Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

80results about How to "Avoid Weld Quality Issues" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

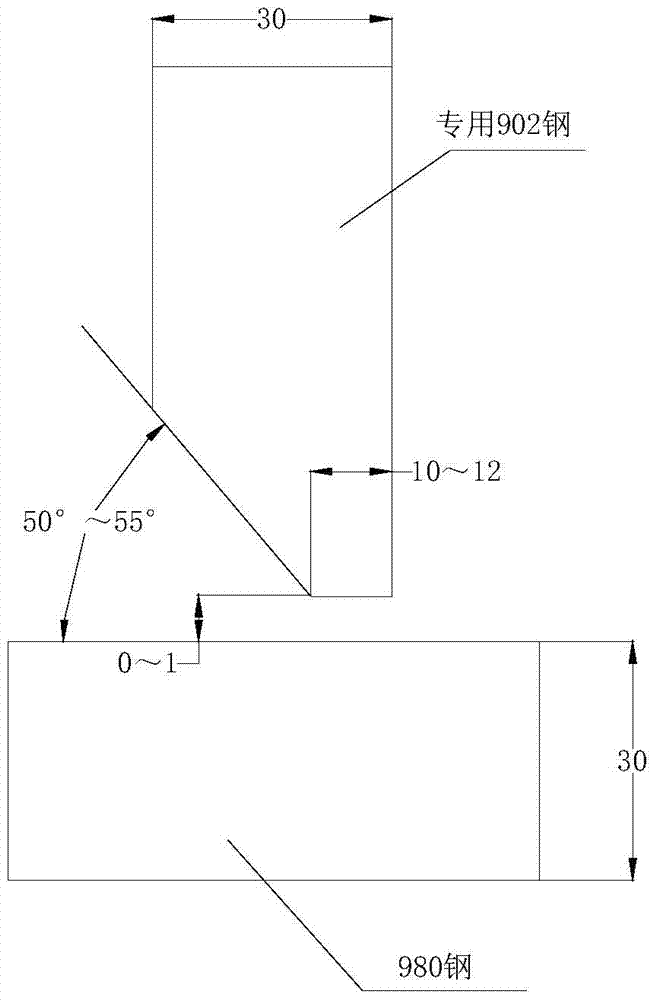

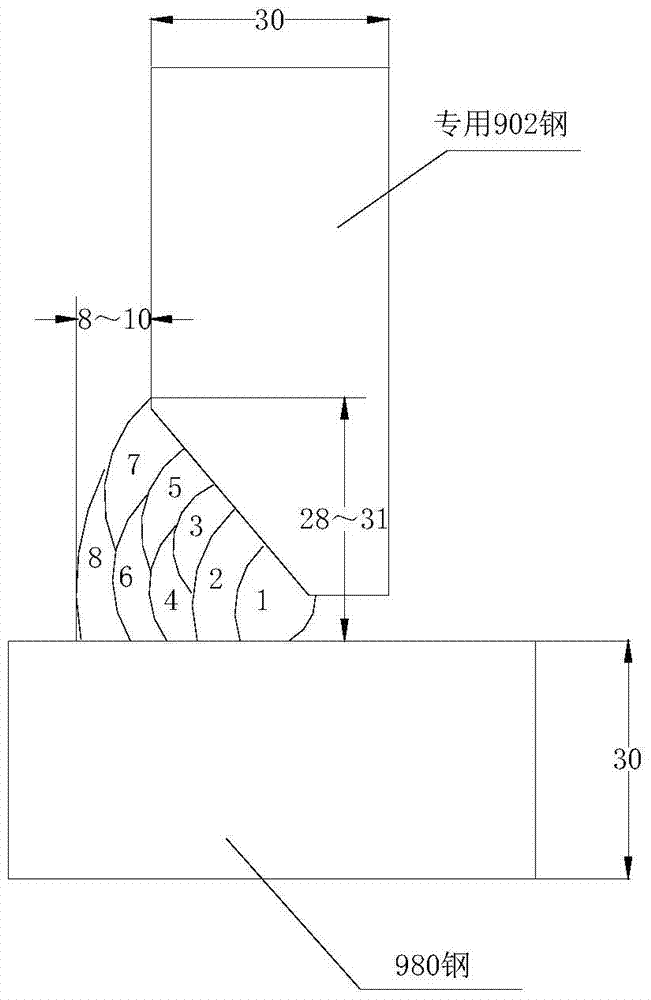

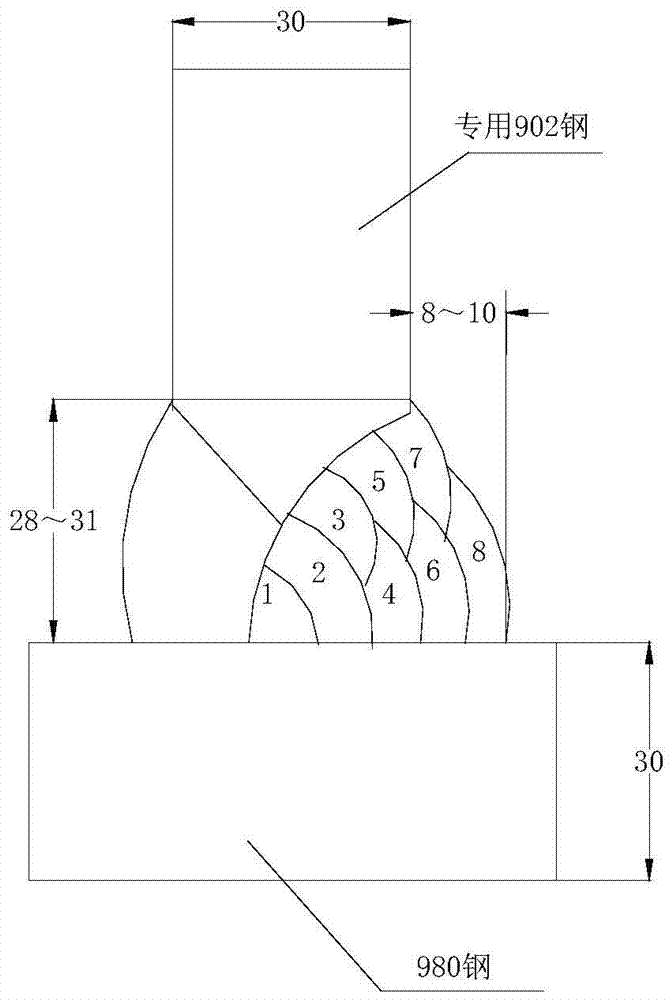

Welding process of ultra-supercritical fossil power unit for welding SA335-P91/P92 steel

