Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

59 results about "Beryllium Powder" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

BERYLLIUM OXIDE POWDER FOR SUPERIOR THERMAL PROPERTIES. Materion manufactures two grades of beryllium oxide powder. The powder is typically supplied in -20 mesh, dry condition. Beryllium oxide powder can be pressed, sintered or extruded into shapes producing a ceramic with superior thermal properties.

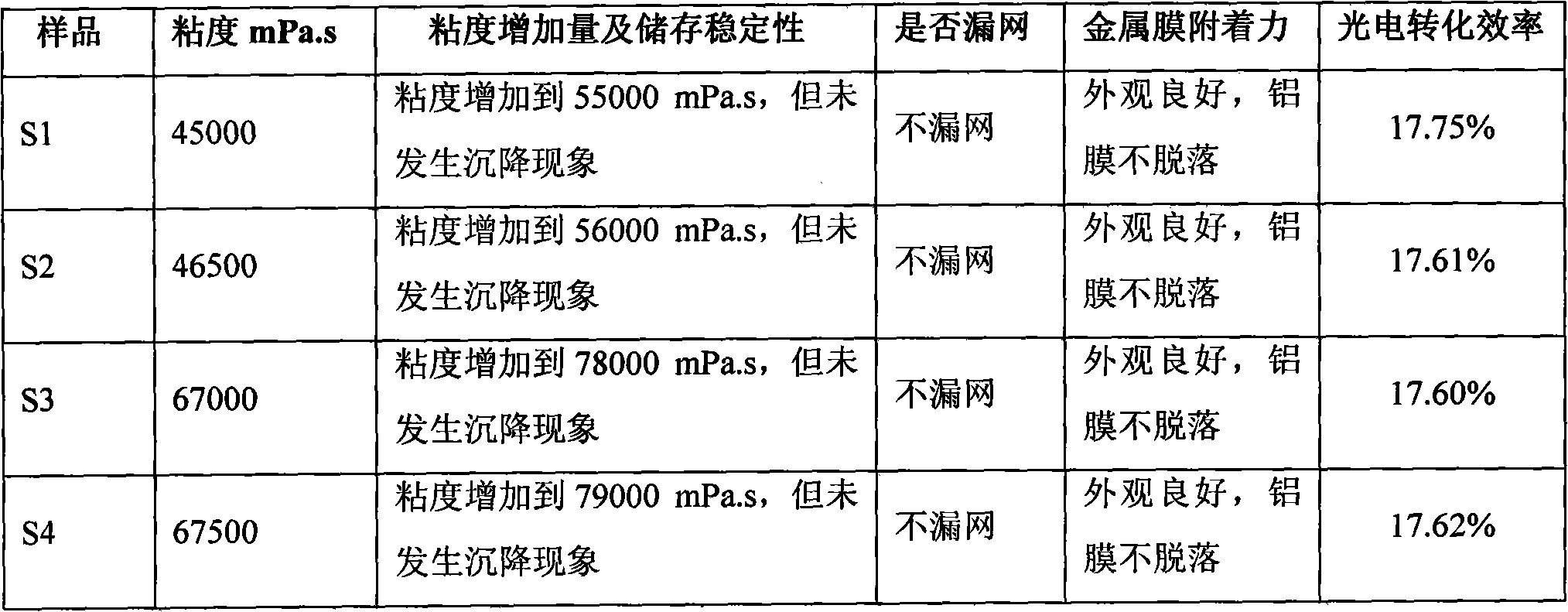

Aluminium conductive paste for solar energy battery and preparation method thereof

ActiveCN101989625AImprove thixotropyEasy constructionFinal product manufactureNon-conductive material with dispersed conductive materialSolar batteryPhotoelectric conversion efficiency

The invention discloses an aluminium conductive paste for a solar energy battery and a preparation method thereof. The paste comprises the following components: aluminium powder, an inorganic binder, an organic carrier, and a metal additive. The metal powder additive has the median particle diameter D50 of 10 to 150 nm, and is one or more of magnesium powder, beryllium powder and lithium powder. The aluminium conductive paste prepared has high storage stability, is difficult to settle and agglomerate, and does not easily slip through a screen in the screen printing process; after the paste is printed on the surface of the crystal silicon solar energy battery and sintered, the series resistance of the battery is reduced greatly, and the filling factor is increased; and the average photoelectric conversion efficiency of the monocrystalline silicon solar battery plate is over 17.60 percent.

Owner:BYD CO LTD

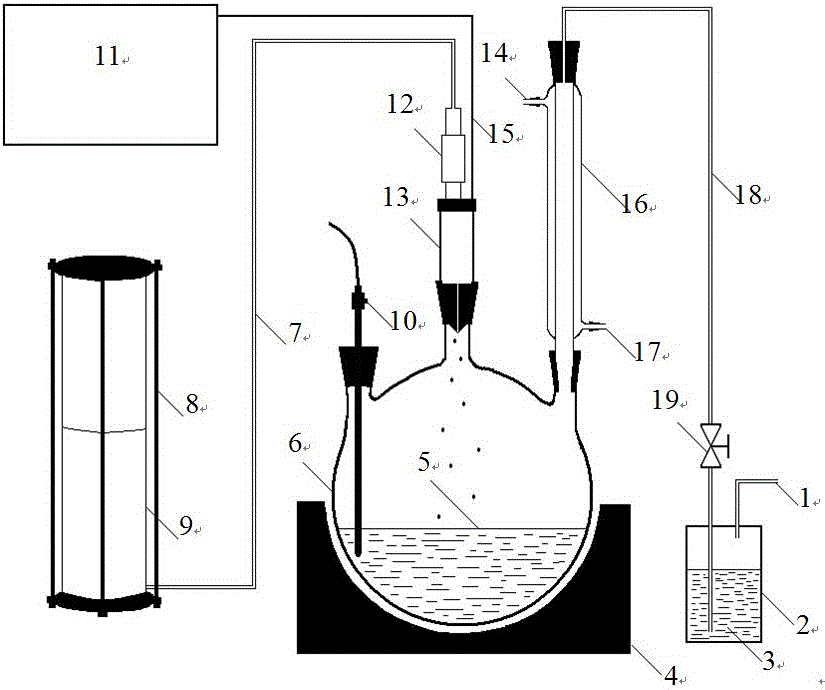

Preparing method of nano beryllium powder

The invention provides a preparation method of nano beryllium powder. The preparation method comprises the steps of: (a) heating the mineral oil solvent to a constant temperature; (b) distributing the organic beryllium ether compound by using a micro-droplet generator, and transporting the organic beryllium ether compound from the liquid storage pipe to the distribution head through a pipeline , forming micro-droplets and spraying into the heated mineral oil solvent; (c) organic beryllium ether compounds are decomposed by heating in mineral oil solvents to generate BeH 2 , the by-product isobutene and ether are discharged; (d) BeH 2 Dehydrogenation by overheating to generate beryllium; (e) distillation and separation of mineral oil solvent and drying to obtain nano-beryllium powder.

Owner:LASER FUSION RES CENT CHINA ACAD OF ENG PHYSICS

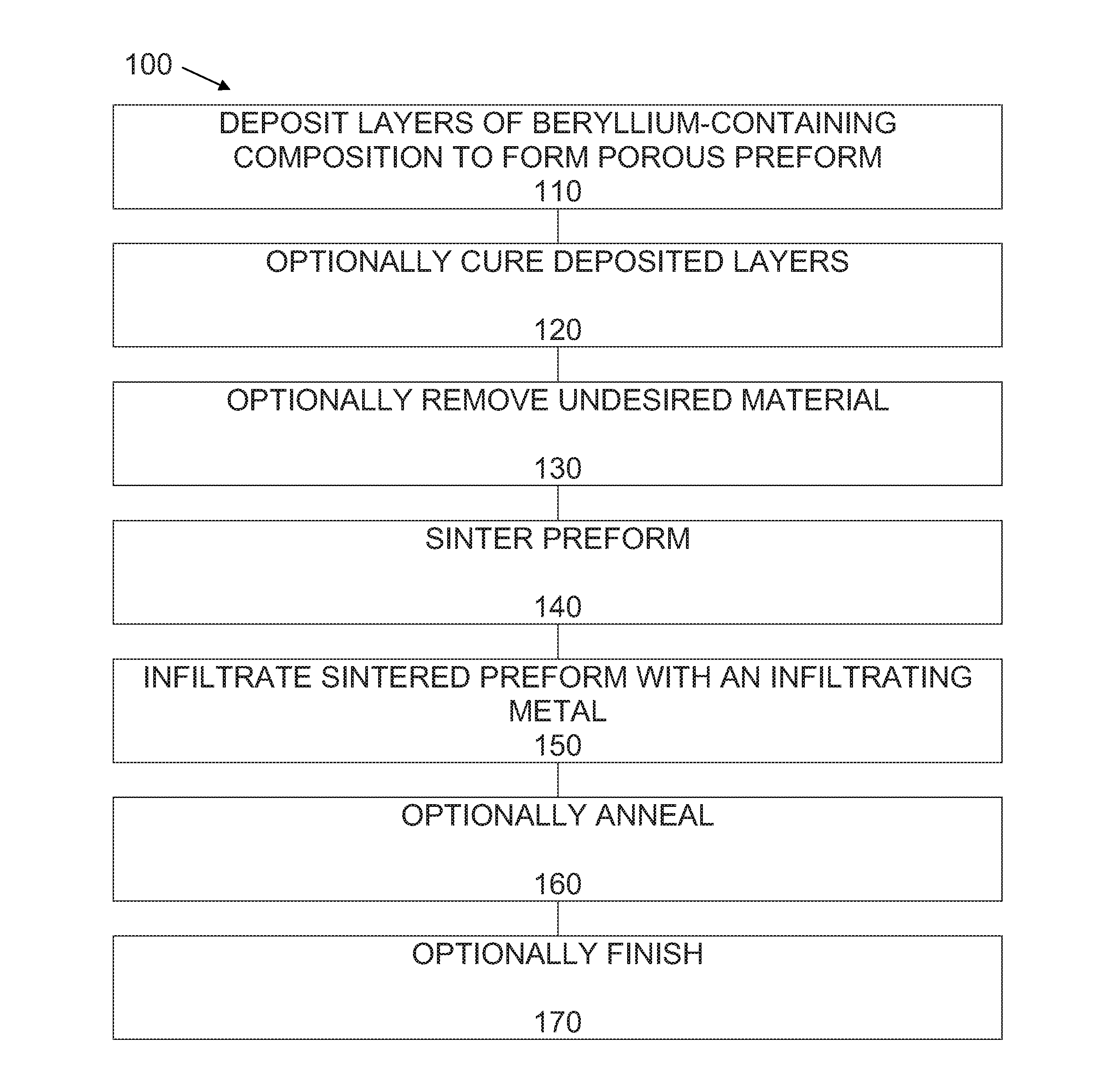

Additive manufacturing of articles comprising beryllium

A method of making an article includes depositing a plurality of layers to form a three-dimensional preform, sintering the preform to form a sintered preform, and infiltrating the preform with at least one metal to form the article. At least one layer of the plurality of layers is formed from a beryllium-containing composition including beryllium powder. The infiltrating metal can be selected from aluminum and magnesium.

