Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

39 results about "Beryllium-Aluminum Alloy" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

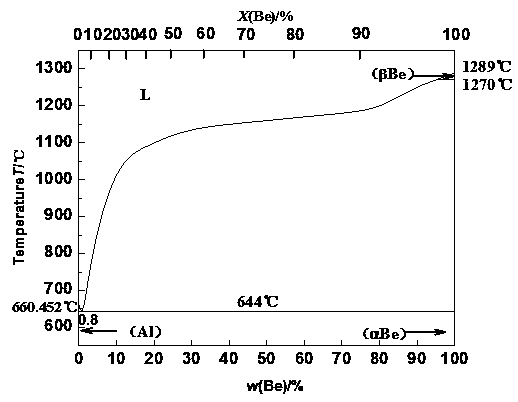

Inventor

A crystalline, inorganic compound composed of beryllium and aluminum in which beryllium increases the alloys thermal and electrical conductivity and emits toxic fumes of beryllium oxides upon heating. Beryllium-aluminum alloy is mainly used in light aircraft construction. Inhalation exposure to its dust and fumes irritates the nose, throat and lungs and can cause pneumonitis. Prolonged exposure can result in a chronic beryllium disease called berylliosis causing granuloma and fibrosis formation in the lungs. Beryllium is associated with an increased risk of developing lung cancer. (NCI05)

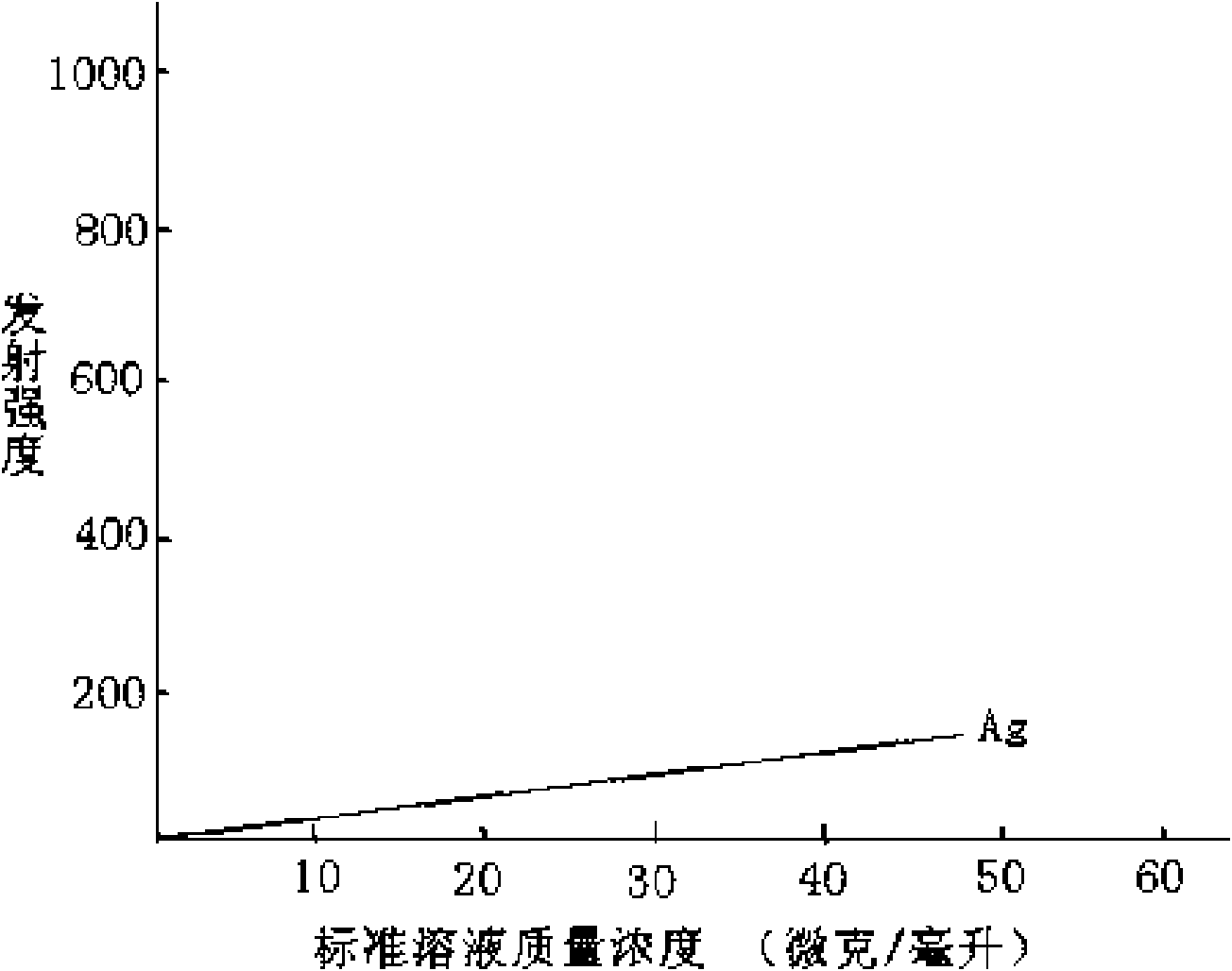

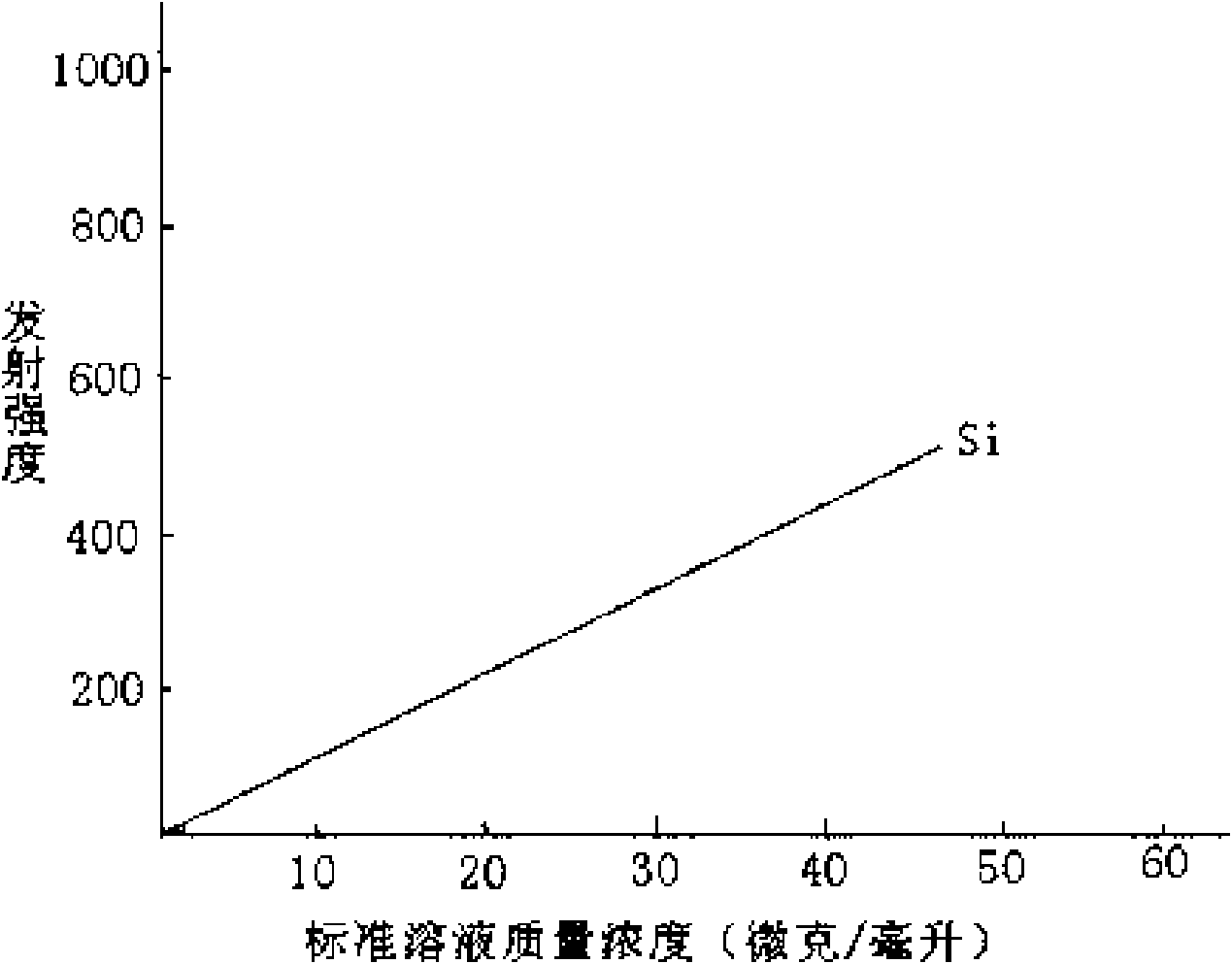

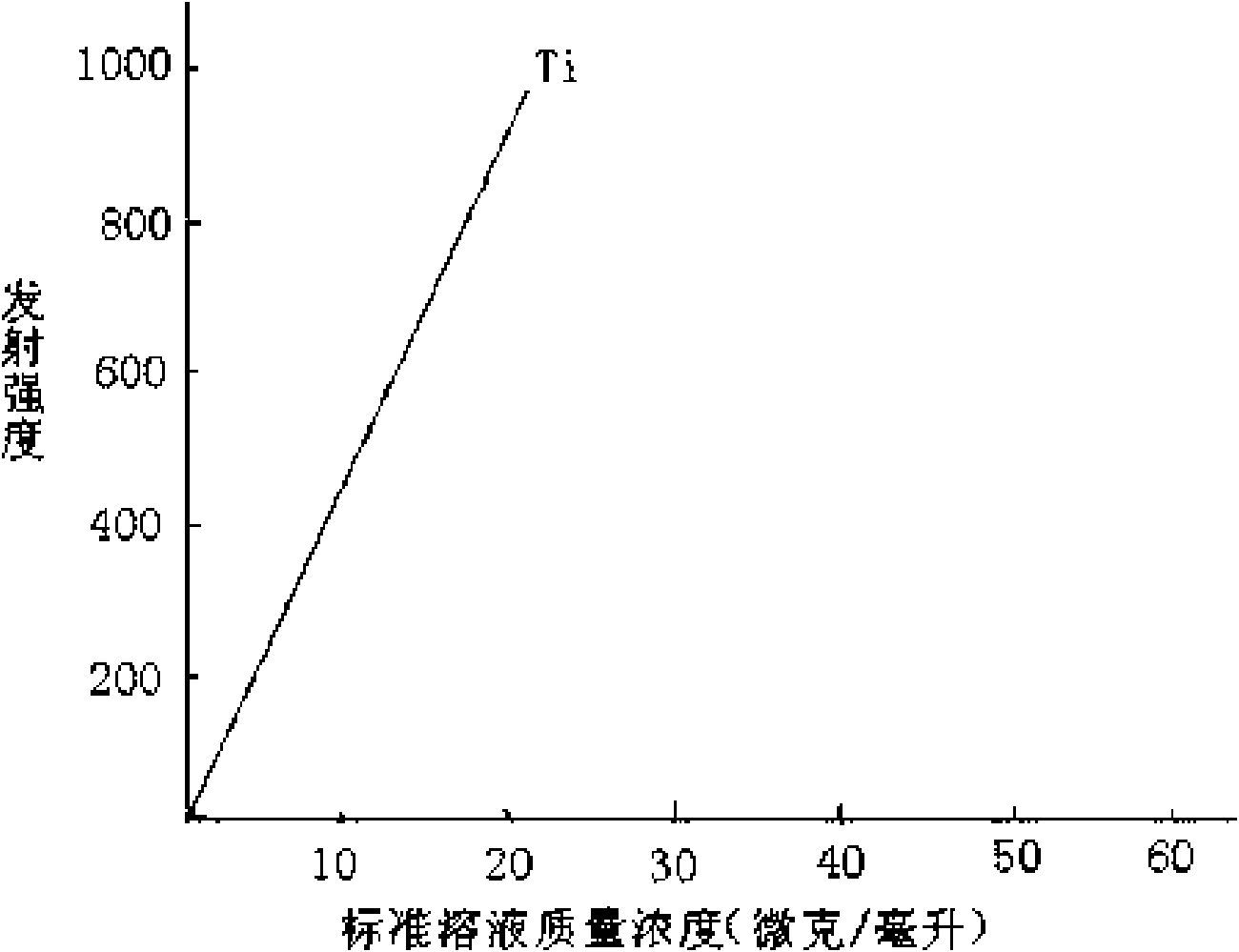

Method for analyzing and detecting alloying elements in beryllium-aluminum alloy

InactiveCN101576498ANo volatile lossImprove accuracyPreparing sample for investigationAnalysis by thermal excitationMass ratioSodium hydroxide

The invention discloses a method for analyzing and detecting alloying elements in a beryllium-aluminum alloy. The method comprises the following steps: weighing a beryllium-aluminum alloy sample to be detected and 20% sodium hydroxide solution in the mass ratio of (0.1 to 5): 100, and putting into a polytetrafluoroethylene plastic beaker; dissolving at a low temperature; oxidizing by adding 30% hydrogen peroxide in a small amount drop by drop, and decomposing excessive hydrogen peroxide by heating after oxidizing; cooling to obtain a mixed solution; weighing the mixed solution, 50% hydrochloric acid and 50% nitric acid in the volume ratio of (5 to 10): (30 to 50): (10 to 20); acidizing and heating until the solution is absolutely clear; cooling and diluting the solution to the required volume with water; shaking the solution up to obtain the beryllium-aluminum alloy sample solution to be detected; then, plotting standard working curves; and finally detecting the samples. The method for analyzing and detecting alloying elements in a beryllium-aluminum alloy in the invention solves the problems of the determination of silver with higher content in the beryllium-aluminum alloy material and the influence thereof on other elements to be detected in the material in the analysis and detection using plasma emission spectra.

Owner:CSIC NO 12 RES INST

Beryllium aluminum alloy and preparation method thereof

InactiveCN107761150AImprove corrosion resistanceGood matting functionAnodisationWater rinsingStructuring element

The invention relates to the field of beryllium aluminum alloy, and particularly discloses beryllium aluminum alloy and a preparation method thereof. The beryllium aluminum alloy comprises a berylliumaluminum alloy matrix and a colored anode oxide film positioned on the surface of the beryllium aluminum alloy matrix. The method comprises the following steps: S1, performing alkaline cleaning on aberyllium aluminum alloy precursor to be treated; S2, performing acid cleaning; S3, performing acid attack; S4, performing anodic oxidation; S5, performing hot water rinsing; S6, dyeing; S7, performing sealing, so as to obtain the beryllium aluminum alloy. The obtained beryllium aluminum alloy is higher in corrosion resistance, has good extinction function, and is more applicable to optical structure elements.

