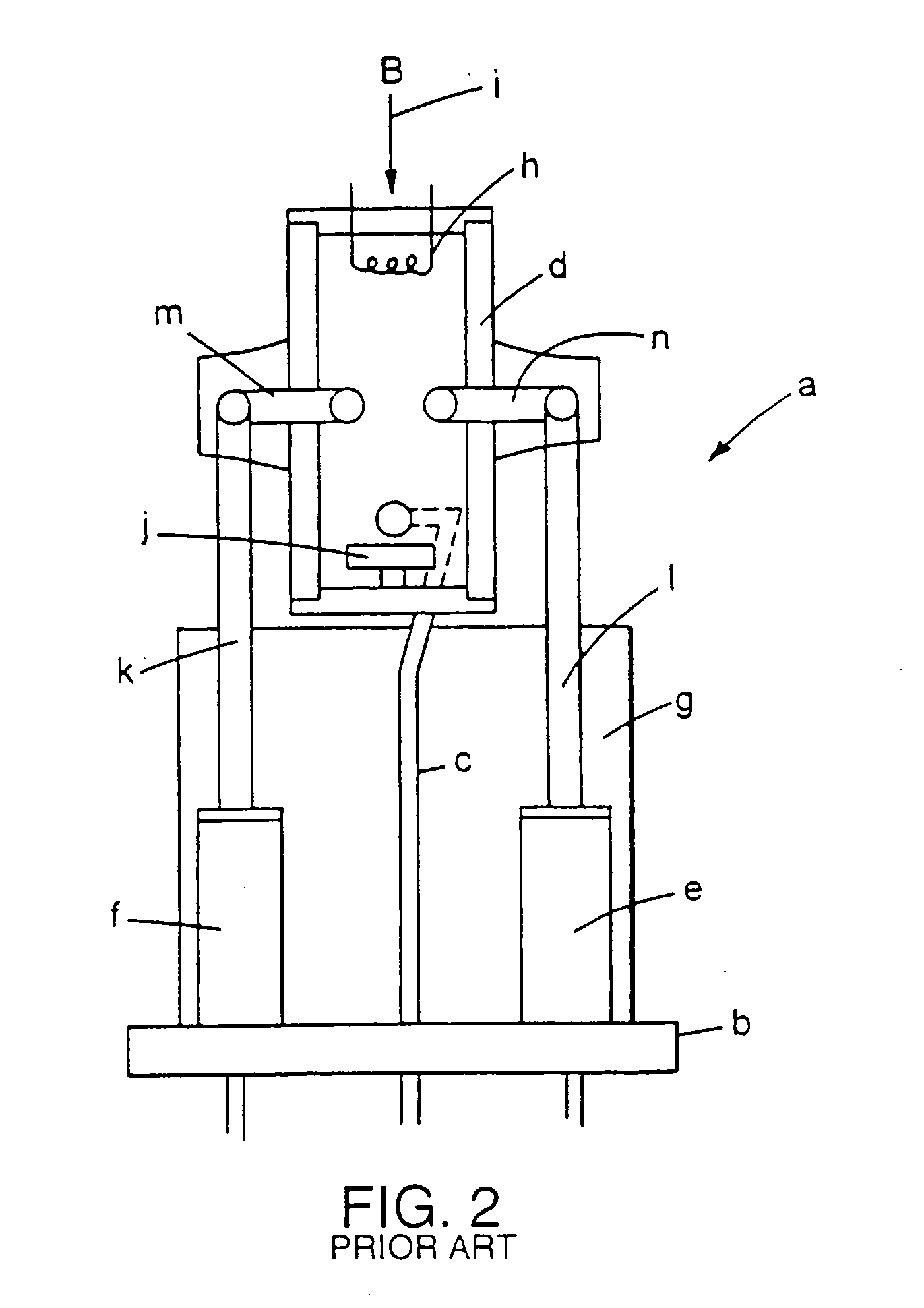

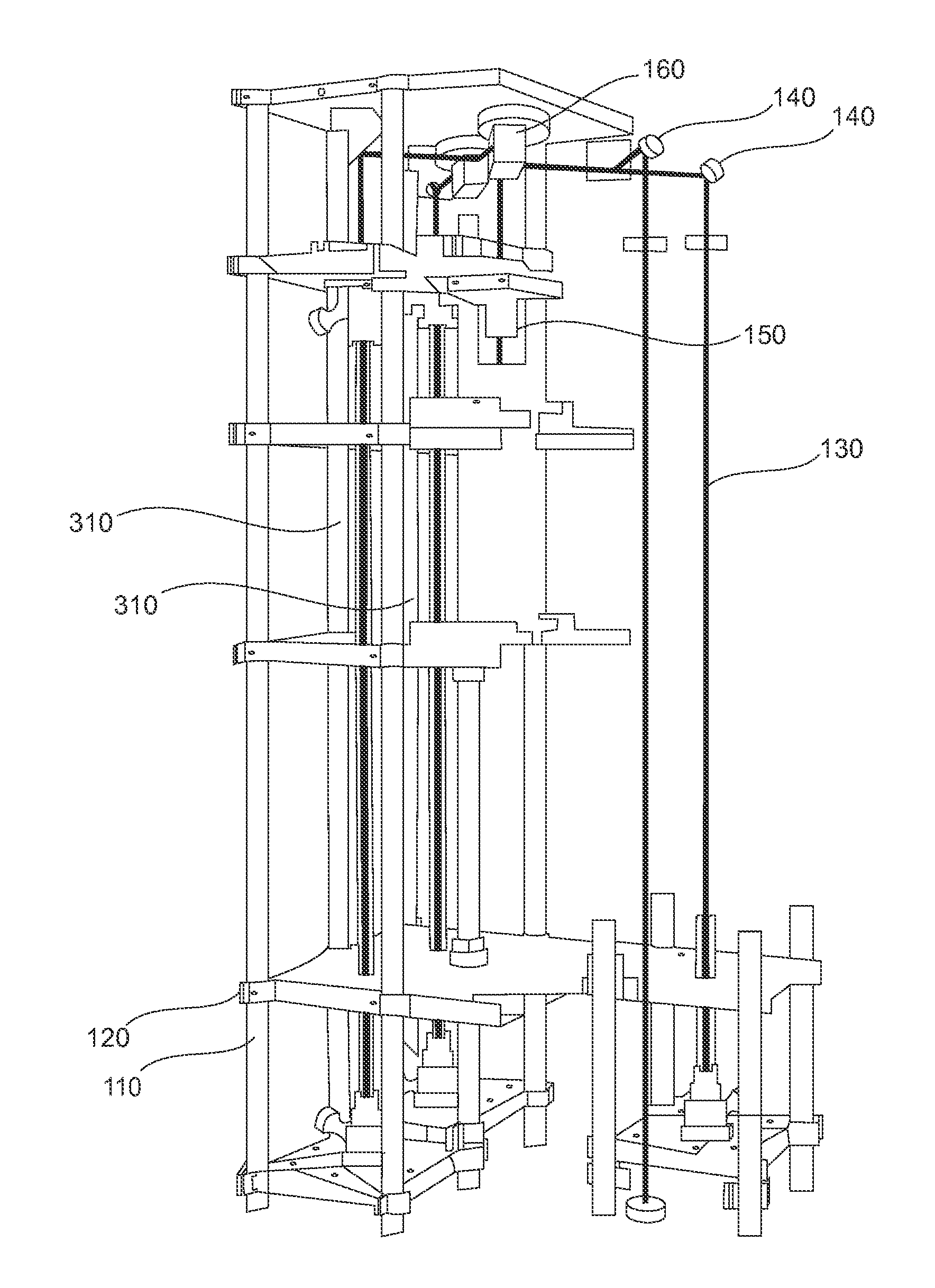

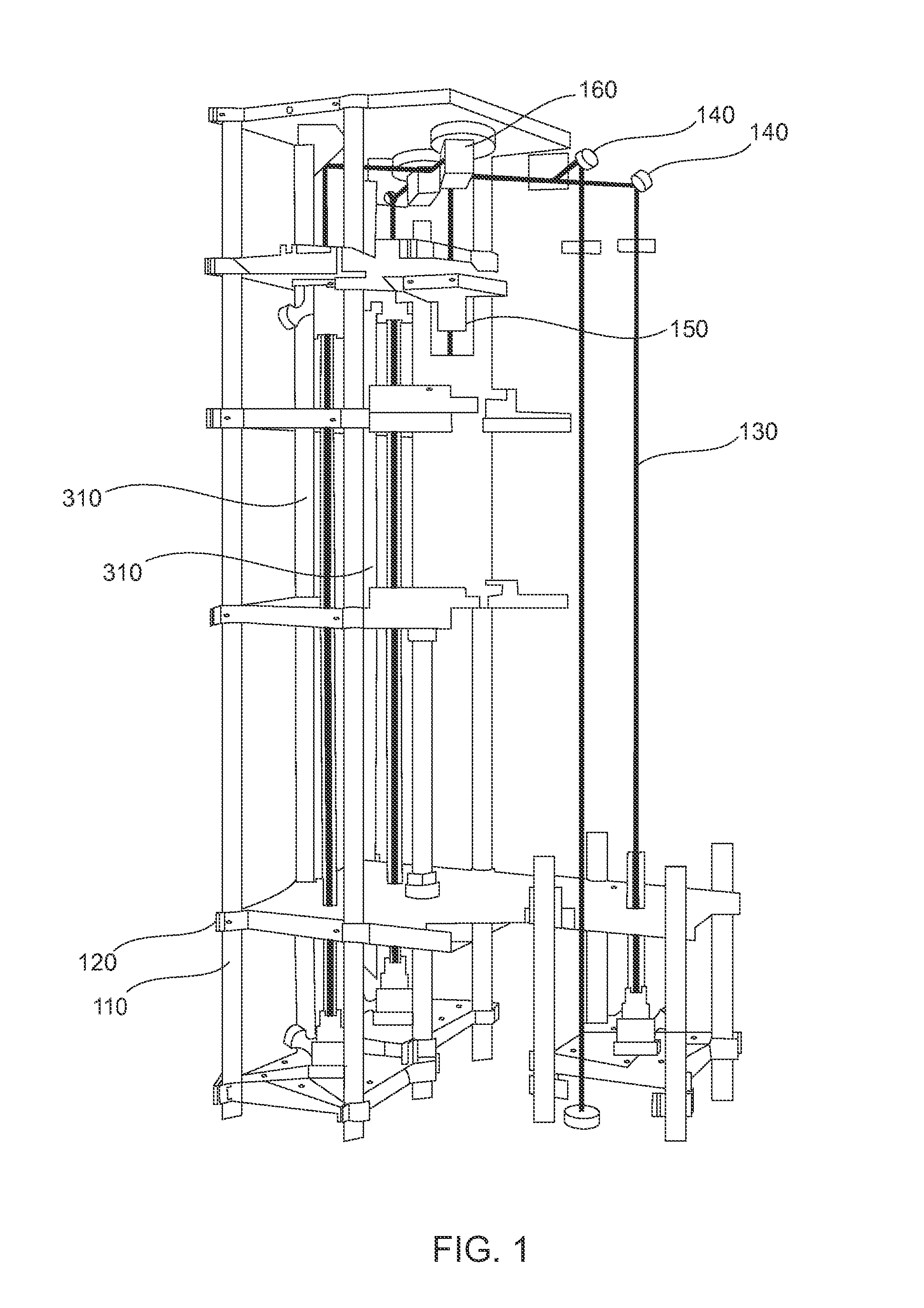

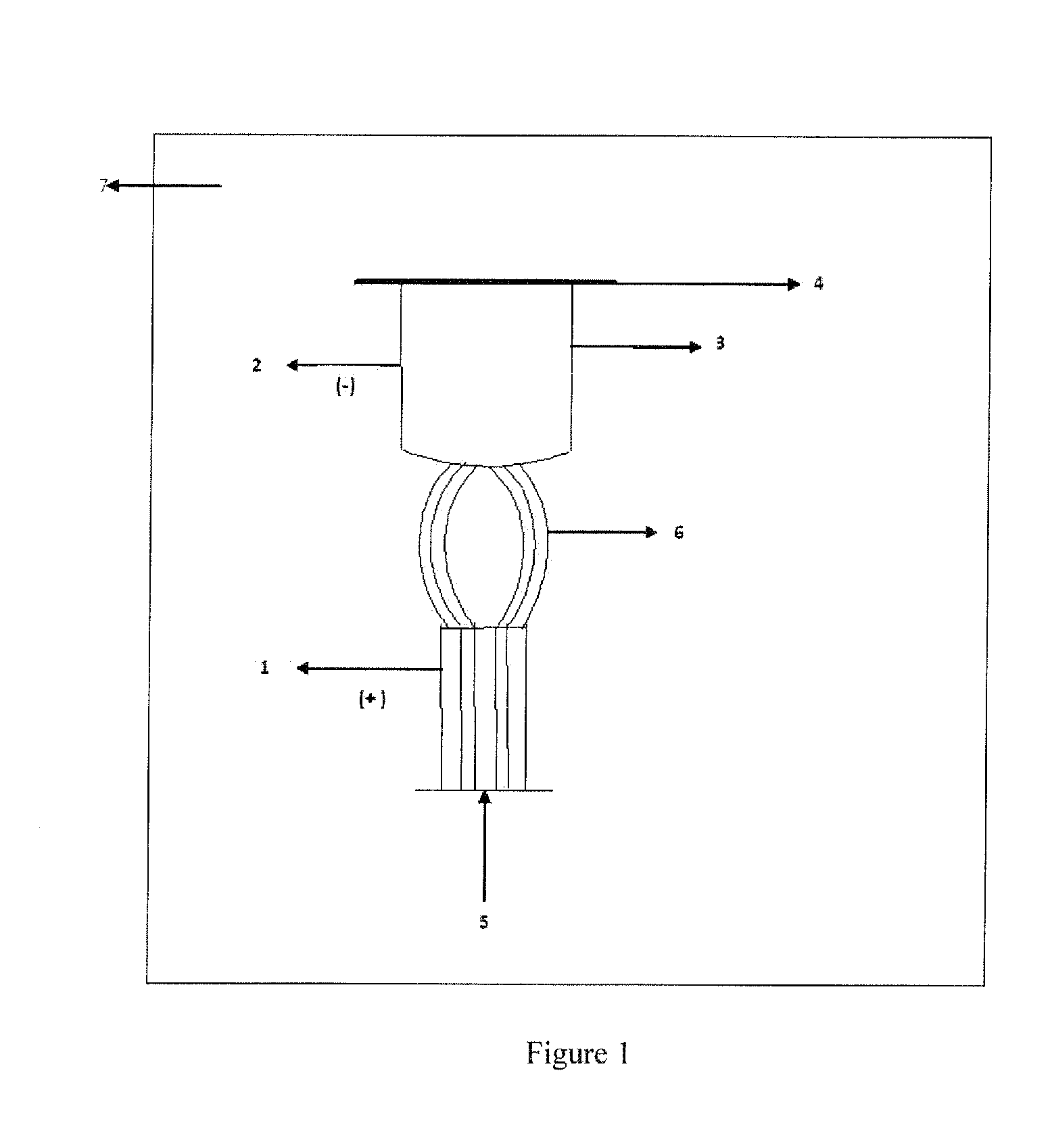

Ion implantation ion source, system and method

InactiveUS20070107841A1Maximizing flow of electronHigh extracted currentSemiconductor/solid-state device manufacturingIon beam tubesDevice materialDesign space

Various aspects of the invention provide improved approaches and methods for efficiently: Vaporizing decaborane and other heat-sensitive materials via a novel vaporizer and vapor delivery system; Delivering a controlled, low-pressure drop flow of vapors, e.g. decaborane, into the ion source; Ionizing the decaborane into a large fraction of B10Hx+; Preventing thermal dissociation of decaborane; Limiting charge-exchange and low energy electron-induced fragmentation of B10Hx+; Operating the ion source without an arc plasma, which can improve the emittance properties and the purity of the beam; Operating the ion source without use of a strong applied magnetic field, which can improve the emittance properties of the beam; Using, a novel approach to produce electron impact ionizations without the use of an arc discharge, by incorporation of an externally generated, broad directional electron beam which is aligned to pass through the ionization chamber to a thermally isolated beam dump;. Providing production-worthy dosage rates of boron dopant at the wafer; Providing a hardware design that enables use also with other dopants, especially using novel hydride, dimer-containing, and indium- or antimony-containing temperature-sensitive starting materials, to further enhance the economics of use and production worthiness of the novel source design and in many cases, reducing the presence of contaminants; Matching the ion optics requirements of the installed base of ion implanters in the field; Eliminating the ion source as a source of transition metals contamination, by using an external and preferably remote cathode and providing an ionization chamber and extraction aperture fabricated of non-contaminating material, e.g. graphite, silicon carbide or aluminum; Enabling retrofit of the new ion source into the ion source design space of existing Bernas source-based ion implanters and the like or otherwise enabling compatibility with other ion source designs; Using a control system in retrofit installations that enables retention of the installed operator interface and control techniques with which operators are already familiar; Enabling convenient handling and replenishment of the solid within the vaporizer without substantial down-time of the implanter; Providing internal adjustment and control techniques that enable, with a single design, matching the dimensions and intensity of the zone in which ionization occurs to the beam line of the implanter and the requirement of the process at hand; Providing novel approaches, starting materials and conditions of operation that enable the making of future generations of semiconductor devices and especially CMOS source / drains and extensions, and doping of silicon gates.

