Thermal dissociation reactor, method for purifying coarse beryllium powder into ingots and method for preparing ultra-high pure metallic beryllium

A reactor and thermal dissociation technology, which is applied in the field of preparing ultra-high-purity metal beryllium, thermal dissociation reactor and its purified coarse beryllium powder into ingots, can solve the problems of high cost, large energy consumption, low production efficiency, etc., and achieve recovery High utilization rate, simple operation, and the effect of saving medicine

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0094] The principles and features of the present invention are described below, and the examples given are only used to explain the present invention, and are not intended to limit the scope of the present invention.

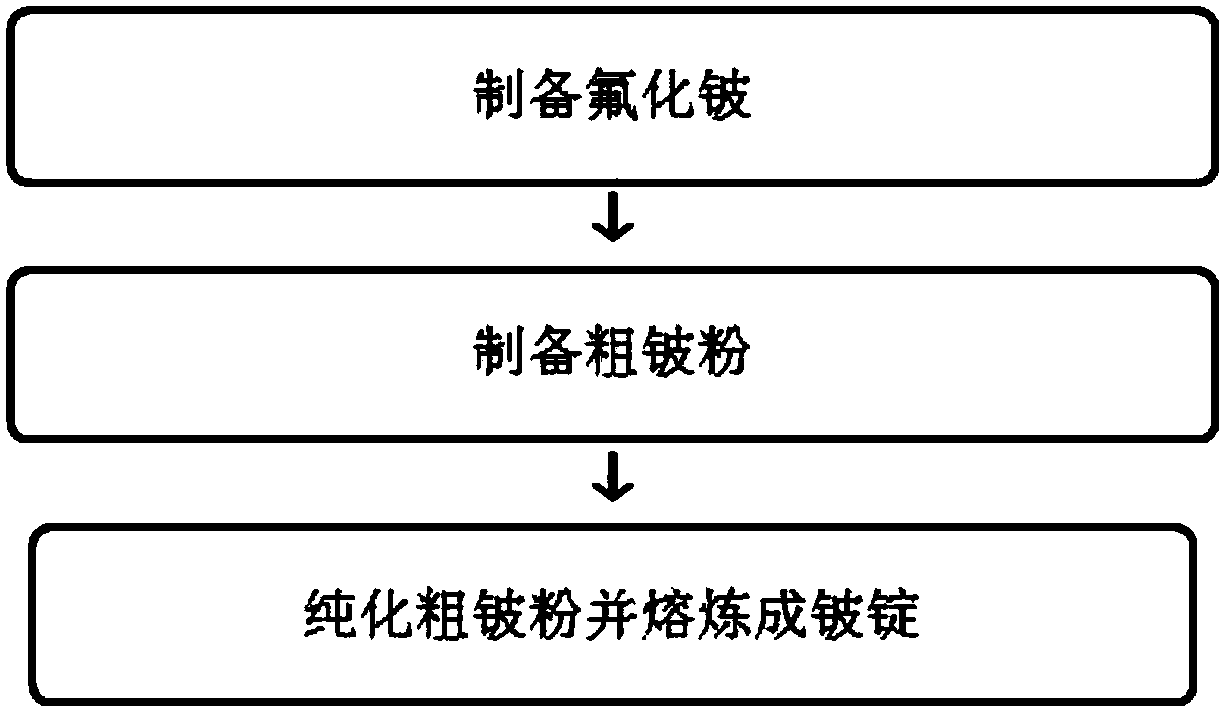

[0095] Such as figure 1 Shown, a kind of mode of preparing ultra-high purity metal beryllium of the present invention comprises following method:

[0096] Process for preparing beryllium fluoride;

[0097] A method for preparing coarse beryllium powder;

[0098] A method of purifying coarse beryllium powder into an ingot.