InactiveCN102615380AImprove the first pass rate of weldingImprove accuracyArc welding apparatusWorkpiece edge portionsShielded metal arc weldingPower flow

The invention relates to a welding process of an ultra-supercritical fossil power unit for welding SA335-P91 / P92 steel. The process is characterized by comprising three aspects of preparation before welding, welding parameter optimization and welding process optimization. In workpiece selection, a manual arc welding electrode is used as a welding workpiece; in welding bead arrangement, a welding bead is arranged in a double V-shaped or U-shaped groove shape, and the surface of the groove is cleaned; contra-aperture assembly is carried out, pipelines to be welded are arranged in the welding bead, each section of pipeline is propped firmly after contra-aperture connection, and the requirements on the contra-aperture of each section of pipeline are that: the staggered joint is 0.1-1.0mm, the gap is 3.0-4.0mm, and the truncated edge is 1.5-2.0mm; a large-diameter thick-wall pipe is fixed in the groove by a positioning block; and a welding area is preheated before welding, and then multi-layer welding bead welding is carried out in a GTAW (gas tungsten arc welding) and SMAW (shielded metal arc welding) combined welding method. According to the welding process disclosed by the invention, a multi-layer welding bead welding technology with a small-dimension electrode, a small current parameter and small swing is adopted, the impact toughness of a weld joint is improved, and the first-pass yield of welding can be greatly improved.