Owner:SEMEQUIP

Solar-thermal fluid-wall reaction processing

InactiveUS20060140848A1Reduce and preventShort staySolar heating energyPigmenting treatmentHydrogenReactor system

The present invention provides a method for carrying out high temperature thermal dissociation reactions requiring rapid-heating and short residence times using solar energy. In particular, the present invention provides a method for carrying out high temperature thermal reactions such as dissociation of hydrocarbon containing gases and hydrogen sulfide to produce hydrogen and dry reforming of hydrocarbon containing gases with carbon dioxide. In the methods of the invention where hydrocarbon containing gases are dissociated, fine carbon black particles are also produced. The present invention also provides solar-thermal reactors and solar-thermal reactor systems.

Owner:UNIV OF COLORADO THE REGENTS OF +1

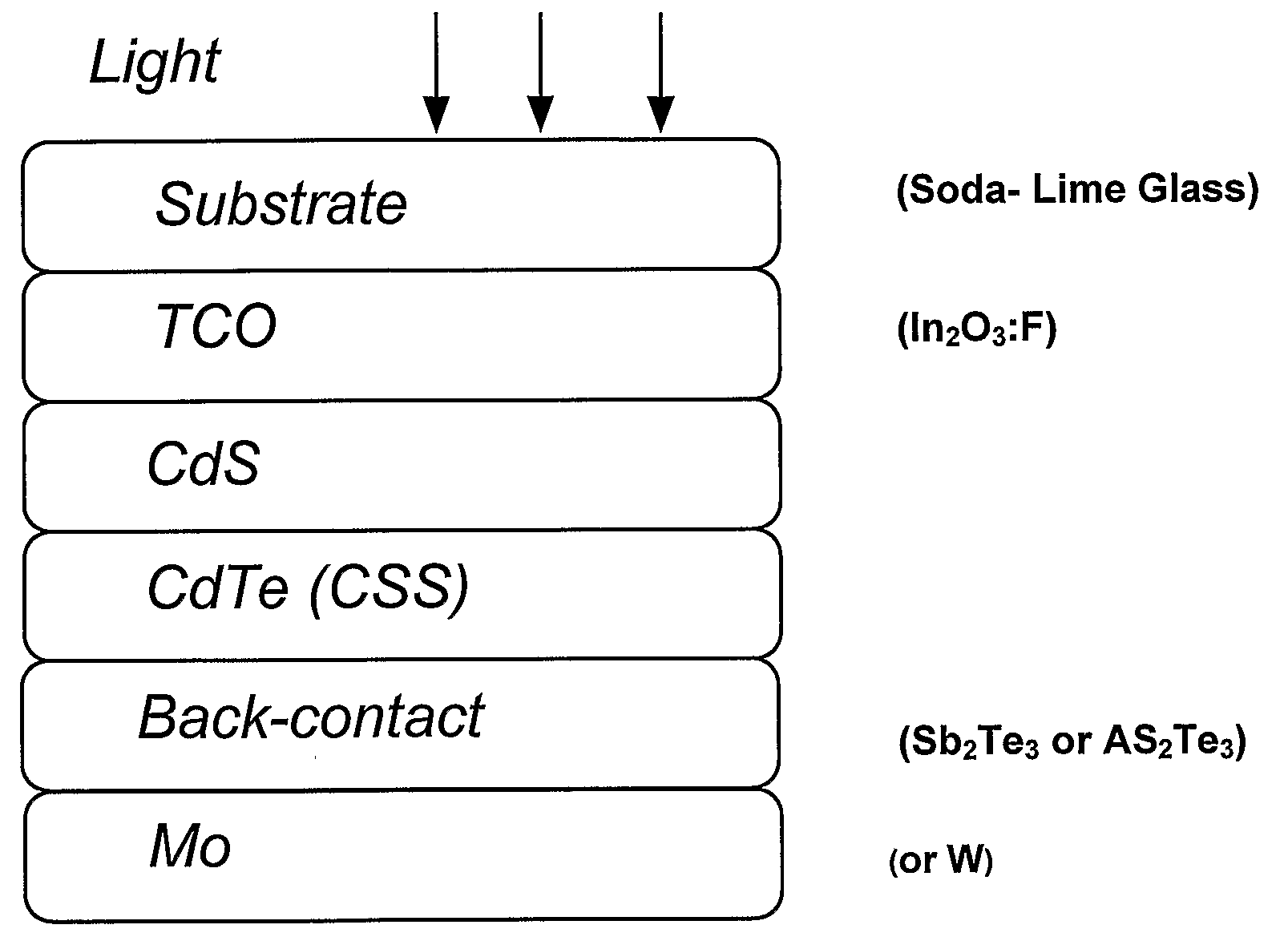

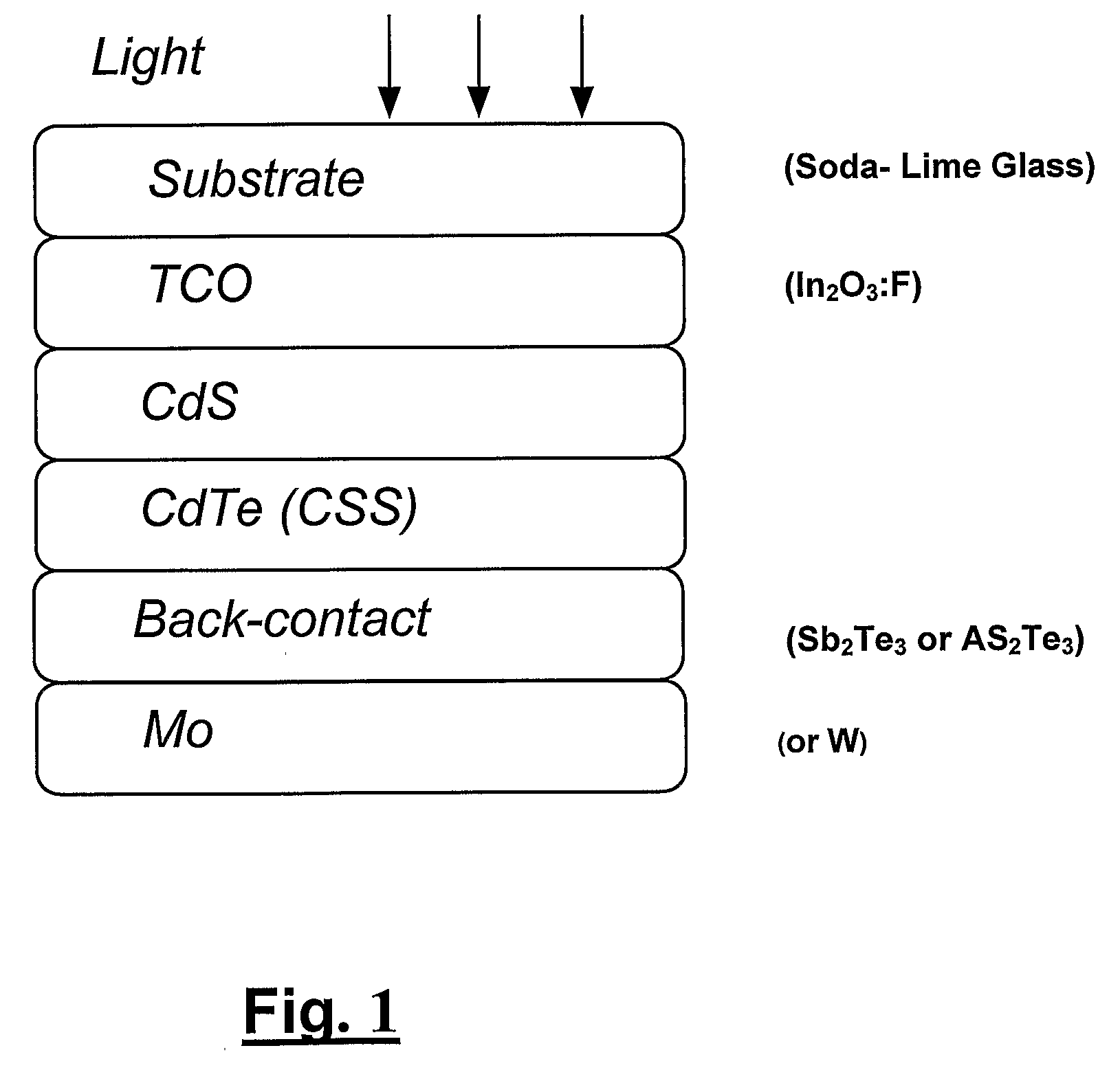

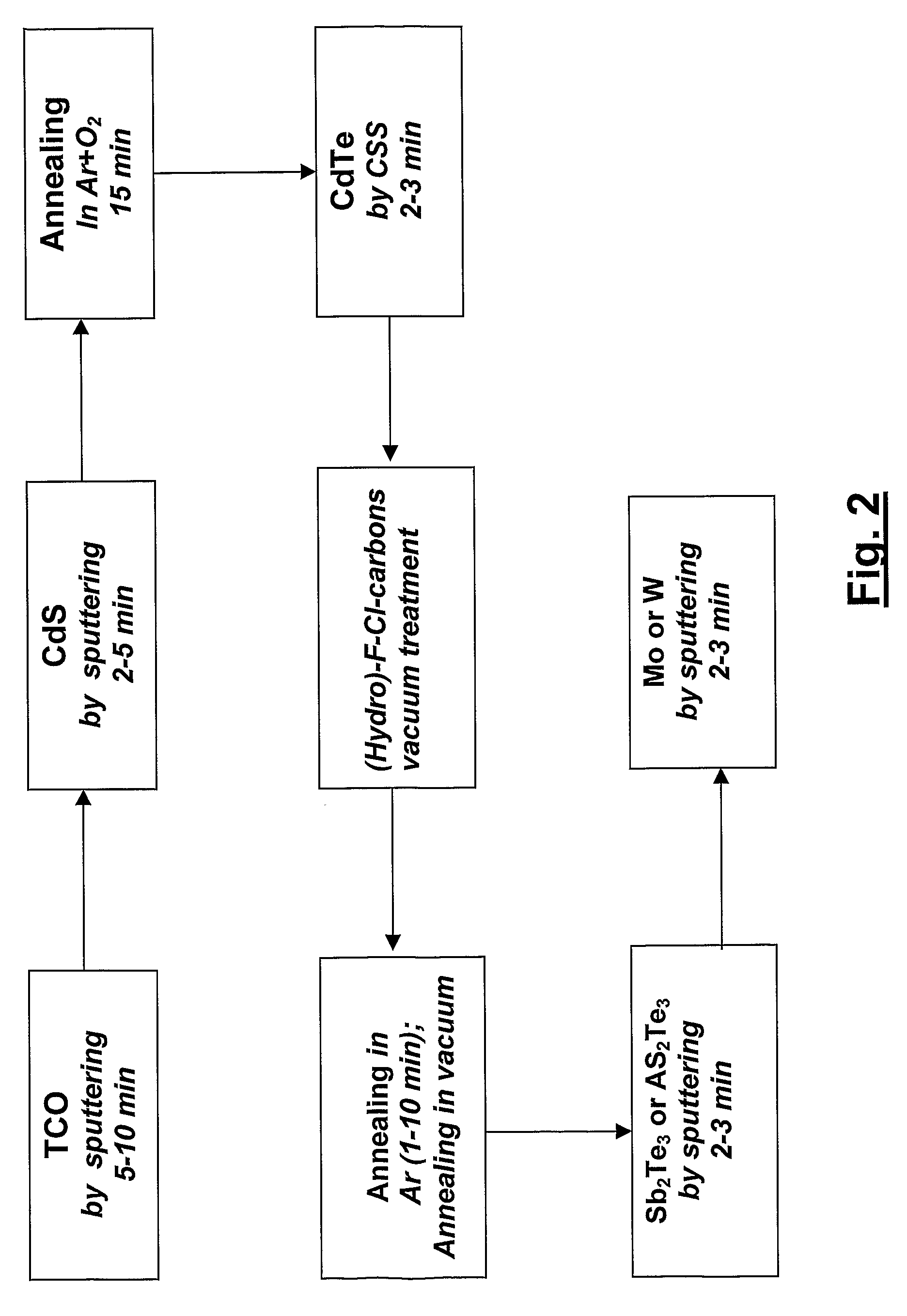

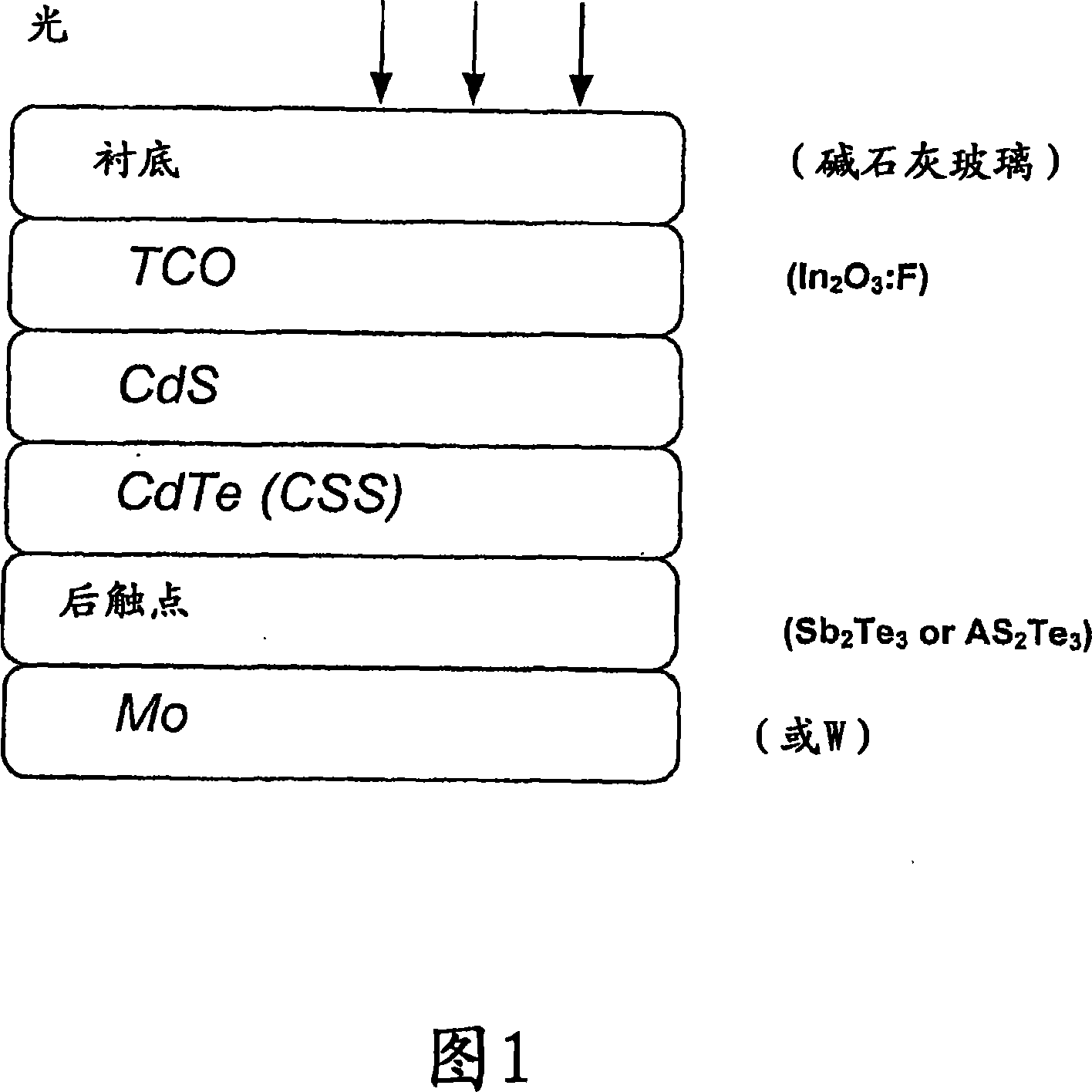

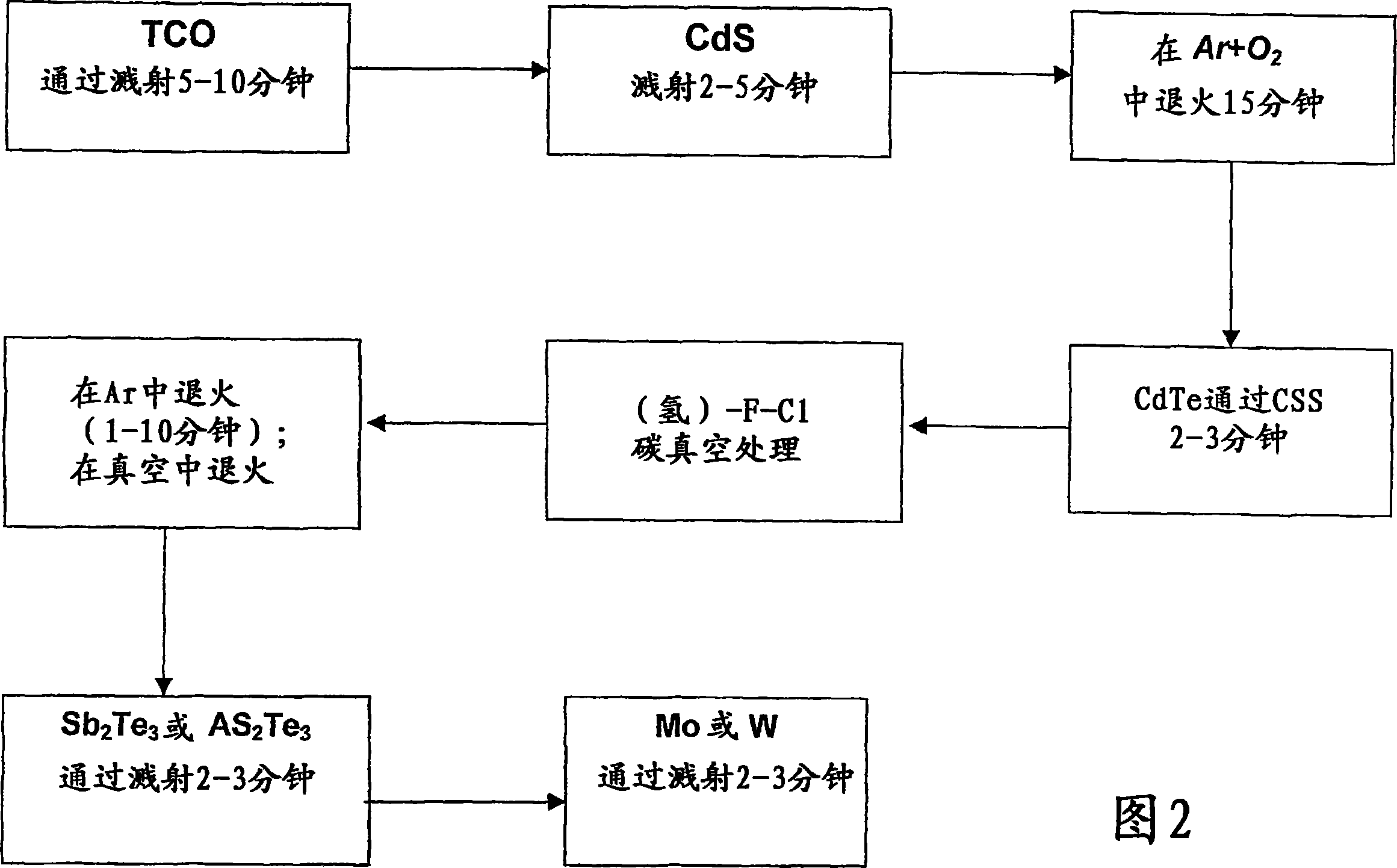

Process for Large-Scale Production of Cdte/Cds Thin Film Solar Cells, Without the Use of Cdci2

InactiveUS20080149179A1Low production costStable and efficient and relatively low-cost CdTe/CdSCoatingsSpecial surfacesChlorofluorocarbonThermal dissociation

A process for large-scale production of CdTe / CdS thin film solar cell the films of the solar cells being deposited as a sequence on a transparent substrate, which comprises the steps of: depositing a film of a transparent conductive oxide (TCO) on the substrate; depositing a film of CdS on the TCO film; treating the CdTe film with Chlorine-containing inert gas; and depositing a back-contact film on the treated CdTe film. The Chlorine-containing inert gas is a Chlorofluorocarbon or a Hydrochlorofluorocarbon product and the treatment is carried out in a vacuum chamber at an operating temperature of 380-420° C. The Chlorine released as a result of the thermal dissociation of the product reacts with solid CdTe present on the cell surface to produce TeCl2 and CdCl2 vapors. Any residual CdCl2 is removed from the cell surface by applying a vacuum to the vacuum chamber while keeping the temperature at the operating value.