Owner:CHANGCHUN INST OF OPTICS FINE MECHANICS & PHYSICS CHINESE ACAD OF SCI

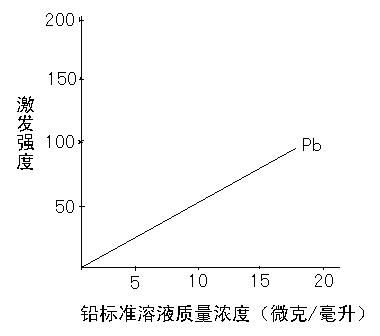

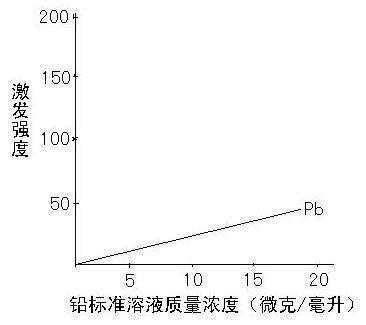

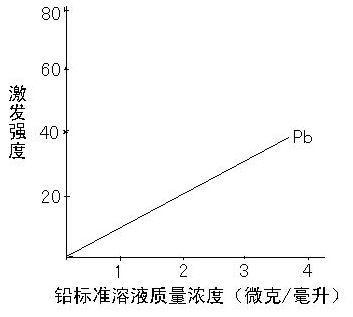

Method for analyzing and detecting lead impurity element in beryllium-aluminum alloy

InactiveCN101929959AMeet the measurement requirementsReduce distractionsAnalysis by thermal excitationUltimate tensile strengthImpurity

The invention discloses a method for analyzing and detecting a lead impurity element in beryllium-aluminum alloy, which comprises the following steps of: preparing to-be-detected sample solution of the beryllium-aluminum alloy, drawing a standard working curve of the lead element, enriching and separating the lead element, exciting the enriched and separated to-be-detected sample solution of the beryllium-aluminum alloy on a plasma emission spectrometer, measuring the emission intensity of the lead element, searching the mass concentration rho of the lead element in the beryllium-aluminum alloy standard solution according to the standard working curve of the lead element, and calculating the mass concentration Cx of the lead element in the to-be-detected sample solution of the beryllium-aluminum alloy. The method fills a gap in analysis and detection of the lead impurity element in the beryllium-aluminum alloy material by adopting plasma emission spectrography, has the characteristics of quickness, low interference, good precision, high accuracy and the like, meets the measurement requirement of the lead impurity element in the beryllium-aluminum alloy material, and has stable, consistent and repeatable measurement result.

Owner:CSIC NO 12 RES INST

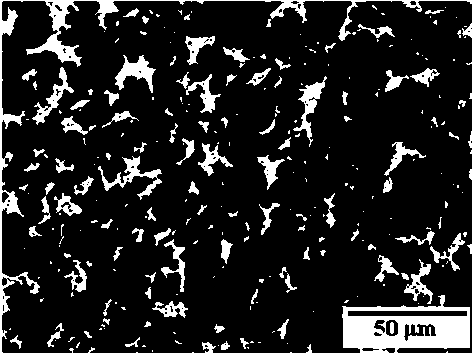

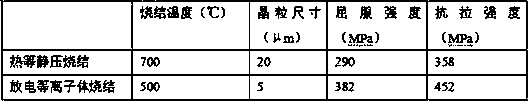

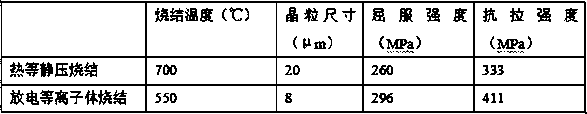

Hot-isostatic-pressing liquid-phase sintering preparation method of beryllium-aluminum alloy

InactiveCN107354332AEnhanced interface bindingImprove performanceMechanical propertyMaterials science

The invention relates to a preparation method of beryllium aluminum alloy, which aims to reduce the difficulty of preparation and improve production efficiency. The preparation method of the beryllium aluminum alloy in the present invention comprises three key steps of raw material mixing, cold isostatic pressing and hot isostatic pressing liquid phase sintering. Compared with other preparation methods of beryllium-aluminum alloys, the method of the present invention selects aluminum alloys containing alloy elements, which improves the wettability of liquid aluminum and solid beryllium during the preparation process of beryllium-aluminum alloys by liquid phase sintering, and has the advantages of low sintering temperature and short sintering time. The advantages of short length and high interface bonding strength can greatly improve the mechanical properties of beryllium aluminum alloy.

Owner:MATERIAL INST OF CHINA ACADEMY OF ENG PHYSICS

High-performance beryllium aluminum alloy and preparation method thereof

The invention discloses a high-performance beryllium aluminum alloy and a preparation method thereof and belongs to the field of aluminum alloy materials and metallurgy. The problem that a beryllium aluminum alloy is poor in corrosion resistance is solved. The beryllium aluminum alloy comprises, by defined mass percentage, Be, Ni, Mg, Ag, Si, Sr, Zr, Cr, Sc, SiC, graphene and the balance Al and inevitable impurities. Due to fusion of metal containing the above elements, silicon carbide after ball grinding, graphene and aluminum powder are added in, and after mixing, slag-off, refining, metamorphism and degassing treatment is performed; finally, casting is performed so that cast ingots can be obtained; and then the cast ingots are subjected to homogenizing treatment and manual aging treatment. According to the high-performance beryllium aluminum alloy and the preparation method thereof, the density and the mechanics performance of the beryllium aluminum alloy are remarkably lowered; andmeanwhile, the strength and the corrosion resistance of a beryllium aluminum alloy matrix are effectively enhanced. The high-performance beryllium aluminum alloy can be applied to an electronic packaging material.

Owner:ZHONGBEI UNIV

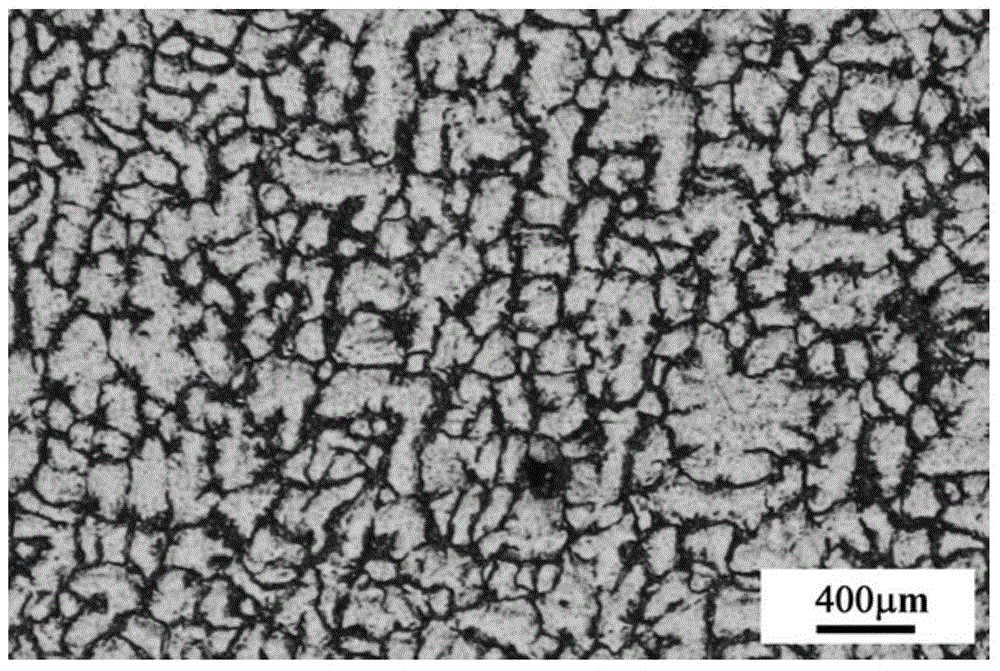

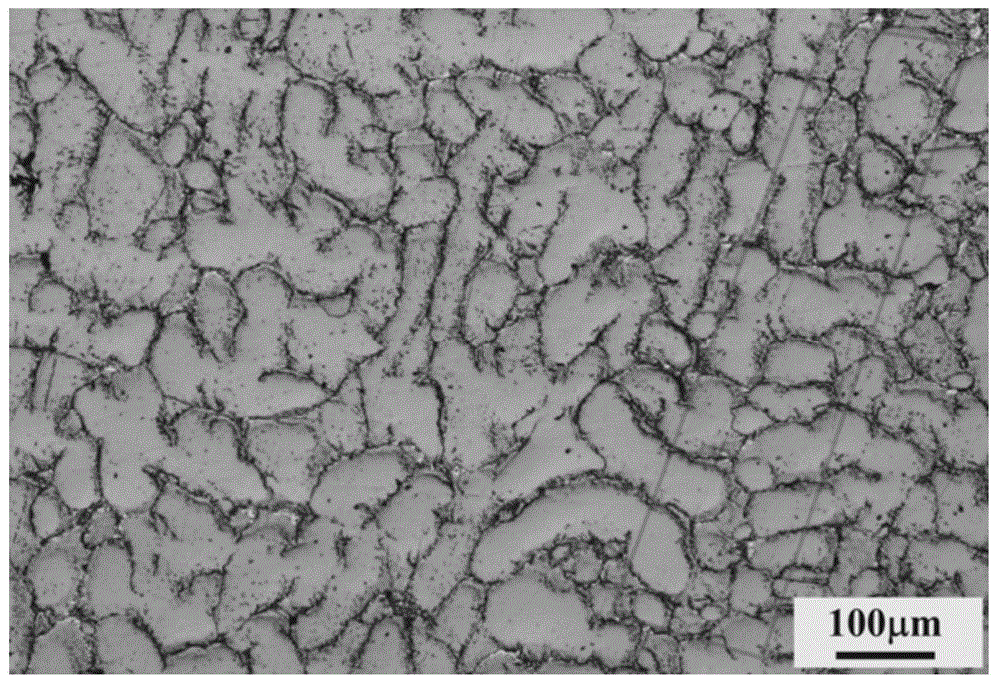

Beryllium-aluminum alloy sheet and manufacturing method thereof

ActiveCN104942271ARefining as-cast structureImprove plastic deformation abilityElectromagnetic castingMechanical property

The invention discloses a beryllium-aluminum alloy sheet and a manufacturing method thereof. The manufacturing method comprises the sequential steps of manufacturing beryllium-aluminum alloy cast ingots, performing hot-pressing preforming on the beryllium-aluminum alloy cast ingots and performing hot-rolling forming on beryllium-aluminum alloy ingot blanks so that the beryllium-aluminum alloy sheet can be obtained. In the step of manufacturing the beryllium-aluminum alloy cast ingots, near-liquidus electromagnetic casting is adopted for manufacturing the beryllium-aluminum alloy cast ingots. The manufacturing method is a composite processing method combining near-liquidus electromagnetic casting, solid-state hot-pressing preforming and precision rolling. Near-liquidus electromagnetic casting is adopted in the step of manufacturing the beryllium-aluminum alloy cast ingots, formation of small and uniform non-dendritic structures is facilitated, and refining of alloy as-cast structures of beryllium-aluminum alloy is facilitated. Alloy dendritic structures of the cast ingots are further fragmented through hot-pressing performing, and the plastic deformation capacity of the alloy is improved. Finally, the sheet of the required thickness is obtained through a precision rolling method, and both the mechanical property and the composition of the produced beryllium-aluminum alloy sheet meet the requirements.

Owner:MATERIAL INST OF CHINA ACADEMY OF ENG PHYSICS

Welding method of cast beryllium-aluminum alloy

ActiveCN109570689AAvoid Weld Quality IssuesGood combinationArc welding apparatusWire cuttingPerformance index

The invention provides a welding method of cast beryllium-aluminum alloy. The welding method of the cast beryllium-aluminum alloy comprises the following steps that (1) the surface of a cast beryllium-aluminum alloy material is dipped in absolute ethyl alcohol, oil dirt attached to the surface of the cast beryllium-aluminum alloy material is cleaned, and the cast beryllium-aluminum alloy materialis cleaned up with deionized water; (2) preparation is conducted before welding, wherein beryllium-aluminum welding wires are prepared by means of wire cutting, and welding of sample sheets and welding of sample rods are conducted; (3) the welding initial current is 5-10 A, the arc extinguishing current is 10-20A, the welding current is 100-150A, the welding speed is 0.5-2 cm / s, and the argon flowof a spray nozzle is 5-20 L / min; (4), heat treatment is conducted on welding samples, and the temperature is 550-600 DEG C and kept for 4-6 h; (5) the sample rod completing heat treatment is machinedto be a mechanical sample. By the adoption of the welding method of the cast beryllium-aluminum alloy, the combination degree between a weld joint and the matrix is good, macroscopic cracks are avoided, and the mechanical performance index of the welded material is 0.9-1 time that of the welded matrix material.