Owner:GUANGDONG SHAOGUAN YUEJIANG POWER GENERATION

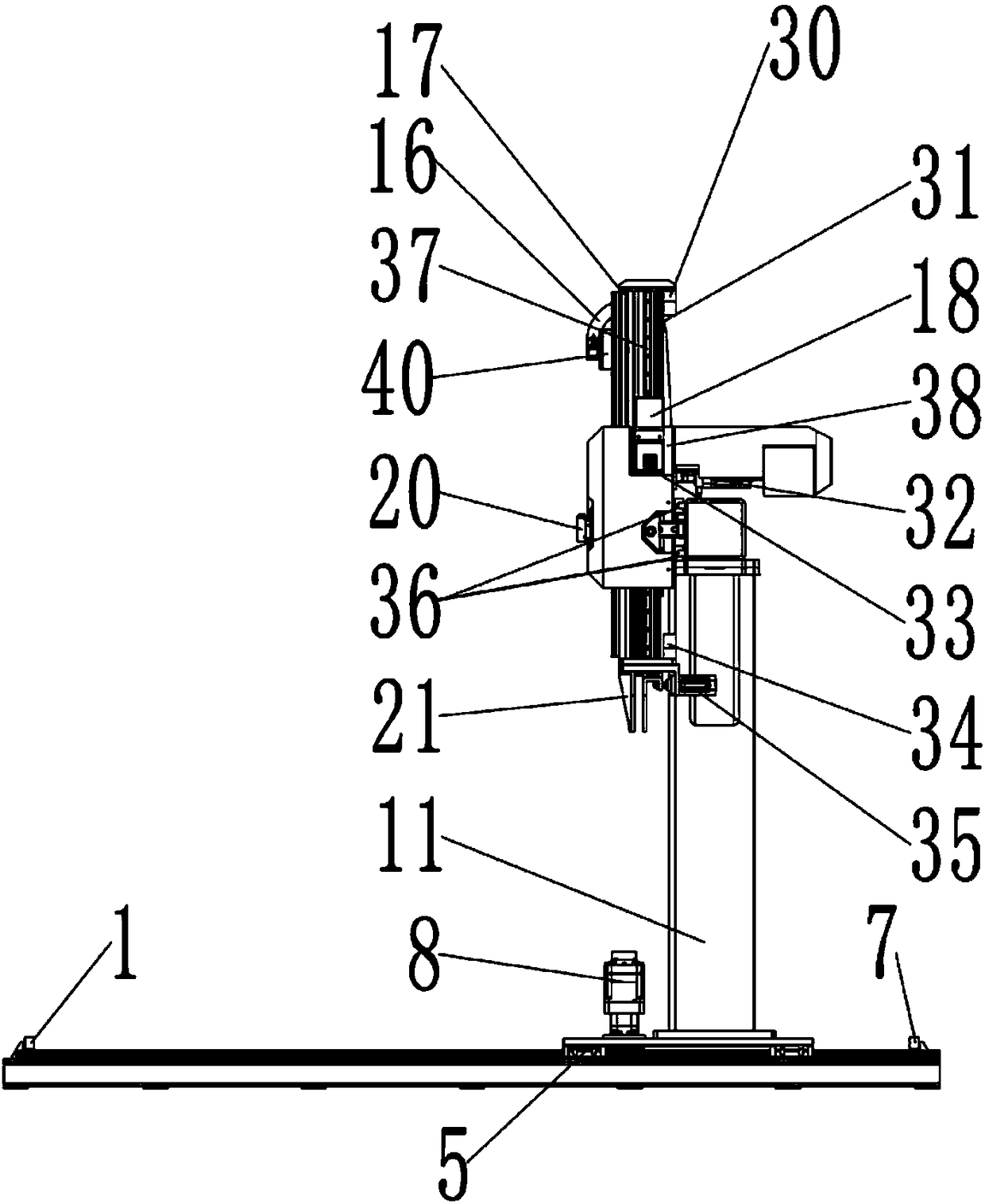

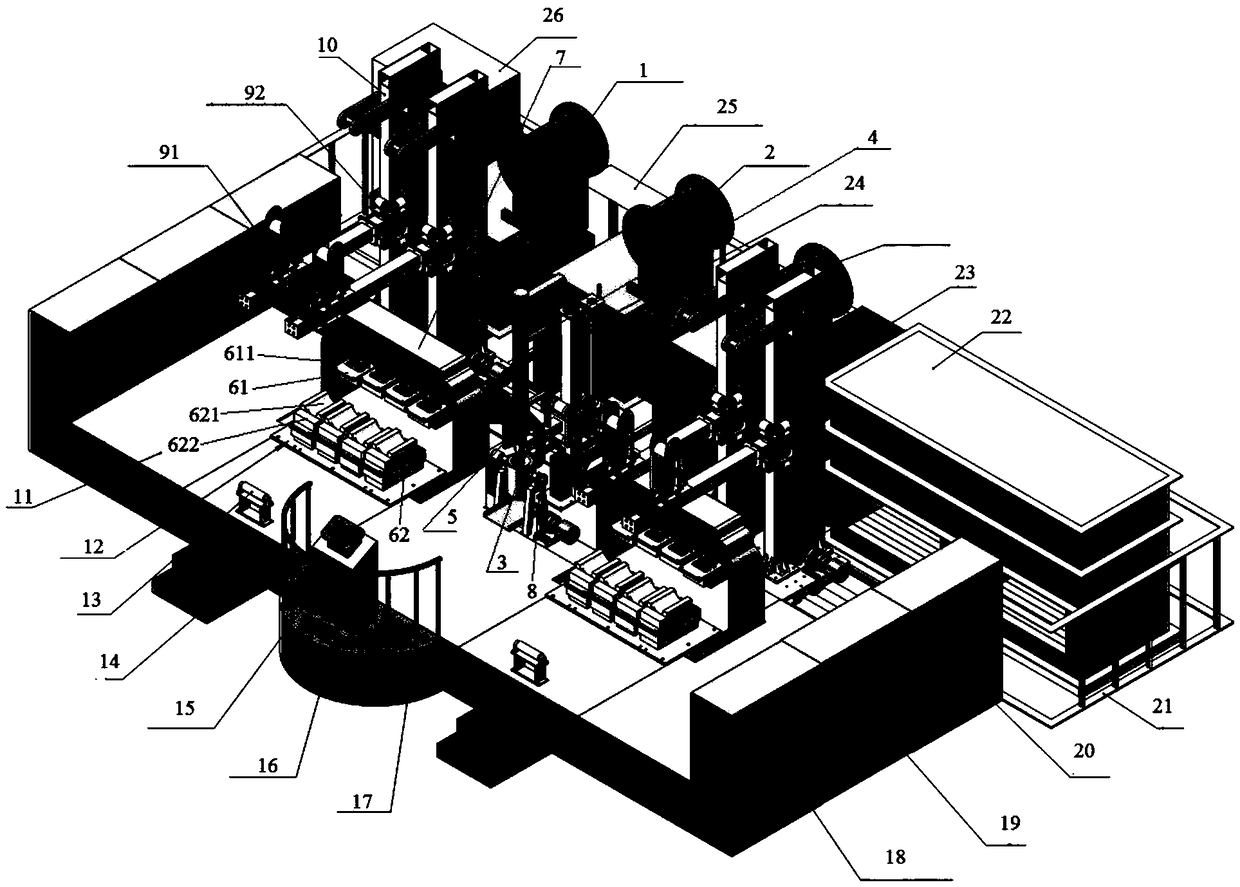

Flexible automatic welding system for tower foot of communication tower and control method thereof

ActiveCN108326476AReduce laborRealize automatic assembly and weldingWelding/cutting auxillary devicesAuxillary welding devicesManufacturing technologyElectrical control

The invention discloses a flexible automatic welding system for a tower foot of a communication tower and a control method thereof, and relates to the technical field of equipment manufacturing. The flexible automatic welding system for the tower foot of the communication tower comprises a plate taking robot, a positioning table, a positioner, a welding robot and an electrical control system; theplate taking robot comprises a ground rail mechanism, a vertical beam mechanism, a cross beam mechanism and a material taking mechanism; the positioner comprises a turning shaft, a rotating shaft, a rotating platform and a positioning device; and the electrical control system comprises an industrial personal computer, a PLC master station, a PLC slave station, a servo amplifier and a welding robotcontrol panel. The plate taking robot sequentially conveys tower foot plates placed on the positioning table to a tower foot bottom plate fixed on the rotating platform according to the assembly sequence of the tower foot, and the positioner is in linkage with the welding robot to carry out spot welding and then carry out full welding. According to the system, automatic assembling and welding ofthe tower feet with multiple types and different inclination angles can be realized, the labor amount of workers is reduced, and the welding quality and efficiency are improved.