Owner:SOLAR SYST & EQUIP

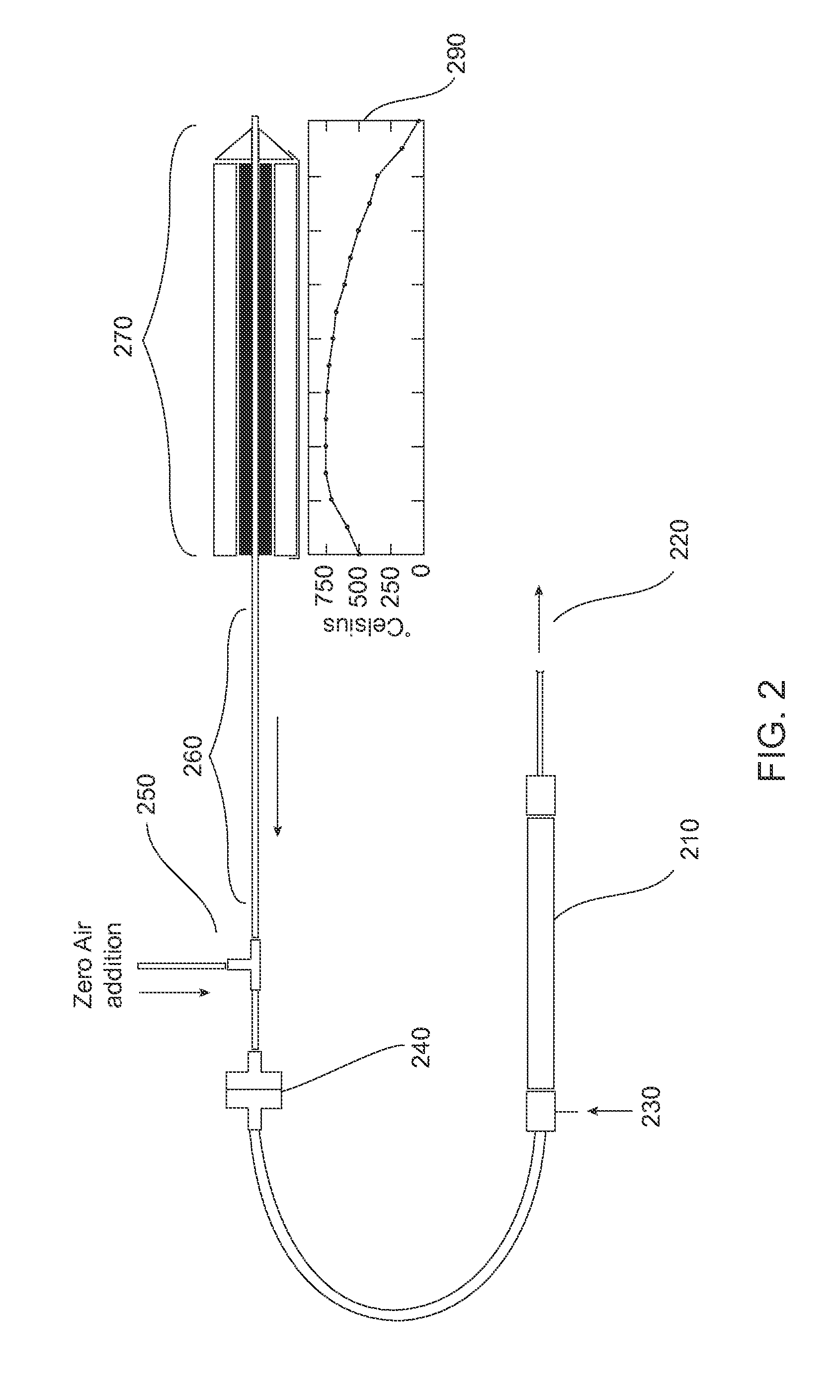

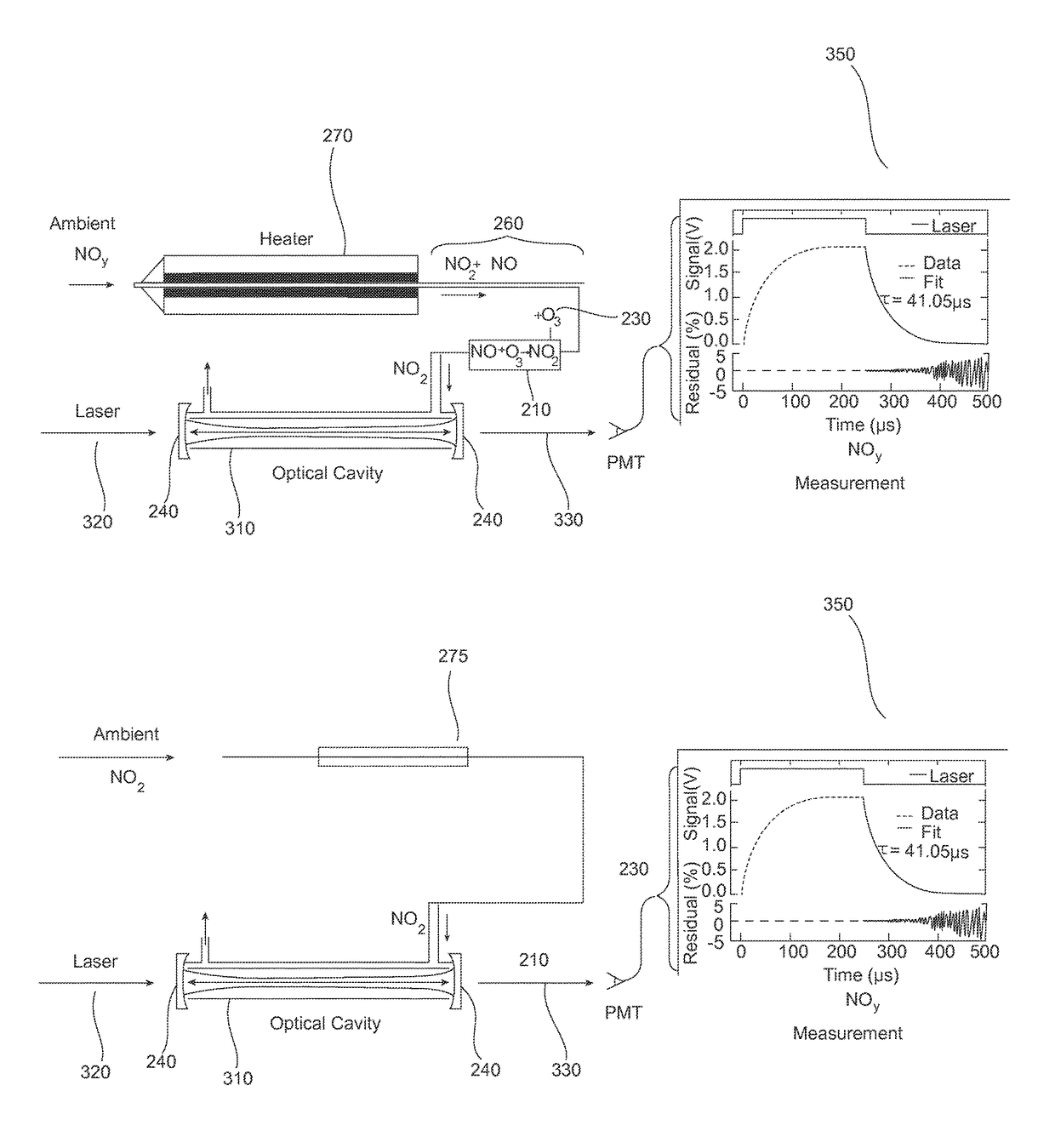

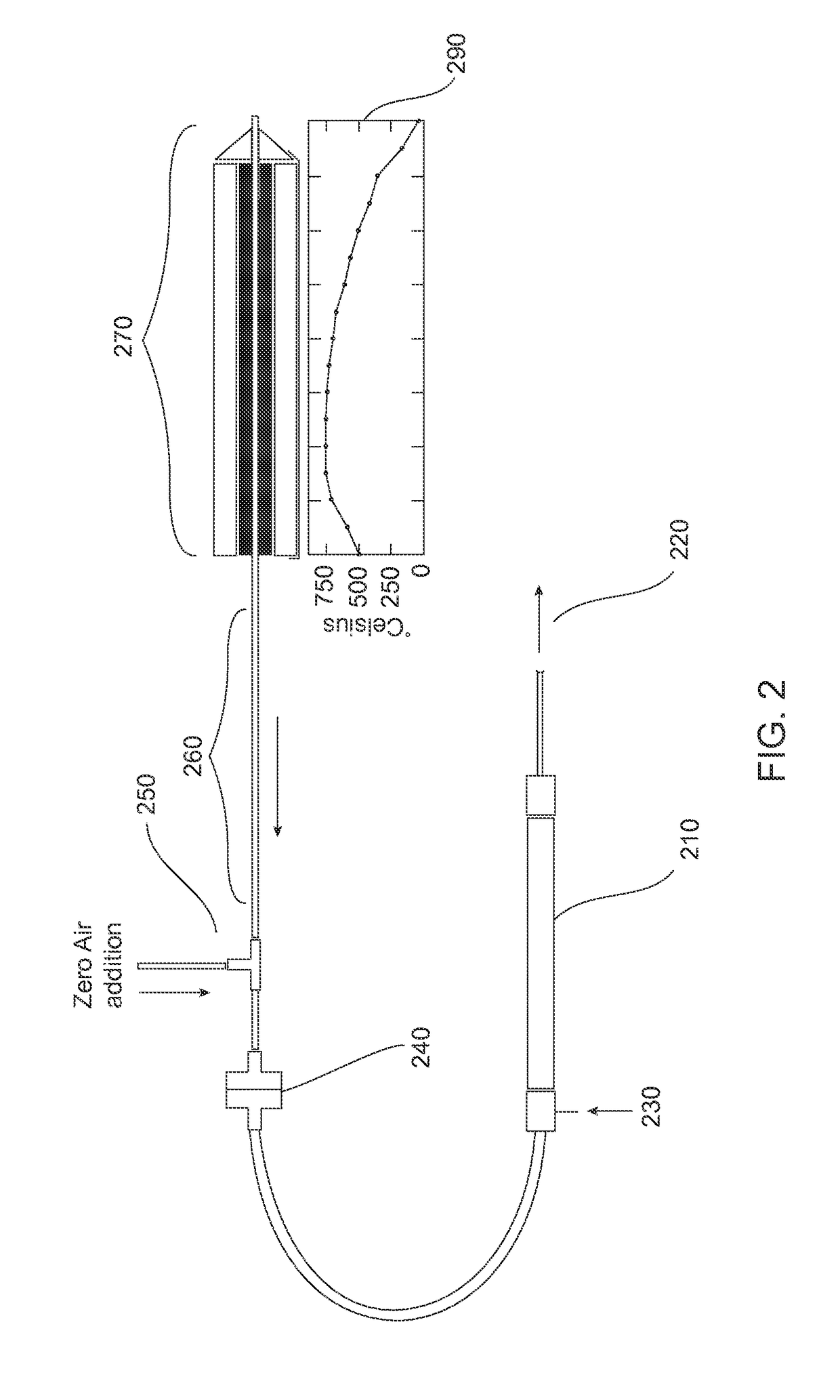

Measurement of Total Reactive Nitrogen, NOy, together with NO2, NO, and O3 via Cavity Ring-down Spectroscopy

ActiveUS20150377850A1Accuracy sufficientSolve the lack of precisionMaterial analysis by electric/magnetic meansMaterial analysis by optical meansThermal dissociationCavity ring-down spectroscopy

A sensitive, compact detector measures total reactive nitrogen (NOy), as well as NO2, NO, and O3. In all channels, NO2 is directly detected by laser diode based cavity ring-down spectroscopy (CRDS) at 405 nm. Ambient O3 is converted to NO2 in excess NO for the O3 measurement channel. Likewise, ambient NO is converted to NO2 in excess O3. Ambient NOy is thermally dissociated at 700C to form NO2 or NO in a heated quartz inlet. Any NO present in ambient air or formed from thermal dissociation of other reactive nitrogen compounds is converted to NO2 in excess O3 after the thermal converter. The precision and accuracy of this instrument make it a versatile alternative to standard chemiluminescence-based NOy instruments.

Owner:THE UNITED STATES OF AMERICA AS REPRESENTED BY THE SECRETARY OF THE COMMERCE

Method of melting oxidic slags and combustion residues

The process for melting oxidic slags and combustion residues having a minimum content of metallized portions such as, e.g., iron and / or carbon carriers, of 3% by weight is carried out in a shaft furnace directly heated by means of fossil fuels via burners. The molten slag bath is transferred into a hearth type furnace immediately adjoining the shaft furnace and in which metals such as, for instance, copper are separated by sedimentation under thermal dissociation and discharged separately via a bottom outlet. The completely oxidized slag reaches a consecutively arranged slag treating reactor via a separate discharge.

Owner:HOLCIM

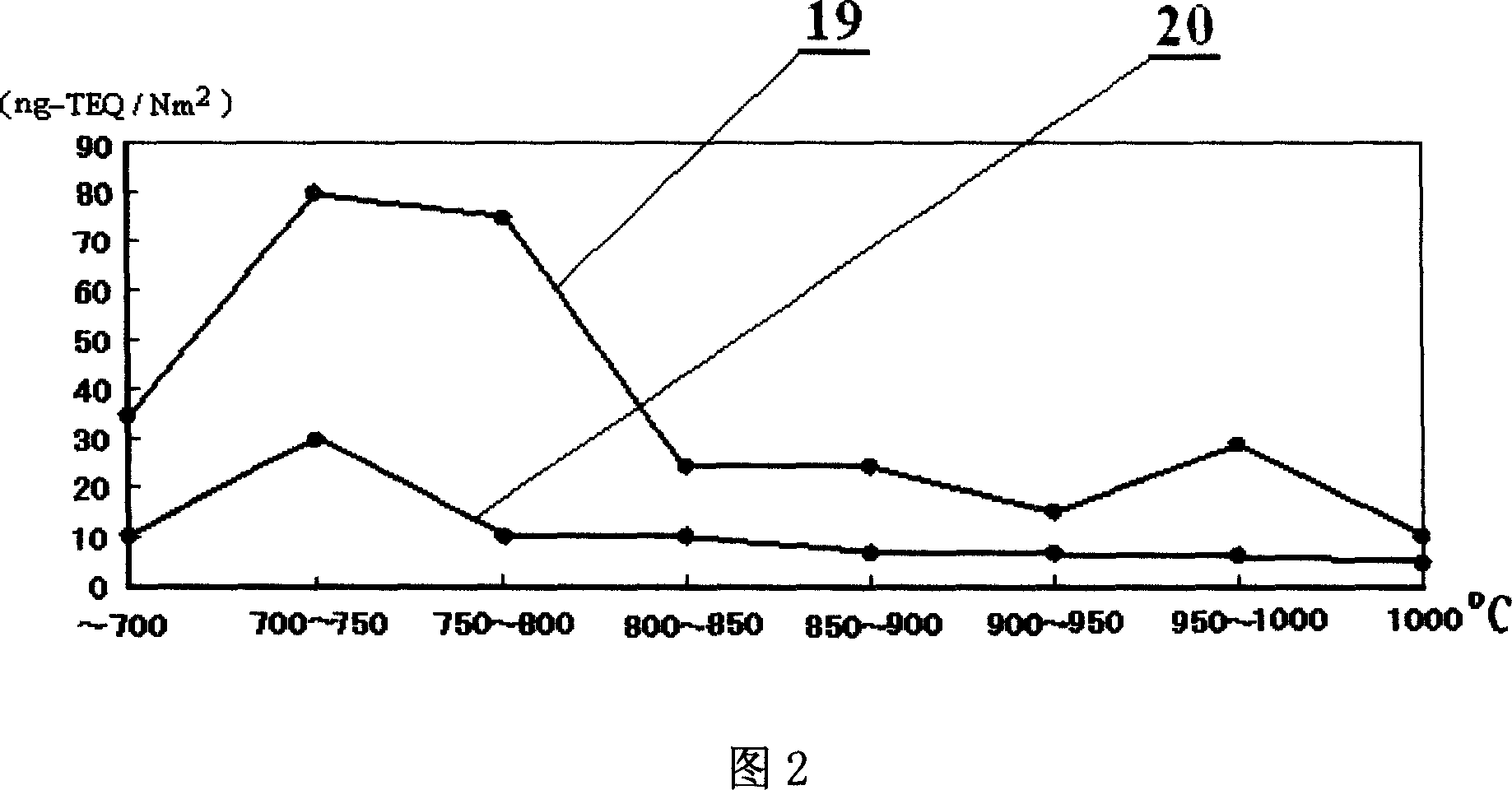

Magnetic air thermal dissociation method and device for solid waste treatment

InactiveCN101062505AImprove adsorption capacitySolid waste disposalEnvironmental resistanceInlet channel

The invention relates to the solid waste thermal decomposition treatment, comprising a igniting the flammable matter, adding solid waste, forcing to add magnetic air to maintain the stable thermal decomposition reaction, emitting of the nonflammable slag, comprising a furnace, treatment chamber, emission chamber with air inlet connected to the air inlet channel, treatment chamber with air exhaust connected with the chimney, air inlet channel having magnetizer, whose inside having strong magnets, the other end of the air inlet channel connected to the air outlet, with air conduit between the wind outlet and the chimney. It improves the thermal decomposition efficiency in the temperature around 600deg.C. It is an environment protective technology without the use of any energy.