Owner:西北稀有金属材料研究院宁夏有限公司

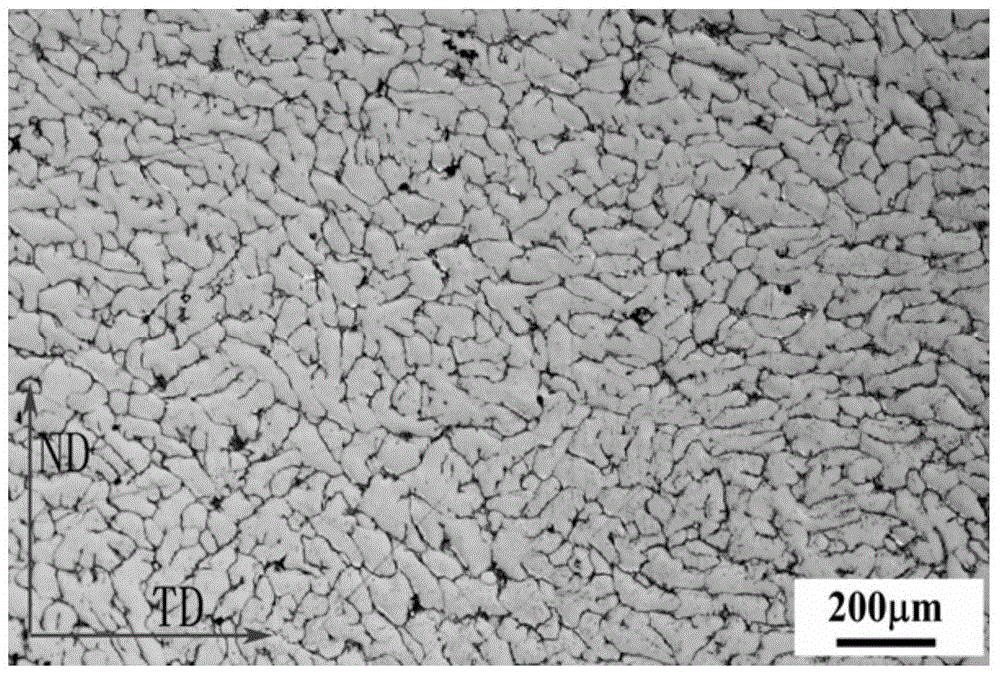

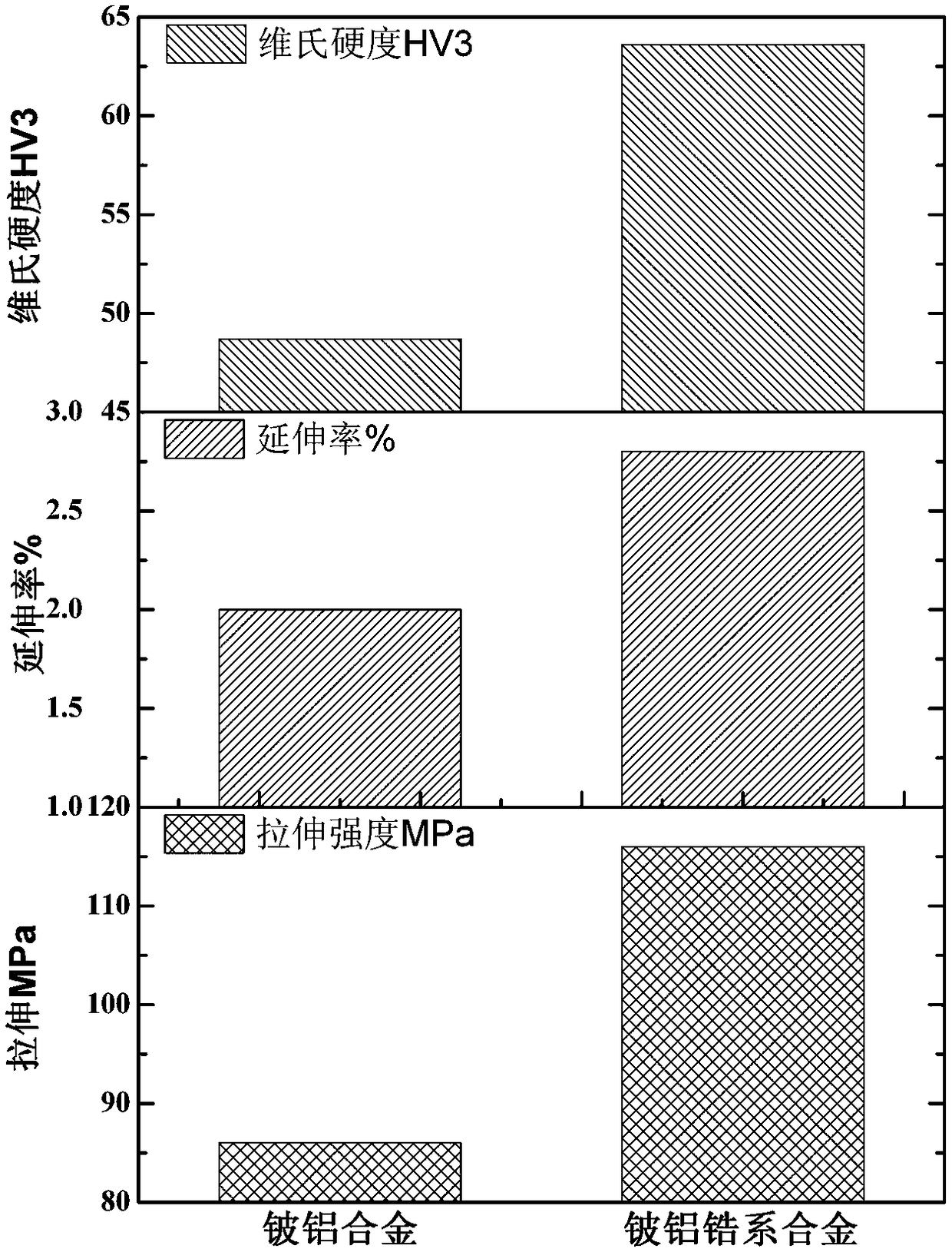

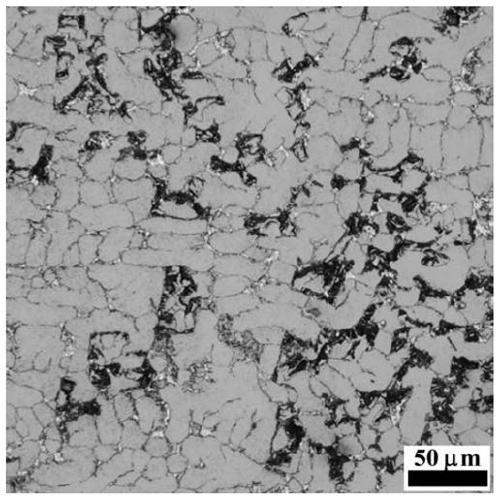

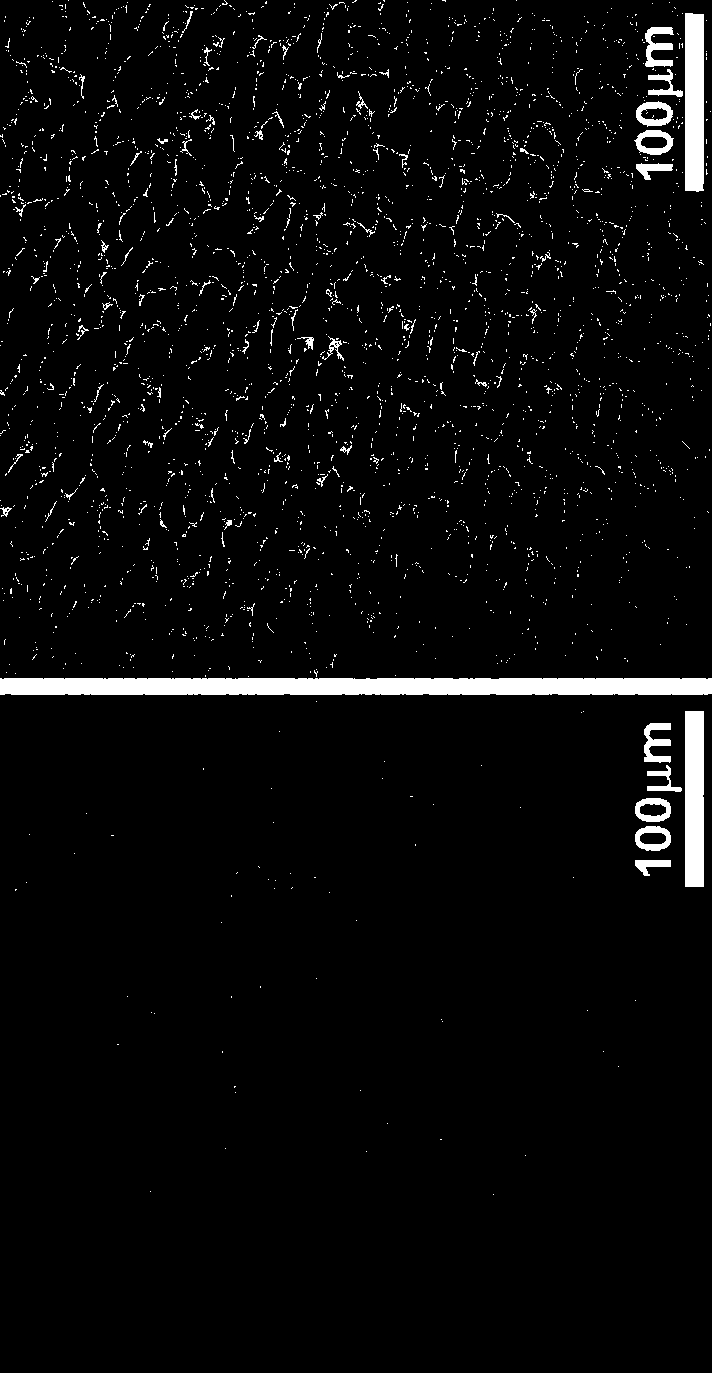

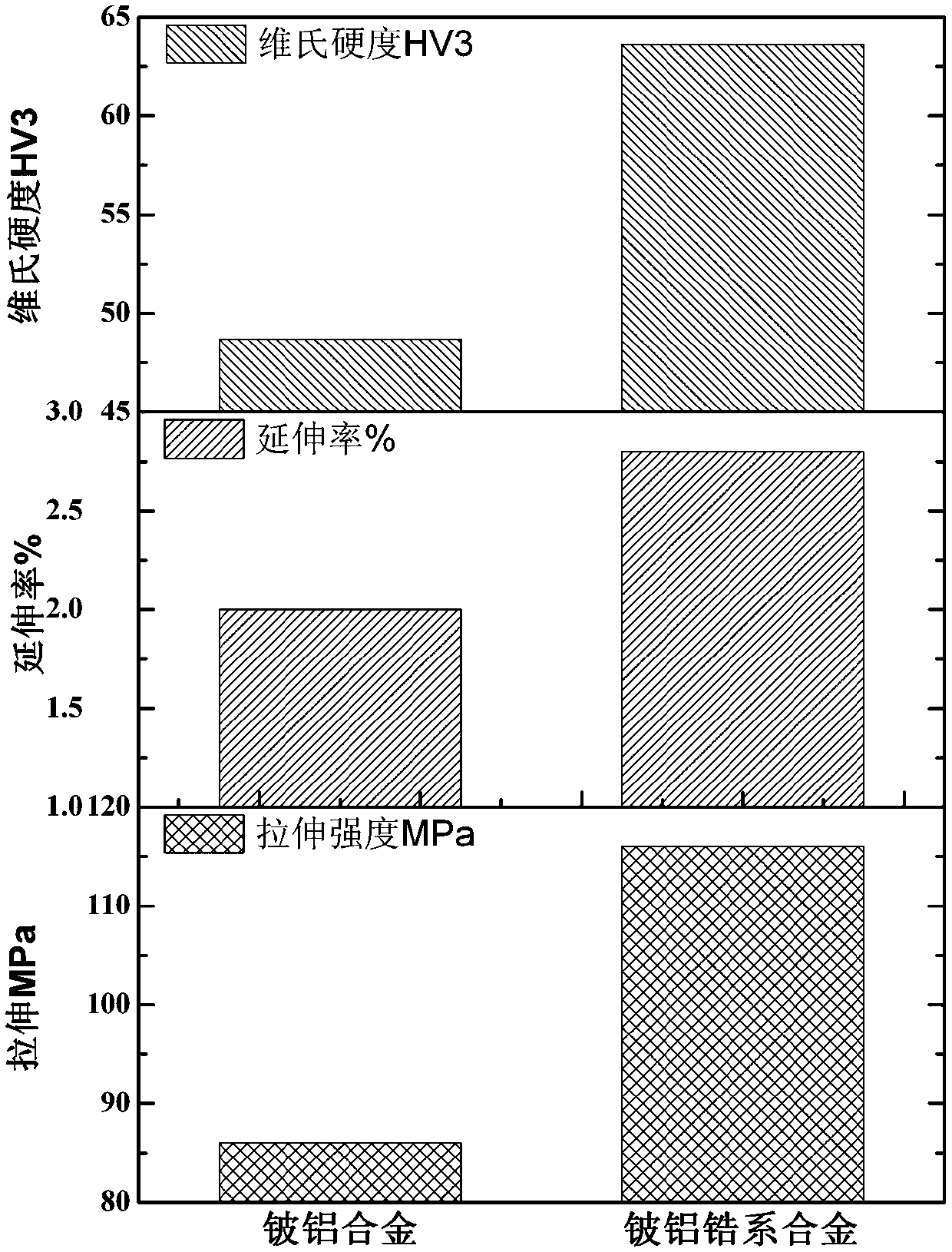

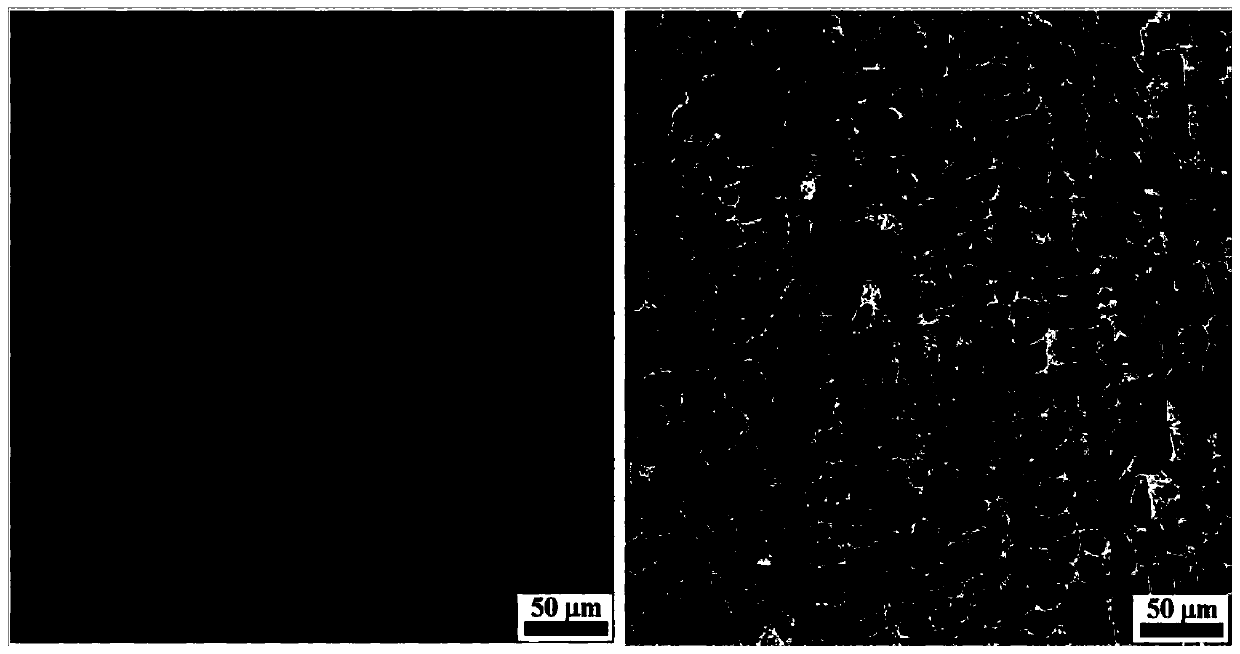

Beryllium-aluminum-zirconium-series multi-element alloy and preparation method thereof

ActiveCN108300921AImprove mechanical propertiesImprove organizationEquiaxed crystalsMechanical property

The invention discloses a beryllium-aluminum-zirconium-series multi-element alloy and a preparation method thereof which aim at solving the problems that at present, a method that a beryllium-aluminumalloy is prepared by adopting powder hot isostatic pressing is complicated in technology and very high in cost and greatly limits application of the beryllium-aluminum alloy. The beryllium-aluminum-zirconium-series multi-element alloy is prepared and formed by adopting the following raw materials of, by weight, 54-80% of metal beryllium, 17-45% of metal aluminum, 0.2-2% of metal zirconium and 0.1-1.0% of add element. In the beryllium-aluminum-zirconium-series multi-element alloy and the preparation method thereof, based on an existing beryllium-aluminum alloy, the metal zirconium and other alloying elements are added, a beryllium-aluminum alloy base material is prepared firstly, then a pre-alloying beryllium-aluminum-zirconium-series multi-element alloy is prepared through a vacuum induction smelting method, and then the beryllium-aluminum-zirconium-series multi-element alloy is obtained through subsequent remelting. According to the beryllium-aluminum-zirconium-series multi-element alloy and the preparation method thereof, by conducting multi-element alloying of zirconium and other elements on the beryllium-aluminum alloy, an equiaxed crystal alloy with the refined structure andthe uniform size can be obtained, structure defects and composition segregation are reduced, and alloy plasticity is improved, so that alloy mechanical properties are greatly improved, and the excellent comprehensive performance is achieved.