Owner:河北省机电一体化中试基地有限公司

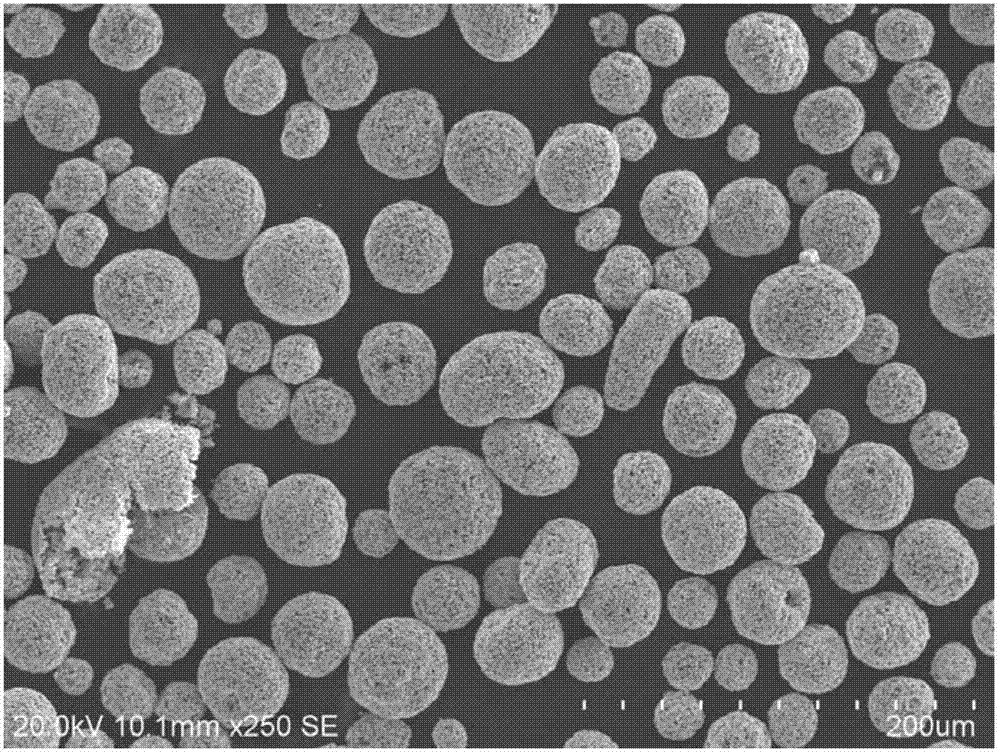

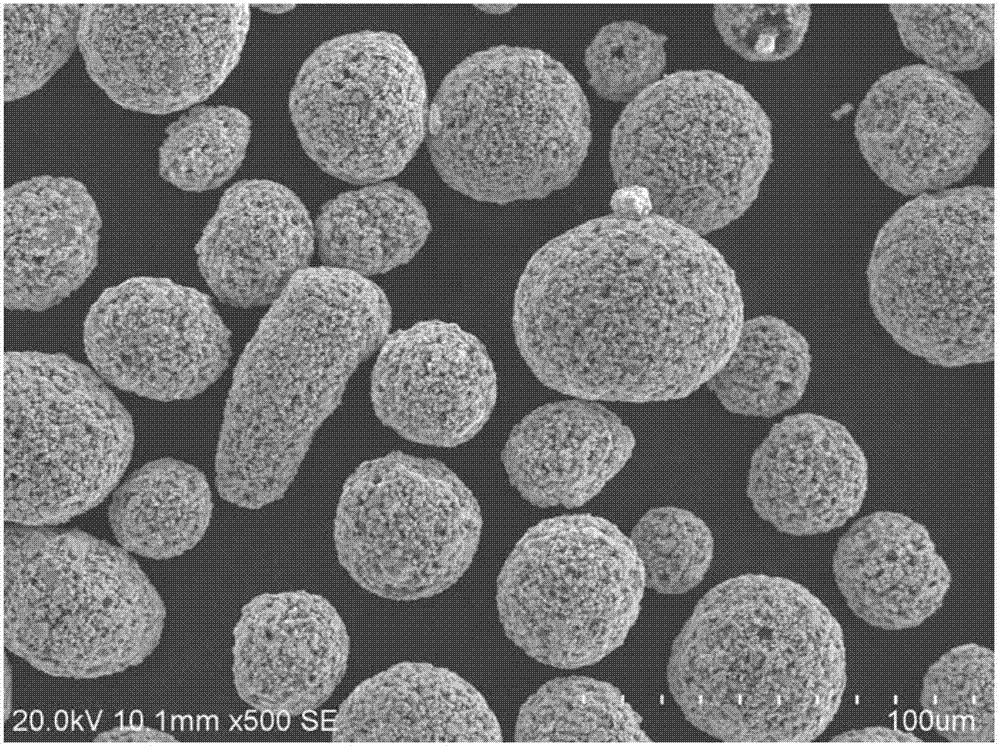

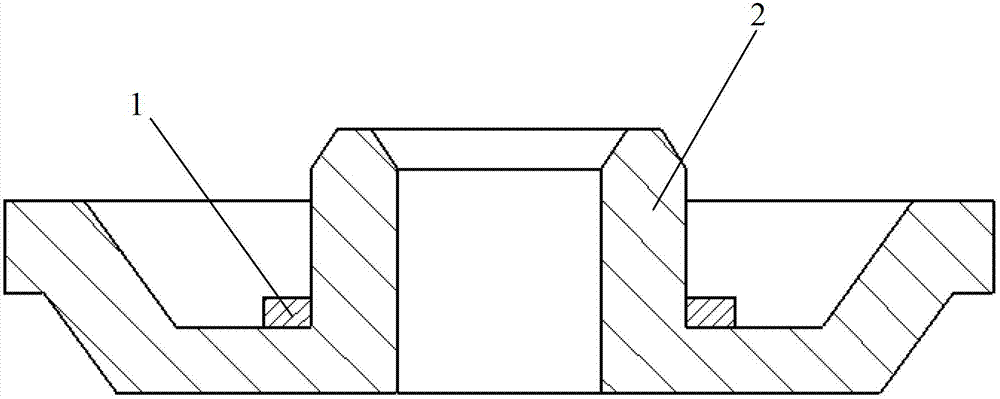

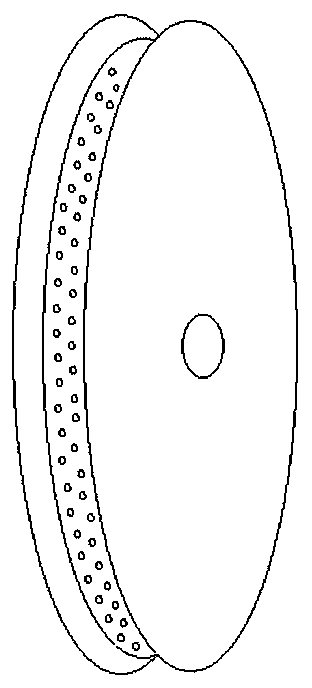

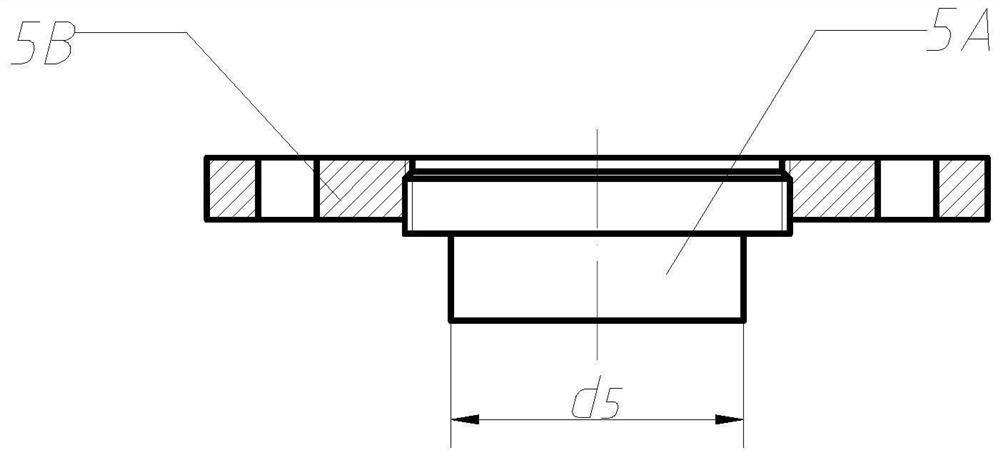

Solder ring for magnetron cathode assembly, method for producing solder ring for magnetron cathode assembly and molybdenum end cap connecting with solder ring

InactiveCN103028859AEfficient weldingGood welding performanceTransit-tube cathodesWelding/cutting media/materialsSpray GranulationAdditive ingredient

The invention discloses a solder ring for a magnetron cathode assembly, a method for producing the solder ring for the magnetron cathode assembly and a molybdenum end cap connecting with the solder ring. Solder powder with uniform ingredients is produced through a spray granulation mode, the solder ring for the magnetron cathode assembly is produced through mould pressing, and the molybdenum end cap connecting with the solder ring is produced through a bonding combination mode. The solder ring has good welding performance; the solder powder which is used by the solder ring comprises uniform ingredients, so that the welding quality problem which is caused by the solder ingredient uniform factor is solved; the finished product rate of the method for producing is high, and the production cost is lowered; and according to the molybdenum end cap connecting with the solder ring for the magnetron cathode assembly, subsequent welding technologies are simplified, the method for producing is simple and practicable, and the finished product rate is high.

Owner:XIAMEN HONGLU TUNGSTEN MOLYBDENUM IND CO LTD