Owner:陈炳炎 +1

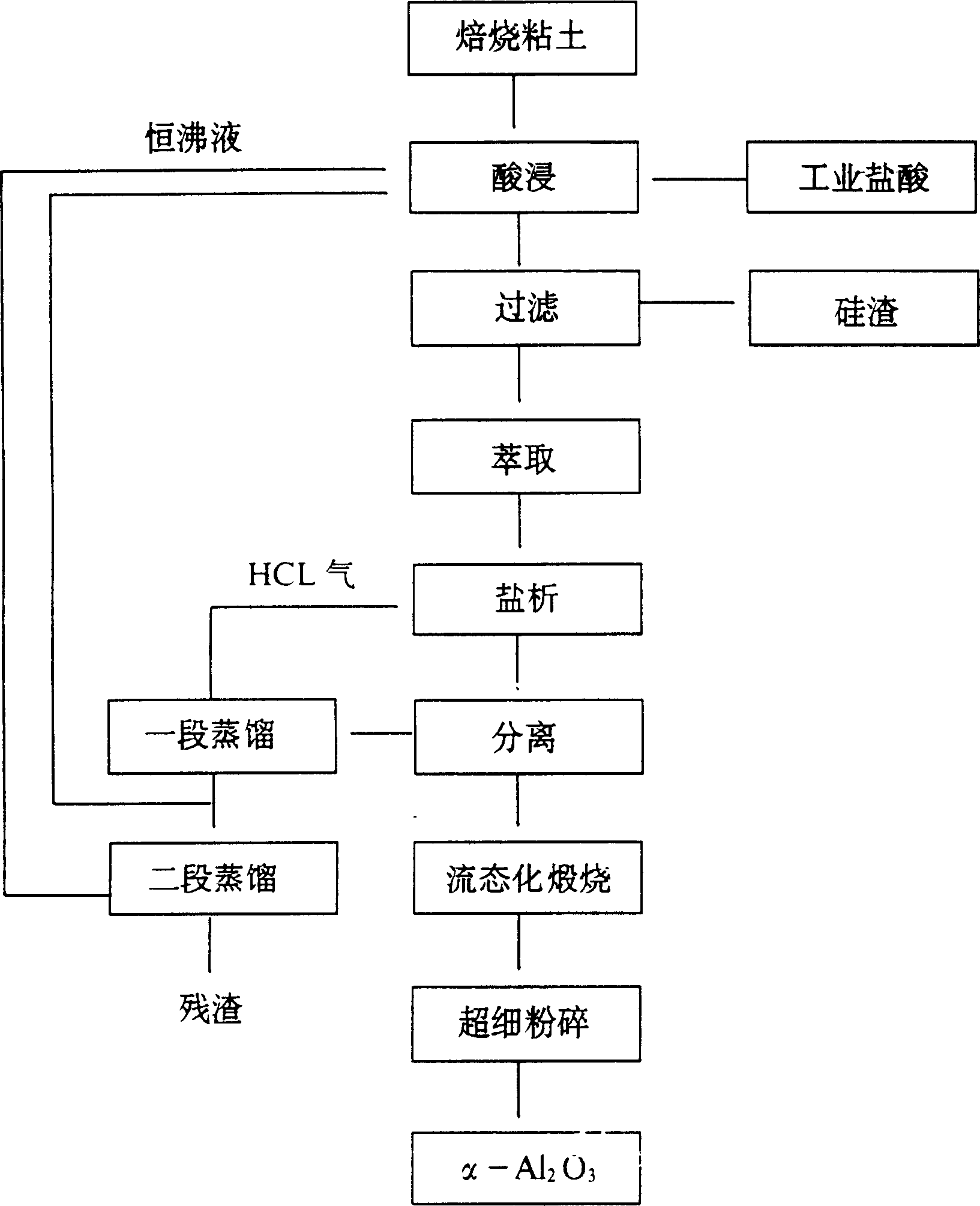

Technological process for preparing submicron alumina using improved salting out method

The invention relates to a process for preparing sub-micron aluminum oxide through improved salting out method comprising the steps of, subjecting the collyrium type clay to hydrochloric acid extraction, extraction, salting-out, thermal dissociation incineration and super fine integration, wherein the extracting agent employs tributyl phosphate, the thinning agent employs petroleum ether or sulphonated kerosene.

Owner:王海舟

Purification of metal hydrocarbon

InactiveUS7005530B2Easy to separateGroup 4/14 element organic compoundsGroup 3/13 element organic compoundsBoiling pointThermal dissociation

A contaminated Group III metal hydrocarbon is purified by providing an adduct of Group III metal hydrocarbon with a Lewis base in a solvent having a boiling point which is up to 200° C., but at least 30° C. higher than the boiling point of the Group III metal hydrocarbon, separating the solvent from the adduct, and heating the adduct for thermal dissociation, thereby releasing the Group III metal hydrocarbon in high purity form.

Owner:SHIN ETSU CHEM IND CO LTD

A process for large-scale production of CdTe/CdS thin film solar cells, without the use of CdCl2

InactiveCN101116190ALow costPhotovoltaic energy generationSemiconductor devicesThermal dissociationEngineering

A process for the large-scale production of CdTe / CdS thin film solar cells, said films being deposited as a sequence on a transparent substrate, comprising the steps of : depositing a film of a transparent conductive oxide (TCO) on said substrate; depositing a film of CdS on said TCO film; depositing a film of CdTe on said CdS film; treating said CdTe film with a Chlorine-containing inert gas; depositing a back-contact film on said treated CdTe film. The Chlorine -containing inert gas is a Chlorof luorocarbon or a Hydrochlorof luorocarbon product and the treatment is carried out in a vacuum chamber at an operating temperature of 380-4200C. The Chlorine released as a result of the thermal dissociation of the product reacts with solid CdTe present on the cell surface to produce TeCl2 and CdCl2 vapors. Any residual CdCl2 is removed from the cell surface by applying vacuum to the vacuum chamber while keeping the temperature at the operating value.