Owner:MATERION

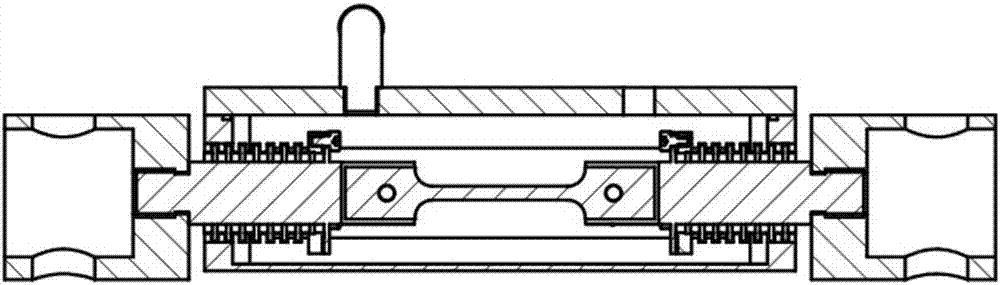

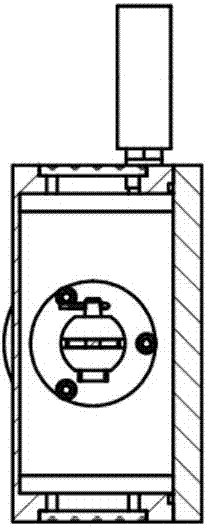

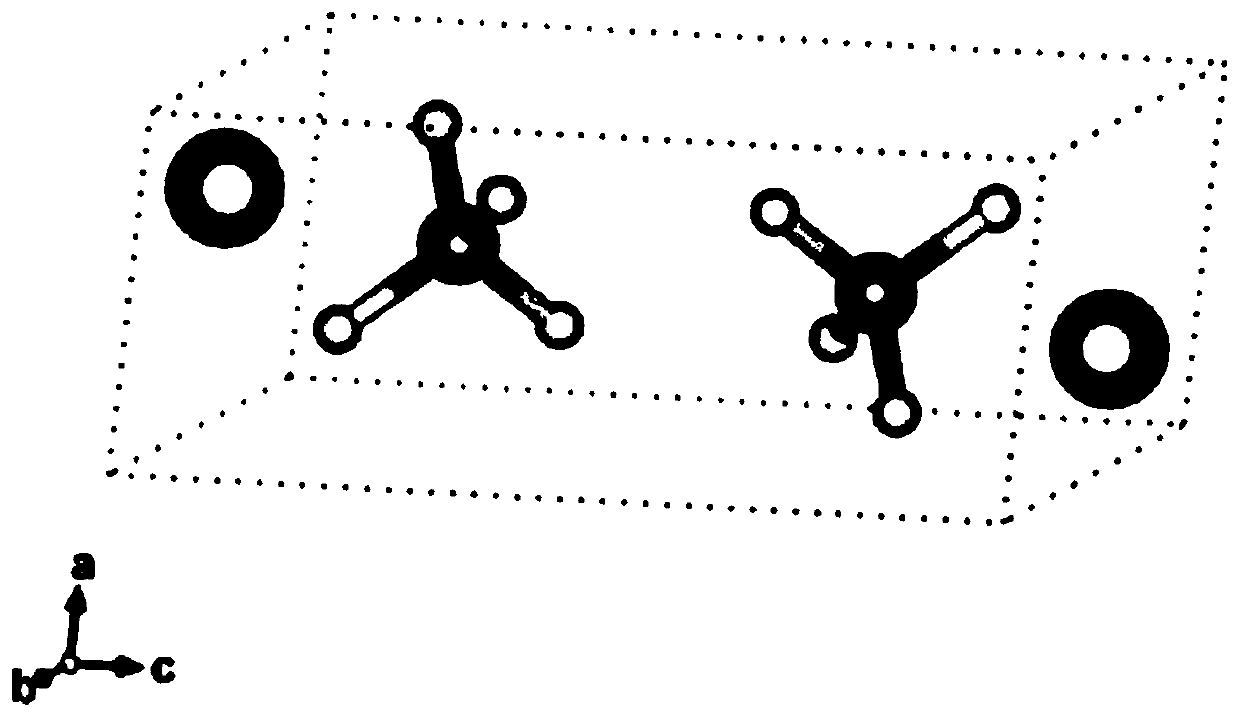

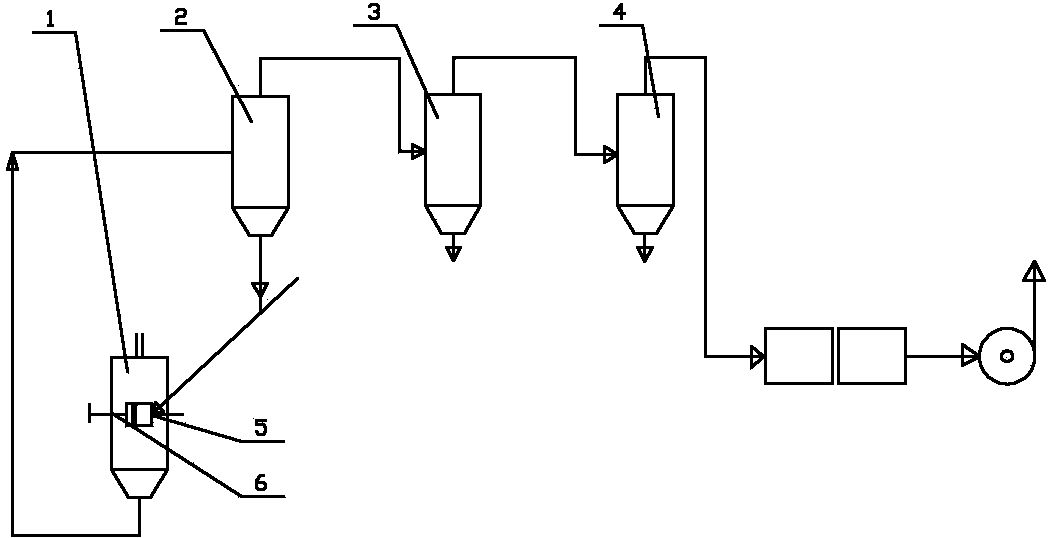

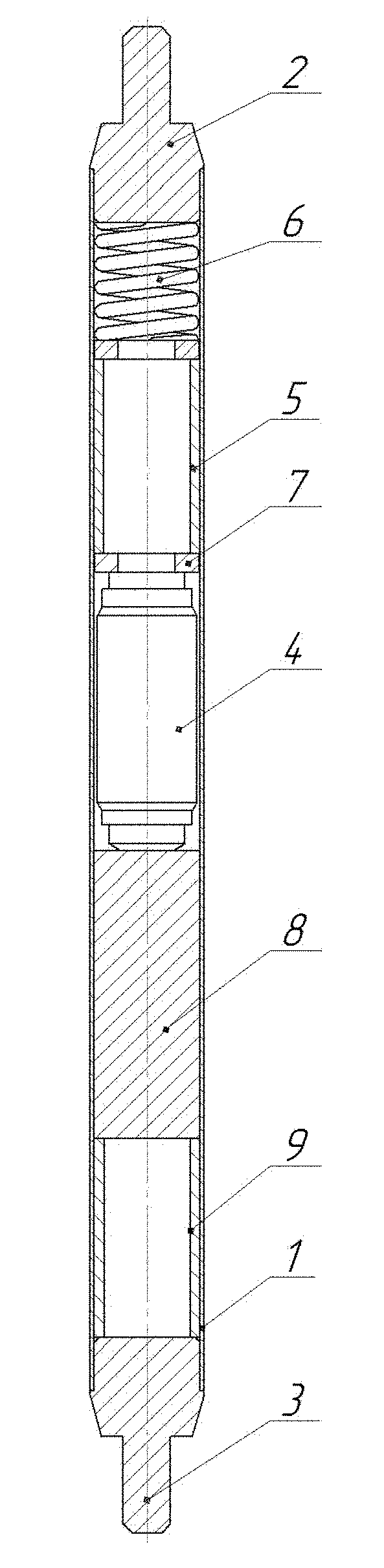

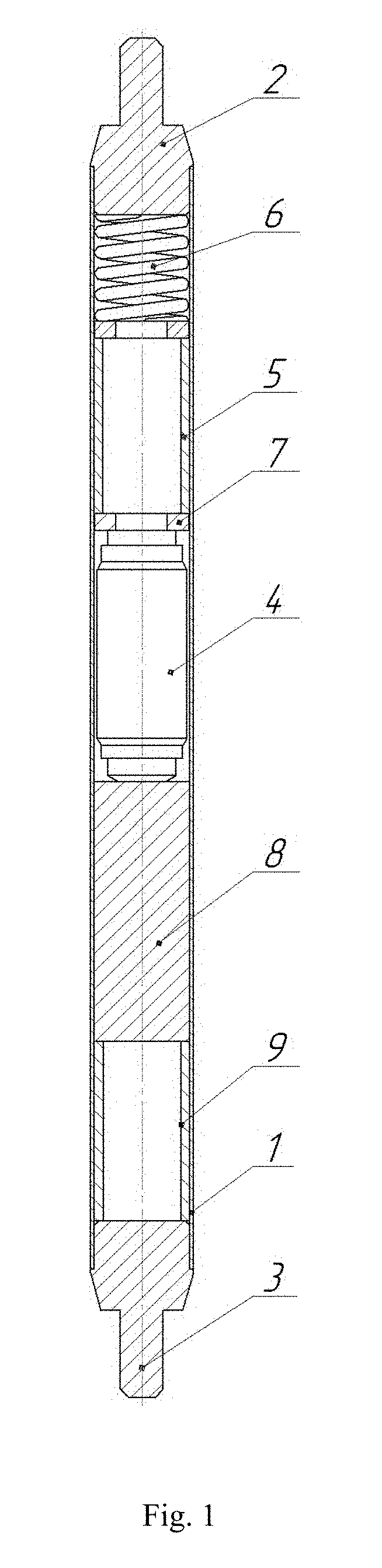

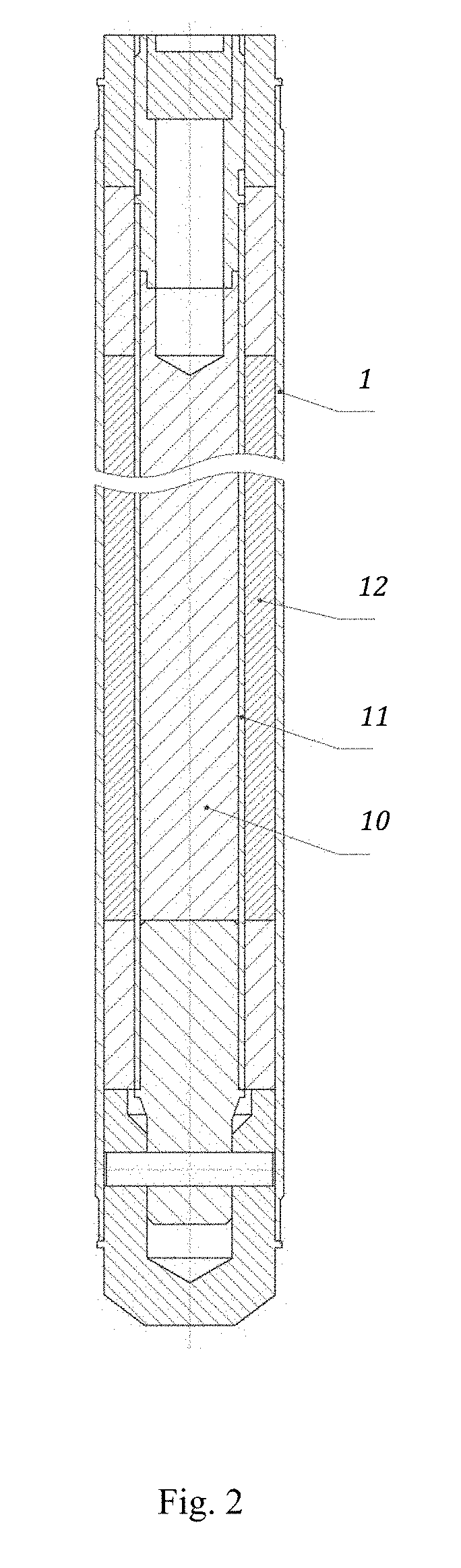

Room-temperature mechanical loading device for metal beryllium in neutron scattering experiment

PendingCN107063872AWon't leakRisk of Hazard PreventionMaterial strength using tensile/compressive forcesNeutron scatteringBeryllium Powder

The invention discloses a room-temperature mechanical loading device for metal beryllium in a neutron scattering experiment. The loading device comprises a sealed cavity, an incident window plate, an emergent window plate, a sealing cover, a sealing ring, a loading rod, a corrugated pipe, a sealing flange, a sample fixture, a dowel, a vacuumization crossover coupling and a vacuum manometer. A sample feeding hole is formed in the sealed cavity of the room-temperature mechanical loading device for metal beryllium in the neutron scattering experiment and matched with the sample fixture to complete loading and unloading of a sample, the cavity is sealed through the sealing cover, mechanical loading of the sample by certain displacement can be ensured to be realized by means of the telescopic characteristic of the corrugated pipe in a telescopic connection assembly when the inside of the sealed cavity is in a negative pressure state, so that metal beryllium powder produced after the sample is broken cannot leak to the outside of the sealing cavity, the device has the advantages of being simple in structure, easy to establish and safe and reliable in performance, and the risk that an experimenter is harmed by metal beryllium powder can be prevented effectively.

Owner:INST OF NUCLEAR PHYSICS & CHEM CHINA ACADEMY OF

High-tenacity silicon carbide ceramic and preparation method thereof

The invention discloses high-tenacity silicon carbide ceramic and a preparation method thereof. The high-tenacity silicon carbide ceramic is characterized by being prepared from the following raw materials in parts by weight: 70-80 parts of silicon carbide, 8-13 parts of stainless steel powder, 2-4 parts of titanium powder, 4-8 parts of nano-zirconia, 1-3 parts of polyvinyl alcohol, 3-6 parts of beryllium powder, 1-2 parts of ammonium polyphosphate, 1-2 parts of a silane coupling agent KH-580, 3-4 parts of graphite, 2-3 parts of sodium lignin sulfonate, 2-3 parts of a sintering aid and 80-100 parts of deionized water. By adding stainless steel powder, the sintering density of the high-tenacity silicon carbide ceramic is improved, the sintering temperature is decreased, and resources are saved; by adding nano-zirconia and metal powder, the shape and the grain boundary characteristics of the ceramic are improved, and breaking energy is consumed, so that the tenacity of the ceramic is improved.

Owner:ANHUI HEHAN OPTOELECTRONICS TECH

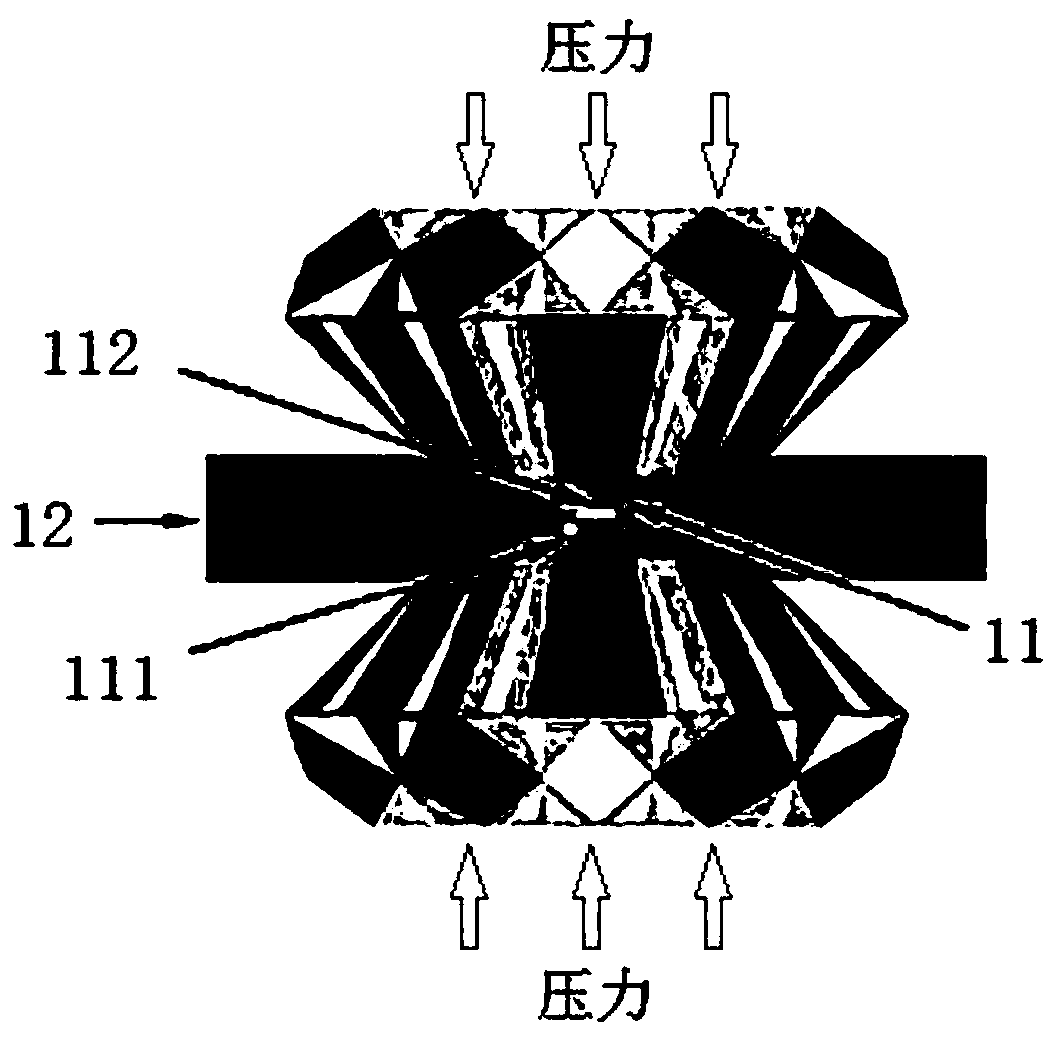

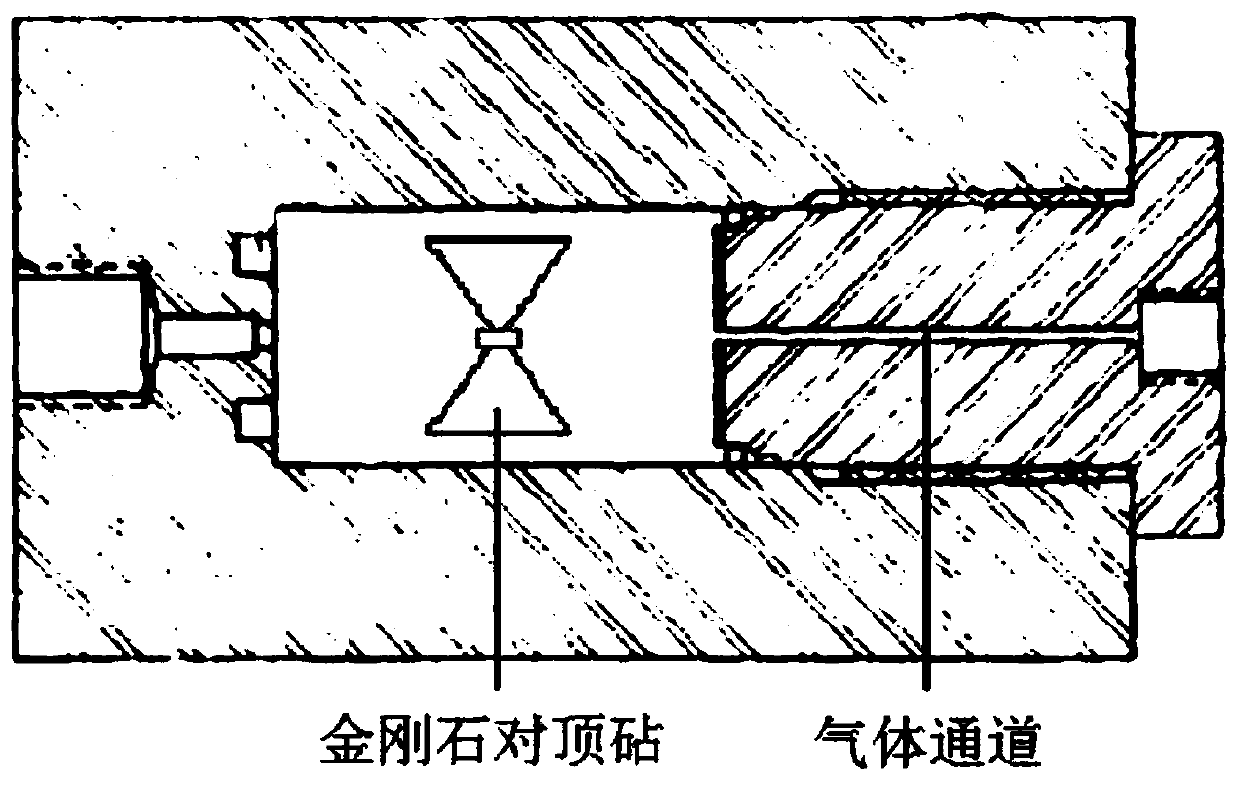

Novel superconducting material and preparation method thereof

ActiveCN110183473AReduce work stressSolve the problem of excessive stress required by the jobBeryllium organic compoundsBeryllium PowderMethane

The invention discloses a novel superconducting material and a preparation method thereof. The novel superconducting material is prepared by pressurizing metal beryllium powder and methane, and the molecular formula of the novel superconducting material is Be<n>(CH<4>)<n>, wherein n is greater than or equal to 2. The preparation method of the novel superconducting material provided by the invention comprises the following steps: providing beryllium powder and a carbon-based hydride, and carrying out pressurization pressing treatment on the beryllium powder and the carbon-based hydride under aclosed condition. The novel superconducting material can obtain superconducting transition at a relatively low pressure of 20-80 GPa, and the problem that the required pressure of an existing hydrogen-based superconductor is too large is solved. The preparation method of the novel superconducting material is simple and efficient and can be well applied to industrial production.