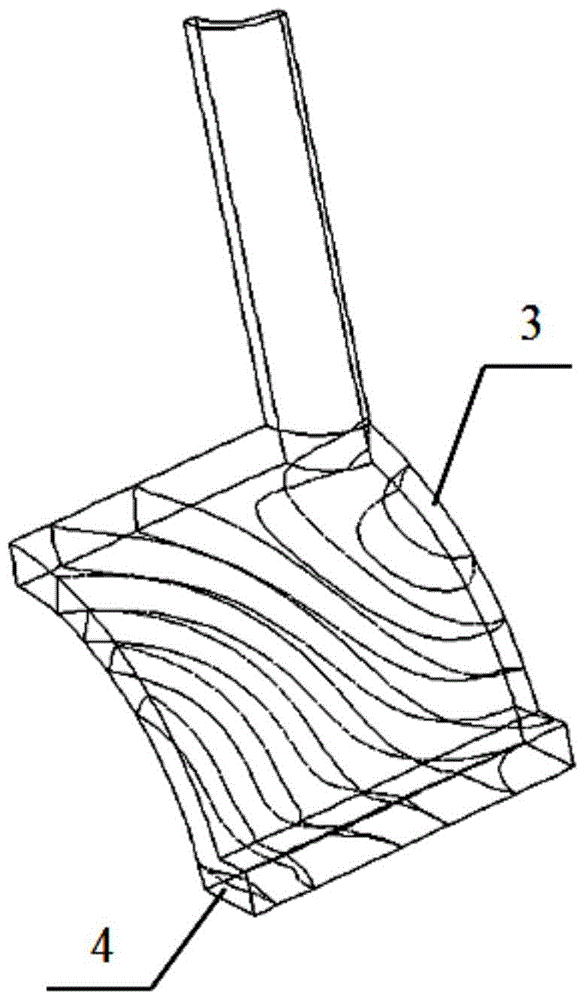

Gang saw cutting head for cutting granites and manufacture method thereof

InactiveCN102922607ASteady chip driving forceImprove wear resistanceStone-like material working toolsTool bitWear resistance

The invention discloses a gang saw cutting head for cutting granites and a manufacture method thereof. The gang saw cutting head for cutting the granites comprises a cutting head body and a welding transition body, wherein the welding transition body is a metal bonding agent sintered together, and the outer surface of a combined body formed by sintering the cutting head body and the welding transition body is provided with a hard wear-resisting phase. By arranging the welding transition body, the problem of the welding quality caused by large difference in metal components of the cutting head body and steel bands is solved, and the cutting head can obtain firm swarf pushing force. By arranging the hard wear-resisting phase, the abrasive resistance of the surface of the cutting head body is improved remarkably, carcass metal on an inner layer is prevented from being abraded, the stable and continuous cutting process is ensured, accordingly mechanical holding force of the metal bonding agent to diamond grains is strengthened effectively, the processing efficiency of a tool is improved, and the service life is prolonged. In the forming process of the hard wear-resisting phase, the diamond grains in the cutting head body and the mechanical holding force of the metal bonding agent are greatly strengthened, and the requirement of cutting the granites is met.