Owner:SOLAR SYST & EQUIP

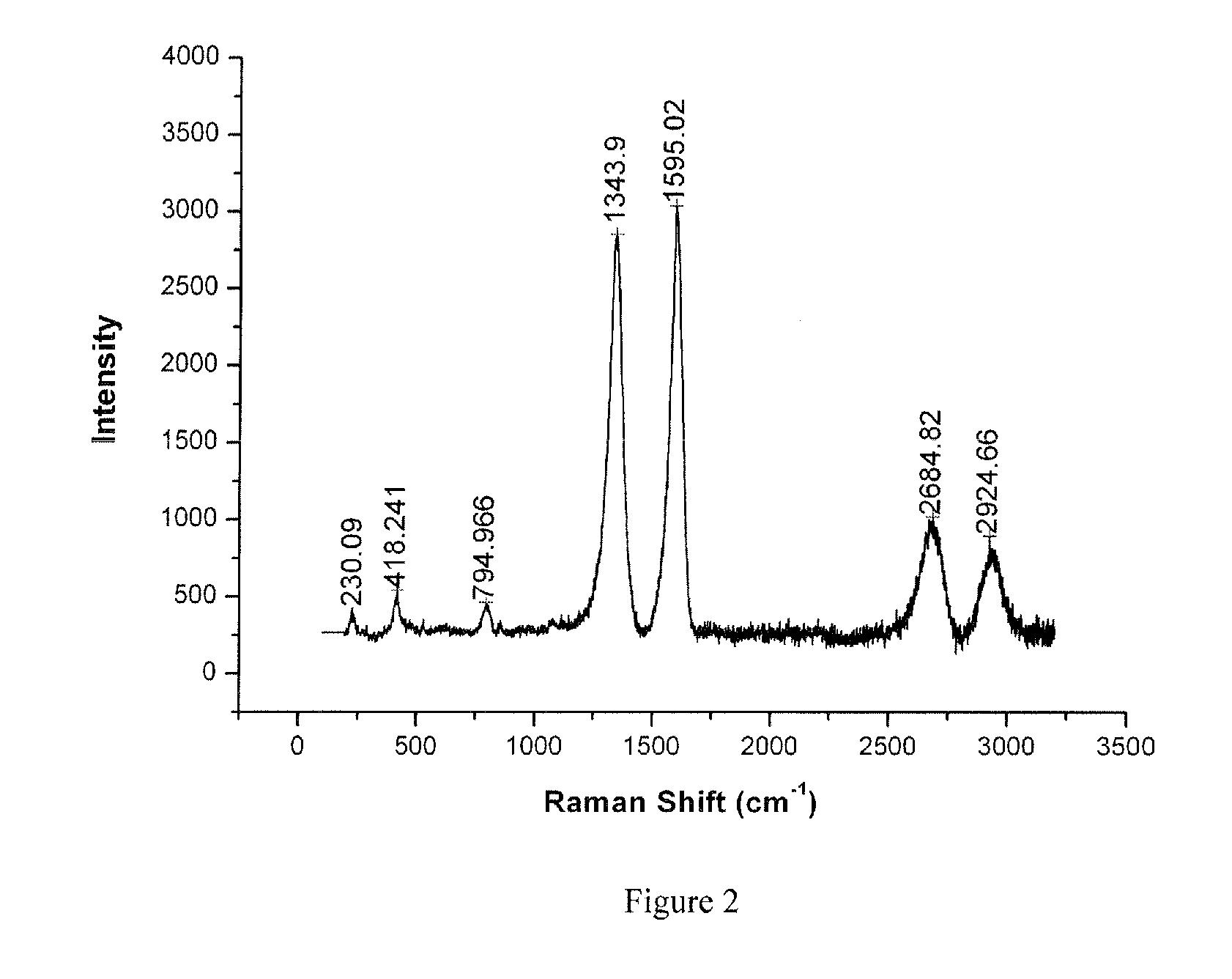

Process for developing a composite coating of diamond like carbon and graphite on silicon carbide grain by indirect arc plasma heating dissociation

InactiveUS20140069327A1Overcome peelingRaise the possibilityPolycrystalline material growthFrom chemically reactive gasesDiamond-like carbonThermal dissociation

The present invention relates to a process for in situ growth of carbonaceous composite coating of diamond like carbon (DLC) and graphite on silicon carbide (SiC) grains by carrying out thermal dissociation of SiC by an indirect arc plasma heating and the said process comprising the steps of: (i) providing SiC grains in a graphite crucible; (ii) passing inert gas in the arc zone situated below the graphite crucible; (iii) passing a inert gas inside the graphite crucible; (iv) heating the graphite crucible by arc plasma for a period in the range of 15 to 30 minutes; (v) continuing the inert gas flow in arc zone and in graphite crucible for 50 to 70 minutes; (vi) cooling the reactor to obtain a carbonaceous composite coating having diamond like carbon (DLC) and graphite on silicon carbide (SiC) grains.

Owner:COUNCIL OF SCI & IND RES

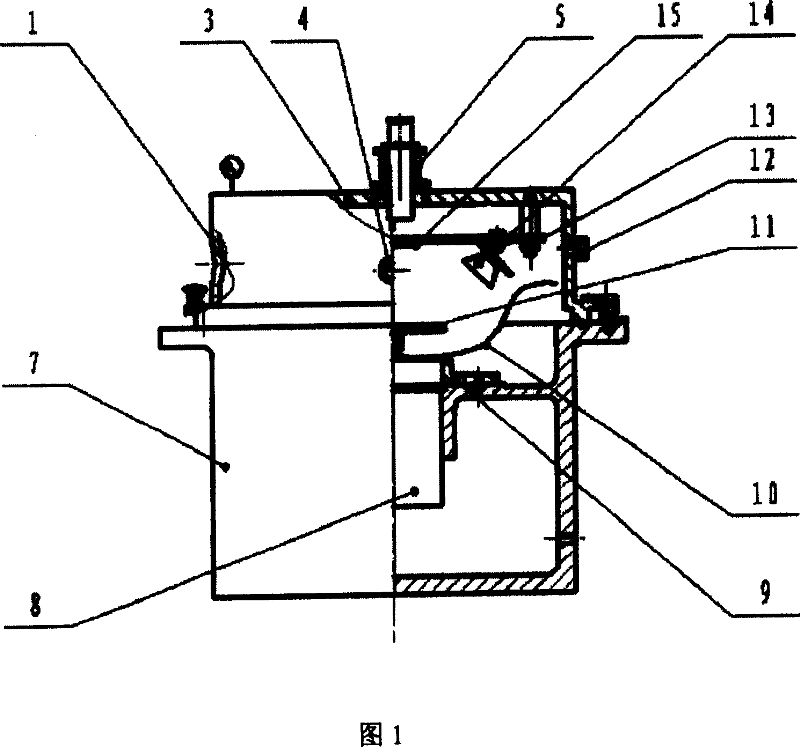

Nanometer film shaping machine

InactiveCN1736616AEvenly heatedUniform light receivingPretreated surfacesCoatingsWhole bodyThermal dissociation

The invention discloses a nano film forming machine for preparing nano functional film, which comprises a vacuum tank body and a generator, the vacuum tank body comprising a cabin and a top cover which is equipped with the cabin, the generator being equipped with the inner of the cabin and being fixed by a supporting flange which is equipped with the cabin, the rotation shaft of the generator being provided with a base-tray, the top cover being equipped with a liquid inlet which locates above the base-tray, the vacuum tank body being equipped with a vacuum adapter for evacuation, in the vacuum tank body being provided with a heat source for thermal dissociation and a light source for photo dissociation, and the heat source and light source equipped upper than base-tray; the invention has a merit of: taking film formation, thermal dissociation or photo dissociation and phase-change in high temperature in a whole body, and guaranteeing the film quality.

Owner:SOUTHEAST UNIV

Purification of metal hydrocarbon

InactiveUS20050004383A1Easy to separateGroup 4/14 element organic compoundsGroup 1/11 element organic compoundsBoiling pointThermal dissociation

A contaminated Group III metal hydrocarbon is purified by providing an adduct of Group III metal hydrocarbon with a Lewis base in a solvent having a boiling point which is up to 200° C., but at least 30° C. higher than the boiling point of the Group III metal hydrocarbon, separating the solvent from the adduct, and heating the adduct for thermal dissociation, thereby releasing the Group III metal hydrocarbon in high purity form.

Owner:SHIN ETSU CHEM IND CO LTD

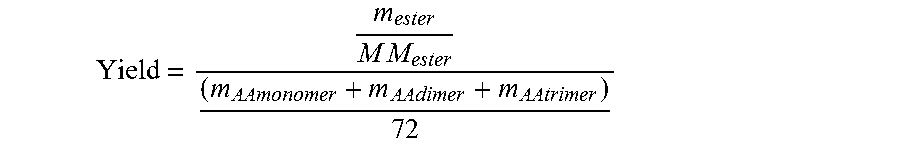

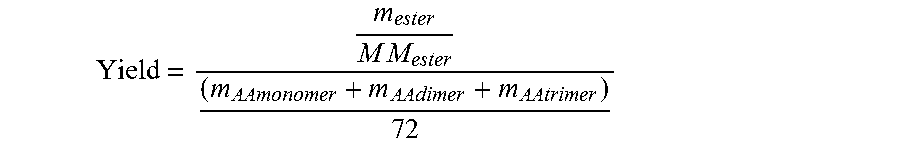

Method for continuous production of light acrylates by esterification of a raw ester-grade acrylic acid

ActiveUS9796651B2Organic compound preparationCarboxylic acid esters preparationAlcoholThermal dissociation

The present invention relates to methods by which the thermal dissociation of Michael adducts present in a stream of crude acrylic acid, called “crude ester grade”, and the esterification reaction of acrylic acid present in the stream of crude acrylic acid, or generated in situ by thermal dissociation, with a light alcohol, are carried out simultaneously.