Owner:SHENZHEN INST OF ADVANCED TECH

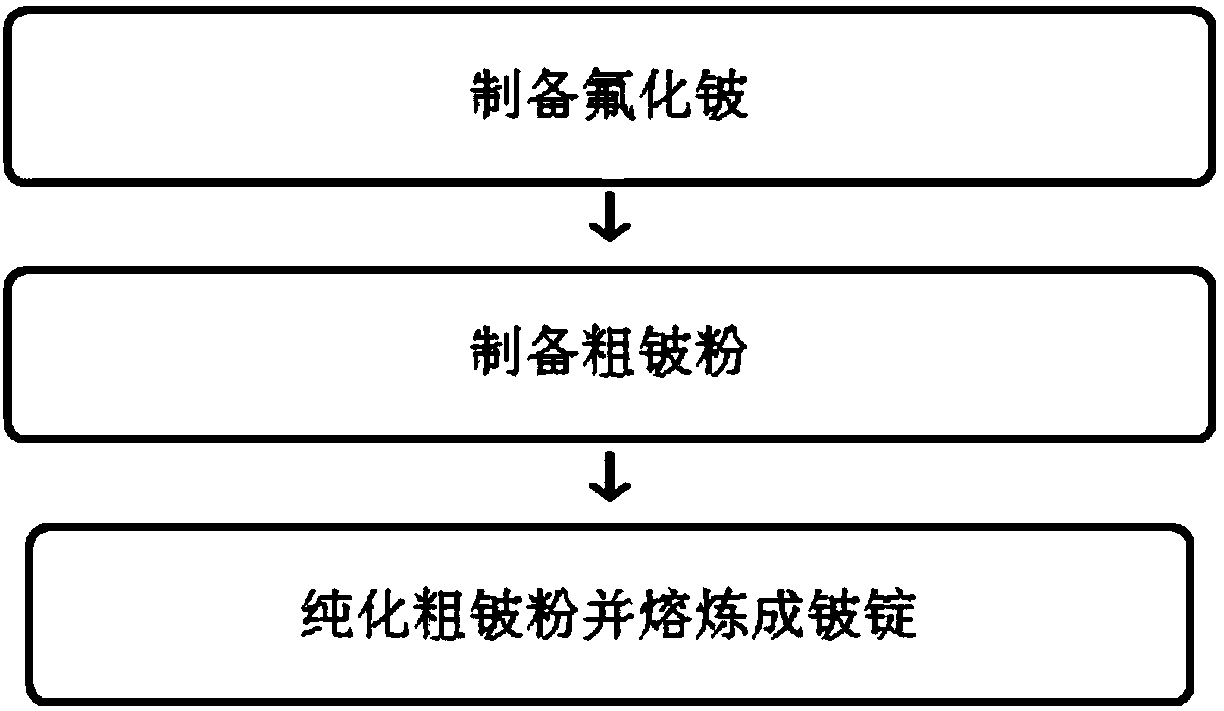

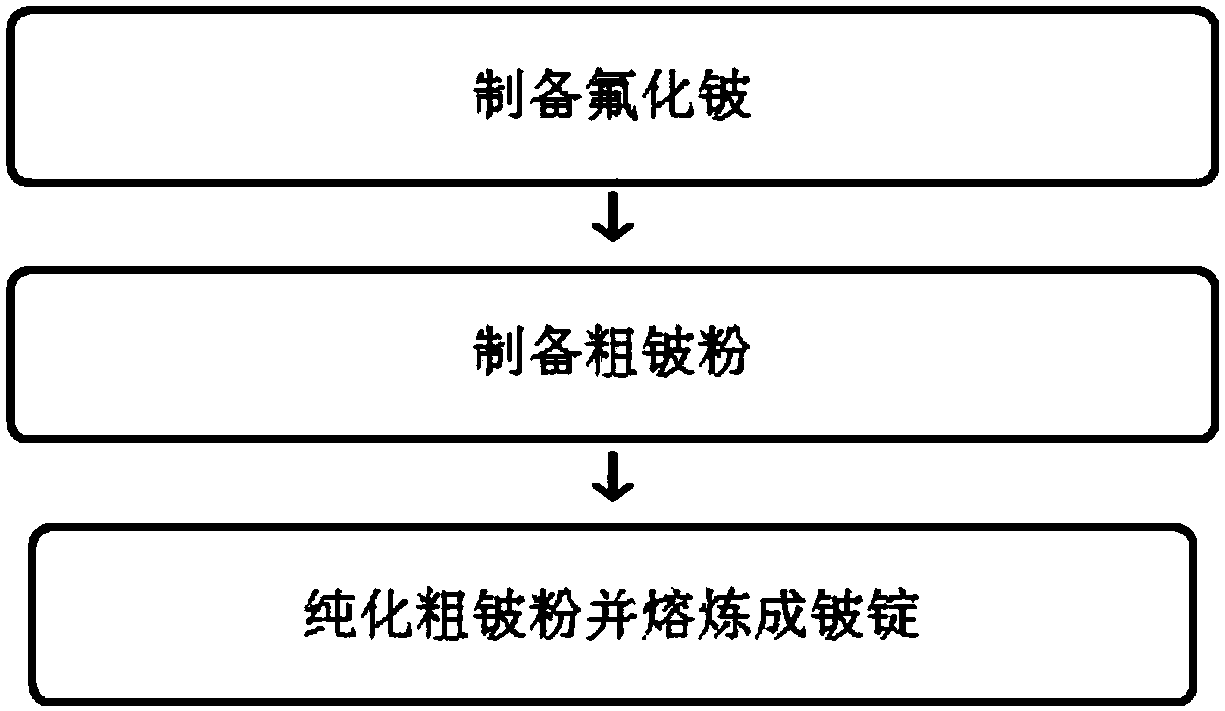

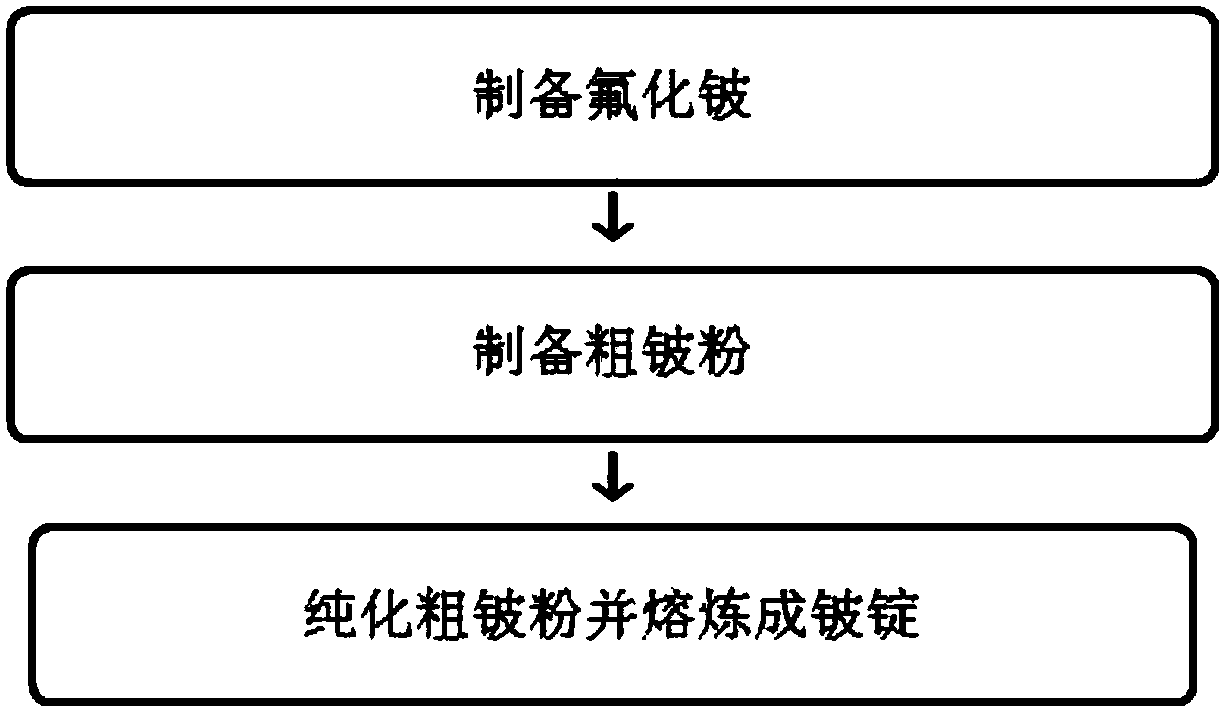

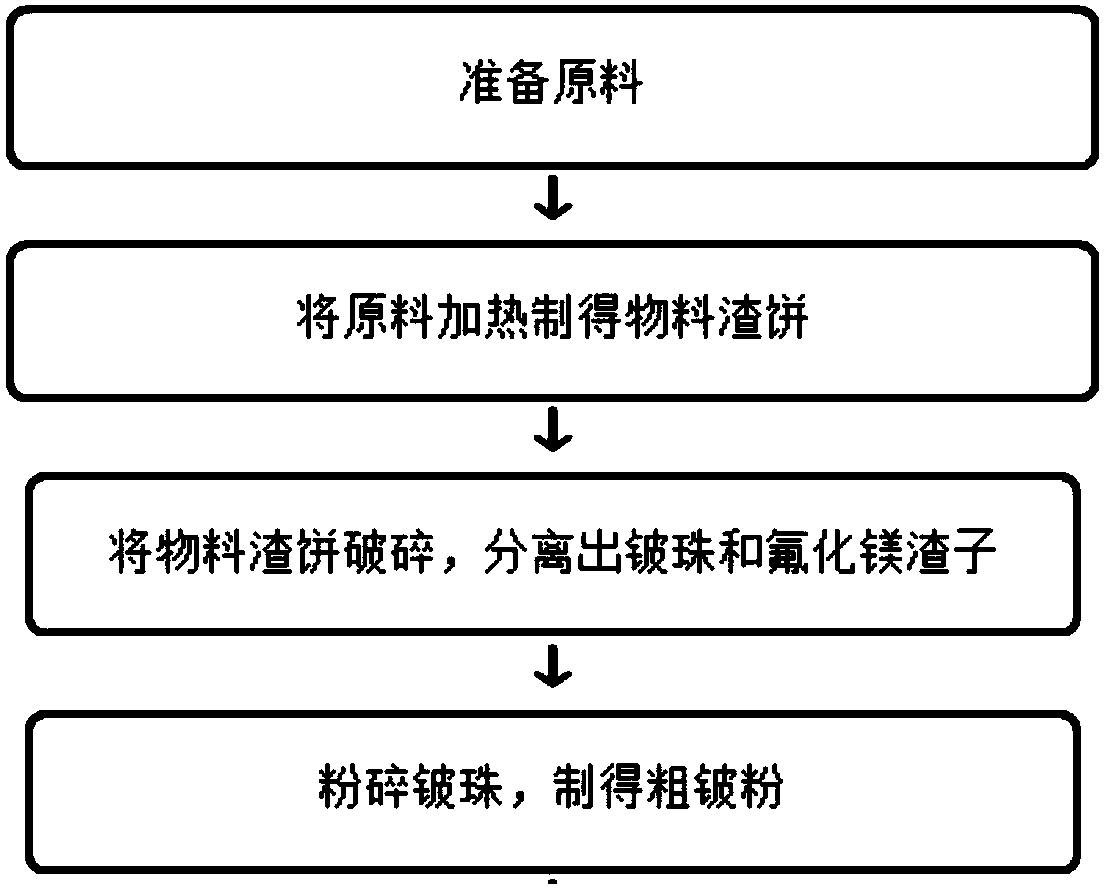

Method of preparing coarse beryllium powder and mode of preparing ultra-high purity metal beryllium

InactiveCN109082540APrecise flow controlReasonable structureProcess efficiency improvementReduction rateSlag

The invention relates to a method of preparing coarse beryllium powder and a mode of preparing ultra-high purity metal beryllium. The coarse beryllium powder is prepared by mixing and heating beryllium fluoride and a magnesium metal. The method comprises the following steps of: adding beryllium fluoride and the magnesium metal into a reduction furnace, powering on for heating, performing crushingto prepare a material slag cake, separating a beryllium bead magnesium fluoride slag, crushing the beryllium bead, and performing quenching and drying to form the coarse beryllium powder. The coarse beryllium powder is purified and smelt to form a beryllium ingot. According to the method of preparing the coarse beryllium powder and the mode of preparing the ultra-high purity metal beryllium, all beryllium fluoride can be reduced at a time; the energy is saved; the environment is protected; a reduction rate is high; a direct recovery rate is greatly increased; the time is short; no other medicine than magnesium is added; the cost is low; a process flow is simple; and the beryllium is high in purity.

Owner:陆世强

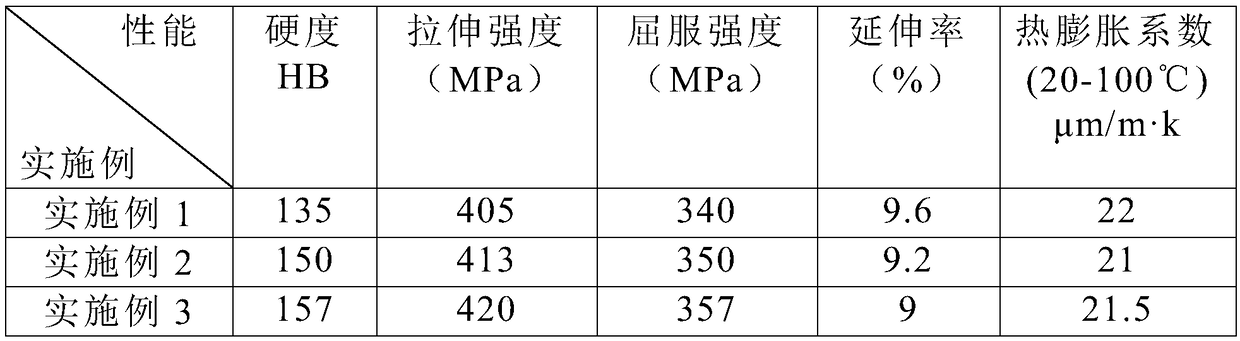

High-strength magnesium-aluminum alloy

The invention belongs to the field of magnesium-aluminum alloys, and particularly relates to a high-strength magnesium-aluminum alloy. The alloy comprises the following raw materials of, by weight, 6.0-9.7% of aluminum powder, 0.40-0.95% of zinc powder, 0.12-0.45% of manganese powder, 0.03-0.05% of copper powder, 0.02-0.06% of silica powder, 0.005-0.008% of iron powder, 0.001-0.004% of nickel powder, 0.001-0.003% of beryllium powder, 0.001-0.003% of a rear earth compound and calcium silicate composition and the balance magnesium powder. The prepared high-strength magnesium-aluminum alloy is high in strength, low in cost and high in market popularization value.