Owner:MATERIAL INST OF CHINA ACADEMY OF ENG PHYSICS

Beryllium aluminum alloy and preparation method thereof

ActiveCN107779713AOvercome prone skinOvercome adverse phenomena such as sheddingLiquid/solution decomposition chemical coatingAcid etchingZinc

The invention relates to the field of beryllium aluminum alloys and particularly discloses a beryllium aluminum alloy and a preparation method thereof. The beryllium aluminum alloy comprises a beryllium aluminum alloy matrix and a nickel-phosphorous alloy layer on the surface of the beryllium aluminum alloy matrix. The preparation method of the beryllium aluminum alloy comprises the steps of performing treatments on a beryllium aluminum alloy precursor including, S1, alkali washing, S2, acid pickling, S3, acid etching, S4, first zinc immersion, S5, zinc removal, S6, second zinc immersion, S7,alkaline nickel preplating and S8, acid chemical nickel-phosphorous alloy plating. The preparation method of the beryllium aluminum alloy can well plate nickel-phosphorous alloy on the surface of theberyllium aluminum alloy. The plated layer on the surface of the beryllium aluminum alloy is glossy, uniform, continuous in surface and free from peeling, falling-off, local roughness and the like.

Owner:CHANGCHUN INST OF OPTICS FINE MECHANICS & PHYSICS CHINESE ACAD OF SCI

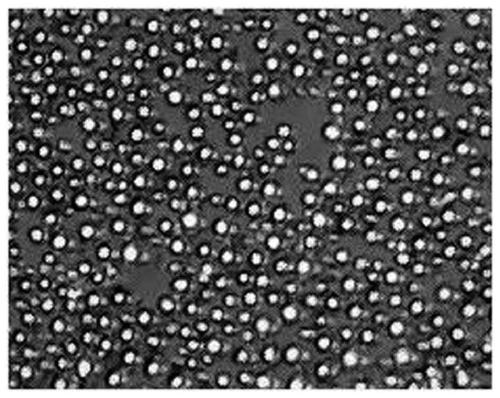

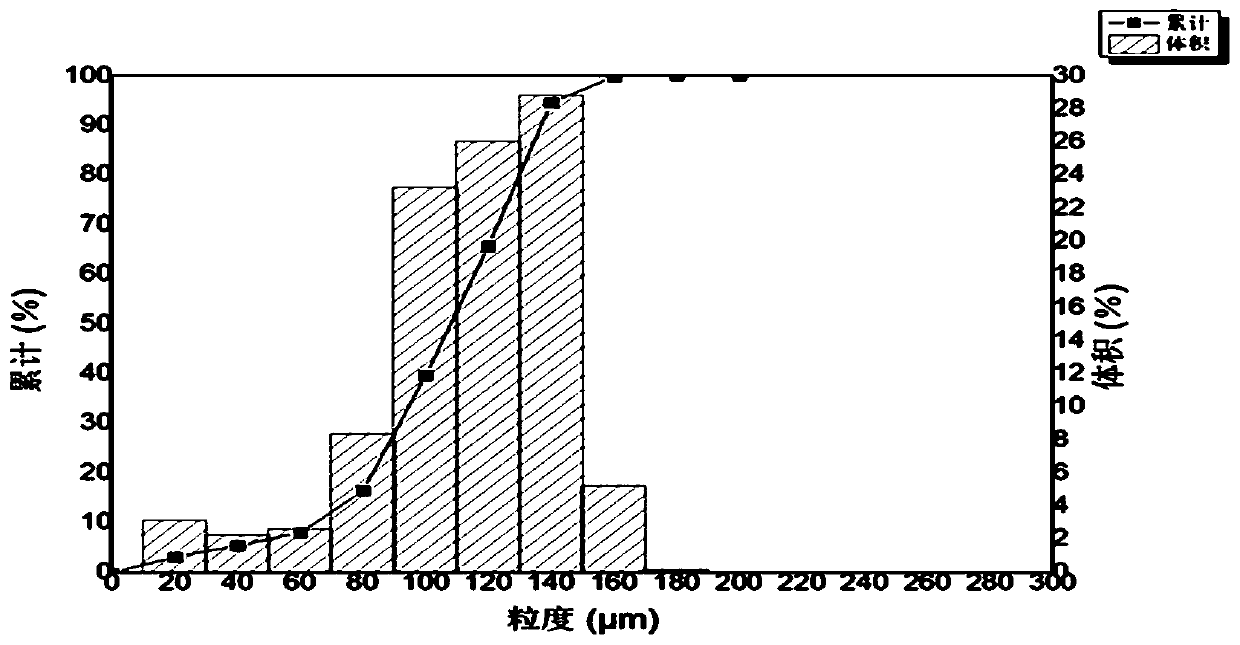

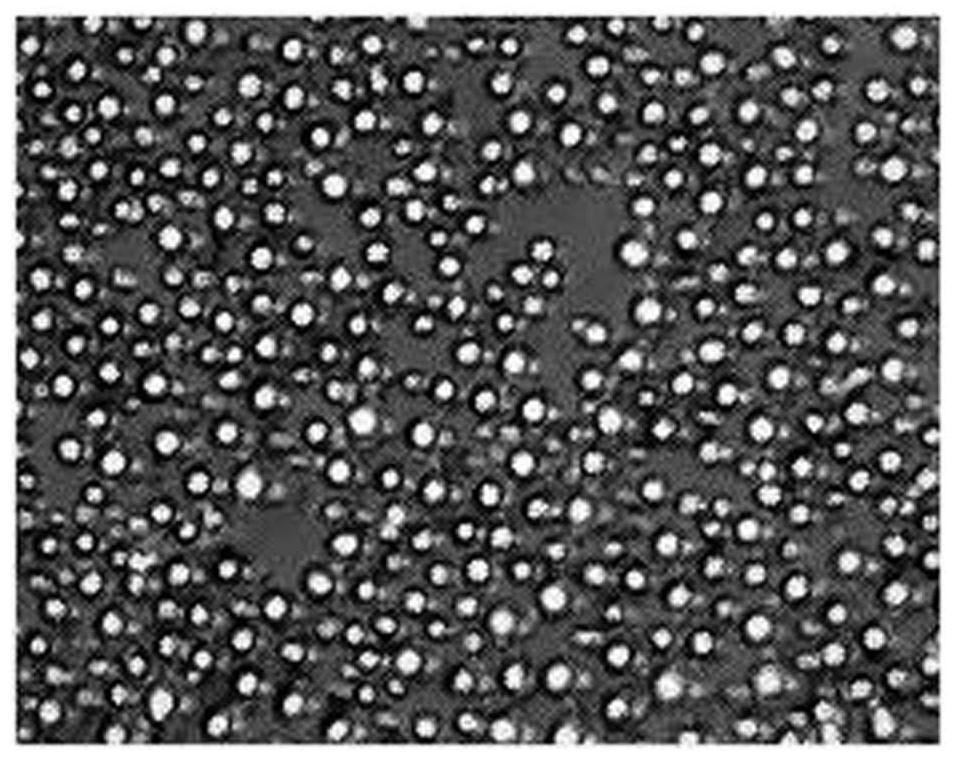

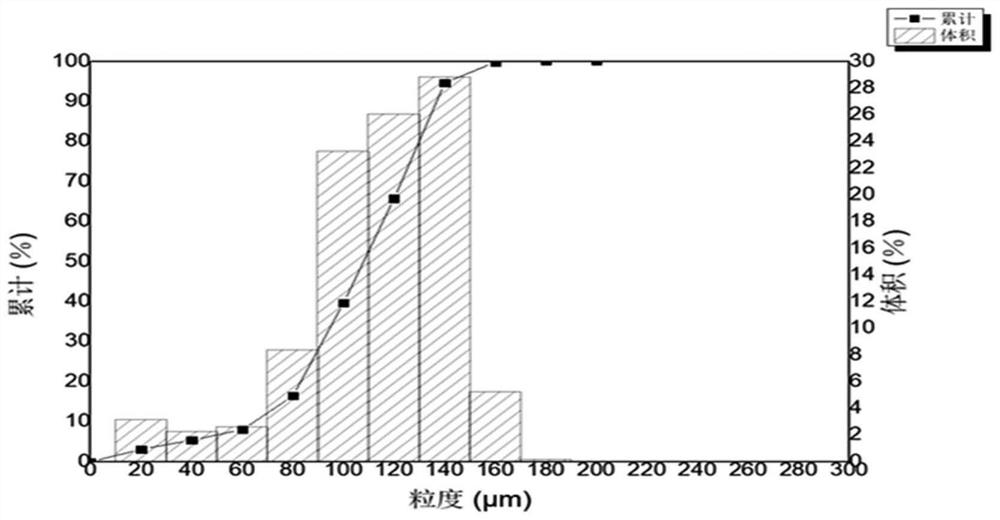

Beryllium-aluminum alloy powder and preparation method and application thereof

ActiveCN111570813AGood sphericityIncrease productivityAdditive manufacturing apparatusTransportation and packagingOxygen contentElectron bunches

The invention provides beryllium-aluminum alloy powder and a preparation method and application thereof. The preparation method comprises the following steps of placing a beryllium-aluminum alloy rodin a vacuum environment; introducing inert gas into the vacuum environment to replace air, wherein the oxygen content in the replaced vacuum environment is smaller than 6 ppm; melting the end surfaceof the beryllium-aluminum alloy rod by means of arc to form a liquid film; crushing the liquid film to fine liquid drops by means of centrifugal force; and carrying out cooling to obtain the beryllium-aluminum alloy powder. The beryllium-aluminum alloy powder may comprise the beryllium-aluminum alloy powder prepared through the preparation method of the beryllium-aluminum alloy powder. The application may comprise application of the beryllium-aluminum alloy powder in the field of laser or electron beam additive manufacturing and / or in the field of laser or electron beam cladding. The inventionhas the beneficial effects that the preparation method is high in production efficiency and low in energy consumption; the prepared beryllium-aluminum alloy powder is good in degree of sphericity, free of hollow powder basically, low in oxygenation amount in the manufacturing process and good in flowability and is a good raw material for 3D printing.

Owner:西藏智材新材料有限公司

Preparation method for ultrafine-grained beryllium-aluminum alloy and product thereof

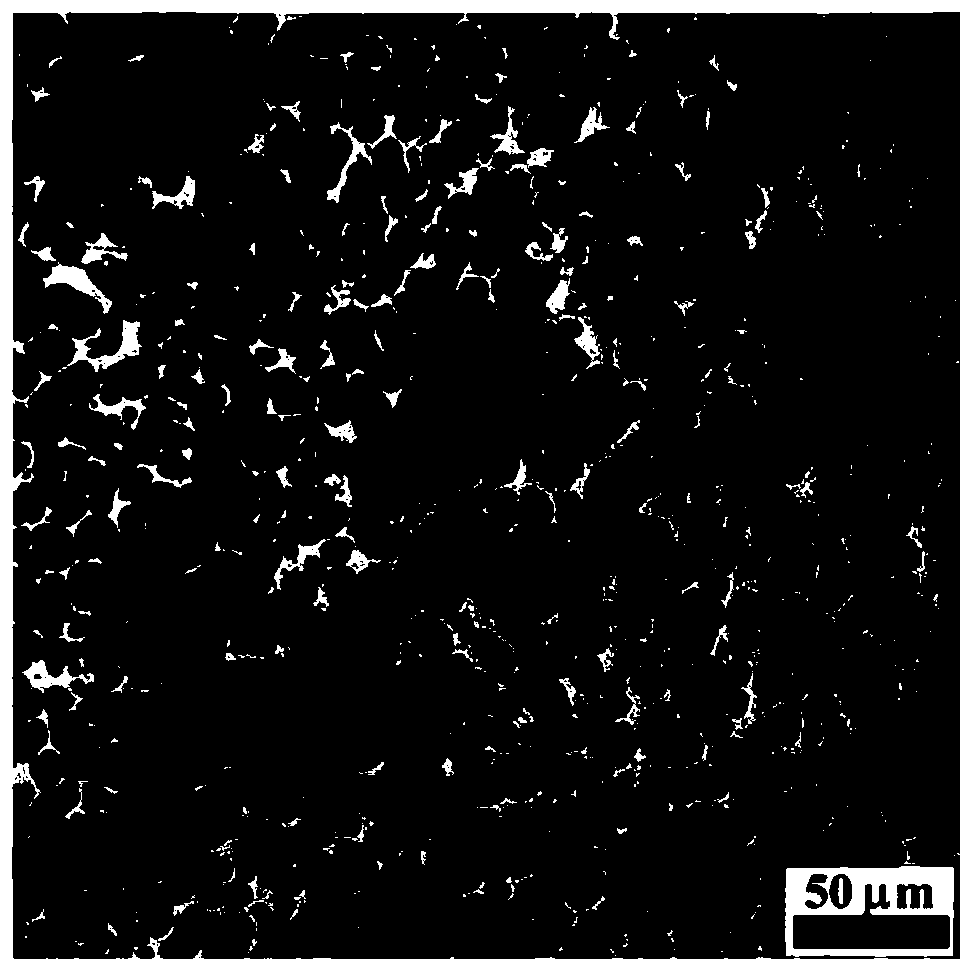

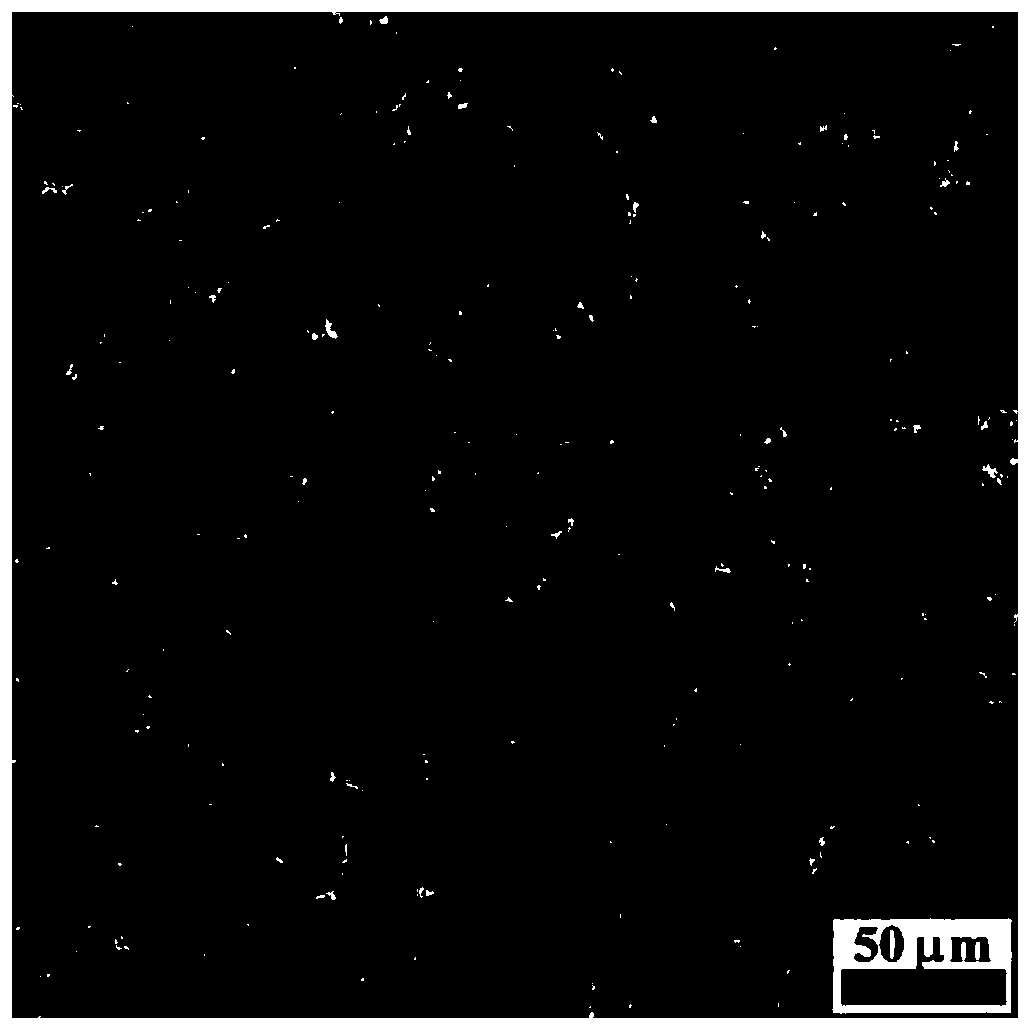

The invention discloses a preparation method for an ultrafine-grained beryllium-aluminum alloy and a product thereof, belongs to the field of non-ferrous metal alloy preparation, and aims at solving the problems that the microstructure of a beryllium-aluminum alloy prepared through a casting method presently is basically presented as thick columnar dendrites, and a beryllium-aluminum alloy with uniform and fine crystalline grains and good performance is difficultly obtained. According to the preparation method disclosed by the invention, mixing and dissolving for alloy components are realizedthrough pre-alloying, rapid cooling for a melt is realized under the condition of a low superheat degree, and finally the novel ultrafine-grained beryllium-aluminum alloy with fine and compact beryllium crystalline grains, uniformly-sized microstructure and equiaxed grains is obtained, so that the mechanical property and the structure uniformity of the beryllium-aluminum alloy are greatly improvedcompared with an alloy in a slowly-cooled state, and meanwhile, segregation is greatly eliminated and the formation of pin holes is suppressed. On the basis of improvement for the preparation method,the beryllium-aluminum alloy disclosed by the invention is more excellent in mechanical property and microstructure, so that more application needs of the special beryllium-aluminum alloy material can be met.