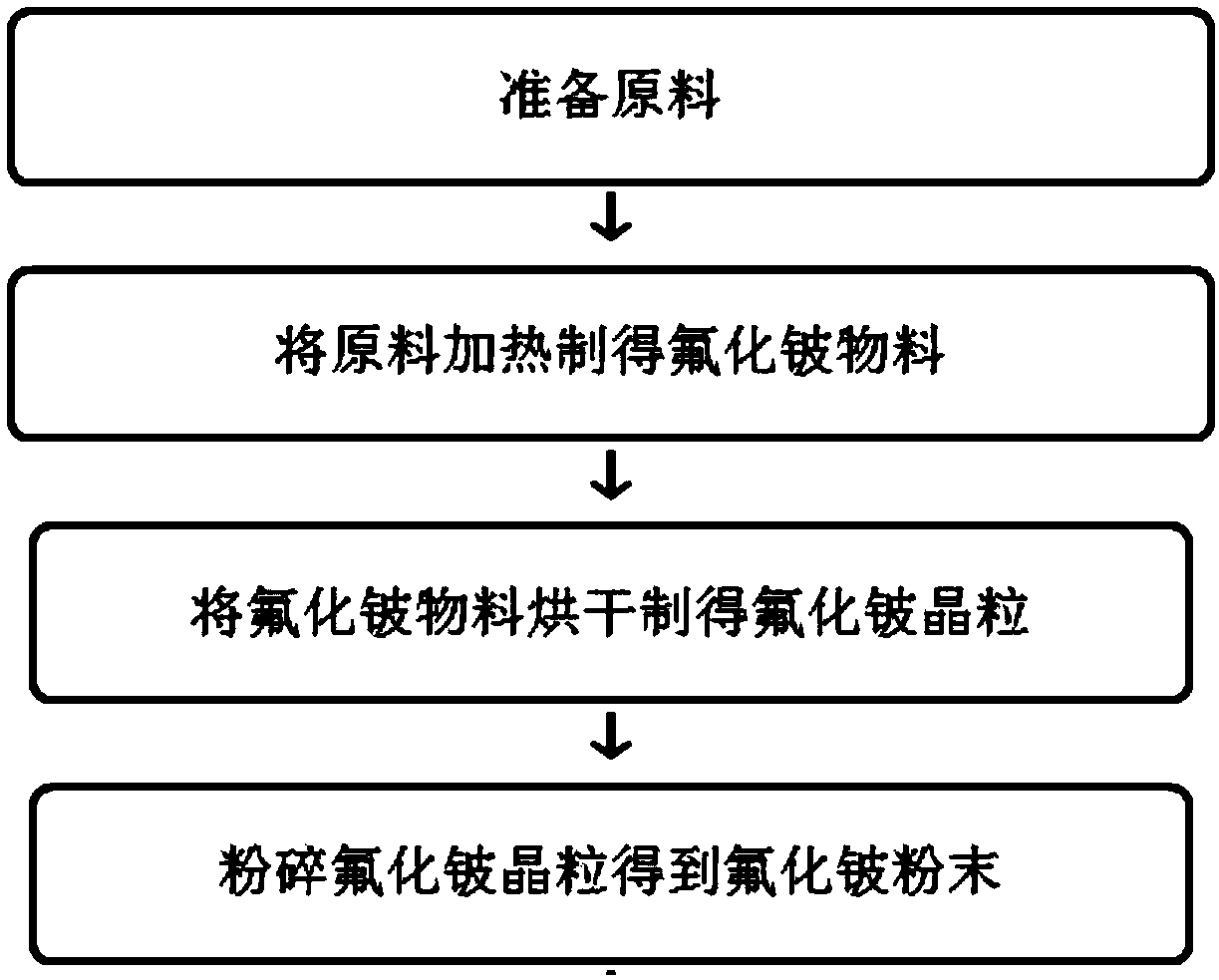

[0099] Such as figure 2 Shown, the specific synthesis of described beryllium fluoride can be prepared through the following steps:

[0100] The first step: preparing raw materials, the raw materials include beryllium hydroxide and hydrofluoric acid;

[0101] Step 2: heating the raw materials to obtain beryllium fluoride materials;

[0102] Step 3: drying the beryllium fluoride material to obtain beryllium fluoride grains;

[0103] St...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com