Owner:广西庆达汽车零部件有限公司

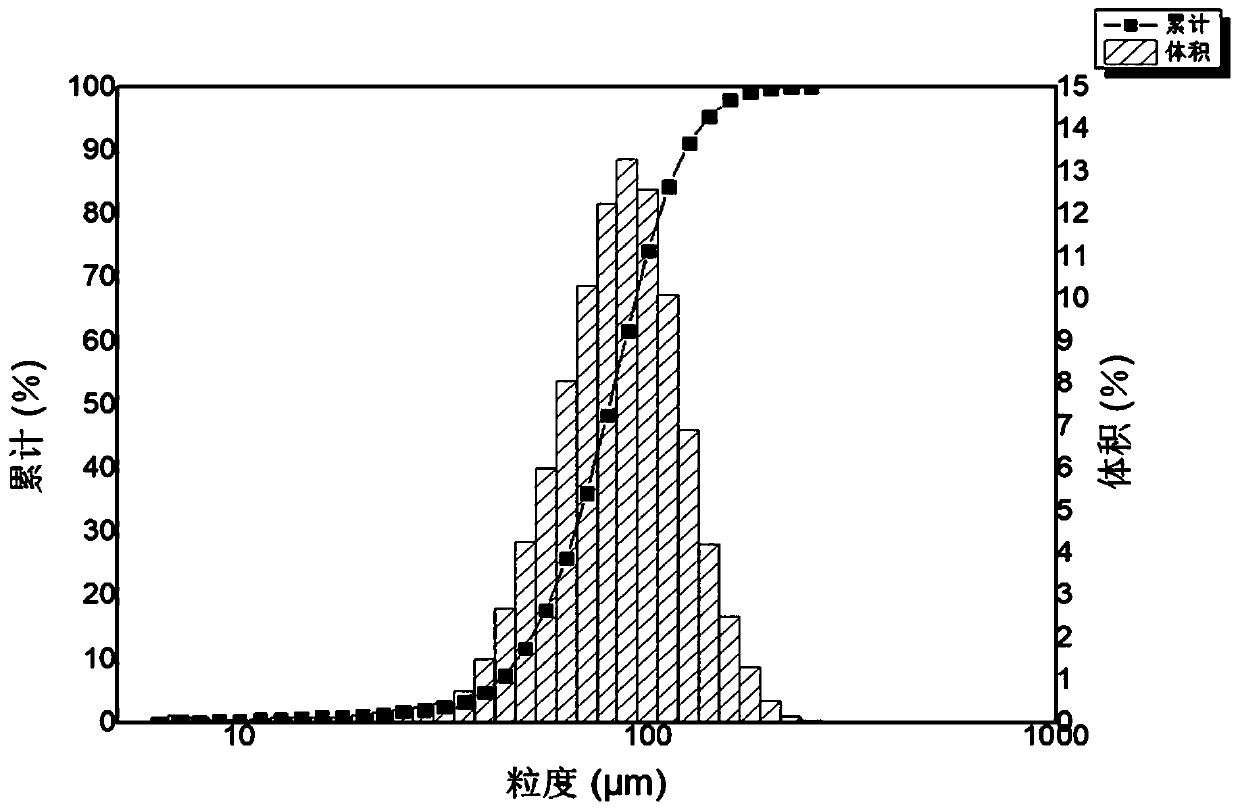

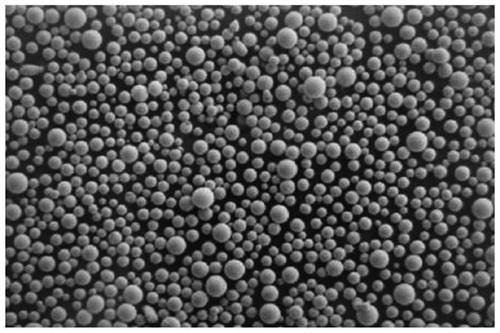

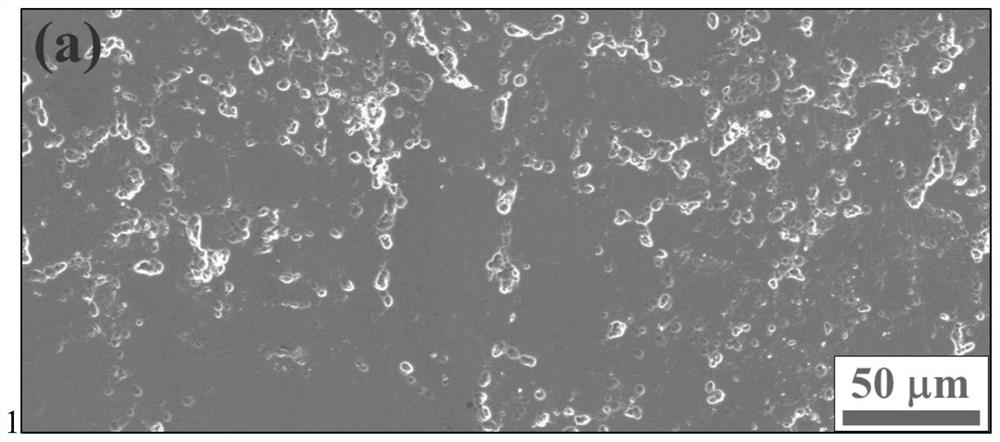

Metal beryllium powder for 3D printing and preparation method and application thereof

ActiveCN111531180AReduce oxygen contentEasy to shapeAdditive manufacturing apparatusTransportation and packagingBeryllium PowderOxygen content

The invention provides metal beryllium powder with high production efficiency for 3D printing and a preparation method and application thereof. The preparation method can comprise the following stepsthat a metal beryllium rod is placed in a vacuum environment; inert gas is introduced into the vacuum environment, wherein the oxygen content in the vacuum environment is not more than 3 ppm; the endface of the metal beryllium rod is melted into a liquid film through electric arcs; the metal beryllium rod is rotated to crush the liquid film into fine particles; and the fine particles are cooled to obtain the metal beryllium powder. The metal beryllium powder can comprise a metal beryllium powder body prepared through adopting the above preparation method. The application can comprise application in the field of laser or electron beam additive manufacturing. The metal beryllium powder has the beneficial effects that the preparation efficiency of the metal beryllium powder is high, and theenergy consumption is low; the prepared metal beryllium powder is good in sphericity, low in oxygen content and good in fluidity, and is a good raw material for 3D printing; and equipment used in theprocess of preparing the spherical metal beryllium powder through is more stable and more reliable, and the production efficiency of the equipment is higher than the production efficiency of other spherical powder preparation equipment.

Owner:西藏智材新材料有限公司

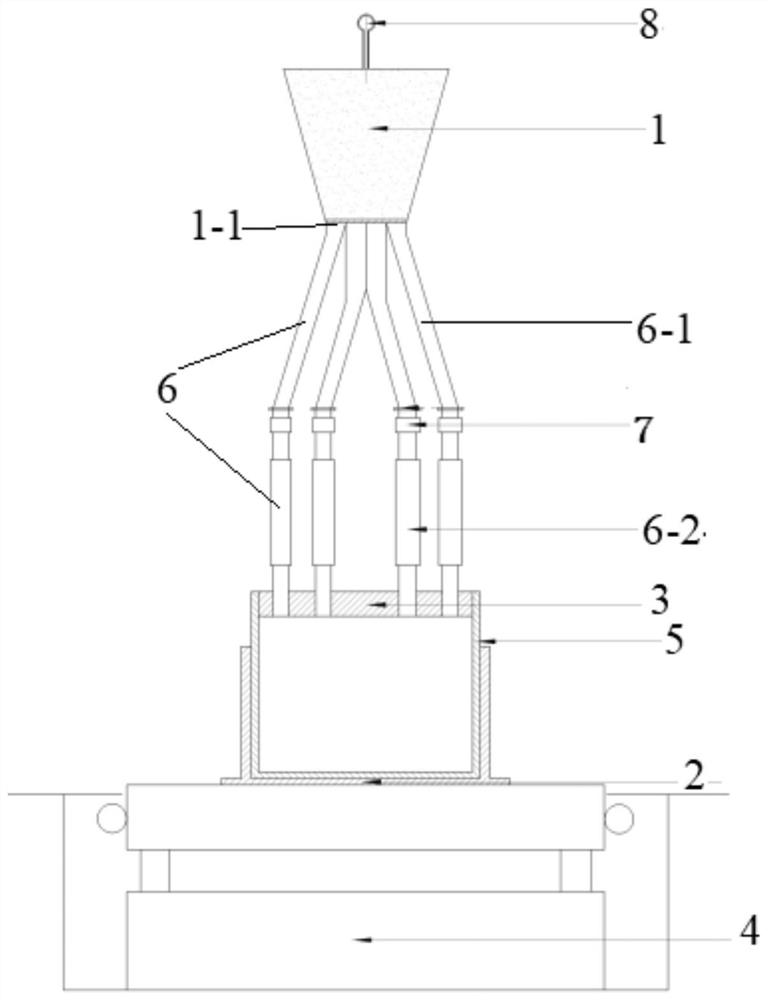

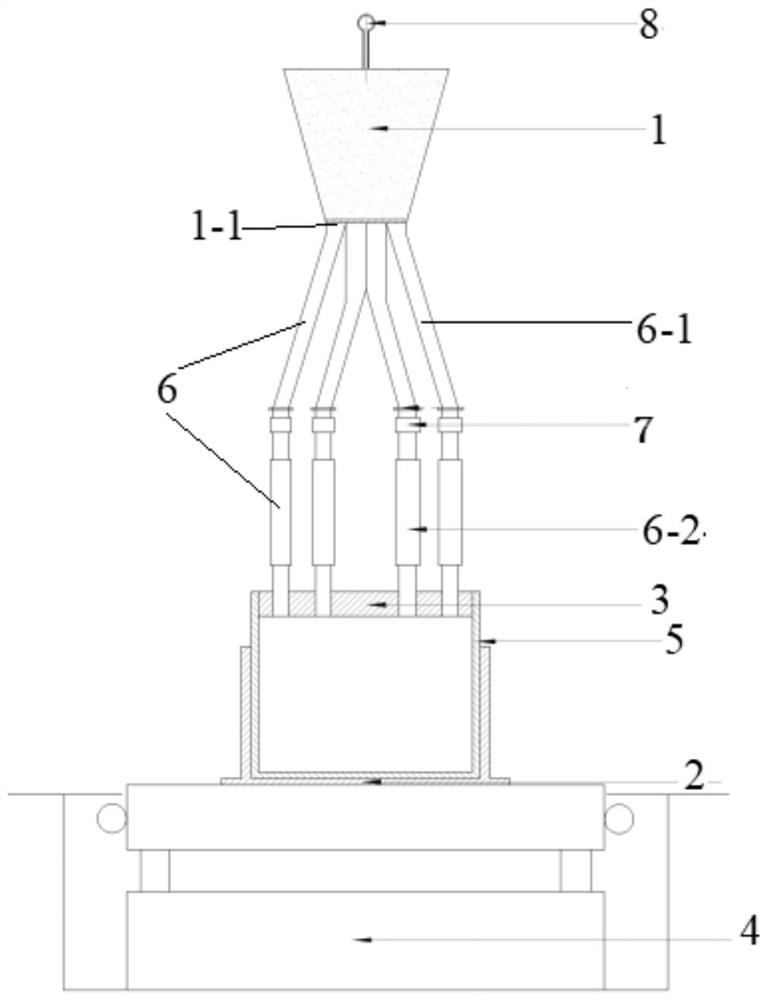

Powder filling method of beryllium material forming blank for CETR

ActiveCN111804909AHigh tap densitySolve the problem of easy inclusionNuclear energy generationMetallurgyElectric machine

The invention discloses a powder filling method of a beryllium material forming blank for a CETR. The method includes the steps that 1, a required beryllium powder filling amount is calculated; 2, materials are prepared and loaded into a feeder of a closed feeding device, and the feeder is sealed; 3, a first vibrating motor is started to drive the feeder to vibrate so as to feed beryllium powder into a sheath connected with the feeder in a sealed mode; and 4, a second vibrating motor is started, the vibrating frequency of a vibrating platform is adjusted, and the beryllium powder in the sheathis compacted by vibration, wherein when the filling amount of the beryllium powder is 90-100%, the vibrating frequency is adjusted to 0-80 Hz, when the filling amount of the beryllium powder is 70-90%, the vibrating frequency is adjusted to 80-120 Hz, and when the filling amount of the beryllium powder is 0-70%, the vibrating frequency is adjusted to 120-180 Hz. By means of the method, the tap density and uniformity of the beryllium powder filling the sheath are guaranteed, the compaction performance requirements can be met, and the powder filling efficiency is high.