Owner:MATERIAL INST OF CHINA ACADEMY OF ENG PHYSICS

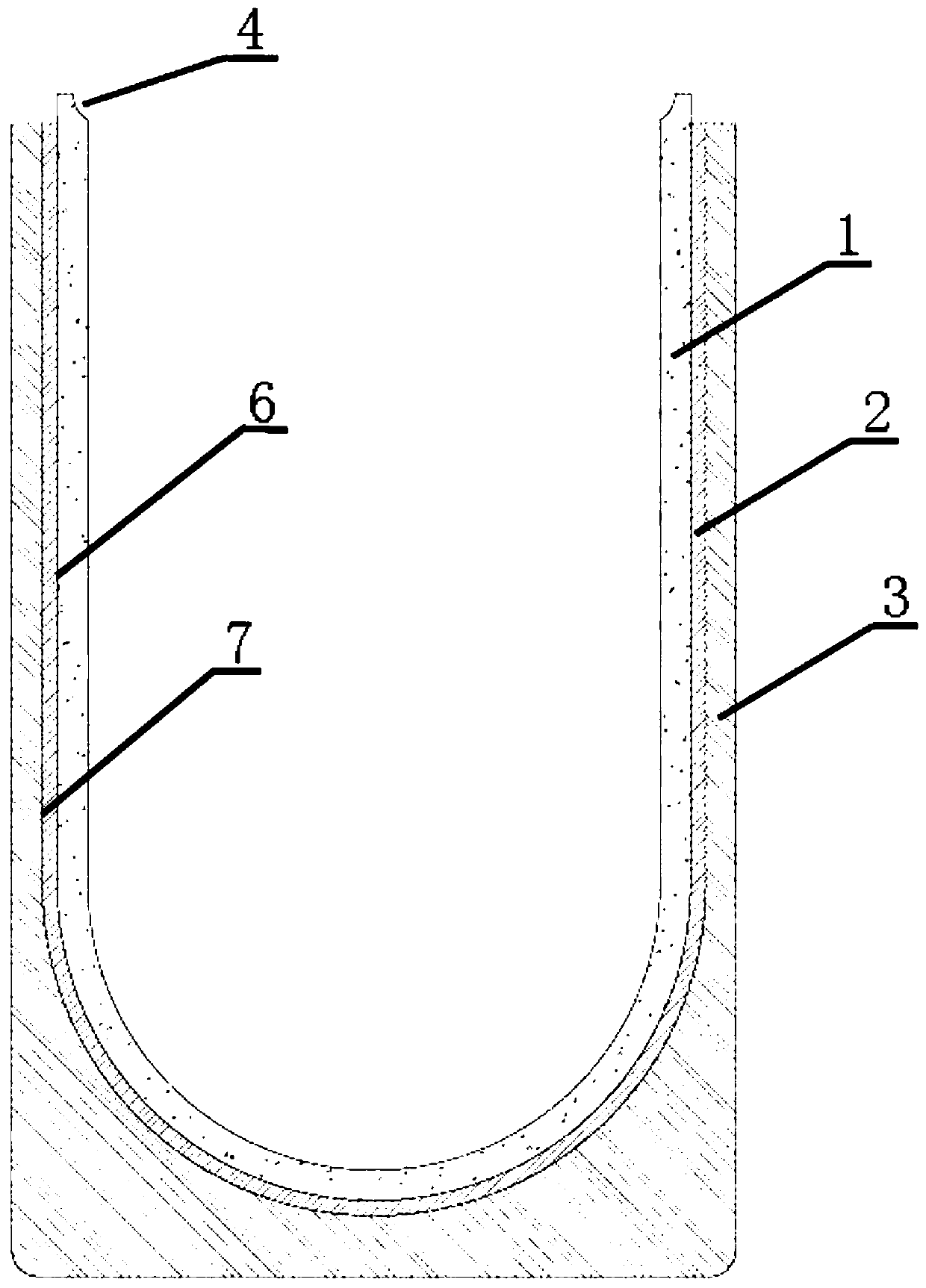

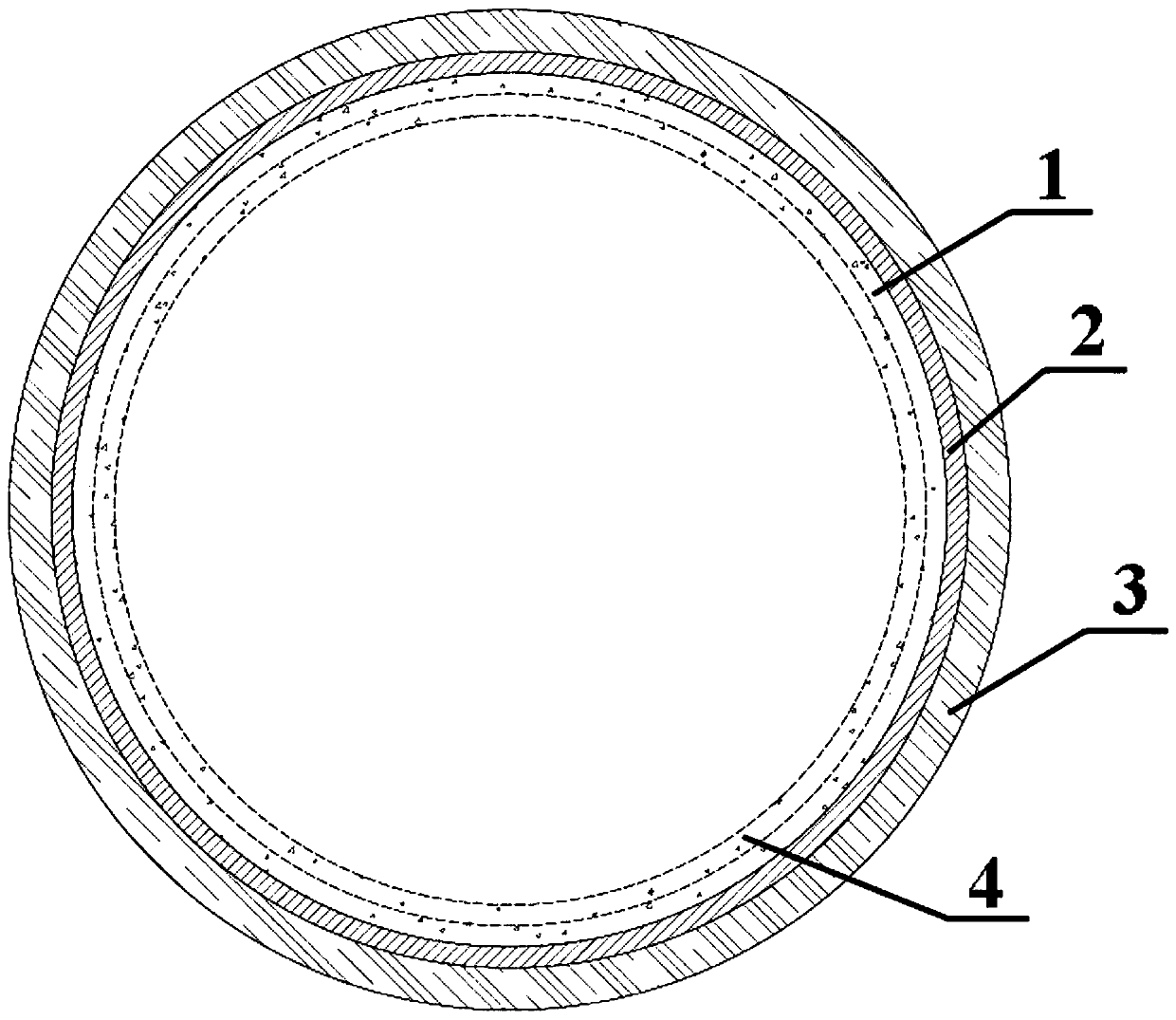

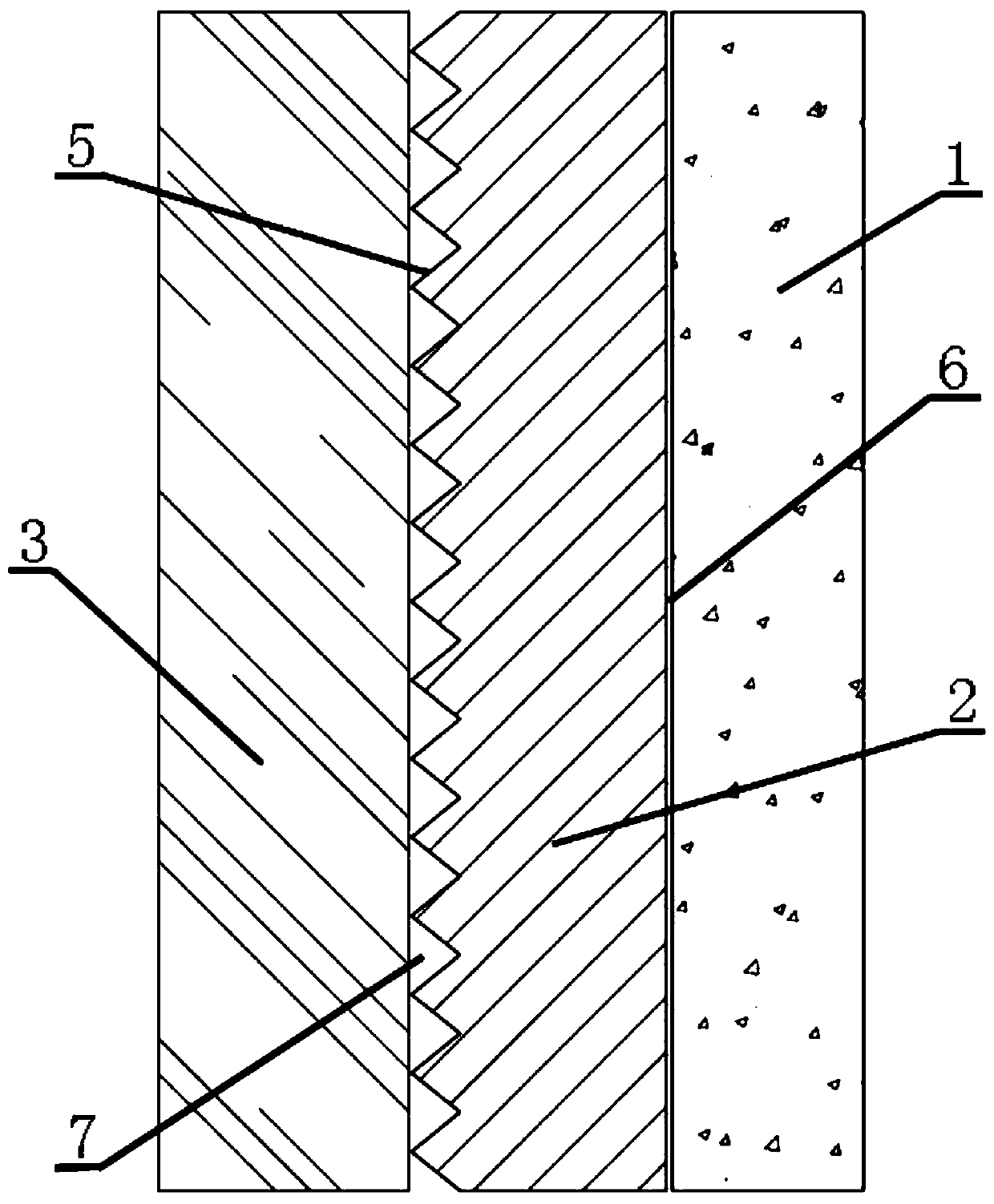

Composite multi-layer crucible for induction melting of bismuth aluminum alloy and preparation method thereof

ActiveCN109824370AImprove structural strengthChemically stableLayered productsCrucibleSmelting process

The invention discloses a composite multi-layer crucible for induction melting of a bismuth aluminum alloy and a preparation method thereof.The problem in the prior art thata crucible suitable for theinduction melting of the bismuth aluminum alloy does not exist is solved. The composite multi-layer crucible comprises an inner layer crucible, a middle layer crucible and an outer layer crucible which are fixedly connected from the inside to the outside; the inner layer crucible is prepared from 92.5-97.5 parts of cerium oxide, 1.0-2 parts of calcium oxide, 0.5-2.0 parts of bismuth oxide and 1.0-3.5 parts of silicon carbide; the middle layer crucible is made of graphite; the outer layer crucible is prepared from 90-95 parts of calcium oxide, 1-3 parts of magnesium oxide, 2-4 parts of ceriumoxide, 1-1.5 parts of zirconiaand 0.5-1.5 parts of clay. The composite multi-layer crucible has a high strength structure, can shield a considerable portion of an induced magnetic field, has stable chemical properties, and has no splashing phenomenon in the smelting process, the degree of oxygenation is low, some single-layer structures can be replaced and can be reused, and the service life is long.