Owner:ARKEMA FRANCE SA

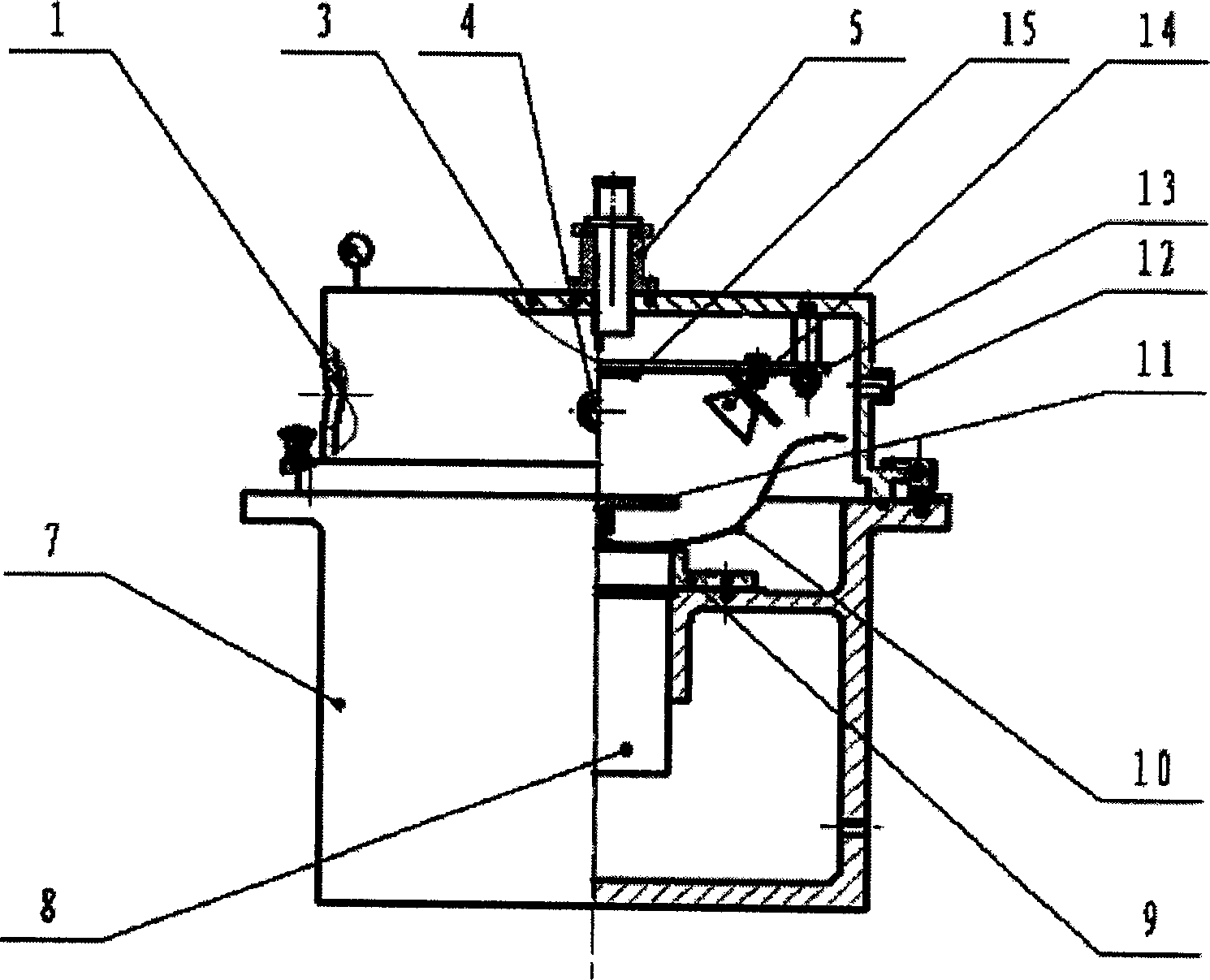

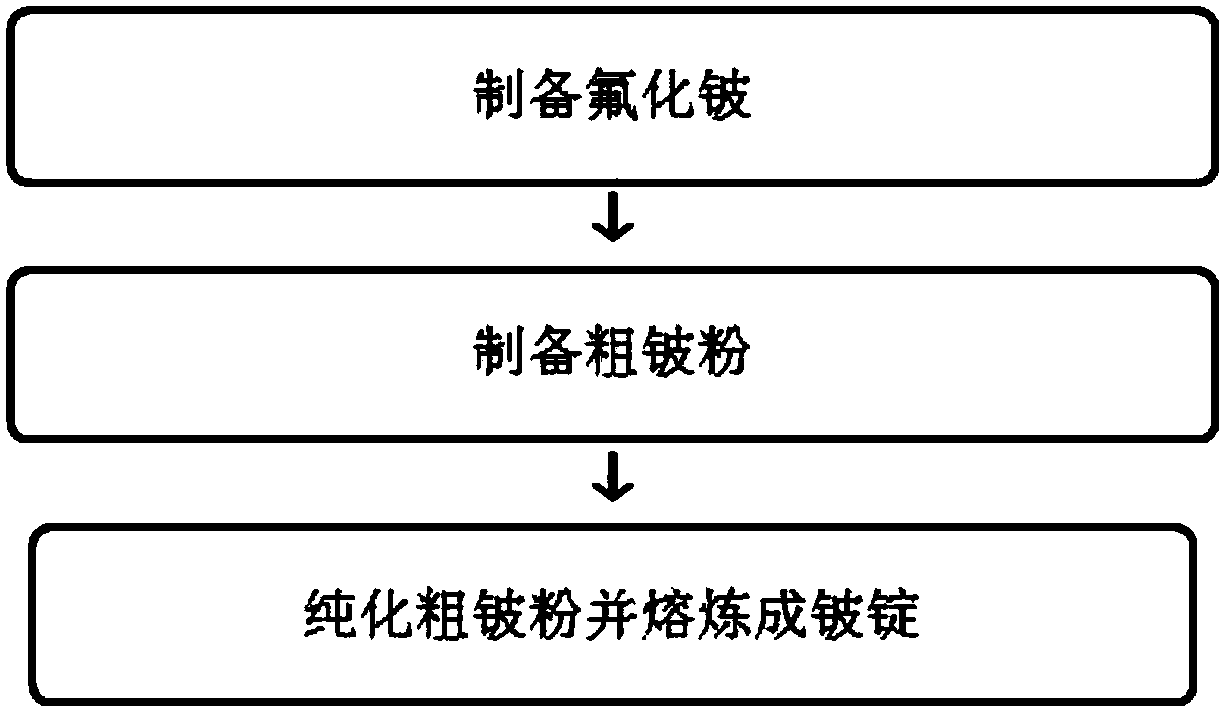

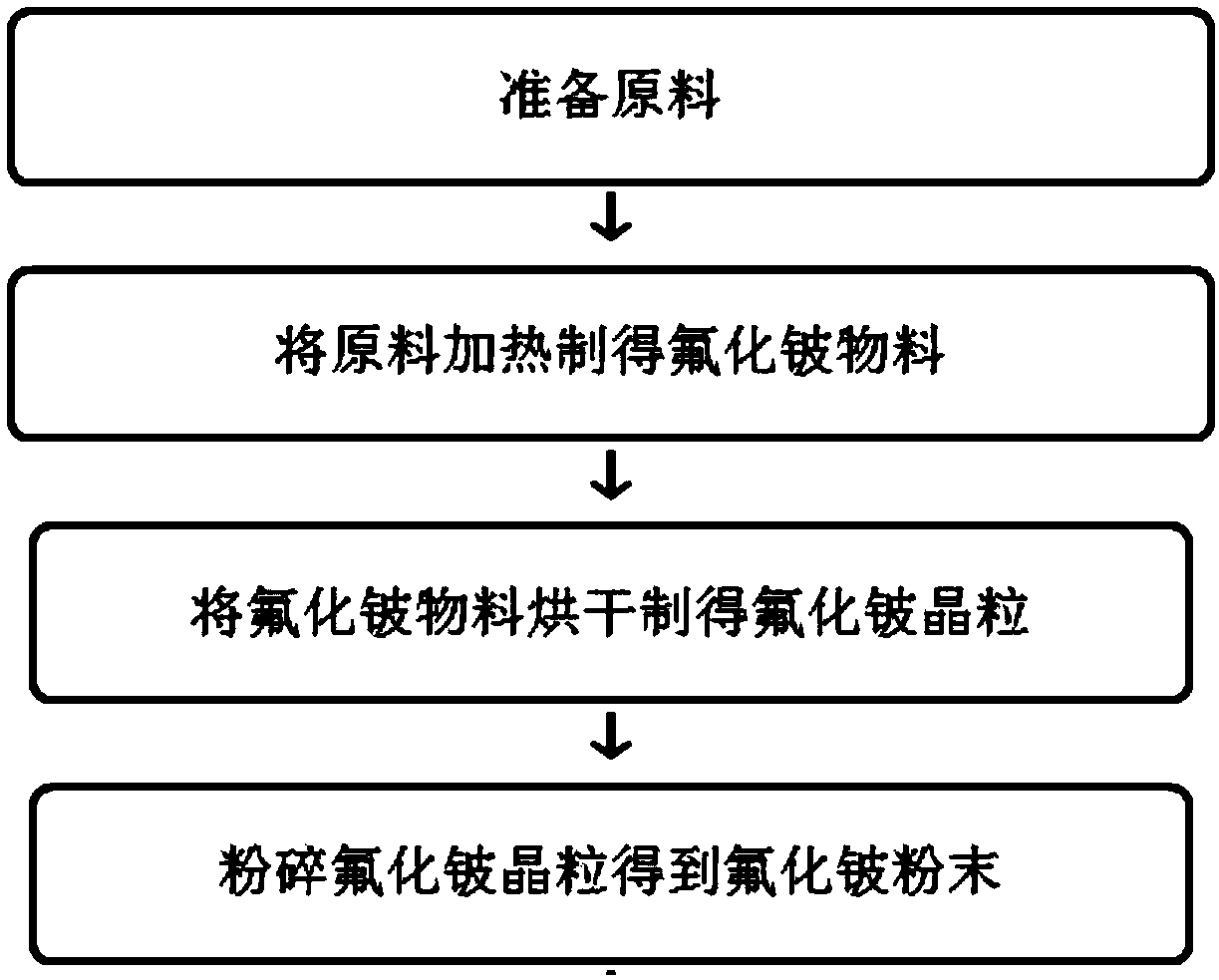

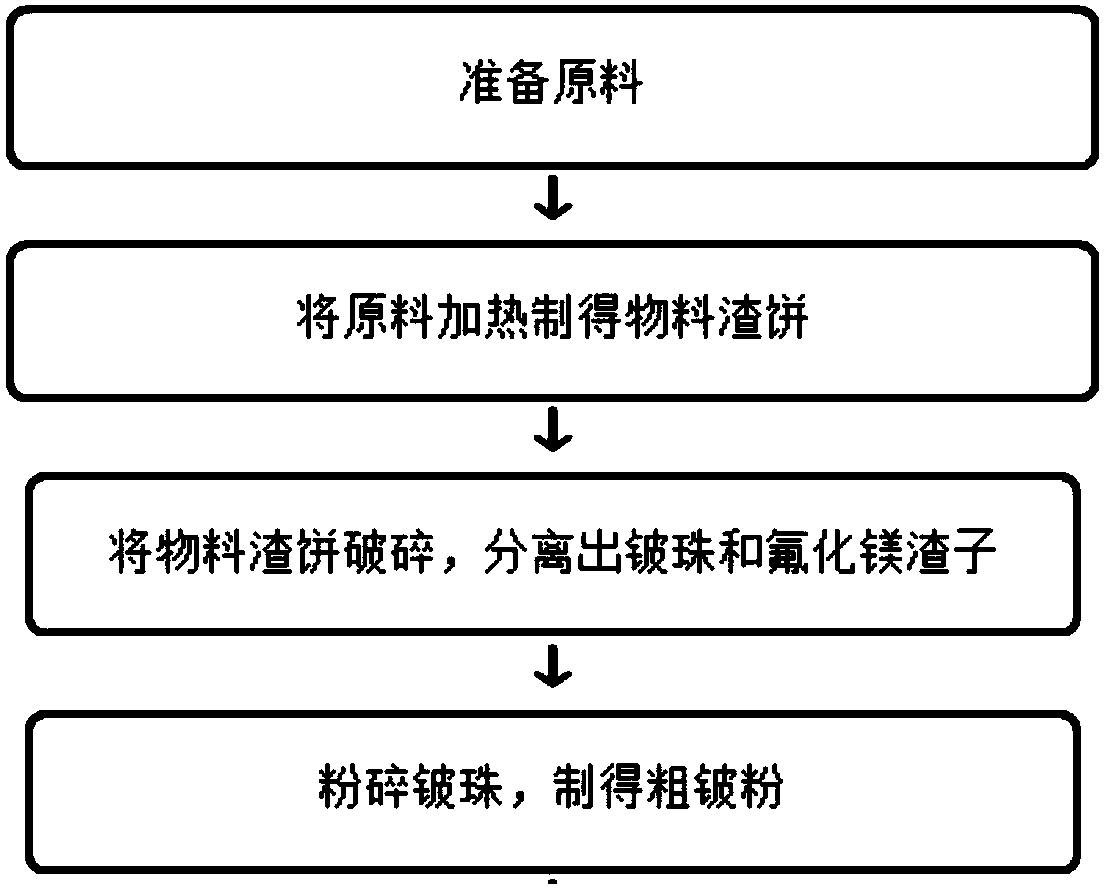

Thermal dissociation reactor, method for purifying coarse beryllium powder into ingots and method for preparing ultra-high pure metallic beryllium

The invention relates to a thermal dissociation reactor, a method for purifying coarse beryllium powder into ingots and a method for preparing ultra-high pure metallic beryllium. The thermal dissociation reactor comprises an iodine containing furnace, a low-temperature reactor and a high-temperature reactor, wherein the iodine containing furnace communicates with the low-temperature reactor, and the low-temperature reactor communicates with the high-temperature reactor. The method for purifying the coarse beryllium powder into the ingots through the thermal dissociation reactor comprises the following steps that the coarse beryllium powder and iodine are reacted in the thermal dissociation reactor, and the mass ratio of the coarse beryllium powder to the iodine is 5:1; beryllium iodide vapor is generated; the beryllium iodide vapor is thermally dissociated and decomposed into metallic beryllium and iodine vapor; collection is carried out to obtain pure beryllium powder; and the pure beryllium powder is smelted into the beryllium ingots in an electron beam smelting furnace. The thermal dissociation reactor is reasonable in structure, simple to assemble and convenient to use; and according to the method for purifying the coarse beryllium powder into the ingots through the thermal dissociation reactor, the operation is simple, the medicament is saved, the energy is saved, the environment is protected, the cost is low, and the purity of the beryllium is extremely high.

Owner:陆世强

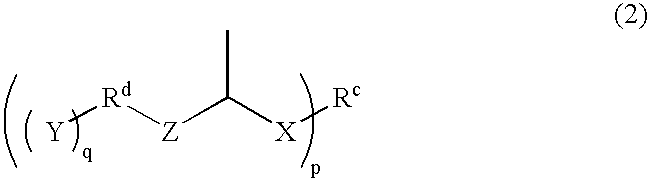

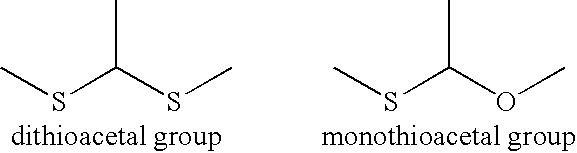

Compound having thermally dissociatable thioacetal skeleton, precursor thereof, cured product thereof, and composition for their production

A compound having thioacetal skeleton, a precursor thereof, a cured product thereof, and a composition for their production are provided for the thermally dissociatable material based on the inventors' finding that a thioacetal group is thermally dissociatable. The use of the thermally dissociatable material of the invention enables softening or liquefaction at any desired timing through thermal dissociation at a temperature below the thermal decomposition temperature of the cured product. It is thus possible to disassemble the structure to which the thermally dissociatable material had been attached in a short time. The thermally dissociatable material is useful as a highly disposable plastic material and is adapted for use as a sealant, coating composition or adhesive. Such material may be used, for example, as a curing agent for urethane curable composition or epoxy curable composition, or as a self-curable material.

Owner:THE YOKOHAMA RUBBER CO LTD

Nanometer film shaping machine

InactiveCN100357038CEvenly heatedUniform light receivingPretreated surfacesCoatingsWhole bodyThermal dissociation

The invention discloses a nano film forming machine for preparing nano functional film, which comprises a vacuum tank body and a generator, the vacuum tank body comprising a cabin and a top cover which is equipped with the cabin, the generator being equipped with the inner of the cabin and being fixed by a supporting flange which is equipped with the cabin, the rotation shaft of the generator being provided with a base-tray, the top cover being equipped with a liquid inlet which locates above the base-tray, the vacuum tank body being equipped with a vacuum adapter for evacuation, in the vacuum tank body being provided with a heat source for thermal dissociation and a light source for photo dissociation, and the heat source and light source equipped upper than base-tray; the invention has a merit of: taking film formation, thermal dissociation or photo dissociation and phase-change in high temperature in a whole body, and guaranteeing the film quality.

Owner:SOUTHEAST UNIV

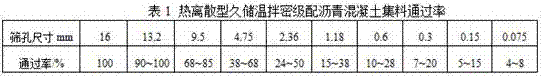

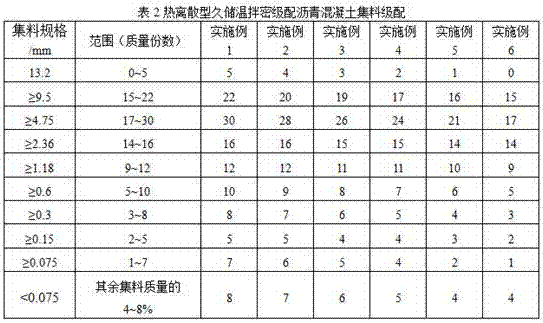

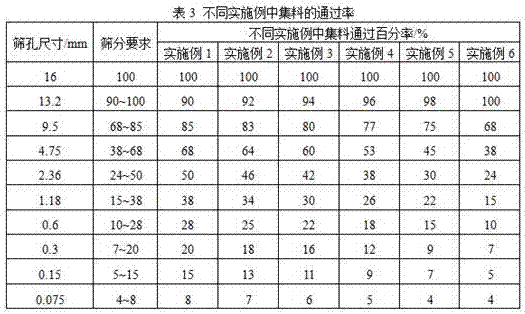

Thermal discrete long-storage temperature-mixed dense grading asphalt concrete and preparation method thereof

ActiveCN105693142BWill not stickReduce mixing energy consumptionClimate change adaptationPorosityRepair material

The invention relates to thermal dissociation type long-time storage warm mixing densely-graded asphalt concrete and a preparation method thereof.The thermal dissociation type long-time storage warm mixing densely-graded asphalt concrete is prepared from, by mass, 100 parts of aggregate, 4-8 parts of mineral powder, 4-6 parts of asphalt, 1-1.5 parts of Spro warm mixing disassociation agent and 1-5 parts of warm mixing agent.The maximum nominal grain diameter of the aggregate is 13 mm, and the design porosity of a mixture is 3.5%-4.5%.The Spro warm mixing discrete agent mainly achieves the effects of heat disassociation and reduction of the viscosity of an asphalt binding material on the mixture.The asphalt concrete can be applied to repairing of local damage such as pit slots, slurry spurting, check crack and fracturing of asphalt pavements, bridge floor asphalt pavement layers and tunnel asphalt concrete runway pavements, it is guaranteed that the pavement performance of the mixture completely meets the requirements for the performance of the hot mixing mixture, the problem that an existing diluted asphalt or emulsified asphalt cold repair material is insufficient in performance is solved, and the problem that a material source is hardly found hot material hot repairing can be solved.