Owner:西北稀有金属材料研究院宁夏有限公司

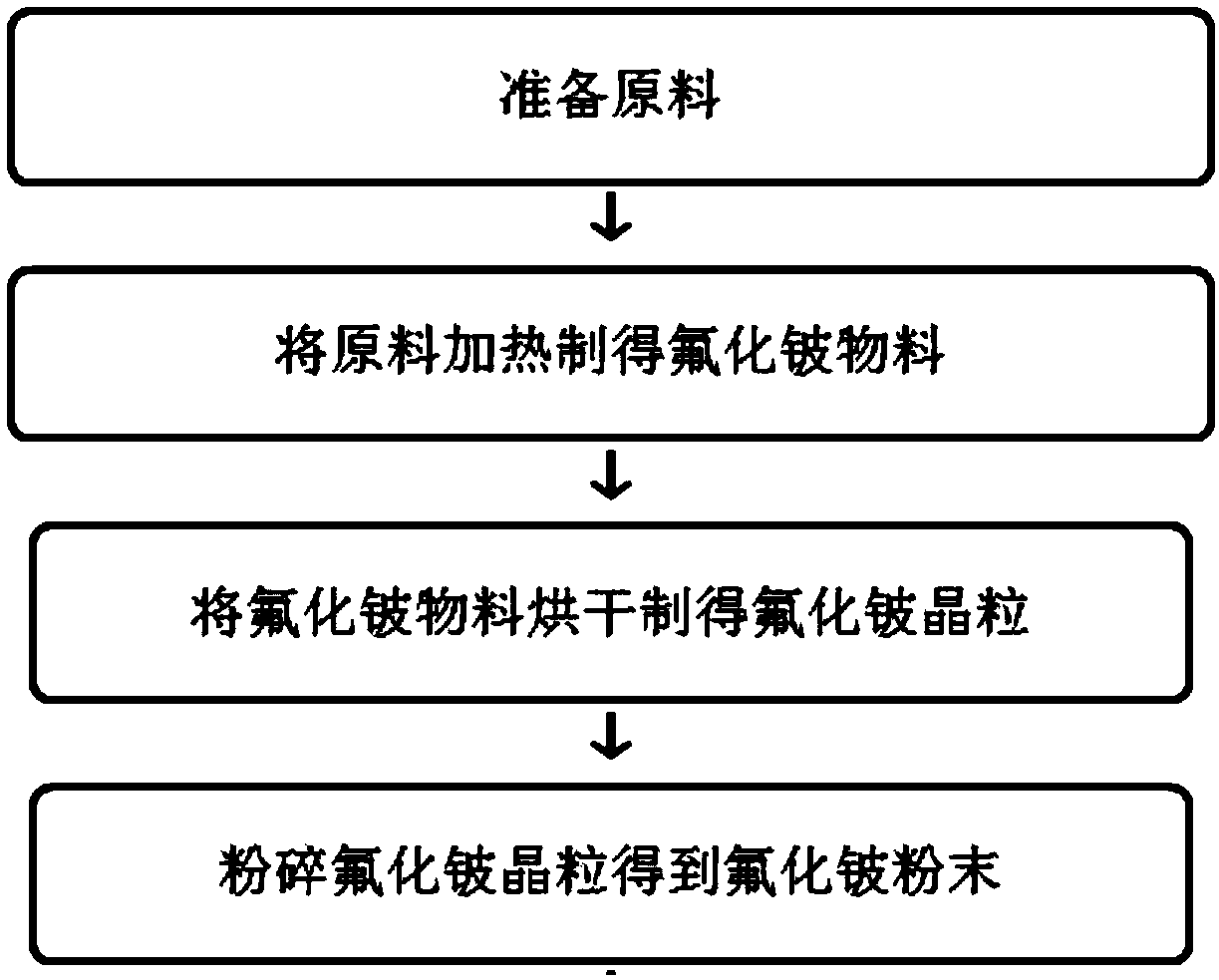

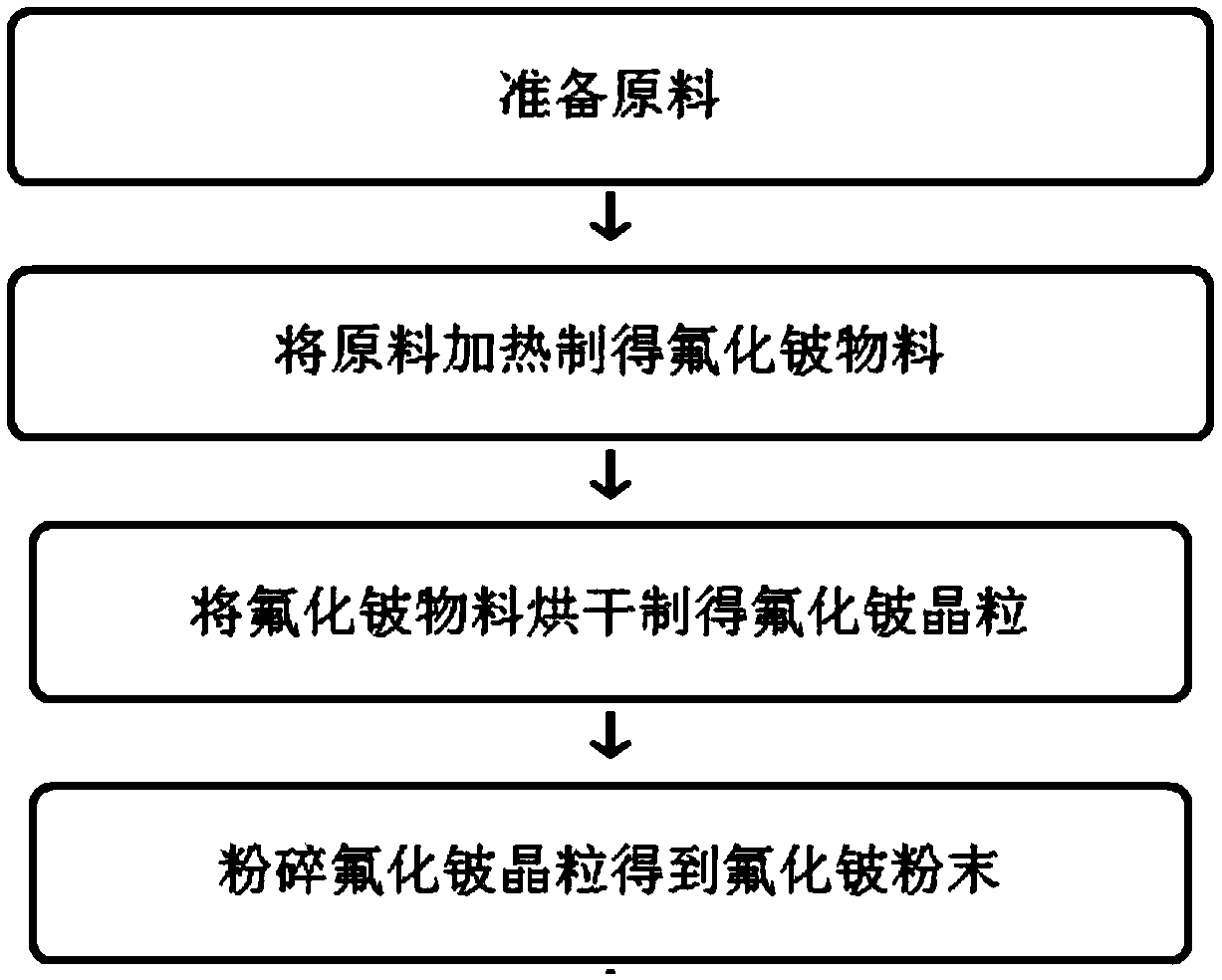

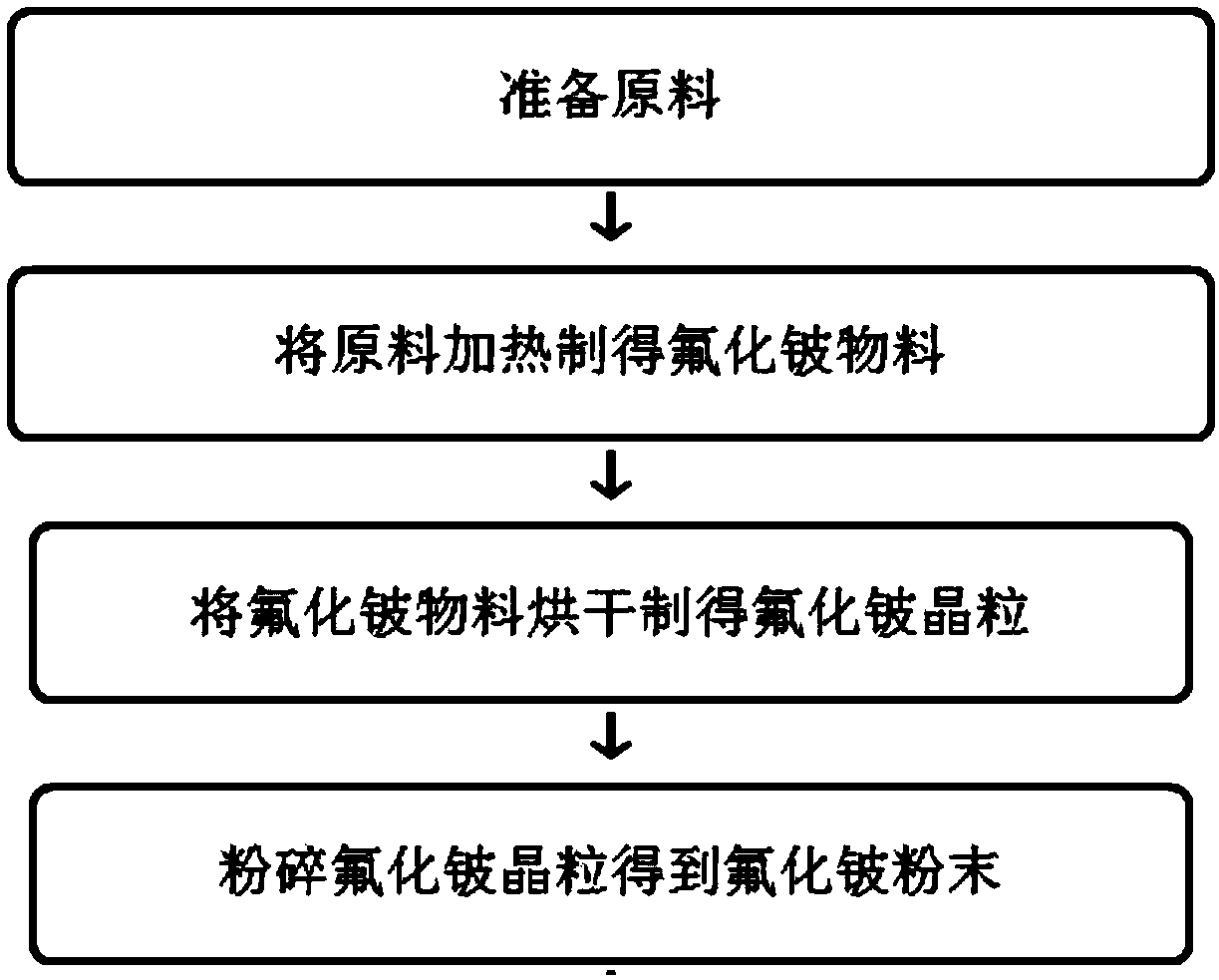

Preparation method of beryllium fluoride and preparation mode of ultrahigh-purity metal beryllium

ActiveCN109110789ASimple processIncrease productivityBeryllium fluorides/double-fluoridesHydrofluoric acidBeryllium hydroxide

The invention relates to a preparation method of beryllium fluoride and a preparation mode of ultrahigh-purity metal beryllium. The beryllium fluoride is prepared by mixing and heating beryllium hydroxide and hydrofluoric acid with the following steps: pouring the beryllium hydroxide and the hydrofluoric acid into a reactor, and sealing; energizing, stirring, and powering on for heating; putting aprepared beryllium fluoride material into a drying box for drying, so as to obtain beryllium fluoride crystal grains; pouring into a stainless steel pulverizer, and pulverizing, so as to obtain beryllium fluoride powder, and storing; preparing the beryllium fluoride powder into coarse beryllium powder, purifying, and smelting into a beryllium ingot. The preparation method of the beryllium fluoride and the preparation mode of ultrahigh-purity metal beryllium have the advantages that the technology is simple, and introduced impurities are fewer; compared with the traditional technology, the production efficiency is higher; the purity of the obtained product is high, energy is saved, the treatment cost is low, and the purity of the prepared beryllium is high.

Owner:陆世强

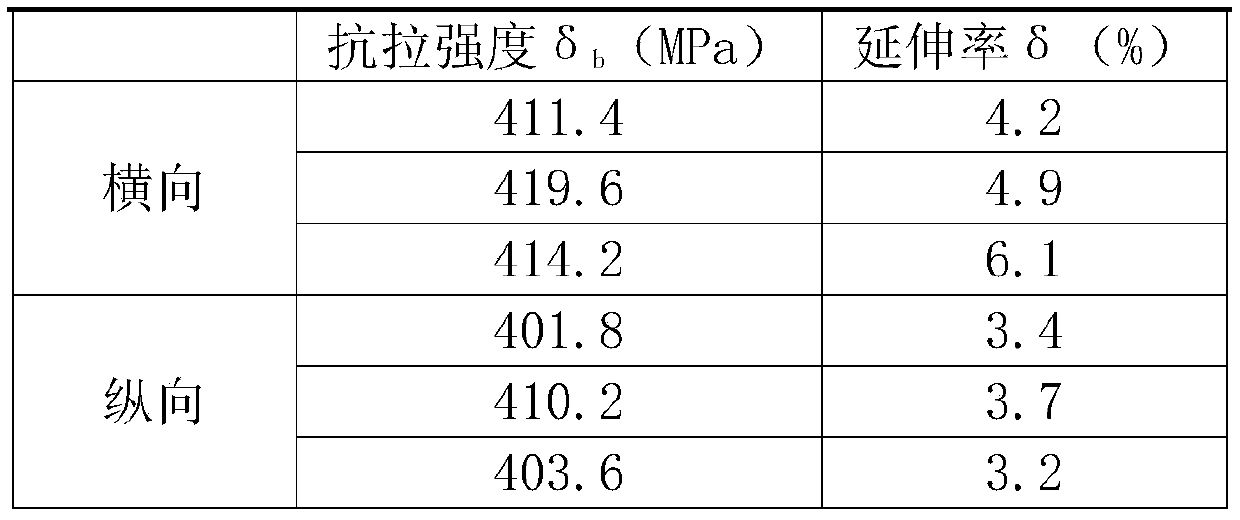

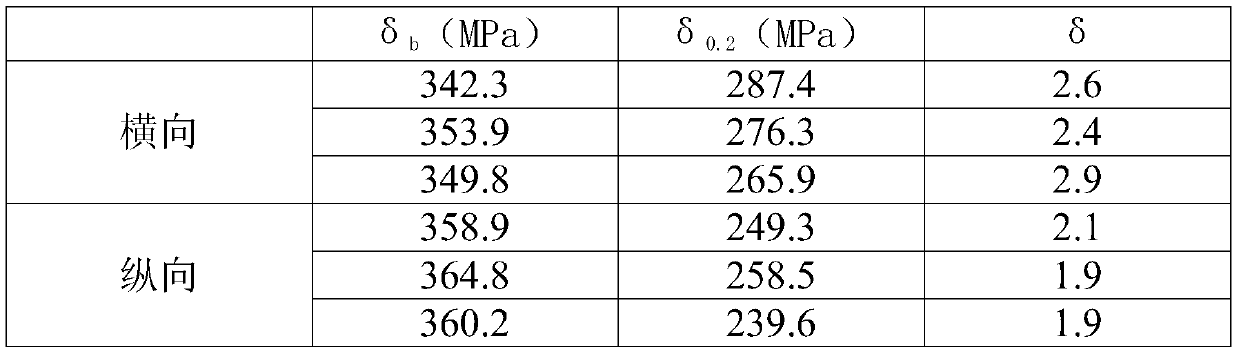

Preparation method of HP40 grade vacuum hot-pressing beryllium material and vacuum hot- pressing beryllium material

InactiveCN110842189AGuaranteed mechanical propertiesGuaranteed ductilityTransportation and packagingMetal-working apparatusBeryllium PowderMold removal

The invention discloses a preparation method of an HP40 grade vacuum hot-pressing beryllium material. The preparation method includes the following steps that 1, beryllium powder with the beryllium content greater than 99.5%, the iron content less than 800 ppm, and an average particle size of 6-14 [mu]m is prepared; 2, a mold is preheated and dried, and then the beryllium powder is filled in sequence, vacuum hot-pressing treatment is conduced, and a shaped beryllium billet is obtained; 3, the shaped beryllium billet is removed from the mold and then subjected to a vacuum heat treatment to obtain the HP40 grade vacuum hot-pressing beryllium material. The invention further discloses the HP40 grade vacuum hot-pressing beryllium material. The HP40 grade vacuum hot-pressing beryllium material has a tensile strength greater than 400 MPa and an elongation rate greater than 3%.

Owner:西北稀有金属材料研究院宁夏有限公司

Preparation method for magnesium-aluminum alloy

The invention discloses a preparation method for a magnesium-aluminum alloy. The method comprises the following steps that (1) activating treatment and melting treatment are conducted, specifically, magnesium powder, aluminum powder, zinc powder, manganese powder, copper powder, silica powder, iron powder, nickel powder, beryllium powder and a rare earth compound and calcium silicate composition are placed into smelting equipment to be heated to 500-550 DEG C, subjected to activating treatment for 10-12 h under 3-10 MPa pressure conditions, then heated to 730-750 DEG C, and subjected to melting treatment for 8-10 h to obtain molten materials; and (2) die-casting forming is conducted, specifically, a secondary injection mode is adopted, the molten materials are compression-injected into a die with the surface coated with a release agent in a die-casting machine, and the finished magnesium-aluminum alloy is obtained. According to the preparation method for the magnesium-aluminum alloy, the material sources are wide, the cost is low, and the machining cost can be greatly lowered; and the prepared magnesium-aluminum alloy further has excellent mechanical performance, the application market for the magnesium-aluminum alloy is greatly expanded, and the alloy has wide popularization prospects.

Owner:广西庆达汽车零部件有限公司

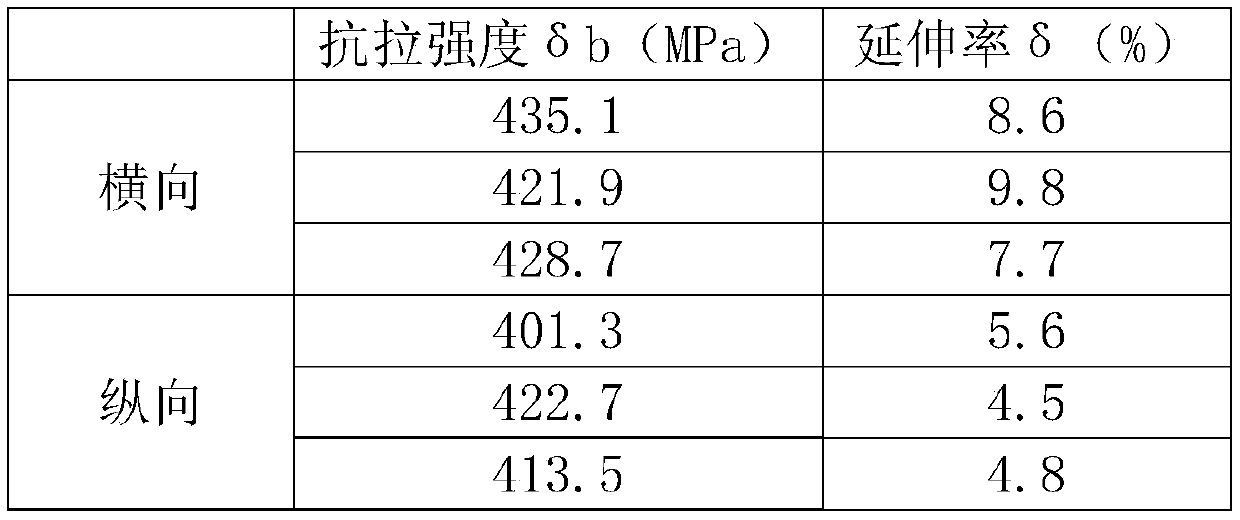

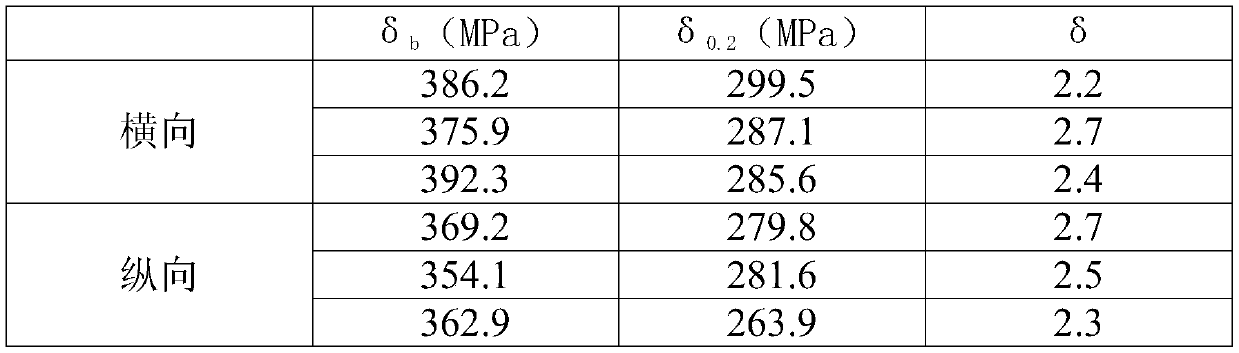

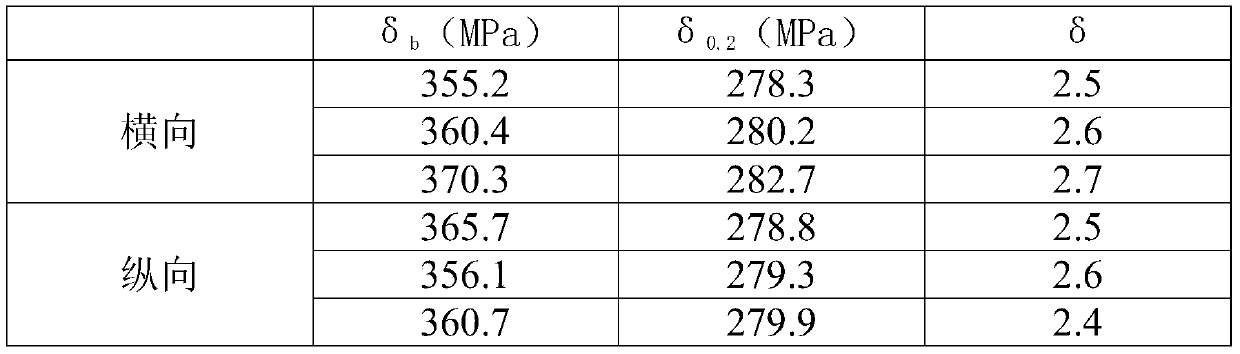

Method for preparing vacuum hot-pressed beryllium material with diameter greater than 300 mm and beryllium material