Owner:山东日能超硬材料有限公司

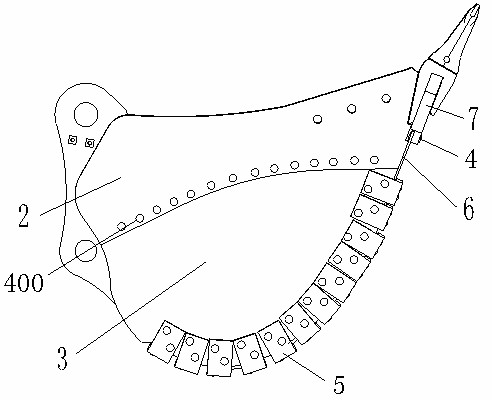

Riveting type digging bucket

InactiveCN102425205AAvoid unstable factorsAvoid Weld Quality IssuesMechanical machines/dredgersBlade plateEngineering

The invention discloses a riveting type digging bucket which comprises a hopper body, wherein the hopper body consists of an arc-shaped bottom plate, a connecting base, a front blade plate and two lateral plates. The riveting type digging bucket is characterized in that outer edges of the arc-shaped bottom plate, the connecting base, the front blade plate and the two lateral plates are provided with riveting holes, two arc-shaped sides of the arc-shaped bottom plate are respectively fixed with the lateral plates through rivets, the connecting base is fixed on the rear end of the arc-shaped bottom plate through a rivet, and the front blade plate is fixed on the rear end of the arc-shaped bottom plate through a rivet.

Owner:SANY HEAVY MACHINERY

Closed runner flat-plate solar heat collector plate core

InactiveCN102620452AReduce maintenancePrevent leakageSolar heat devicesSolar thermal energy generationAnti freezingEngineering

The invention discloses a closed runner flat-plate solar heat collector plate core. The closed runner flat-plate solar heat collector plate core comprises a heat absorption plate, a plurality of exhaust pipes which are arranged at the back of the heat absorption plate, a collection pipe which is arranged at one end of the heat absorption plate and connected with one end of each exhaust pipe, and a sleeve type vacuum heat-preserving heat exchange device which is arranged at the other end of the heat absorption plate, wherein the sleeve type vacuum heat-preserving heat exchange device consists of a vacuum heat-preserving sleeve, a heat conduction medium sleeve which is sleeved in the vacuum heat-preserving sleeve and a heated medium straight-through pipe which is sleeved in the heat conduction medium sleeve; a heat conduction medium bin is formed between the heat conduction medium sleeve and the heated medium straight-through pipe; and the other end of each exhaust pipe is connected with the heat conduction medium bin. The closed runner flat-plate solar heat collector plate core has the advantages that a heat conduction medium can be packaged before manufacturing of the plate core is finished, the plate core is convenient to install, the problem about the quality of pipeline welding or connection in the installation process is effectively solved, the heat conduction medium is prevented from being leaked, the heat conduction medium has anti-freezing and anti-scale functions, the maintenance of a flat-plate solar heat collector is greatly reduced, and an application range is expanded.