Owner:CCCCRUITONG ROAD & BRIDGE MAINTENANCE TECH

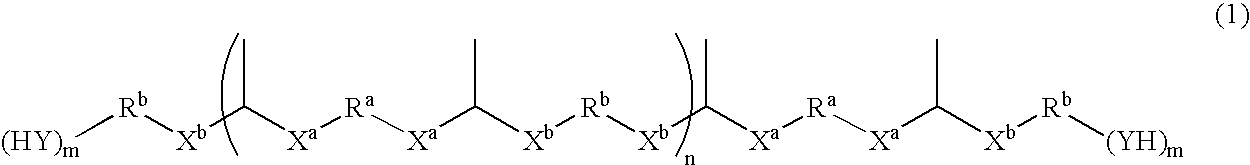

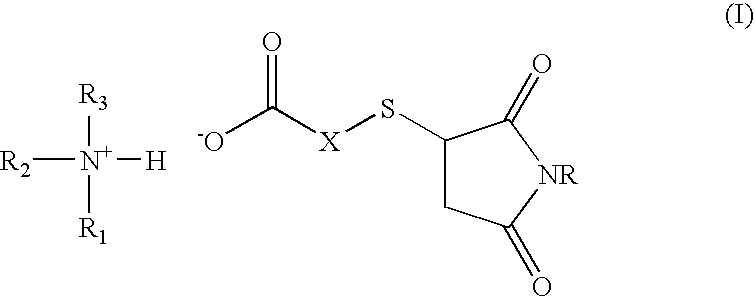

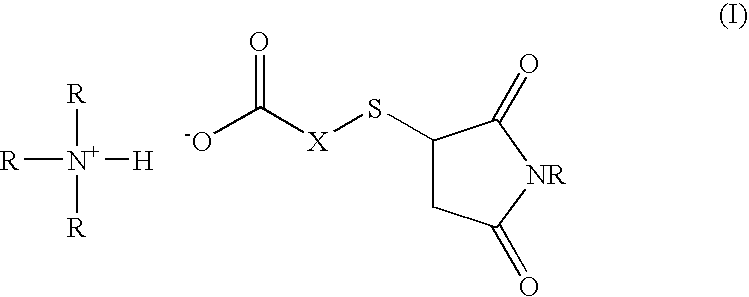

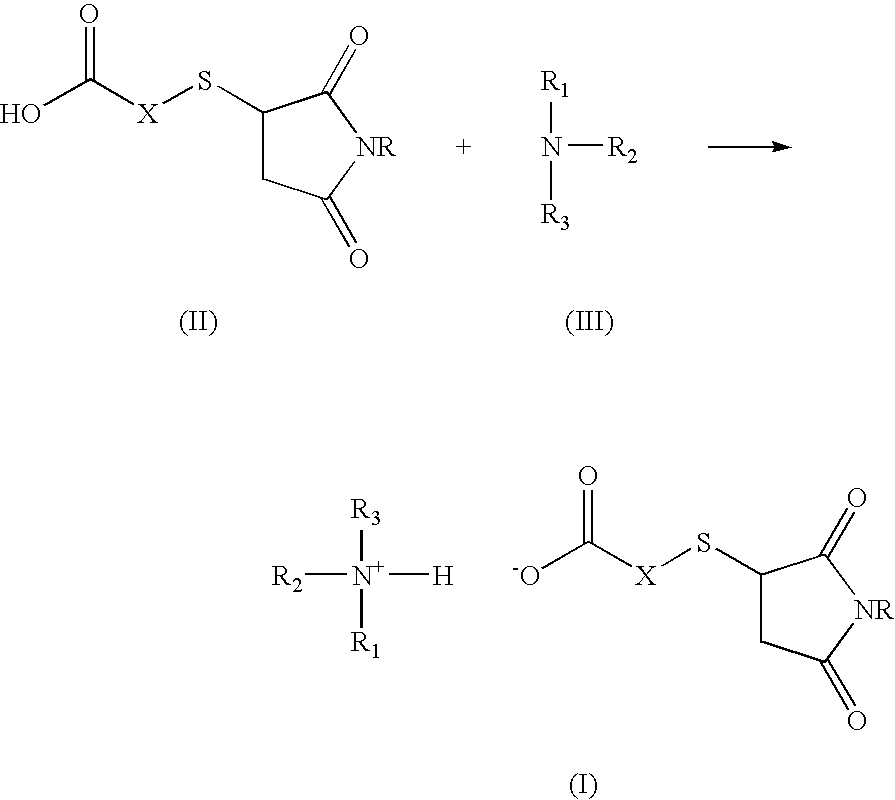

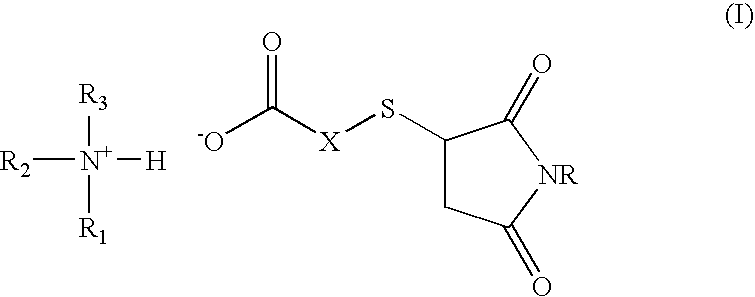

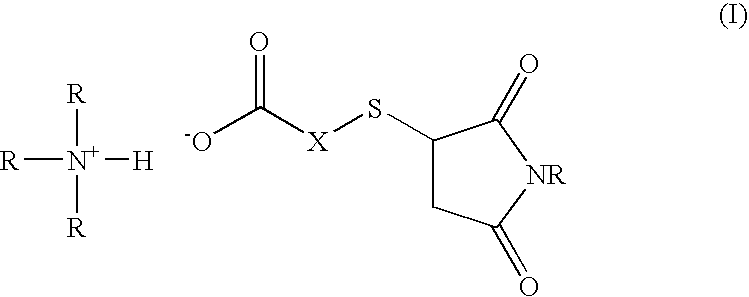

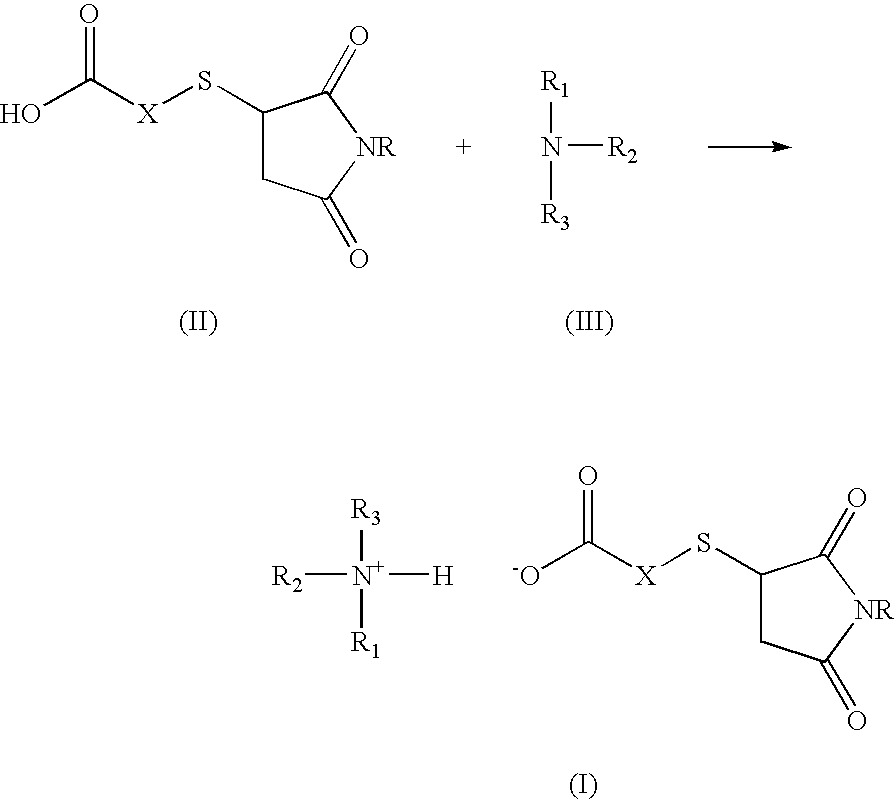

Amine salt compound of carboxylic acid having thermal dissociation portion and compounding agent for rubber vulcanization and rubber composition containing the same

InactiveUS20080146746A1Improve vulcanization efficiencyImprove heat aging resistanceOrganic chemistryOrganic compound preparationArylVulcanization

To provide a compound which has a higher vulcanization efficiency and superior heat aging resistance compared to conventional compounding agents for rubber compositions and which is environmentally friendly.An amine salt compound of a carboxylic acid containing a thermal dissociation portion having the Formula (I):wherein R represents an organic group selected from a C1 to C20 alkyl group, a C3 to C10 cycloalkyl group, a C6 to C20 aryl group and a C7 to C30 alkaryl group, R1, R2 and R3 independently represent a hydrogen atom or a C1 to C20 organic group which may have a heteroatom and / or a substituent group and X represents a C2 to C20 organic group which may have a heteroatom and / or a substituent group and a compounding agent for rubber vulcanization and a rubber composition containing the same.

Owner:YOKOHAMA RUBBER CO LTD

High-mach-number low-temperature array nozzle used for HF/DF chemical laser

ActiveCN106848810AHigh freezing efficiencyImprove thermal dissociation efficiencyLaser constructional detailsHydrogenCombustor

The invention relates to a high-mach-number low-temperature array nozzle used for HF / DF chemical laser. The array nozzle comprises more than two nozzle assembling units which are arranged in parallel; a nozzle unit is formed between the two nozzle assembling units; the nozzle unit is a typical two-dimensional slit Laval nozzle; a row of hydrogen nozzle holes are formed in the wall surface of each of the nozzle assembling units on the two sides of the tail end of an outlet expansion section of the corresponding nozzle unit separately; a row of main helium nozzle holes are formed in the wall surface of each of the nozzle assembling units on the two sides of an outlet expansion section between the hydrogen nozzle holes and a throat-shaped channel separately; and a row of combustor helium nozzle holes are formed in the wall surface of each of the nozzle assembling units on the two sides of the inlet end of the corresponding nozzle unit separately. By adopting a high-mach-number low-temperature array nozzle design concept, the efficient fluorine atom freezing efficiency of the high-mach-number low-temperature nozzle is maintained; and by introducing a Russia novel nozzle combustor helium adding strategy, the thermal dissociation efficiency of the combustor is greatly improved.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

Measurement of total reactive nitrogen, NOy, together with NO2, NO, and O3via cavity ring-down spectroscopy

ActiveUS9804138B2Accuracy sufficientSolve the lack of precisionAir quality improvementMaterial analysisThermal dissociationCavity ring-down spectroscopy

A sensitive, compact detector measures total reactive nitrogen (NOy), as well as NO2, NO, and O3. In all channels, NO2 is directly detected by laser diode based cavity ring-down spectroscopy (CRDS) at 405 nm. Ambient O3 is converted to NO2 in excess NO for the O3 measurement channel. Likewise, ambient NO is converted to NO2 in excess O3. Ambient NOy is thermally dissociated at 700 C to form NO2 or NO in a heated quartz inlet. Any NO present in ambient air or formed from thermal dissociation of other reactive nitrogen compounds is converted to NO2 in excess O3 after the thermal converter. The precision and accuracy of this instrument make it a versatile alternative to standard chemiluminescence-based NOy instruments.

Owner:THE UNITED STATES OF AMERICA AS REPRESENTED BY THE SECRETARY OF THE COMMERCE

Coal gas and pulverized coal synergistic power generation and polygeneration device and method

ActiveCN104776426BEfficient cascade utilizationReduce productionCombustion using gaseous and pulverulent fuelEnergy inputCogenerationBottle

Owner:李大鹏

Method for continuous production of light acrylates by esterification of a raw ester-grade acrylic acid

ActiveUS20160159725A1Organic compound preparationPreparation from carboxylic acid esters/lactonesAlcoholThermal dissociation

The present invention relates to methods by which the thermal dissociation of Michael adducts present in a stream of crude acrylic acid, called “crude ester grade”, and the esterification reaction of acrylic acid present in the stream of crude acrylic acid, or generated in situ by thermal dissociation, with a light alcohol, are carried out simultaneously.