The invention discloses a method for preparing a vacuum hot-pressed beryllium material with a diameter greater than 300 mm, which includes the following steps: 1, preparing beryllium powder with a beryllium weight content greater than 99% and an average particle size of 10 to 14 [mu]m; 2, baking the beryllium powder in a graphite mold with an inner diameter greater than 300 mm, and then placing the beryllium powder in a vacuum hot-pressing furnace for pressure sintering; 3, cooling the pressure-sintered beryllium powder to room temperature and then demolding the same to obtain a vacuum hot-pressed beryllium material with a diameter greater than 300 mm. The invention also discloses a vacuum hot-pressed beryllium material with a diameter greater than 300 mm. The method has the characteristics of high pressing force, a large pressed product diameter , high pressing efficiency and low pressing cost.

Owner:西北稀有金属材料研究院宁夏有限公司

High-hardness aluminum-made projection lamp support and processing method thereof

The invention relates to a high-hardness aluminum-made projection lamp support and a processing method thereof and belongs to the technical field of lighting electrical appliance part process. The projection lamp support is prepared by melting the following raw material ingredients in mass percent: 0.02 to 0.08% of manganese powder, 0.2 to 0.8% of silicon powder, 0.025 to 0.08% of titanium powder,0.1 to 0.3% of cobalt powder, 0.05 to 0.20% of beryllium powder, 0.08 to 0.25% of potassium fluoborate and the balance of aluminum powder and unavoidable impurities. In a processing process, alloy liquid is purified by adding a covering agent, and hardness and corrosion resistance of alloy are improved by effective thermal treatment and degreasing electroplating.

Owner:宁波摩尔克斯灯杆技术有限公司

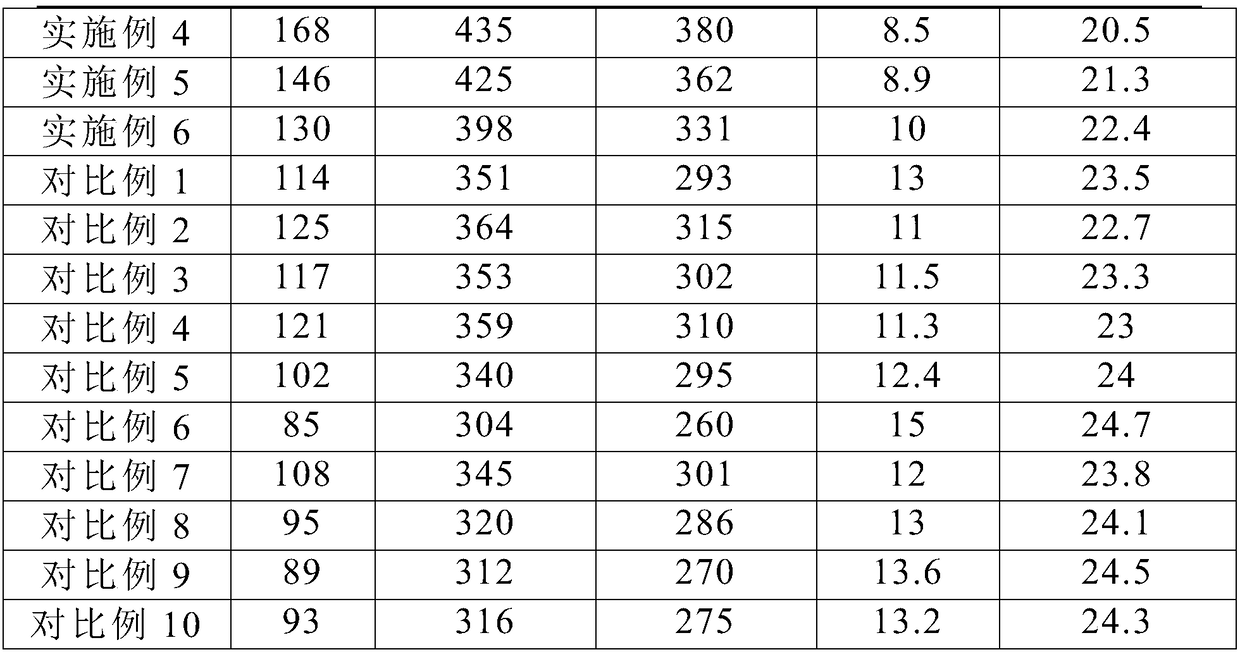

Beryllium coarse powder crushing device and production method for beryllium coarse powders using same

The invention relates to a beryllium coarse powder crushing device and a production method for beryllium coarse powder using same. The beryllium coarse powder crushing device comprises a disc mill, a gravity classifier and a cyclone classifier which are sequentially connected; the disc mill comprises a cone-shaped casing, a fixing disc and a moving disc; the fixing disc and the moving disc are arranged inside the cone-shaped casing. According to the beryllium coarse powder crushing device, the disc mill which is provided with the fixing disc and the moving disc is used, beryllium scraps or powders are milled into powder satisfying requirements due to high speed revolution of the moving disc, classification is performed sequentially through the gravity classifier and the cyclone classifier, finally coarse powder with the grain diameter of 30 to 10 microns is obtained, and pure beryllium powder is obtained through impact milling to be provided for beryllium materials of different sizes. The production method for the beryllium coarse powder using the beryllium coarse powder crushing device is simple in technology, short in period and enables 1 to 10 kg beryllium coarse powder to be obtained per hour.

Owner:西北稀有金属材料研究院宁夏有限公司

Alloy for precise machining clamp and preparation method for alloy

The invention discloses alloy for a precise machining clamp and a preparation method for the alloy. The clamp comprises the following raw materials of, by mass, 1.5%-2.3% of beryllium powder, 1.9%-2.7% of zirconium powder, 5.3%-6.1% of calcium, 3.0%-3.8% of molybdenum powder, 0.8%-1.5% of vanadium powder, 0.3%-0.7% of tin powder, 7.2%-8% of copper powder, and the balance aluminum powder. According to the alloy for the precise machining clamp and the preparation method for the alloy, the alloy obtained after the beryllium powder, zirconium powder, calcium, molybdenum powder, vanadium powder, tin powder, copper powder and aluminum powder are subjected to smelting, rapid hardening, hydrogen decrepitation, cold press molding and segmental calcination under the action of scientific cooperation of the component contents is uniform in structure, has high hardness, high breaking tenacity and corrosion resistance, can be applied to the precise machining clamp, and can further eliminate residual stress of a high-temperature part when being matched with the high-temperature part, and the usage reliability and the size precision of the part are ensured. The alloy for the precise machining clamp and the preparation method for the alloy have the advantages that service life is long, high production efficiency is high, the size precision of the machined part is high, the part product quality and yield are improved, pollution to the environment is avoided, and the alloy and the preparation method are suitable for industrial production.

Owner:舒城久联精密机械有限公司

Aluminium conductive paste for solar energy battery and preparation method thereof

ActiveCN101989625BImprove thixotropyEasy constructionFinal product manufactureNon-conductive material with dispersed conductive materialSolar batteryPhotoelectric conversion efficiency

The invention discloses an aluminium conductive paste for a solar energy battery and a preparation method thereof. The paste comprises the following components: aluminium powder, an inorganic binder, an organic carrier, and a metal additive. The metal powder additive has the median particle diameter D50 of 10 to 150 nm, and is one or more of magnesium powder, beryllium powder and lithium powder. The aluminium conductive paste prepared has high storage stability, is difficult to settle and agglomerate, and does not easily slip through a screen in the screen printing process; after the paste isprinted on the surface of the crystal silicon solar energy battery and sintered, the series resistance of the battery is reduced greatly, and the filling factor is increased; and the average photoelectric conversion efficiency of the monocrystalline silicon solar battery plate is over 17.60 percent.

Owner:BYD CO LTD

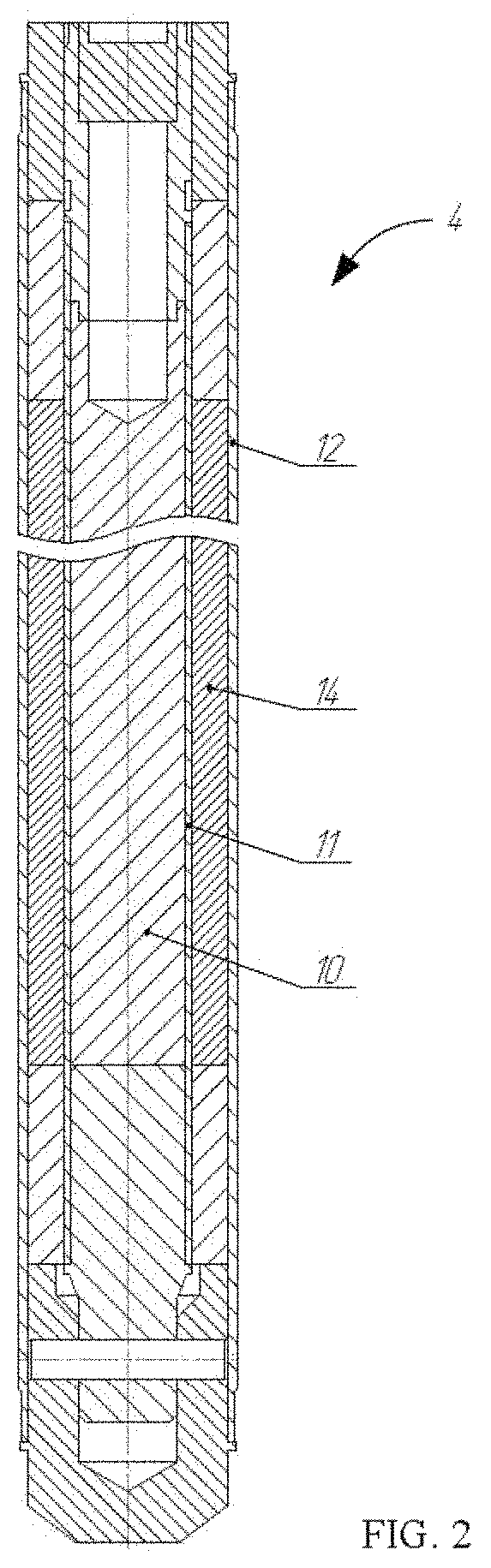

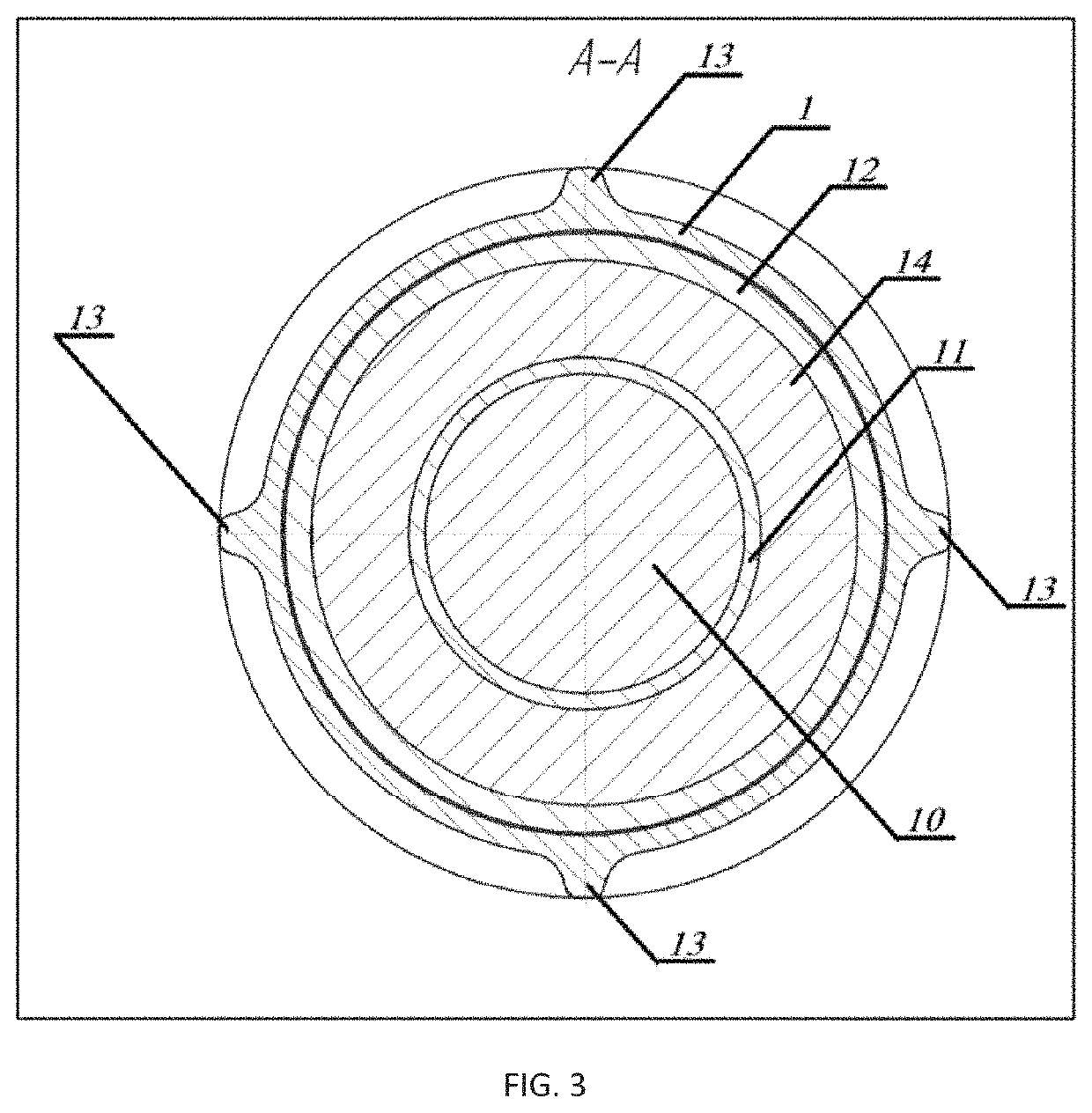

Secondary startup neutron source

ActiveUS10636537B2Improve reliabilityImprovement of fail-free operationNuclear energy generationNeutron sourcesNiobiumAlloy

The invention relates to nuclear engineering and more particularly to controlled reactor start-up. The invention addresses a secondary startup neutron source by creating additional safety barriers between the coolant and the source active part materials. The secondary startup neutron source is designed as a steel enclosure housing an ampule containing antimony in the central enclosure made of a niobium-based alloy unreactive with antimony, with a beryllium powder bed located between the antimony enclosure and the ampule enclosure. An upper gas collector, located above the ampule serves as a compensation volume collecting gaseous fission products. The ampule is supported by a reflector and a bottom gas collector. The gas collectors, reflector, ampule enclosure and washers are made of martensite-ferrite grade steel.