Owner:MATERIAL INST OF CHINA ACADEMY OF ENG PHYSICS

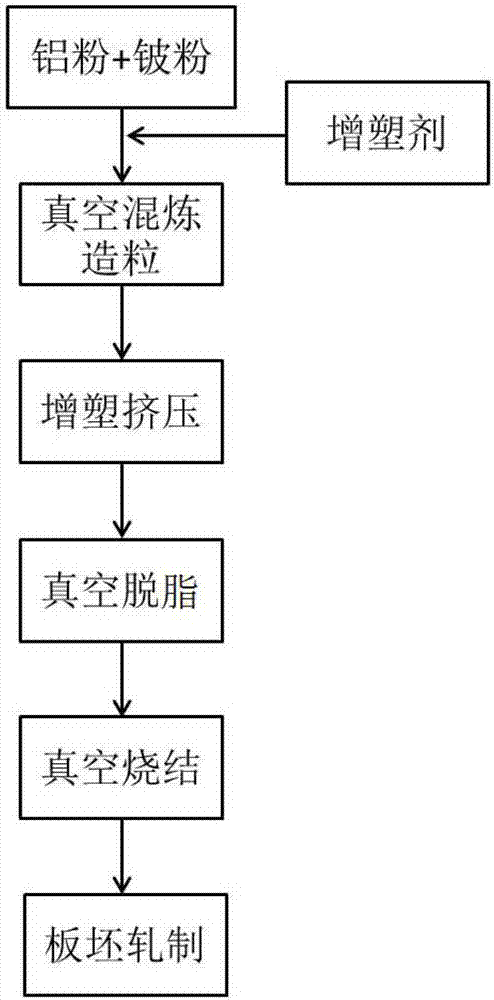

Plasticizing extrusion-forming preparation method for deformable beryllium aluminum alloy plate

The invention discloses a plasticizing extrusion-forming preparation method for a deformable beryllium aluminum alloy plate. The plasticizing extrusion-forming preparation method for the deformable beryllium aluminum alloy plate comprise the steps of material proportioning, mixing, extruding and blank discharging, degreasing and rolling. By adoption of the preparation method, the problems of specific gravity segregation, composition segregation and the like of the deformable beryllium aluminum alloy plate are solved, and the problem of non-uniformity of beryllium aluminum alloy on the microscale is also solved; and the beryllium aluminum alloy blank which is compact in structure and good in performance is obtained, and the subsequent plastic deformation capacity of the beryllium aluminum alloy blank can be improved easily.

Owner:KINKOU SUZHOU COPPER IND CO LTD

Novel method for anodic oxidation of beryllium aluminum alloy

ActiveCN108193252AAvoid harmEase of industrial productionAnodisationMaterials scienceSurface smoothness

The invention discloses a novel method for anodic oxidation of a beryllium aluminum alloy material, and belongs to the field of alloy materials. The method is composed of the following steps that (1),the surface of the beryllium aluminum alloy is treated in a machining manner so as to improve the surface smoothness, and then is repeatedly washed with deionized water to be clean; (2), the beryllium aluminum alloy material subjected to the surface treatment is soaked with an organic solution for 5-10 minutes to remove oil; (3), a chemical oil removal process is carried out on the beryllium aluminum alloy material, and the duration time is 10-15 seconds; (4), chemical polishing is carried out on the surface of the beryllium aluminum alloy by utilizing an acidic solution, wherein the polishing time is 10-15 seconds; (5), a proper cathode and anode area ratio is determined, a proper rack is selected to fix an anode, a proper interelectrode distance is selected to fix the positions of the two poles, and then an anodic oxidation process is started; and (6), hole sealing is carried out by adopting a potassium dichromate solution after the oxidation process is finished. According to the method, anodic oxidation is carried out on the surface of the beryllium aluminum alloy, so that the corrosion tendency of the beryllium aluminum alloy is prevented and reduced, and the corrosion resistance and the surface performance of the beryllium aluminum alloy are improved.

Owner:西北稀有金属材料研究院宁夏有限公司

Beryllium aluminum alloy and preparing method thereof

InactiveCN107740084AHighly corrosiveImprove conductivityMetallic material coating processesTime rangeSodium fluoride

The invention relates to the field of beryllium aluminum alloys and particularly discloses a beryllium aluminum alloy and a preparing method thereof. The beryllium aluminum alloy comprises a berylliumaluminum alloy base body and a chemical oxide film located on the surface of the beryllium aluminum alloy base body. The method includes the steps that firstly, a beryllium aluminum alloy precursor needing to be treated is subjected to alkaline washing; secondly, acid pickling is conducted; thirdly, acid etaching is conducted; fourthly, chemical oxidizing is conducted; and fifthly, the berylliumaluminum alloy is obtained after hot washing. The chemical oxidization time ranges from 5 min to 7 min, and the temperature ranges from 25 DEG C to 30 DEG C; oxidation liquid used in chemical oxidization is chromic anhydride and sodium fluoride, and the prepared beryllium aluminum alloy has high corrosion-resisting performance and electric conduction performance.

Owner:CHANGCHUN INST OF OPTICS FINE MECHANICS & PHYSICS CHINESE ACAD OF SCI

Titanium doped beryllium-aluminum alloy and preparation method thereof

The invention discloses a titanium doped beryllium-aluminum alloy and a preparation method thereof, and belongs to the field of alloy materials and preparation thereof. In the titanium doped beryllium-aluminum alloy, titanium particles are placed at the bottom of a water cooling copper crucible, and a beryllium block and an aluminum block are arranged above the titanium particles; pre-vacuumizingis carried out in a melting furnace, and then the melting furnace is filled with argon; electric arc melting is carried out; and after metal is completely molten, power is off for solidification, a magnetic field continues to be applied in the solidification process for stirring, and finally a titanium doped beryllium-aluminum alloy block is obtained. In the prepared titanium doped beryllium-aluminum alloy, a Be12Ti reinforced body is synthesized in situ, and the Be12Ti reinforced body has good dispersity. Meanwhile, the prepared titanium doped beryllium-aluminum alloy has higher hardness, theapplication range of the beryllium-aluminum alloy can be effectively expanded, and high application value is achieved. The preparation method is simple, operation is easy, the production process andperiod are short, the requirements of industrial large-scale production and application can be met, good application value and application prospects are achieved, and the titanium doped beryllium-aluminum alloy is worthy of large-scale application and popularization.

Owner:MATERIAL INST OF CHINA ACADEMY OF ENG PHYSICS

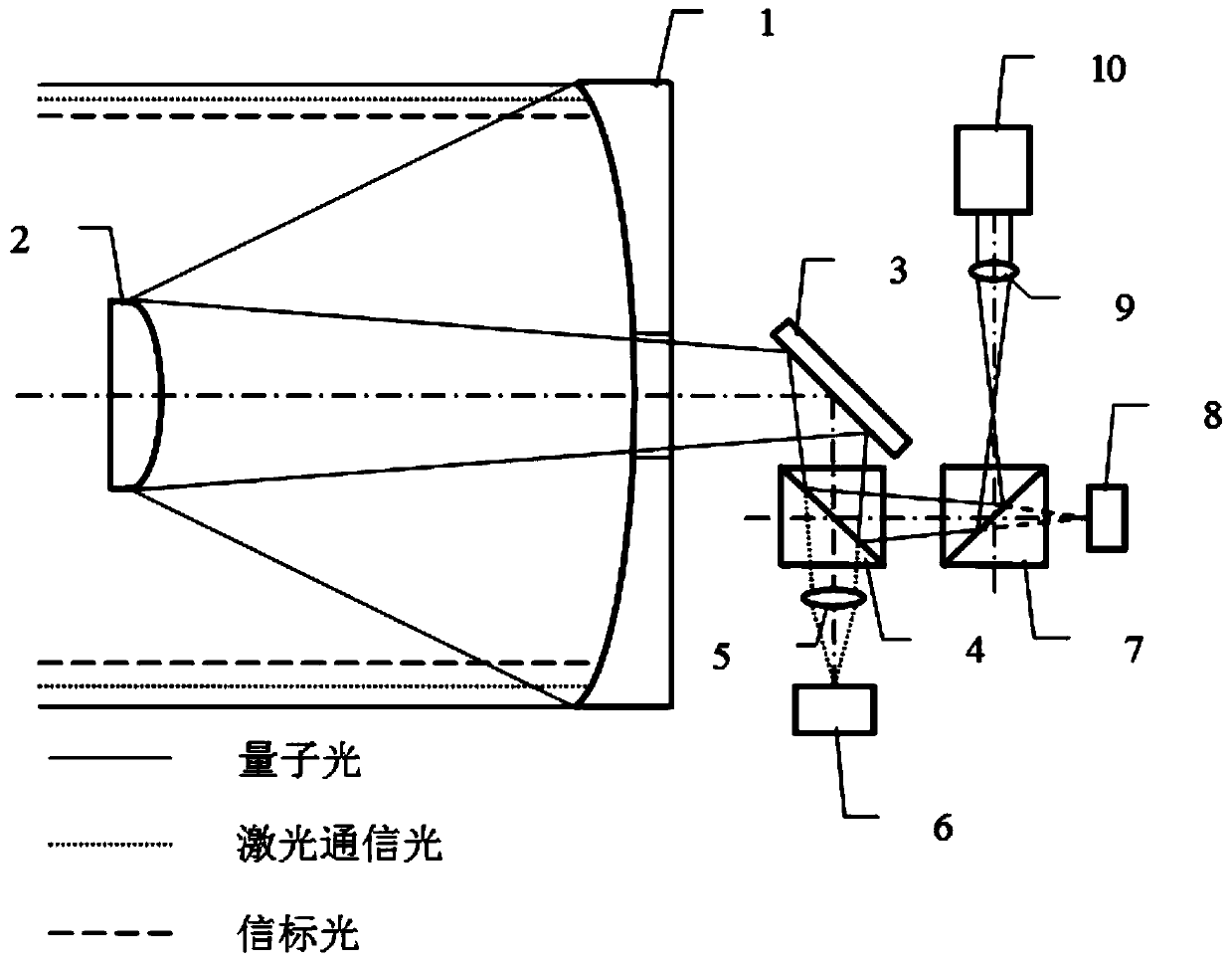

Light and small athermalization quantum communication ground station telescope optical system

ActiveCN109889277AAchieve athermalizationLarge aperturePhotonic quantum communicationElectromagnetic transmittersBeam splitterMetallic materials

The invention discloses a light and small athermalization quantum communication ground station telescope optical system which is composed of a primary mirror (1), a secondary mirror (2), an electric deflection reflector (3), a first beam splitter prism (4), a laser communication focus shrinkage mirror (5), a laser communication module (6), a second beam splitter prism (7), a precise tracking detector (8), a quantum communication collimating mirror (9) and a quantum communication module (10). The whole system comprises a primary mirror, a secondary mirror, a lens cone and other structural materials which are made of the same metal material and are made of aluminum alloy or beryllium aluminum alloy, the focal plane of each subsystem can coincide with a sensor without a temperature focusing mechanism when the environment temperature changes, and athermalization is achieved. Meanwhile, the primary mirror is made of a light metal material, an additional supporting structure is not needed, the relative aperture can be large, the cylinder length is shortened, and the weight is reduced. The whole optical system realizes laser communication and quantum communication at the same time throughthe mode. The optical system can be applied to a horizontal or polar axis type ground station telescope.

Owner:INST OF OPTICS & ELECTRONICS - CHINESE ACAD OF SCI

Technology for producing single-crystal conductive copper rod with upward continuous casting method

ActiveCN107354507AImprove product qualityImprove continuityPolycrystalline material growthFrom frozen solutionsElectrolysisSingle crystal

The invention discloses a technology for producing a single-crystal conductive copper rod with an upward continuous casting method. The technology comprises steps as follows: an electrolytic copper raw material is put in a closed mixing melting furnace for melting, aluminum-antimony alloy powder, europium oxide powder and beryllium-aluminum alloy powder are added to a molten copper liquid, nitrogen and carbon monoxide mixed gas is introduced into the closed mixing melting furnace through a ventilation inlet in the bottom of the closed mixing melting furnace, and the mixed gas is discharged from a ventilation outlet in the top of the closed mixing melting furnace; a molten mixture is transferred into an upward continuous casting melting furnace and is enabled to enter an upward continuous casting crystallizer under the siphoning action, a crystallized conductive copper rod in the upward continuous casting crystallizer is drawn out of the top of the upward continuous casting crystallizer by a drawing device, and finally, the prepared conductive copper rod is packaged into coils. Compared with a polycrystalline conductive copper rod, the produced single-crystal conductive copper rod has the advantages that elongation percentage can be increased by 60%-80%, and specific resistivity can be reduced by 15%-20%.

Owner:江苏裕铭铜业有限公司

Beryllium aluminum alloy for instruments and meters of electrical equipment

The invention discloses a beryllium aluminum alloy for instruments and meters of electrical equipment. The beryllium aluminum alloy consists of the nine components in parts by weight: 5-10 parts of beryllium, 48-51 parts of aluminum, 14-18 parts of zirconium, 8-12 parts of niobium, 17-21 parts of copper, 10-13 parts of rhenium, 11-14 parts of molybdenum, 6-9 parts of antimony and 9-12 parts of indium. The beryllium aluminum alloy disclosed by the invention consists of the nine components of the beryllium, the aluminum, the zirconium, the niobium, the copper, the rhenium, the molybdenum, the antimony and the indium, and has the characteristics of being high in strength, good in abrasion resistance, high in heat-resisting impact strength and long in service life.

Owner:SUZHOU LOTTE CHEM TECH

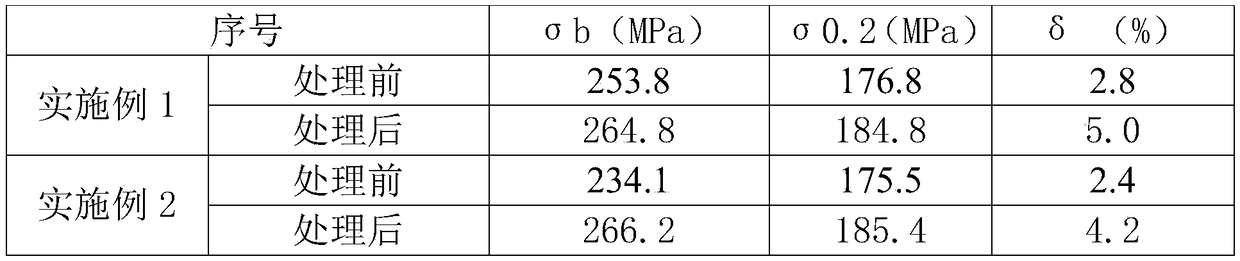

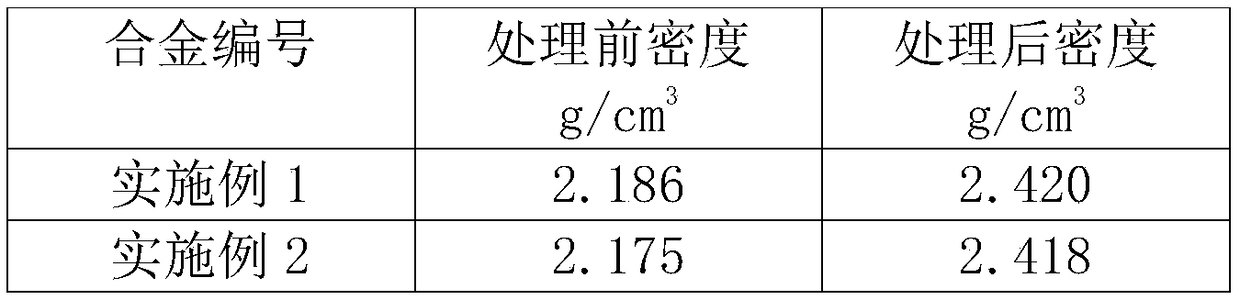

Method for improving ductility of casting beryllium aluminum alloy

The invention discloses a method for improving ductility of casting a beryllium aluminum alloy. The method comprises the following steps that (1) polishing is carried out on the surface of a casting,and when impurities in the surface is removed, the casting is put into a hot isostatic pressing furnace; (2) an initial pressure is stamped into the furnace, wherein temperature is heated to 500 DEG Cwith a heating rate which is less than or equal to 5 DEG C / min and kept for 30 minutes; (3) the temperature is continuously heated to 590 + / -10 DEG C at the same heating rate, a hot isostatic pressing treatment pressure is enabled to be 110-130 MPa, and the treatment time is 150-180 minutes; and (4) after the treatment is completed and the temperature is cooled to 200 DEG C with the heating ratewhich is less than 5 DEG C / min, and power-off and the cooling are carried out. According to the method, a medium used for the hot isostatic pressing is argon, the performance of a beryllium-aluminum alloy phase interface is improved after the casting is treated through the hot isostatic pressing, the strength and the ductility rate of the alloy are improved, certain casting defects in a casting product after the treatment are improved, and the compactness of the alloy is further improved; and the strength of the alloy treated by the hot isostatic pressing is increased by about 10%, and the ductility rate is improved by 60% or above.