Owner:ARKEMA FRANCE SA

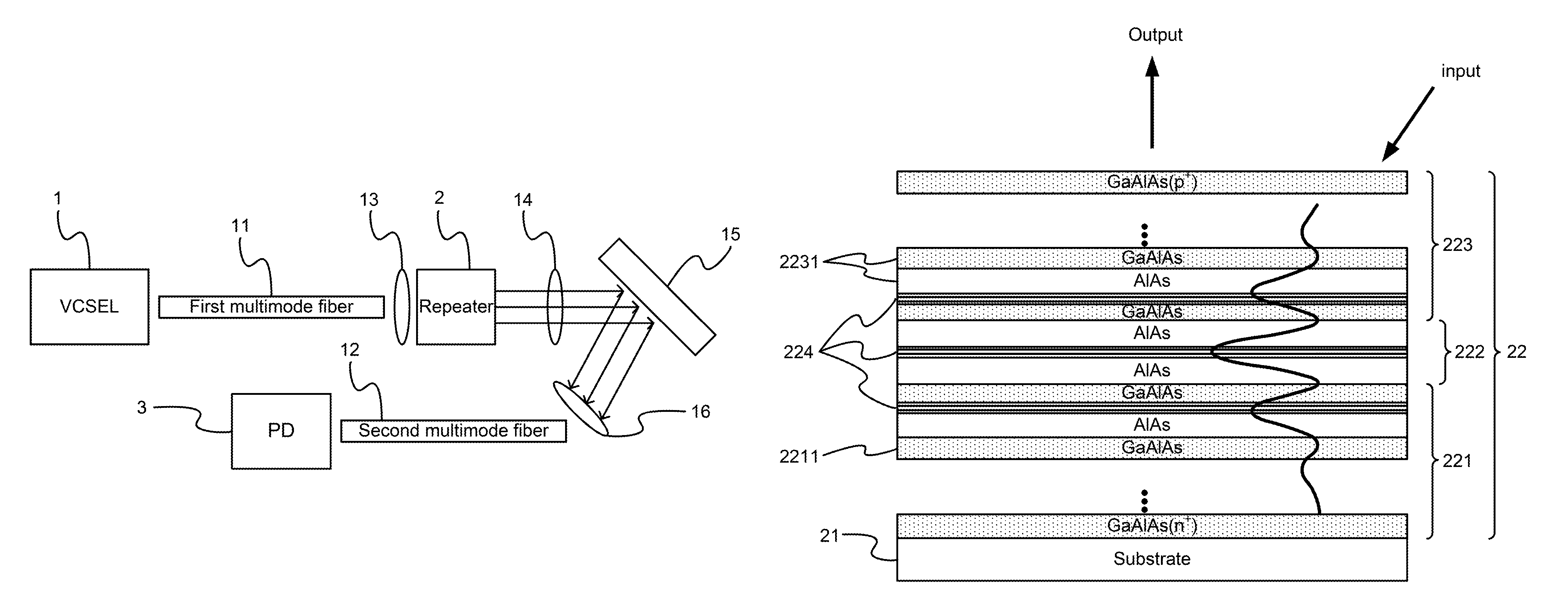

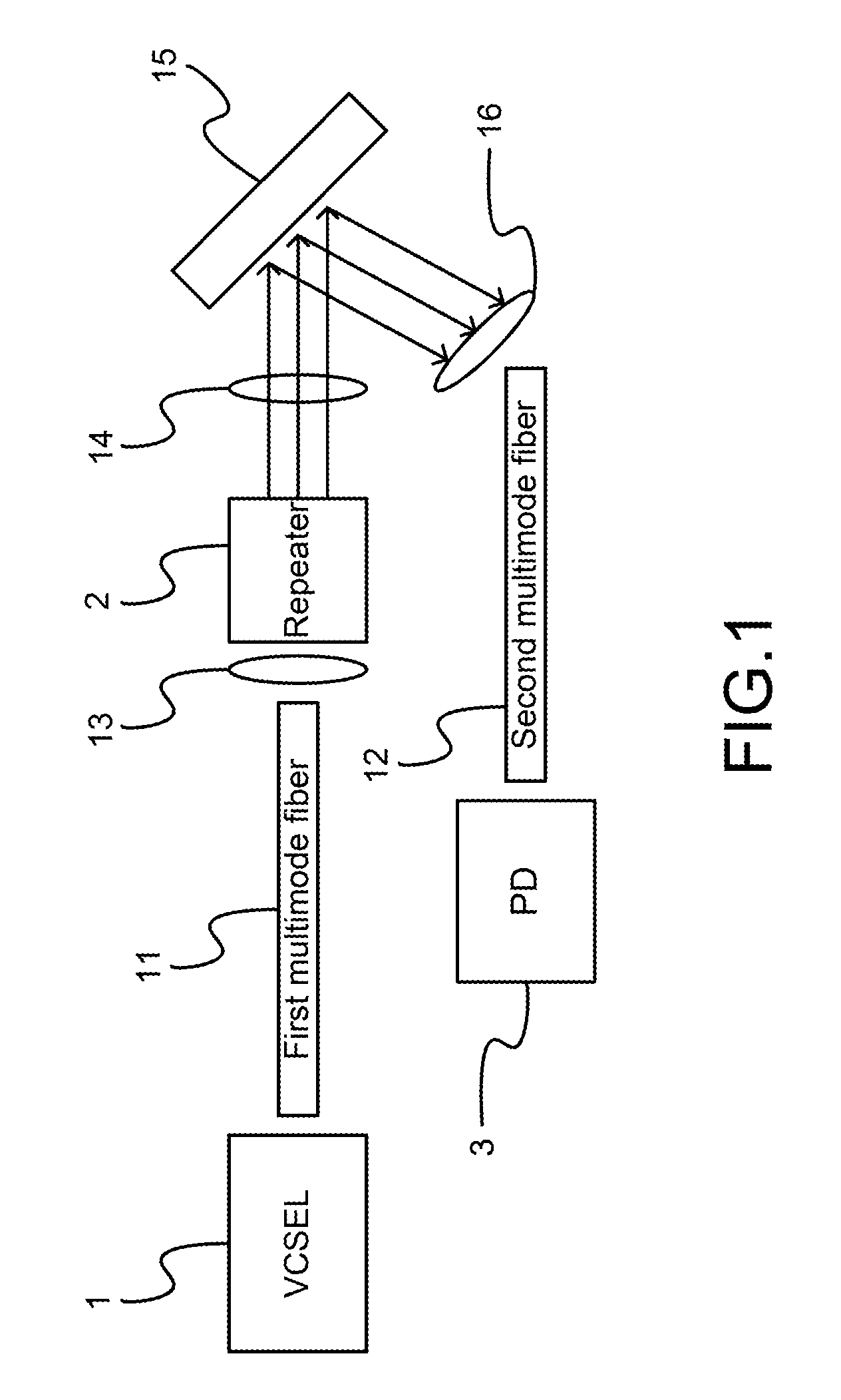

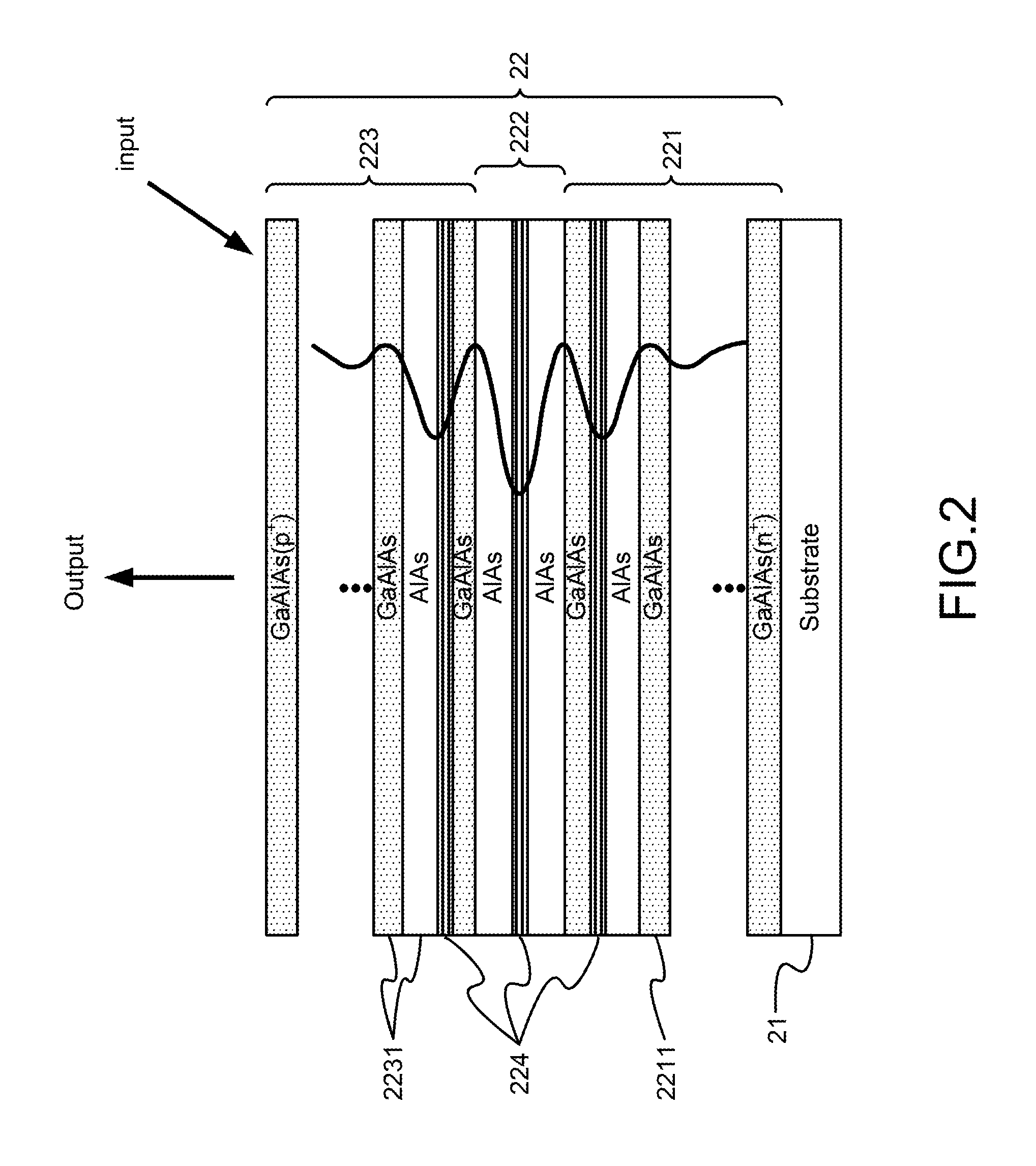

Device of optical passive repeater used in optical multimode communication

ActiveUS9287980B2Increase reachWithout integrityOptical mode multiplex systemsMultimode transmissionSignal qualityEngineering

An optical passive repeater is provided. The repeater is operated under a state of polariton Bose-Einstein condensation (BEC). A phase transition from a thermal polariton state to a condensed polariton state is controlled, where system temperatures and densities are lower than thermal dissociation temperatures and nonlinear saturation densities, respectively. Original input multimode laser signals are transformed into final output single-mode laser signals. Thus, the polariton BEC passive repeater becomes a power-efficient and low-cost device to increase the reach of optical links without sacrificing its signal quality and integrity.

Owner:NATIONAL TSING HUA UNIVERSITY

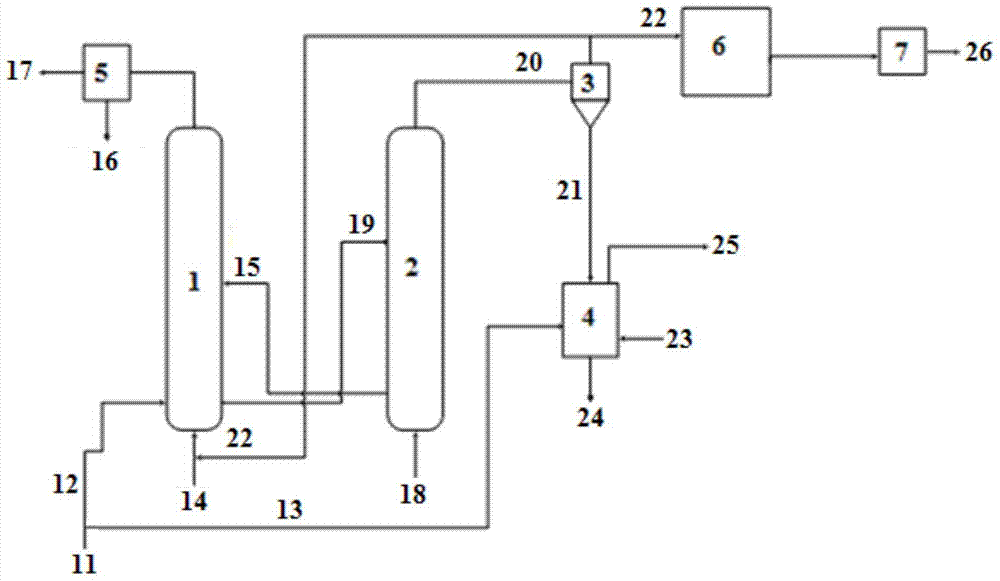

Coal pyrolysis and gasification combined production method

ActiveCN105441138BTake advantage ofSolve the whereabouts problemSpecial form destructive distillationGranular/pulverulent flues gasificationHigh carbonFluidized bed

The invention relates to a joint production method of coal pyrolysis and gasification, the method comprising: (1) separating coarse coal powder and fine coal powder from raw coal; (2) separating the coarse coal powder in a fluidized bed (3) Gasify the semi-coke produced by pyrolysis in a fluidized bed to obtain a gas stream and high-temperature semi-coke, which are separated from the gas stream product gas and solid particles, and at least part of the high-temperature semi-coke and / or at least part of the product gas are returned to the pyrolysis process as a heat source for the pyrolysis process; (4) the separated in step (1) The fine coal powder and the solid particles separated in step (3) are subjected to pulverized coal gasification. The joint production method of coal pyrolysis and gasification provided by the present invention realizes the joint supply of heat, gas, oil and chemicals, and obtains a higher carbon conversion rate.

Owner:CHINA PETROLEUM & CHEM CORP +1

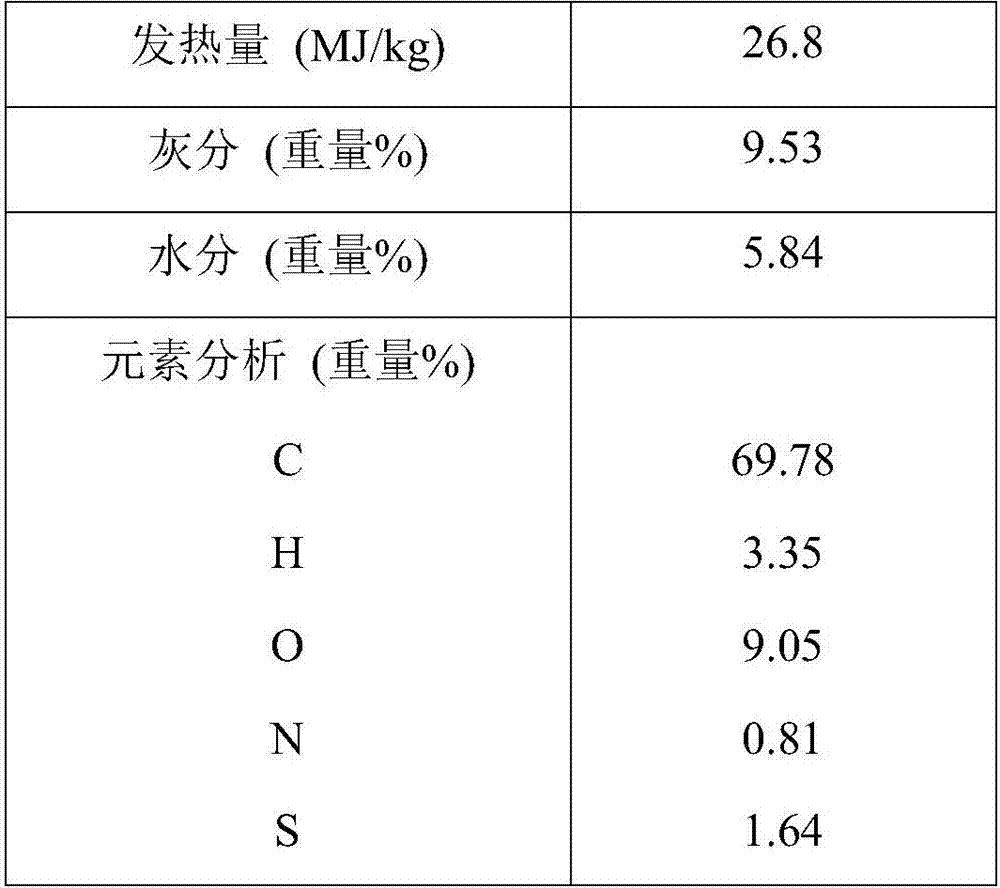

Powder coal grading clean grading utilization technology using thermal dissociation as the first stage

InactiveCN101063039BTake advantage ofReliable workmanshipLiquid hydrocarbon mixture productionSpecial form destructive distillationChemical industryFluidized bed drying

The invention discloses a dust coal grading clean multigang utilizing technique with decomposition as the first grade, which comprises the following steps: processing and sorting raw coal through raw coal processing machine; getting the raw coal with a finite grain size; entering into fluidized-bed drying pyrogenic installation; proceeding dry pyrogenic reaction; getting high carbon half pulverized coke; entering into multiple circulating fluidized bed gasifying installation; proceeding multiple circulating gasifying reaction; getting synthesis gas; leading into chemical industry production; entering solid phase ash coke with low carbon content into circulating fluidized bed boiler; flaming completely. This invention possesses stable craft and low cost, which can utilize all of heat energy in craft course.

Owner:董久明

Amine salt compound of carboxylic acid having thermal dissociation portion and compounding agent for rubber vulcanization and rubber composition containing the same

InactiveUS7662891B2Improve efficiencyImprove heat aging resistanceOrganic chemistryOrganic compound preparationArylVulcanization

To provide a compound which has a higher vulcanization efficiency and superior heat aging resistance compared to conventional compounding agents for rubber compositions and which is environmentally friendly.An amine salt compound of a carboxylic acid containing a thermal dissociation portion having the Formula (I):wherein R represents an organic group selected from a C1 to C20 alkyl group, a C3 to C10 cycloalkyl group, a C6 to C20 aryl group and a C7 to C30 alkaryl group, R1, R2 and R3 independently represent a hydrogen atom or a C1 to C20 organic group which may have a heteroatom and / or a substituent group and X represents a C2 to C20 organic group which may have a heteroatom and / or a substituent group and a compounding agent for rubber vulcanization and a rubber composition containing the same.

Owner:THE YOKOHAMA RUBBER CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com

![[non-volatile memory cell and fabrication thereof] [non-volatile memory cell and fabrication thereof]](https://images-eureka-patsnap-com.libproxy1.nus.edu.sg/patent_img/b6ac861f-e8cb-4a13-9d57-f91624ef13d2/US20050045943A1-20050303-D00000.png)

![[non-volatile memory cell and fabrication thereof] [non-volatile memory cell and fabrication thereof]](https://images-eureka-patsnap-com.libproxy1.nus.edu.sg/patent_img/b6ac861f-e8cb-4a13-9d57-f91624ef13d2/US20050045943A1-20050303-D00001.png)

![[non-volatile memory cell and fabrication thereof] [non-volatile memory cell and fabrication thereof]](https://images-eureka-patsnap-com.libproxy1.nus.edu.sg/patent_img/b6ac861f-e8cb-4a13-9d57-f91624ef13d2/US20050045943A1-20050303-D00002.png)