Owner:JOINT CO AKME ENG

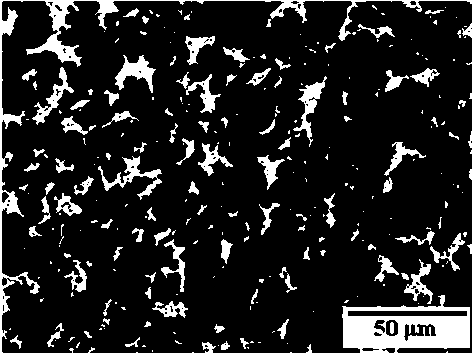

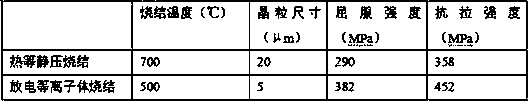

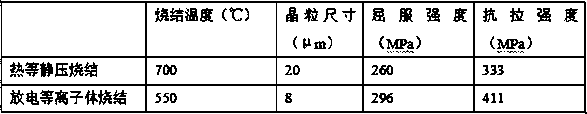

Beryllium aluminum alloy discharging plasma sintering preparation method

The invention relates to a beryllium aluminum alloy discharging plasma sintering preparation method, which comprises the following steps of mixing beryllium powder and aluminum alloy power according to the design ingredient proportion; charging the mixed materials into a soft mold; making the materials into a cold pressing blank through cold isopressing; charging the cold pressing mold into a graphite mold; then, putting the graphite mold into an SPS furnace body; performing vacuum pumping and pressurization; performing discharging plasma sintering. Compared with other preparation methods, themethod has the advantages that the work procedure is simple; the sintering temperature is low; the sintering time is short; the tissue is fine and uniform; the mechanical performance is good. The beryllium aluminum alloy powder metallurgy process is simplified; the production efficiency is improved; in addition, the method is hopeful to be applied to the field of aerospace. The beryllium aluminumalloy can select a polynary aluminum alloy system; the beryllium aluminum alloy meeting different service condition requirements can be prepared according to the characteristics of the aluminum alloyin different series.

Owner:MATERIAL INST OF CHINA ACADEMY OF ENG PHYSICS

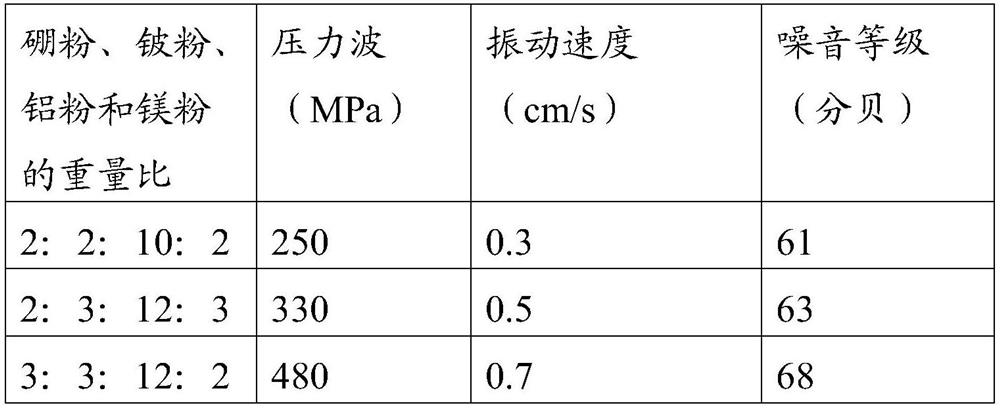

Intrinsic safety type carbon dioxide gasifying agent and preparation method thereof

InactiveCN113149797AEnsure safetyConvenience guaranteedNon-explosive desensitisers/phlegmatisersPtru catalystFirming agent

The invention relates to an intrinsically safe carbon dioxide gasifying agent and a preparation method thereof. The intrinsically safe carbon dioxide gasifying agent is prepared from a solid fuel, a passivator, a catalyst and a curing agent in proportion, and the solid fuel is a mixture of boron powder, beryllium powder, aluminum powder and magnesium powder; the passivator is selected from calcium oxide, silicon dioxide, calcium carbonate or calcium chloride; the catalyst is nano silver or nano nickel; and the curing agent is polyurethane or epoxy resin. The preparation process is carried out in a closed metal container, the mixture is poured into a mold after being uniformly stirred, and is air-dried at normal temperature to form a solid agent column, so that the safety risk under the normal operation environment and transportation condition is eliminated. The intrinsic safety type carbon dioxide gasifying agent is mixed with solid carbon dioxide according to a certain proportion, the solid carbon dioxide can be instantly gasified and expanded by hundreds of times through excitation and combustion of an electric detonator and release of a large amount of heat energy, rocks are broken through huge expansion pressure, and the intrinsic safety type carbon dioxide gasifying agent has the remarkable advantages of intrinsic safety and environmental protection.

Owner:江苏夏谷科技有限公司 +1

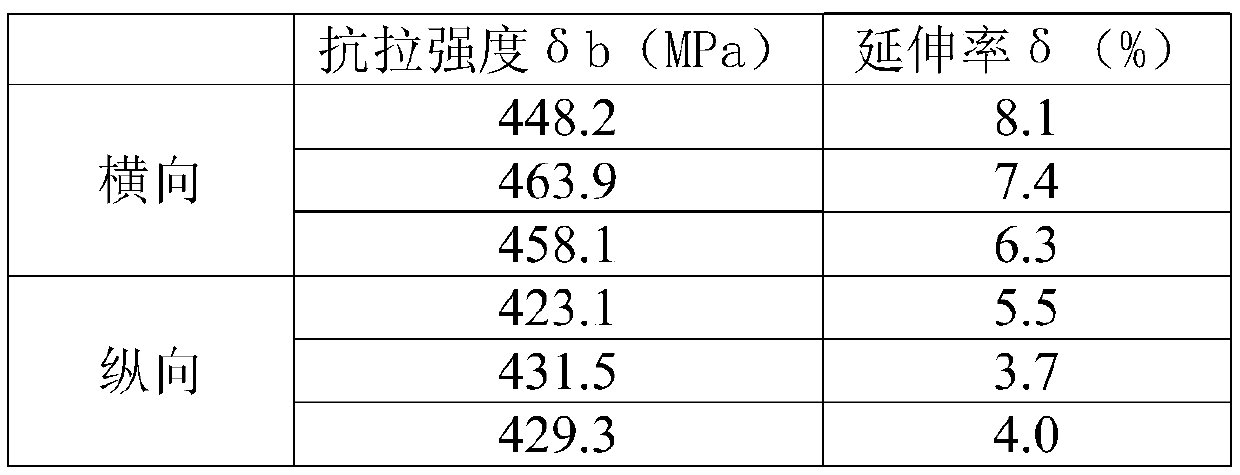

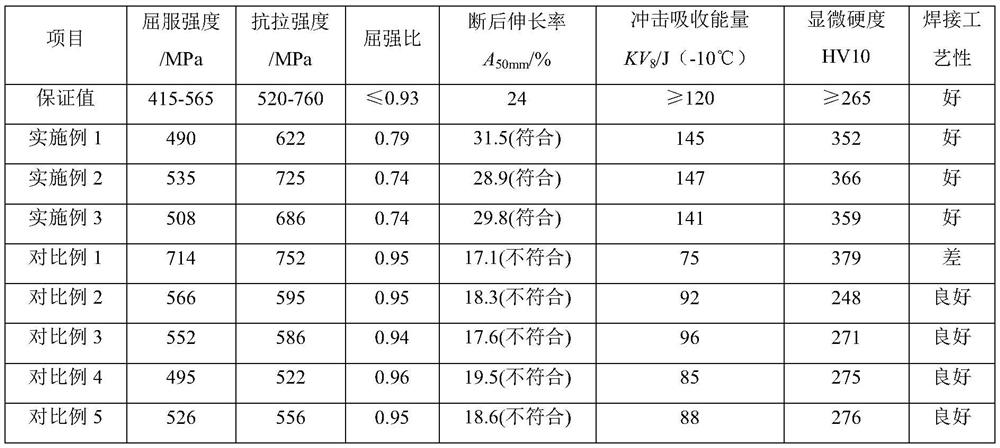

L415J steel welding matched flux-cored wire for coal slurry conveying pipe

ActiveCN111843289AEvenly distributedSimple welding processWelding/cutting media/materialsSoldering mediaNiobiumMicrosphere

The invention belongs to the field of welding materials, and particularly relates to an L415J steel welding matched flux-cored wire for a coal slurry conveying pipe. The L415J steel welding matched flux-cored wire comprises an outer skin and a flux core; and the flux core comprises the following components of, 0.2%-0.28% of hollow cage-shaped carbon microspheres, 4.2%-5.6% of nano bismuth powder,3.5%-4.9% of nano beryllium powder, 1.2%-2.0% of manganese fluoride powder, 1.2%-1.5% of molybdenum powder, 1.2%-1.6% of chromium powder, 0.12%-0.2% of niobium powder, 0.12%-0.2% of vanadium powder, 0.12%-0.2% of titanium powder and the balance FHT100.25 iron powder, wherein the sum of the mass of the molybdenum powder and the mass of the chromium powder is not smaller than 2.5%, and the sum of the mass of the niobium powder, the vanadium powder and the titanium powder is not larger than 0.5%. The yield strength, the tensile strength, the yield ratio, the percentage elongation after fracture,the impact absorption energy and the hardness of the obtained deposited metal meet the use requirements, and the welding manufacturability of the welding wire is good.

Owner:ZHENGZHOU UNIV

Thermal dissociation reactor, method for purifying coarse beryllium powder into ingots and method for preparing ultra-high pure metallic beryllium

The invention relates to a thermal dissociation reactor, a method for purifying coarse beryllium powder into ingots and a method for preparing ultra-high pure metallic beryllium. The thermal dissociation reactor comprises an iodine containing furnace, a low-temperature reactor and a high-temperature reactor, wherein the iodine containing furnace communicates with the low-temperature reactor, and the low-temperature reactor communicates with the high-temperature reactor. The method for purifying the coarse beryllium powder into the ingots through the thermal dissociation reactor comprises the following steps that the coarse beryllium powder and iodine are reacted in the thermal dissociation reactor, and the mass ratio of the coarse beryllium powder to the iodine is 5:1; beryllium iodide vapor is generated; the beryllium iodide vapor is thermally dissociated and decomposed into metallic beryllium and iodine vapor; collection is carried out to obtain pure beryllium powder; and the pure beryllium powder is smelted into the beryllium ingots in an electron beam smelting furnace. The thermal dissociation reactor is reasonable in structure, simple to assemble and convenient to use; and according to the method for purifying the coarse beryllium powder into the ingots through the thermal dissociation reactor, the operation is simple, the medicament is saved, the energy is saved, the environment is protected, the cost is low, and the purity of the beryllium is extremely high.