Owner:西北稀有金属材料研究院宁夏有限公司

Method for determination of beryllium content in beryllium-aluminum alloy

InactiveCN102539490AReliable quantitative determinationImprove anti-interference abilityMaterial electrochemical variablesPyrroleCoefficient of variation

Provided is a method for quantitative determination of beryllium content in a beryllium-aluminum alloy by using a molecular imprinting method. The method is characterized in that beryllium-pyrrole / graphite imprinting electrodes are used as working electrodes, calomel electrodes are used as reference electrodes, and platinum filament electrodes are used as three-electrode systems of counter electrodes. Under the condition that potential of hydrogen (pH) is equal to 1-4, temperature ranges from 20 to 80 DEG C, and scanning speed ranges from 30 to 600mv / s, coefficient of variation (CV) curves in sulfuric acid beryllium standard solution of different densities are measured so as to obtain linear response relation, determination limits and the like. Compared with other electrodes, current intensity is improved by one magnitude, and measuring sensitivity is greatly improved.

Owner:JIANGNAN UNIV

Release agent used for precision casting of beryllium-aluminum alloy and preparation method of release agent

ActiveCN109014025AFully fill the gapImprove permeabilityFoundry mouldsFoundry coresPhosphoric acidSilicon oxide

The invention discloses a release agent used for precision casting of a beryllium-aluminum alloy and a preparation method of the release agent. The release agent comprises, by weight, 70-80% of deionized water, 4.7-6.0% of sodium silicate, 10.0-13.0% of aluminum oxide, 2.0-3.5% of silicon oxide, 0.8-1.3% of sodium dihydrogen phosphate, 0.4-0.7% of disodium hydrogen phosphate, 1.5-2.5% of calcium chloride, 0.8-1.2% of graphene oxide and 1.0-1.8% of sodium tetraborate. The release agent has the advantages of simple ingredients and preparation, scientific component ratio and non-toxic harmless raw materials and can be stored for a long time for later use. The release agent can effectively achieve isolation between the beryllium-aluminum alloy and a die shell wall for protection, ensures fastand easy release from a die, does not affect the surface quality of an alloy part and a die shell and is conducive to repeated use of the die shell as well as the precision casting process of the beryllium-aluminum alloy, thereby greatly improving the working efficiency and reducing the alloy melting-casting cost.

Owner:MATERIAL INST OF CHINA ACADEMY OF ENG PHYSICS

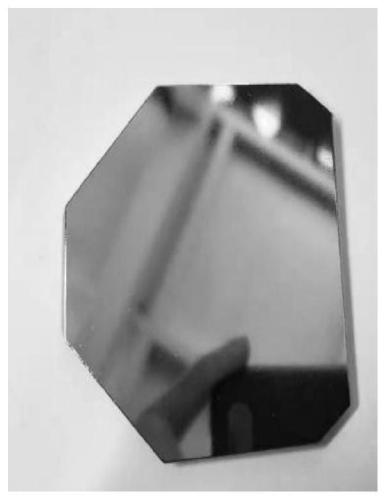

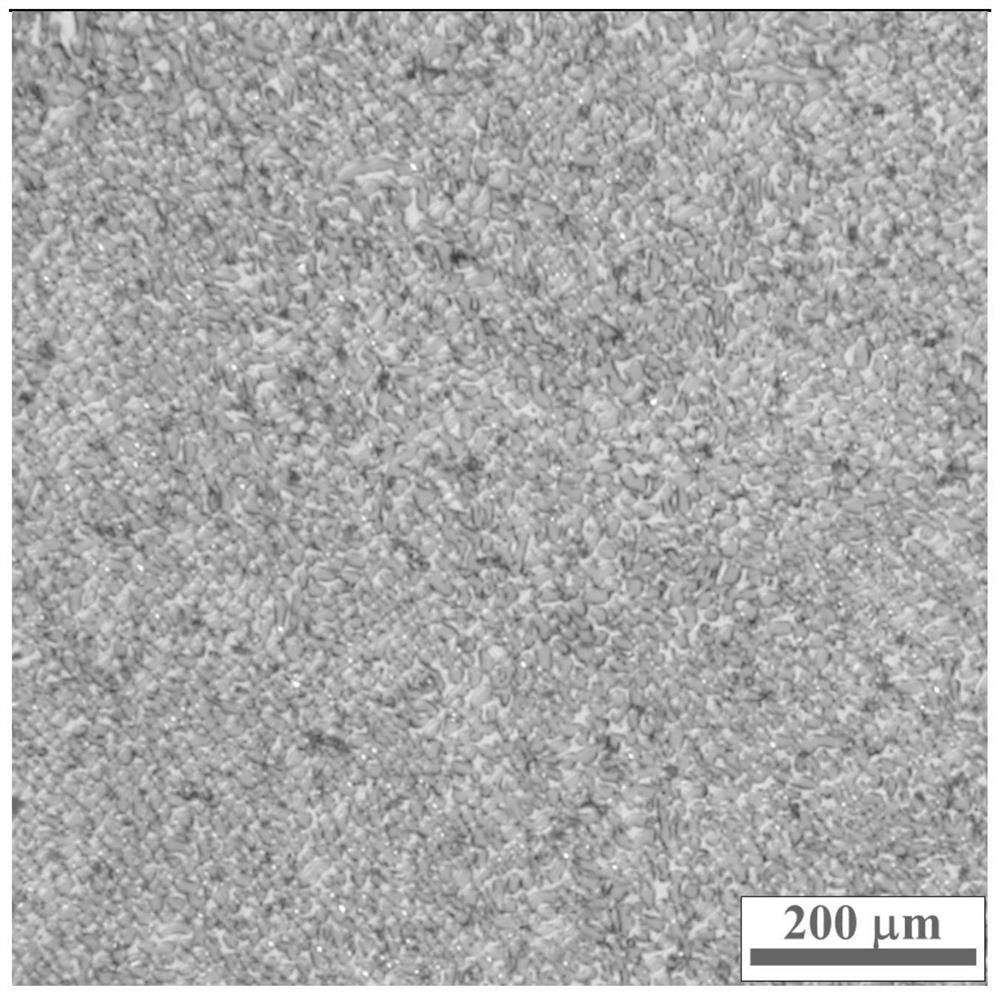

Beryllium aluminum alloy discharging plasma sintering preparation method

The invention relates to a beryllium aluminum alloy discharging plasma sintering preparation method, which comprises the following steps of mixing beryllium powder and aluminum alloy power according to the design ingredient proportion; charging the mixed materials into a soft mold; making the materials into a cold pressing blank through cold isopressing; charging the cold pressing mold into a graphite mold; then, putting the graphite mold into an SPS furnace body; performing vacuum pumping and pressurization; performing discharging plasma sintering. Compared with other preparation methods, themethod has the advantages that the work procedure is simple; the sintering temperature is low; the sintering time is short; the tissue is fine and uniform; the mechanical performance is good. The beryllium aluminum alloy powder metallurgy process is simplified; the production efficiency is improved; in addition, the method is hopeful to be applied to the field of aerospace. The beryllium aluminumalloy can select a polynary aluminum alloy system; the beryllium aluminum alloy meeting different service condition requirements can be prepared according to the characteristics of the aluminum alloyin different series.

Owner:MATERIAL INST OF CHINA ACADEMY OF ENG PHYSICS

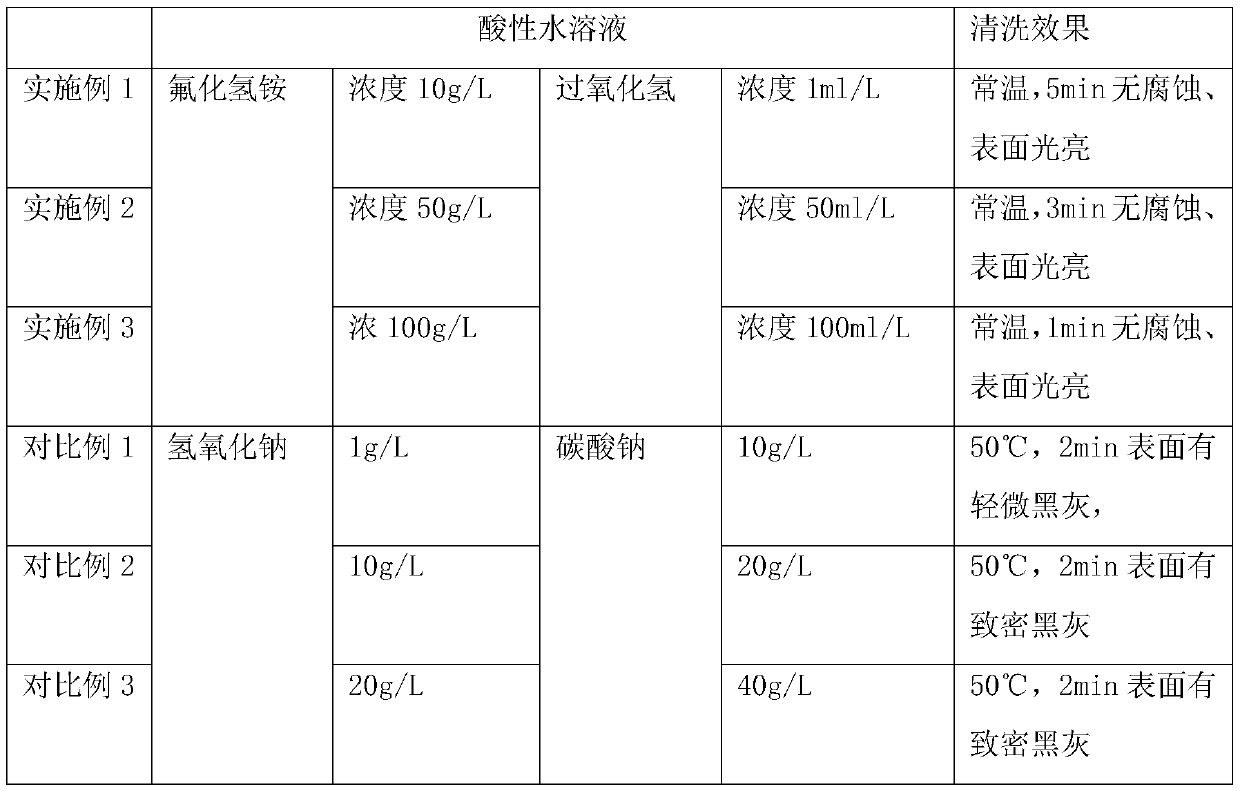

Method for chemical plating of nickel-phosphorus alloy on surface of beryllium-aluminum alloy

ActiveCN110344036AEasy to prepareImprove stabilityLiquid/solution decomposition chemical coatingChemical platingBond Force

The invention relates to a method for chemical plating of a nickel-phosphorus alloy on the surface of a beryllium-aluminum alloy. The method includes the following steps that sand blasting is performed; degreasing treatment is performed; the surface of the beryllium-aluminum alloy is cleaned through an ammonium bifluoride and hydrogen peroxide acidic aqueous solution; cleaning is performed alternately with cold water and hot water; the surface of the beryllium-aluminum alloy is dipped in a nickel-ion-containing mixed aqueous solution for nickel dipping; cleaning is performed alternately with cold water and hot water; nickel plating is performed on the surface of the beryllium-aluminum alloy; and a nickel-plated beryllium-aluminum alloy is put in a drying oven for heat preservation. The method is simple and easy to implement, solution preparation is simple, and the solution stability is extremely high; acidic high-temperature chemical nickel plating is performed after nickel dipping isfinished, whether a low-phosphorous solution or an intermediate-phosphorous solution or a high-phosphorous solution is adopted, the chemical nickel-plated layer is uniform, the phenomena such as localplating omission, needle holes and pitting are avoided, the chemical nickel-plated layer is good in bonding force and not prone to falling off, the surface crystallization is uniform and delicate, and the slight yellow luster of metal nickel is shown.