Owner:杨宪杰

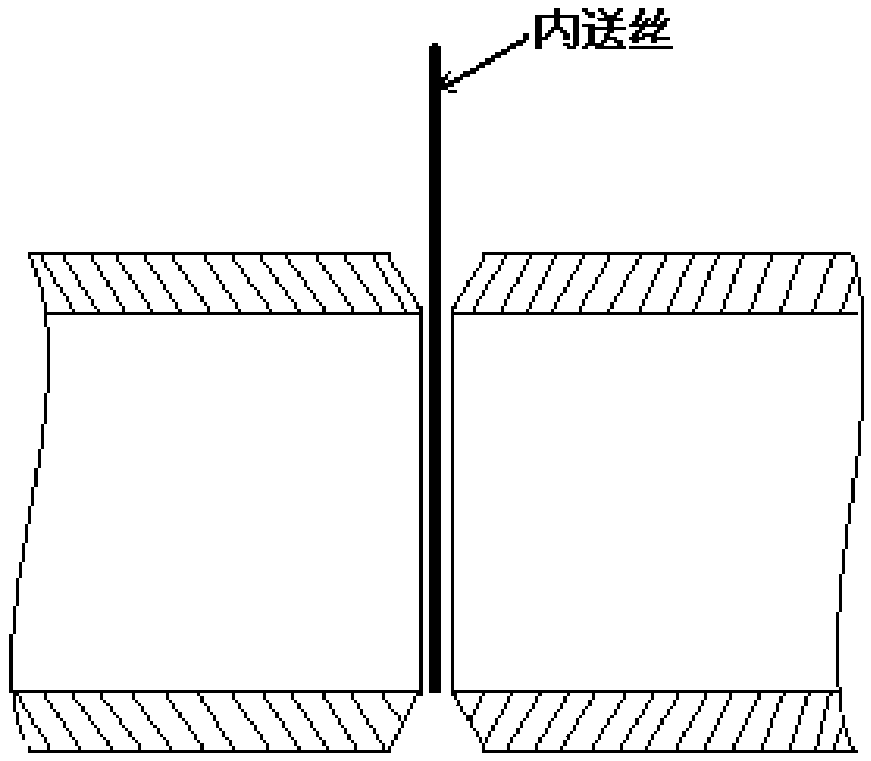

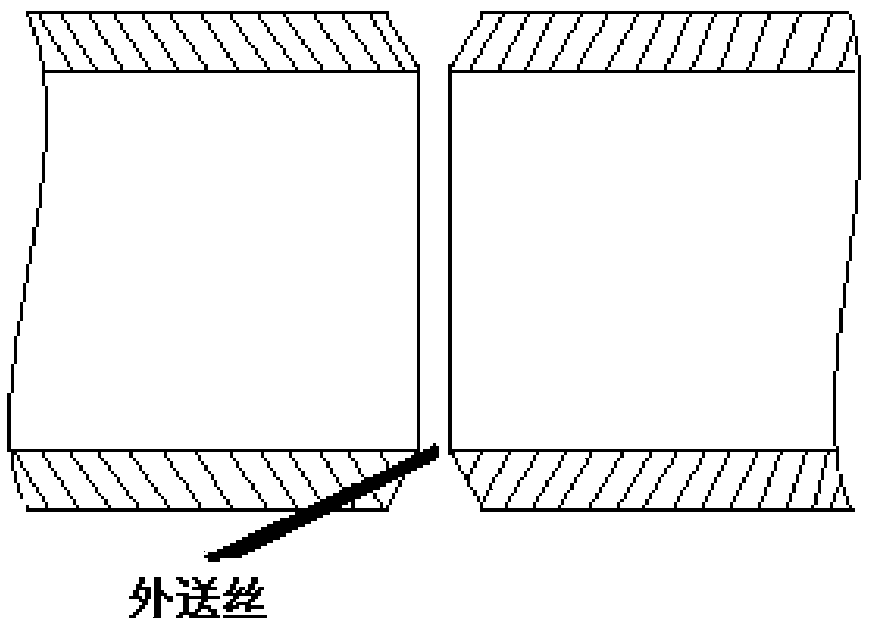

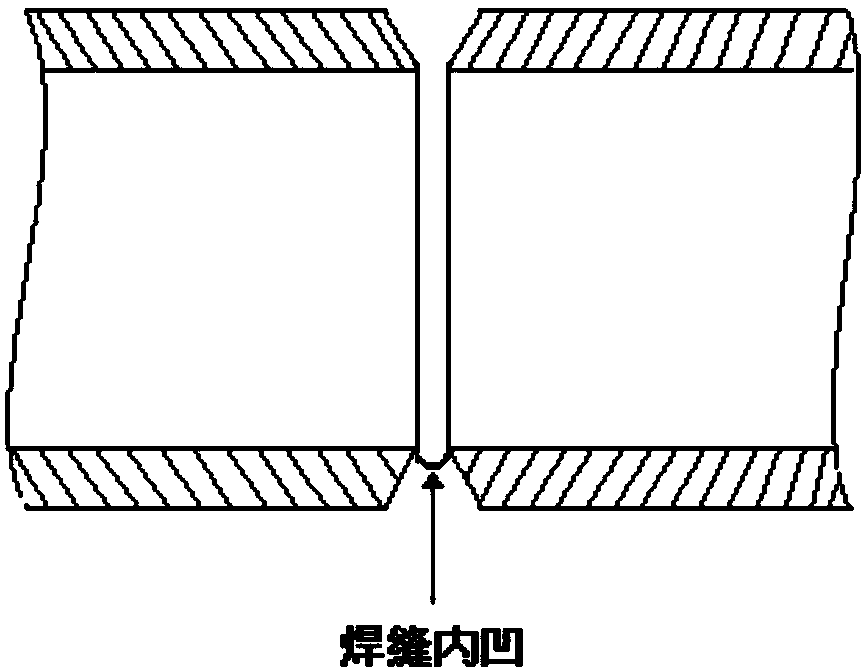

Priming method for melting pole MIG welding in pipeline welding

The invention relates to a priming method for melting pole MIG welding in pipeline welding and belongs to the technical field of pipeline welding. During welding, V-shaped welding grooves are oppositely formed in butt-joint end faces of two pipes to be welded respectively, the bottom gap of the V-shaped grooves is 3 mm to 5 mm, the angle of the groove on one side is 30 degrees to 35 degrees, semi-automatic melting pole MAG welding equipment is adopted as a welding machine for priming welding, and mixed gas of argon and carbon dioxide is adopted as protection gas and comprises, by volume, 95% of argon and 5% of carbon dioxide. The method adopts the common semi-automatic melting pole MAG welding equipment to achieve an MIG welding effect, the construction cost can be reduced, the construction efficiency is improved, and welding defects in conventional operation methods are avoided.