Owner:陆世强

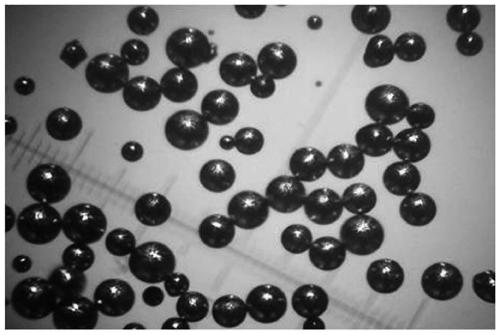

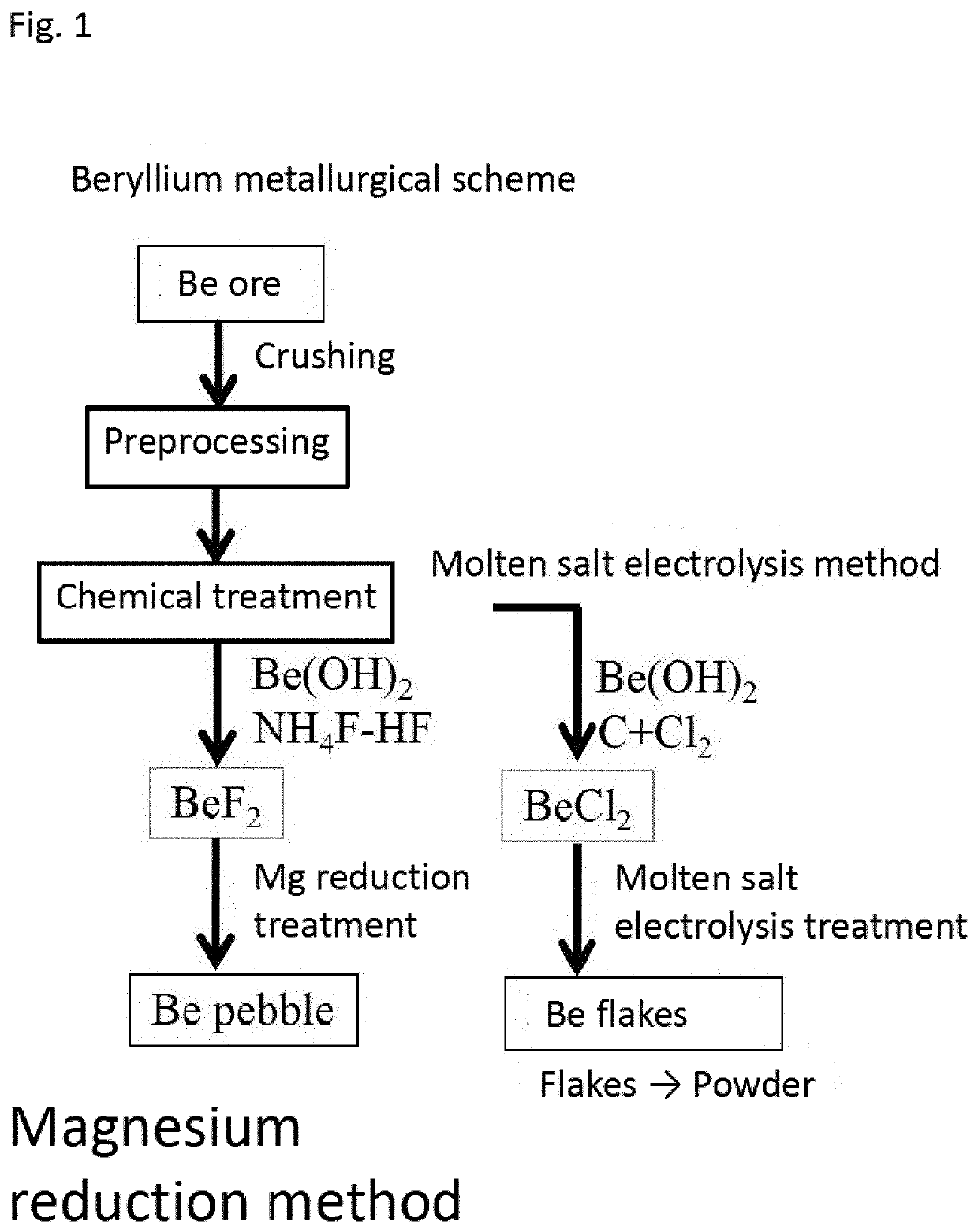

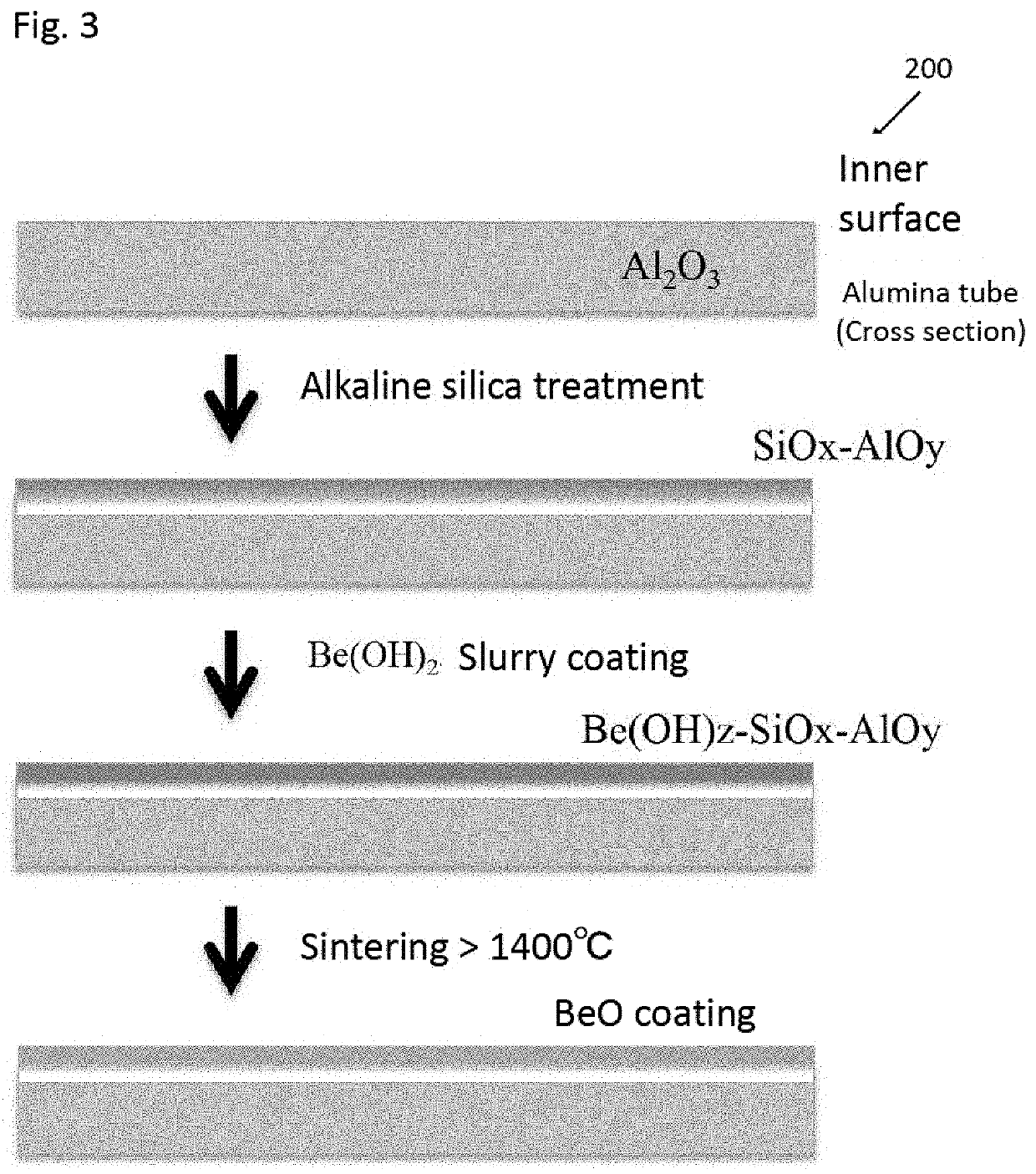

Continuous Producing Method of Beryllium Metal Sphere

ActiveUS20210114103A1Efficient mass productionLow costNuclear energy generationTransportation and packagingBeryllium hydroxideSlurry coating

To produce metallic beryllium spheres with high sphericity in a large quantity efficiently at a low cost by a simple method. The continuously producing method of metal beryllium spheres, comprising the steps of: collecting granulated beryllium spheres produced b by charging beryllium powder into a rotary kiln; classifying the collected beryllium spheres by particle size with an automatic sieve; and crushing particles of beryllium spheres of non-target diameters and mixing them with the raw material beryllium powder for reuse. The rotary kiln has a core tube the inner surface of which is coated with beryllium oxide by sintering the slurry coating of beryllium hydroxide applied after alkaline silica treatment.

Owner:SK KAKEN CO LTD

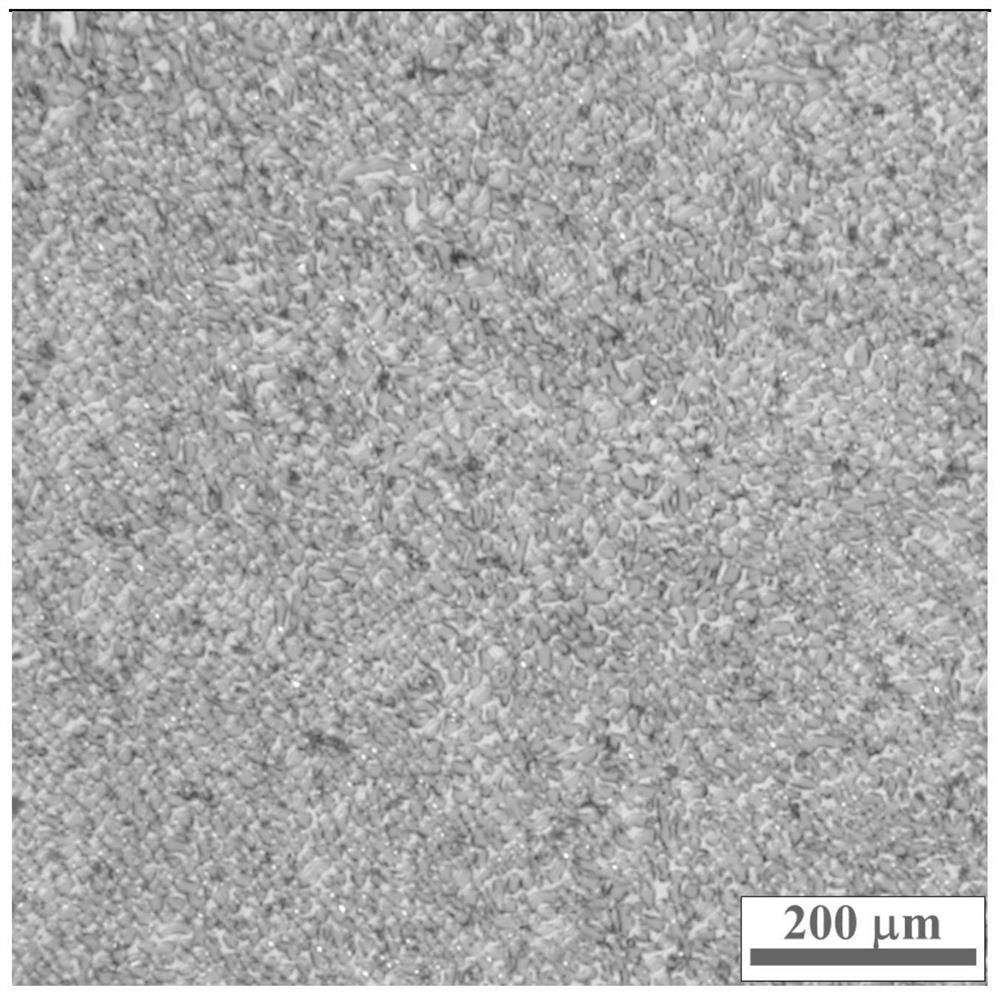

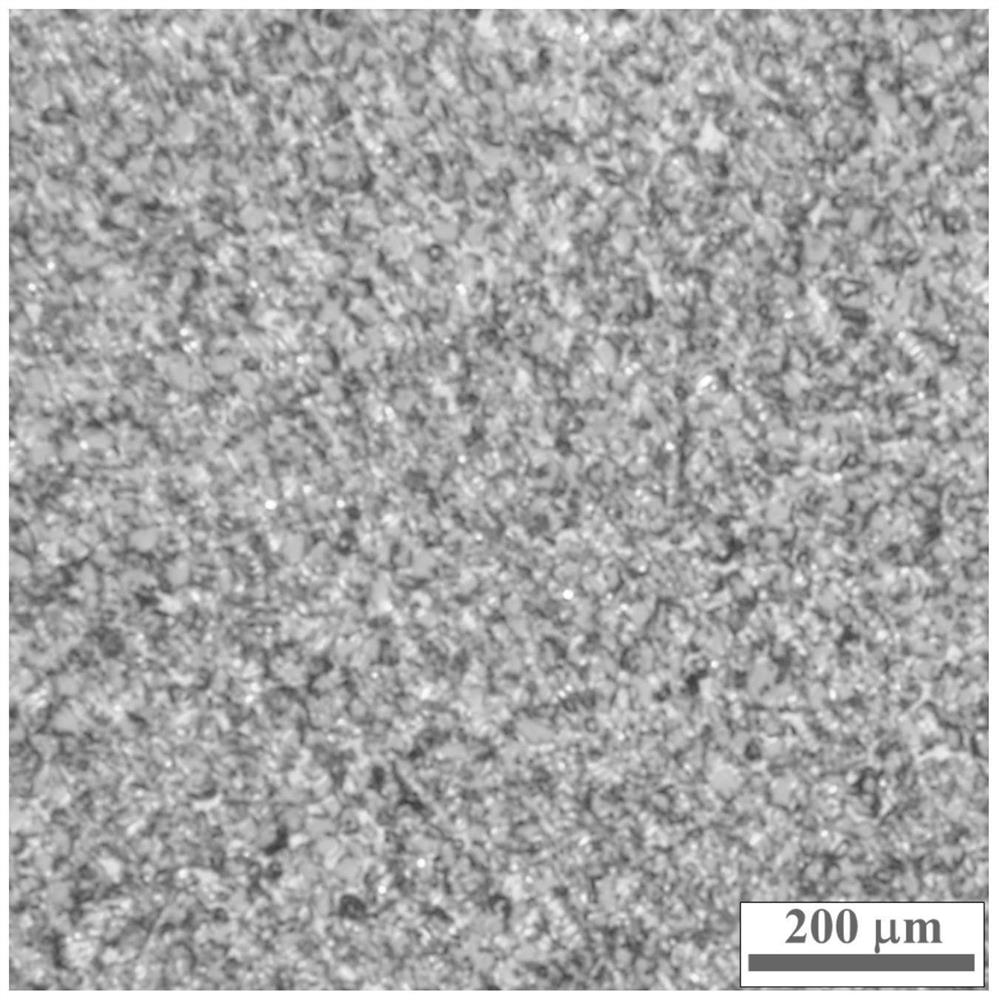

Preparation method of beryllium-aluminum alloy surface composite reinforced modified layer

The invention discloses a preparation method of a beryllium oxide / aluminum oxide double-phase particle composite reinforced modification layer on the surface of a beryllium-aluminum alloy. A mode of pre-sintering ternary premixed composite powder of micron metal aluminum powder, nano aluminum oxide powder and nano beryllium oxide powder on the surface of the beryllium-aluminum alloy is adopted, and electron beam remelting and subsequent heat treatment are combined to obtain an alloy surface modification layer with high hardness and gradient distribution of strengthening phase particles. By adopting the technical route, adverse effects caused by the use of metal beryllium powder and cracking failure of the surface modification layer can be avoided, metallurgical bonding between the modification layer and an alloy matrix is realized, and the structural stability of the surface modification layer is ensured. The method is simple, convenient and feasible in process route, can effectively meet the requirement for the thermophysical property of a surface coating when the cast beryllium-aluminum alloy is used as an electronic encapsulating material, and has a good practical engineering application prospect.

Owner:MATERIAL INST OF CHINA ACADEMY OF ENG PHYSICS

A powder loading method for beryllium material forming blanks for cetr reactor

ActiveCN111804909BHigh tap densitySolve the problem of easy inclusionNuclear energy generationMetallurgyElectric machine

The invention discloses a powder filling method for beryllium material forming blanks for CETR reactor, comprising: step 1, calculating the required filling amount of beryllium powder; step 2, preparing the material, loading it into a feeder of a closed feeding device, and sealing it; Step 3, start the first vibration motor, drive the feeder to vibrate and feed the beryllium powder into the package that is sealed with the feeder; Step 4, start the second vibration motor, adjust the vibration frequency of the vibration platform, and correct the The beryllium powder in the package is vibrated; when the beryllium powder loading is 90-100%, the vibration frequency is adjusted between 0-80Hz; when the beryllium powder loading is 70-90%, the vibration frequency is adjusted between 80-80Hz Between 120Hz; when the beryllium powder loading weight is 0-70%, adjust the vibration frequency between 120-180Hz. The invention ensures the tap density and uniformity of the beryllium powder filled in the envelope, can meet the performance requirements of the compact, and has high powder filling efficiency.

Owner:西北稀有金属材料研究院宁夏有限公司

Anti-corrosion and anti-abrasion die and preparation method thereof

InactiveCN108015290AImprove antibacterial propertiesImprove corrosion resistanceTurbinesOther manufacturing equipments/toolsFiberManufacturing technology

The invention relates to the technical field of die manufacturing and particularly relates to an anti-corrosion and anti-abrasion die and a preparation method thereof. The anti-corrosion and anti-abrasion die is prepared from the following raw materials according to the weight proportion: 20 to 26 parts of a ceramic powder, 12 to 16 parts of titanium nitride, 9 to 14 parts of a graphite powder, 5to 9 parts of an aluminium powder, 4 to 7 parts of a beryllium powder, 3 to 8 parts of a copper powder, 8 to 11 parts of nanometer titanium dioxide, 6 to 10 parts of an iron powder, 14 to 18 parts ofdiatomite, 6 to 11 parts of carbon fiber, 2 to 5 parts of a defoamer and 3 to 7 parts of a curing agent. According to the anti-corrosion and anti-abrasion die and the preparation method thereof, the nanometer titanium dioxide, the diatomite, the carbon fiber and the copper powder are selected as raw materials for preparing the die, wherein the nanometer titanium dioxide, the diatomite and the carbon fiber are matched with one another, so that the prepared die has enhanced antibacterial capability and improved corrosion resistance, and further the beryllium powder and the copper powder form analloy under high temperature, so that the anti-abrasion performance of the die is improved; the service life of the die is remarkably prolonged and the cast intensity is remarkably enhanced; moreover,the defects of molten metal cinder adhesion and corrosion to the die can be overcome, cast surface quality is improved, and the production cost is lowered.

Owner:扬州汇翔精密冲件有限公司

A high-strength magnesium-aluminum alloy

The invention belongs to the field of magnesium-aluminum alloys, and particularly relates to a high-strength magnesium-aluminum alloy, which comprises the following raw materials by weight percentage: 6.0-9.7% of aluminum powder, 0.40-0.95% of zinc powder, 0.12-0.45% of manganese powder, copper Powder 0.03~0.05%, silicon powder 0.02~0.06%, iron powder 0.005~0.008%, nickel powder 0.001~0.004%, beryllium powder 0.001~0.003%, rare earth compound and calcium silicate assembly 0.001~0.003%, the rest is magnesium powder. The high-strength magnesium-aluminum alloy prepared by the invention has high strength and low price, and has wide market promotion value.

Owner:广西庆达汽车零部件有限公司

Powder metallurgy method

InactiveCN107779663ASimple structureHigh tensile strengthTransportation and packagingMetal-working apparatusWaxDie casting

The invention provides a powder metallurgy method. Raw materials are adopted in percentage by weight: 9.3 percent of micro-powder wax, 2.1 percent to 4.4 percent of beryllium powder, 4.1 percent to 5.2 percent of zinc stearate, 4.3 percent of an anti-wear agent, 5 percent of tungsten powder, 2 percent of europium powder and the balance of lead powder and difficult-to-remove impurities; the powdermaterials are stirred for 5h to 6h at high temperature of 260 DEG C to 280 DEG C by utilizing a stirrer, are sufficiently mixed and then are subjected to mixed pressing, die casting and fine pressingto obtain a finished product. The powder metallurgy method has the advantages that the structure is simple, the tensile strength and the rigidity of the product are improved and the service life of the product is greatly prolonged.

Owner:宁波市海曙古林新睦粉末冶金厂

Operational Neutron Source

ActiveUS20170330642A1Improve reliabilityImprovement of fail-free operationNuclear energy generationReactors manufactureNiobiumAlloy

The invention relates generally to nuclear engineering and more particularly to controlled reactor start-up. The invention improves reliability of an operational neutron source by creating additional safety barriers between the coolant and the source active part materials. The operational neutron source is designed as a steel enclosure housing an ampule containing antimony and beryllium with separate antimony and beryllium cavities positioned coaxially. The antimony is contained in the central enclosure made of a niobium-based alloy unreactive with antimony. A beryllium powder bed is located between the antimony enclosure and the ampule enclosure. The ampule enclosure is made of martensite-ferrite steel poorly reacting with beryllium. An upper gas collector is located above the ampule, which serves as a compensation volume collecting gaseous fission products. At the bottom, the ampule is supported by a reflector and a bottom gas collector. The gas collectors, reflector and washers are made of martensite-ferrite grade steel.

Owner:JOINT CO AKME ENG

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com