Owner:CHANNGCHUN CHANGGUANG ADVANCED OPTICS TECH CO LTD

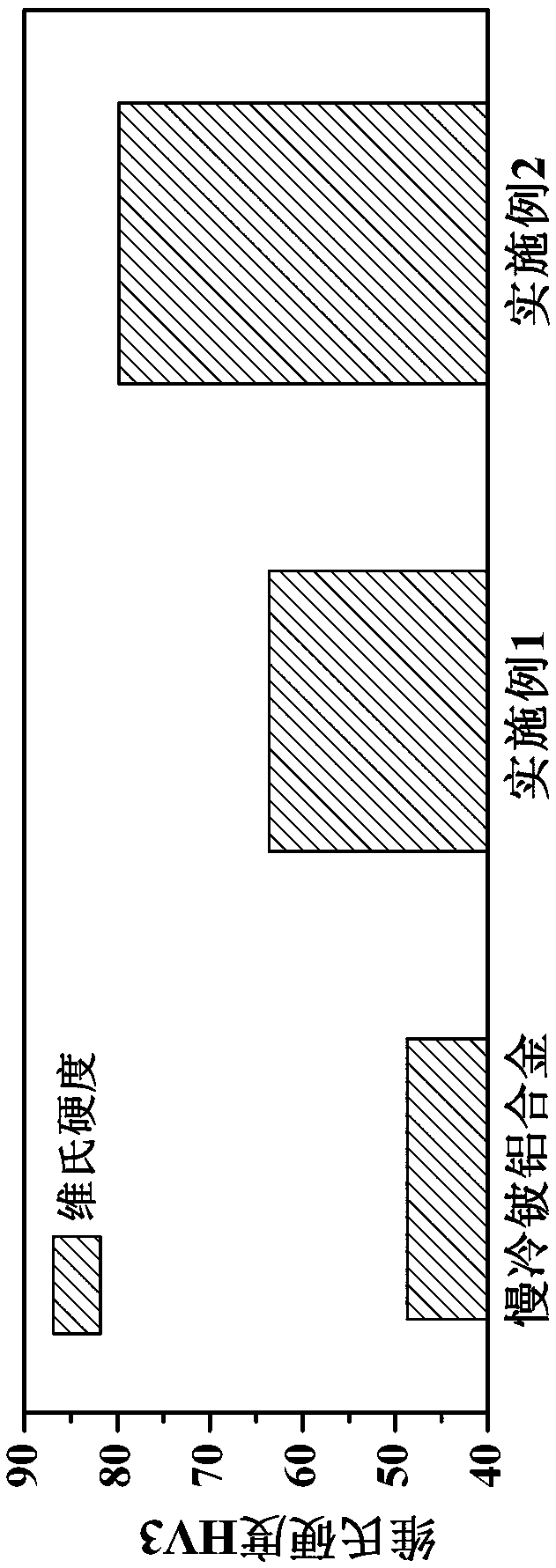

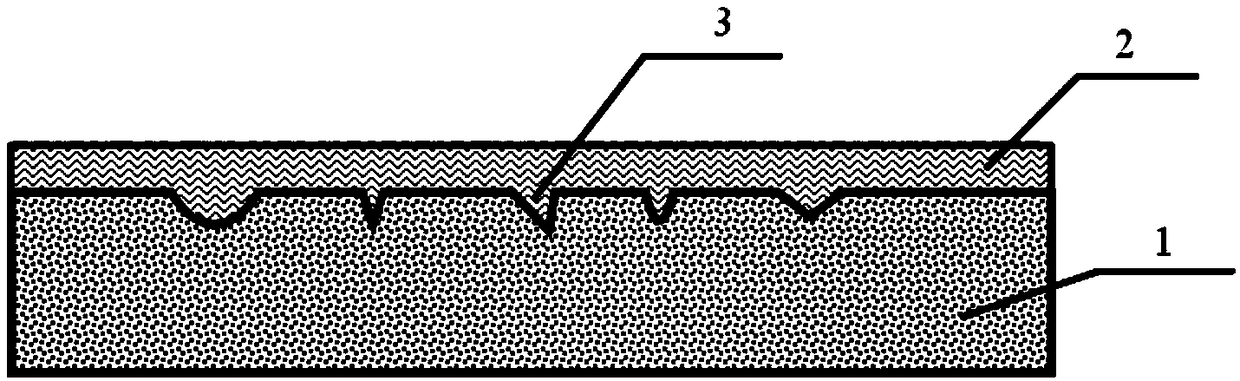

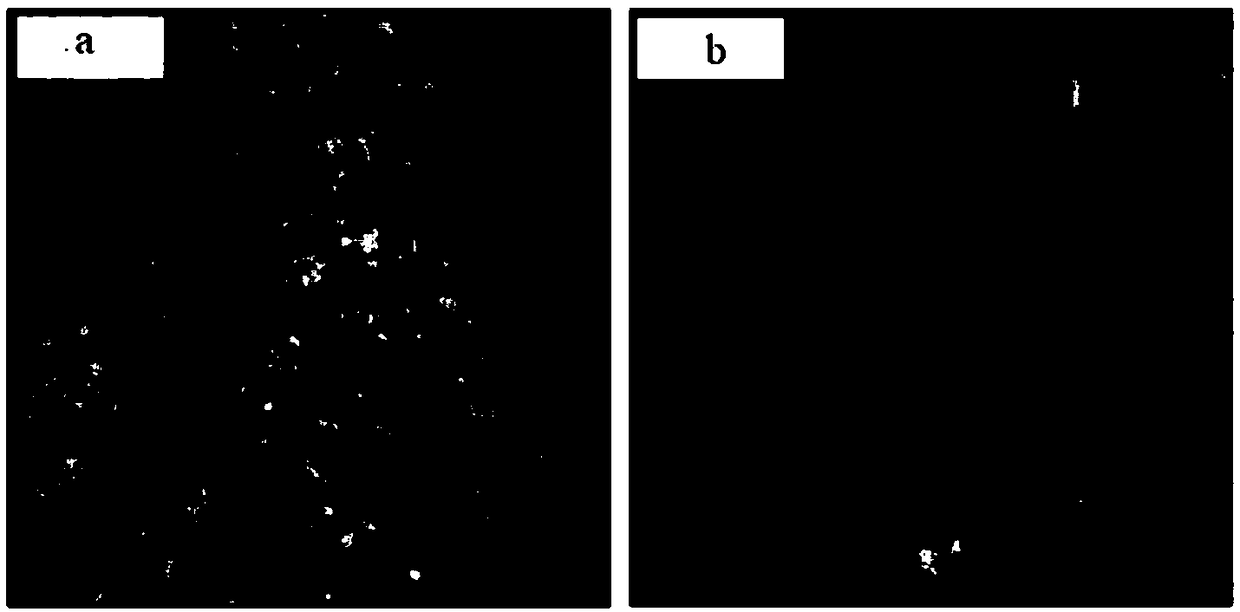

Preparation method of beryllium-aluminum alloy surface composite reinforced modified layer

The invention discloses a preparation method of a beryllium oxide / aluminum oxide double-phase particle composite reinforced modification layer on the surface of a beryllium-aluminum alloy. A mode of pre-sintering ternary premixed composite powder of micron metal aluminum powder, nano aluminum oxide powder and nano beryllium oxide powder on the surface of the beryllium-aluminum alloy is adopted, and electron beam remelting and subsequent heat treatment are combined to obtain an alloy surface modification layer with high hardness and gradient distribution of strengthening phase particles. By adopting the technical route, adverse effects caused by the use of metal beryllium powder and cracking failure of the surface modification layer can be avoided, metallurgical bonding between the modification layer and an alloy matrix is realized, and the structural stability of the surface modification layer is ensured. The method is simple, convenient and feasible in process route, can effectively meet the requirement for the thermophysical property of a surface coating when the cast beryllium-aluminum alloy is used as an electronic encapsulating material, and has a good practical engineering application prospect.

Owner:MATERIAL INST OF CHINA ACADEMY OF ENG PHYSICS

Special composite slag removing agent for beryllium aluminum alloy refining, preparation method and slag removing method

The invention discloses a special composite slag removing agent for beryllium aluminum alloy refining, a preparation method and a slag removing method. The slag removing agent comprises the followingcomponents in parts by weight: 30-50 parts of sodium tetraborate, 2-8 parts of AlB12 intermediate alloy, 2-5 parts of hexachloroethane, 7-10 parts of sodium hexafluorisilicate, 2-6 parts of sodium fluoroaluminate, 1-5 parts of sodium fluoride, 5-12 parts of potassium chloride, 6-13 parts of beryllium chloride, 2-5 parts of lithium chloride, 2-5 parts of sodium carbonate, and 1-3 parts of clay. Theslag removing agent achieves excellent high-temperature stability and reliability under the vacuum condition, and is excellent in adhesiveness after melting, high in spreadability, quick in slag collection, easy incrustation of slag skin and excellent in slag removing and refining effect. Through the synergistic effect of all the components, oxides in melts, magnesium-contained impurities and hydrogen achieve excellent slag removing and absorbing effects; and meanwhile, the slag skin can effectively cover the surfaces of the melts, so that the temperature loss can be effectively reduced, thesplashing of the melts is inhibited, and new melting slag and secondary oxidation are prevented.

Owner:MATERIAL INST OF CHINA ACADEMY OF ENG PHYSICS

A kind of beryllium-aluminum-zirconium multi-element alloy and its preparation method

ActiveCN108300921BImprove mechanical propertiesImprove organizationEquiaxed crystalsMechanical property

The invention discloses a beryllium-aluminum-zirconium-series multi-element alloy and a preparation method thereof which aim at solving the problems that at present, a method that a beryllium-aluminumalloy is prepared by adopting powder hot isostatic pressing is complicated in technology and very high in cost and greatly limits application of the beryllium-aluminum alloy. The beryllium-aluminum-zirconium-series multi-element alloy is prepared and formed by adopting the following raw materials of, by weight, 54-80% of metal beryllium, 17-45% of metal aluminum, 0.2-2% of metal zirconium and 0.1-1.0% of add element. In the beryllium-aluminum-zirconium-series multi-element alloy and the preparation method thereof, based on an existing beryllium-aluminum alloy, the metal zirconium and other alloying elements are added, a beryllium-aluminum alloy base material is prepared firstly, then a pre-alloying beryllium-aluminum-zirconium-series multi-element alloy is prepared through a vacuum induction smelting method, and then the beryllium-aluminum-zirconium-series multi-element alloy is obtained through subsequent remelting. According to the beryllium-aluminum-zirconium-series multi-element alloy and the preparation method thereof, by conducting multi-element alloying of zirconium and other elements on the beryllium-aluminum alloy, an equiaxed crystal alloy with the refined structure andthe uniform size can be obtained, structure defects and composition segregation are reduced, and alloy plasticity is improved, so that alloy mechanical properties are greatly improved, and the excellent comprehensive performance is achieved.

Owner:MATERIAL INST OF CHINA ACADEMY OF ENG PHYSICS

A kind of composite slag remover specially used for beryllium aluminum alloy refining and its preparation method and method of slag removal

ActiveCN109735733BImprove adsorption capacitySuppress splashLithium chlorideSodium hexafluoroaluminate

The invention discloses a special composite slag removing agent for beryllium aluminum alloy refining, a preparation method and a slag removing method. The slag removing agent comprises the followingcomponents in parts by weight: 30-50 parts of sodium tetraborate, 2-8 parts of AlB12 intermediate alloy, 2-5 parts of hexachloroethane, 7-10 parts of sodium hexafluorisilicate, 2-6 parts of sodium fluoroaluminate, 1-5 parts of sodium fluoride, 5-12 parts of potassium chloride, 6-13 parts of beryllium chloride, 2-5 parts of lithium chloride, 2-5 parts of sodium carbonate, and 1-3 parts of clay. Theslag removing agent achieves excellent high-temperature stability and reliability under the vacuum condition, and is excellent in adhesiveness after melting, high in spreadability, quick in slag collection, easy incrustation of slag skin and excellent in slag removing and refining effect. Through the synergistic effect of all the components, oxides in melts, magnesium-contained impurities and hydrogen achieve excellent slag removing and absorbing effects; and meanwhile, the slag skin can effectively cover the surfaces of the melts, so that the temperature loss can be effectively reduced, thesplashing of the melts is inhibited, and new melting slag and secondary oxidation are prevented.

Owner:MATERIAL INST OF CHINA ACADEMY OF ENG PHYSICS

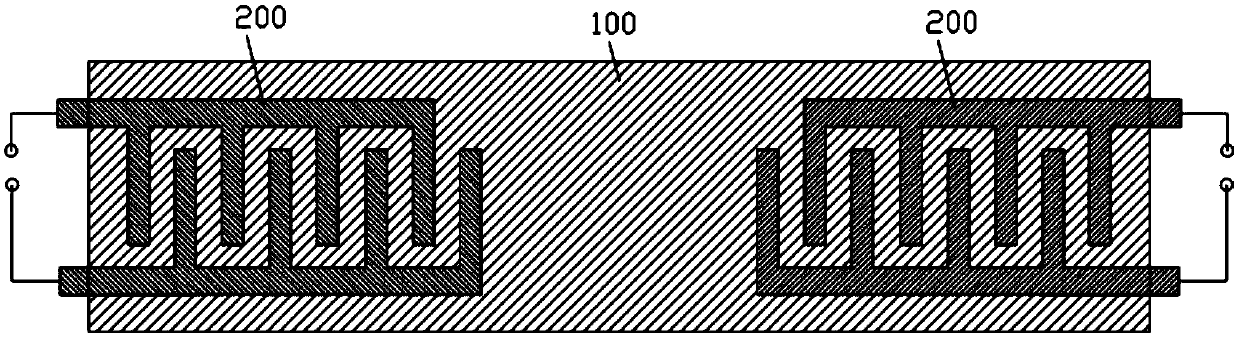

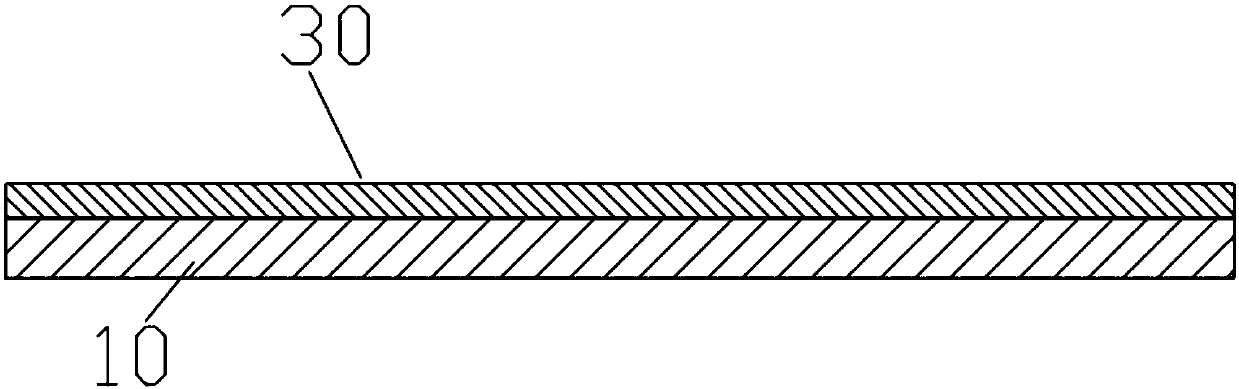

Multilayer piezoelectric substrate provided with beryllium aluminum alloy film and preparation method thereof

ActiveCN109660225AExtended service lifeImprove temperature stabilityImpedence networksHexagonal crystal systemMetal

The invention provides a multilayer piezoelectric substrate provided with a beryllium aluminum alloy film, comprising a piezoelectric substrate layer and a conductive layer which are sequentially arranged, wherein the conductive layer is a beryllium aluminum alloy film. According to the multilayer piezoelectric substrate in the invention, beryllium aluminum alloy is adopted as a sputtering film, beryllium is a hexagonal crystal system and is easy to combine with the piezoelectric substrate layer with the same lattice structure, aluminum in the alloy can serve as a sound transmission material,thereby improving the sound transmission efficiency, so that the problem of poor bonding due to the fact that the lattice structures are different between the aluminum film and the piezoelectric substrate is solved by utilizing beryllium; moreover, both the alloy film and the aluminum film are metal films, and the alloy film and the aluminum film are combined by means of metal bonding, so that thebonding state is good, and the films are not easy to fall off.

Owner:BEIFANG UNIV OF NATITIES

A kind of beryllium aluminum alloy powder and its preparation method and application

ActiveCN111570813BGood sphericityIncrease productivityAdditive manufacturing apparatusTransportation and packagingMetallurgyElectron bunches

The invention provides a beryllium aluminum alloy powder and a preparation method and application thereof. The preparation method may include the following steps: placing the beryllium aluminum alloy rod in a vacuum environment; passing an inert gas into the vacuum environment to replace the air, and after the replacement, the oxygen content in the vacuum environment is below 6 ppm; using an electric arc to make the beryllium aluminum alloy rod The end face is melted to form a liquid film; the liquid film is broken into fine droplets by centrifugal force; cooled to obtain beryllium aluminum alloy powder. The beryllium aluminum alloy powder may include beryllium aluminum alloy powder prepared by the above-mentioned preparation method of beryllium aluminum alloy powder. The applications may include applications in the field of laser or electron beam additive manufacturing, and / or applications in the field of laser or electron beam cladding. The beneficial effects of the present invention may include: the preparation method has high production efficiency and low energy consumption; the prepared spherical beryllium aluminum alloy powder has good sphericity, basically no hollow powder, low oxygen increase in the preparation process, good fluidity, and is 3D Good raw material for printing.

Owner:西藏智材新材料有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com