High-hardness aluminum-made projection lamp support and processing method thereof

A processing method and technology for floodlights, which are applied to high-hardness aluminum floodlight brackets and their processing fields, can solve the problems of unsatisfactory mechanical strength, hardness and density of alloys, difficulty in industrialized production, and complicated preparation processes. Achieve the effect of improving corrosion resistance, inhibiting the formation of coarse grains, and improving comprehensive performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

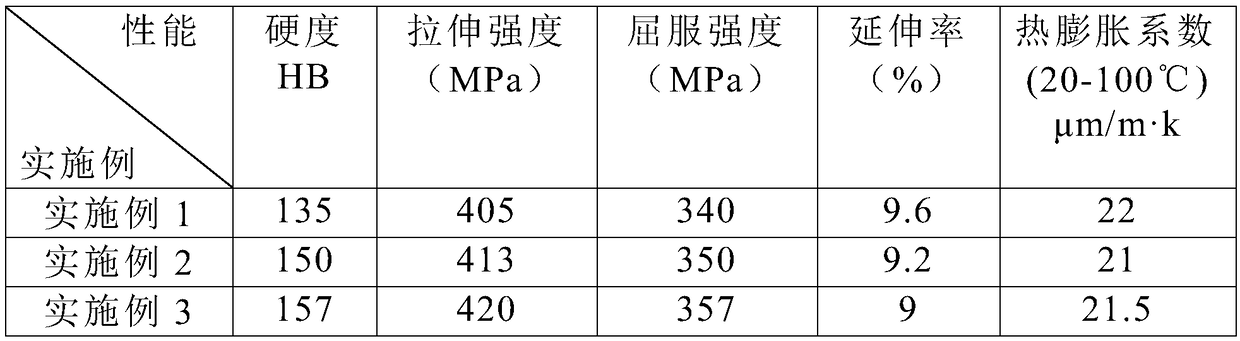

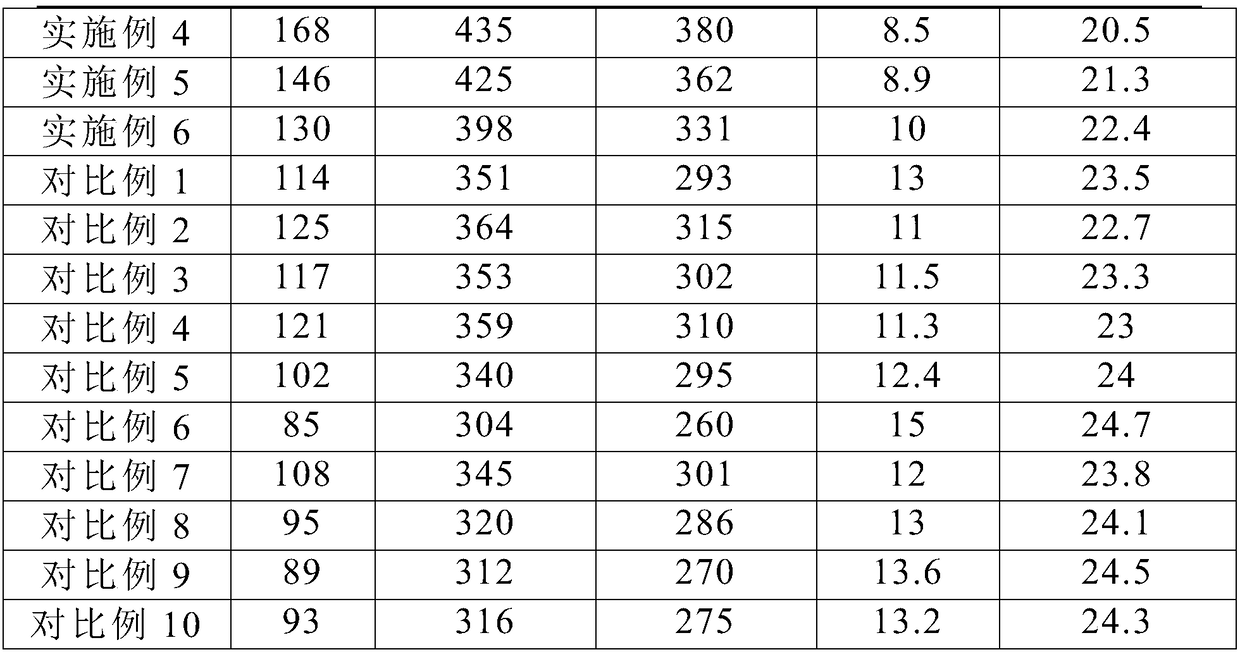

Examples

Embodiment 1

[0025]A high-hardness aluminum floodlight bracket, which is made by smelting the following raw material components in mass percentage: manganese powder: 0.02%, silicon powder: 0.2%, titanium powder: 0.025%, cobalt powder : 0.1%, beryllium powder: 0.05%, potassium fluoroborate: 0.08%, the balance is aluminum powder and unavoidable impurities.

[0026] Weigh the raw materials according to the raw material components and mass percentages of the above-mentioned projection lamp bracket, melt manganese powder, silicon powder, titanium powder, cobalt powder, beryllium powder, potassium fluoroborate and aluminum powder into alloy liquid, and add Covering agent accounting for 1.5% of the total mass of the melt, wherein the covering agent is composed of the following mass percentage components SiO 2 : 50%, KCl: 25%, borax: 10%, cryolite: 15%;

[0027] Refining and degassing the alloy liquid at 740°C for 8 minutes;

[0028] The refined alloy liquid is poured into the mold to make a cas...

Embodiment 2

[0031] A high-hardness aluminum floodlight bracket, which is made by smelting the following raw material components in mass percentage: manganese powder: 0.03%, silicon powder: 0.3%, titanium powder: 0.035%, cobalt powder : 0.15%, beryllium powder: 0.08%, potassium fluoroborate: 0.1%, the balance is aluminum powder and unavoidable impurities.

[0032] Weigh the raw materials according to the raw material components and mass percentages of the above-mentioned projection lamp bracket, melt manganese powder, silicon powder, titanium powder, cobalt powder, beryllium powder, potassium fluoroborate and aluminum powder into alloy liquid, and add Covering agent accounting for 1.7% of the total mass of the melt, wherein the covering agent consists of the following mass percentage components SiO 2 : 52%, KCl: 23%, borax: 10%, cryolite: 15%;

[0033] Refining and degassing the alloy liquid at 745°C for 9 minutes;

[0034] The refined alloy liquid is poured into the mold to make a slab,...

Embodiment 3

[0037] A high-hardness aluminum floodlight bracket, which is made by smelting the following raw material components in mass percentage: manganese powder: 0.04%, silicon powder: 0.4%, titanium powder: 0.04%, cobalt powder : 0.17%, beryllium powder: 0.1%, potassium fluoroborate: 0.1%, the balance is aluminum powder and unavoidable impurities.

[0038] Weigh the raw materials according to the raw material components and mass percentages of the above-mentioned projection lamp bracket, melt manganese powder, silicon powder, titanium powder, cobalt powder, beryllium powder, potassium fluoroborate and aluminum powder into alloy liquid, and add Covering agent accounting for 2% of the total mass of the melt, wherein the covering agent consists of the following components in mass percent SiO 2 : 54%, KCl: 25%, Borax: 8%, Cryolite: 13%;

[0039] Refining and degassing the alloy liquid at 750°C for 10 minutes;

[0040] The refined alloy liquid is poured into the mold to make a billet, t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com