Owner:PANGANG GRP ENG TECH

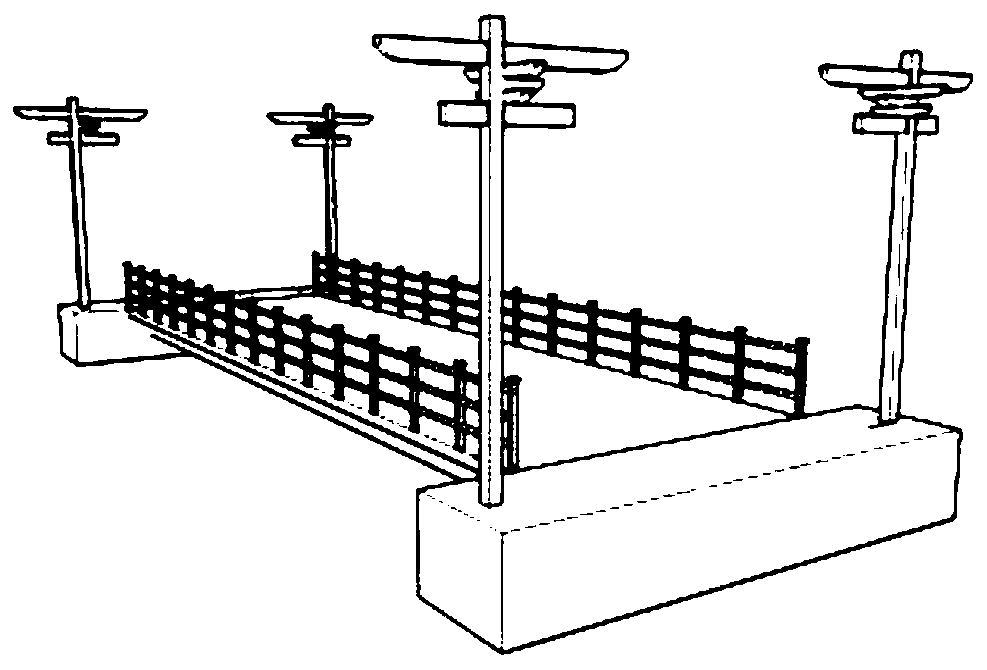

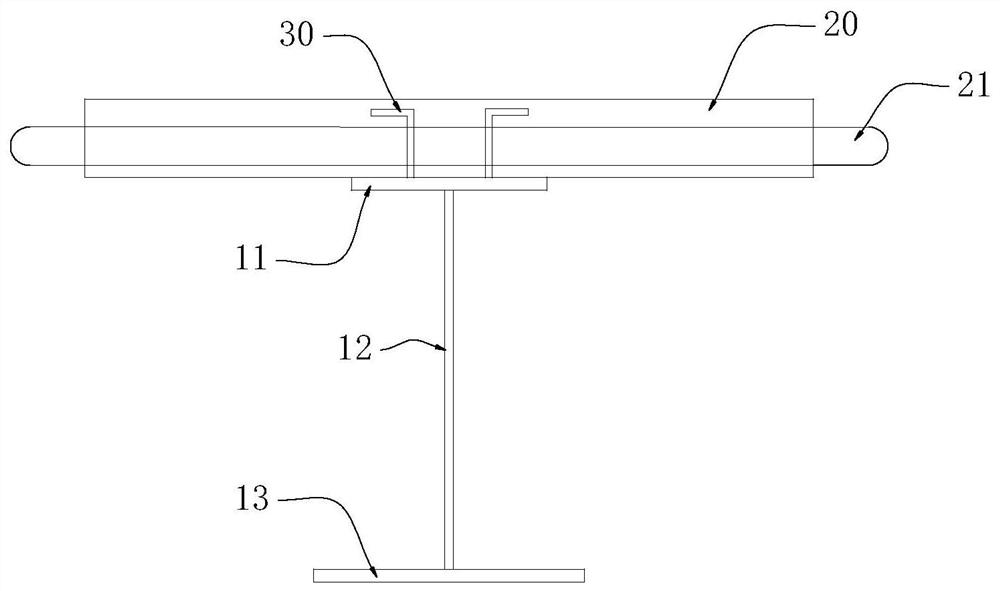

Road cold-bent U-shaped composite beam bridge and construction method thereof

ActiveCN110106772AImprove fatigue performanceLess prone to fatigueBridge structural detailsBridge materialsWelding residual stressAsphalt

The invention discloses a road cold-bent U-shaped composite beam bridge and a construction method thereof. The road cold-bent U-shaped composite beam bridge is structurally characterized in that a plurality of U-shaped steel plates are spliced into a bridge body steel structure; and concrete pouring areas are arranged on the U-shaped steel plates, an asphalt layer is laid on concrete, a gantry isarranged at the bridge head, and guardrails and lamp posts are arranged on the two sides of the bridge. Compared with the prior art, the U-shaped steel plates are formed in a cold-bending mode and donot need to be welded, and thus the welding quality problem and welding residual stress are avoided; steel beam segments spliced in a factory are transported to a site, and then the concrete is pouredto form the bridge; the steel beam segments replace construction formworks, the construction technology is optimized, the construction quality is improved, and the construction period is shortened; and the bearing capacity of cold-bent U-shaped composite beams is three times that of equal-span hollow slab beams, the concrete cracking disease can be reduced, and bridge durability is improved.

Owner:HOHAI UNIV

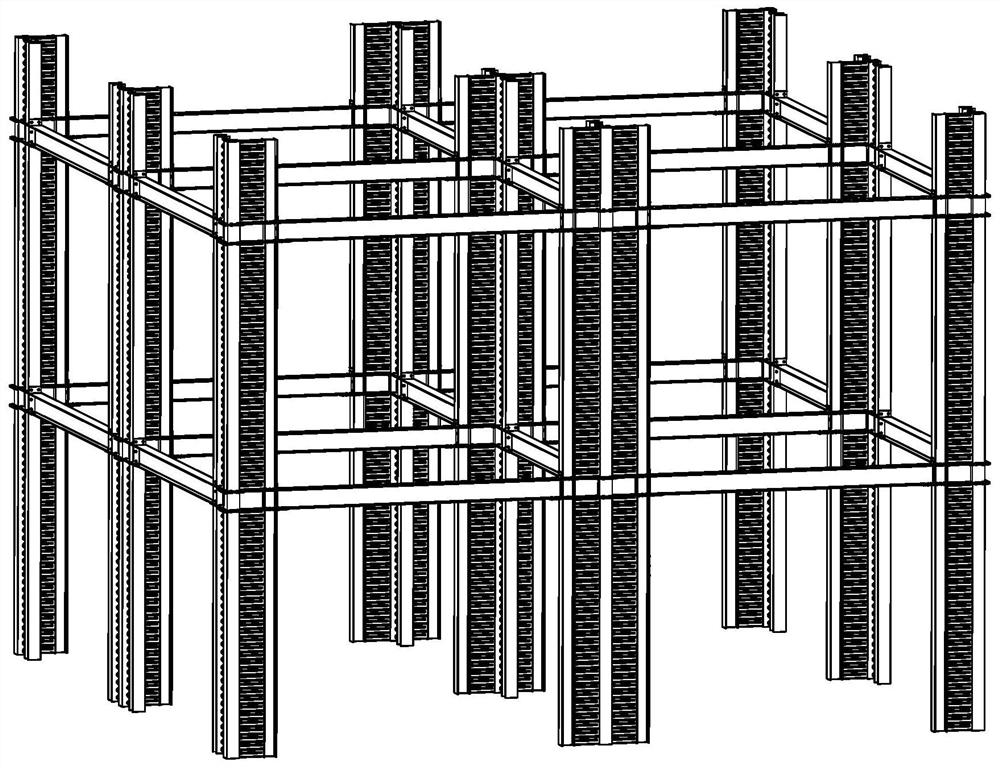

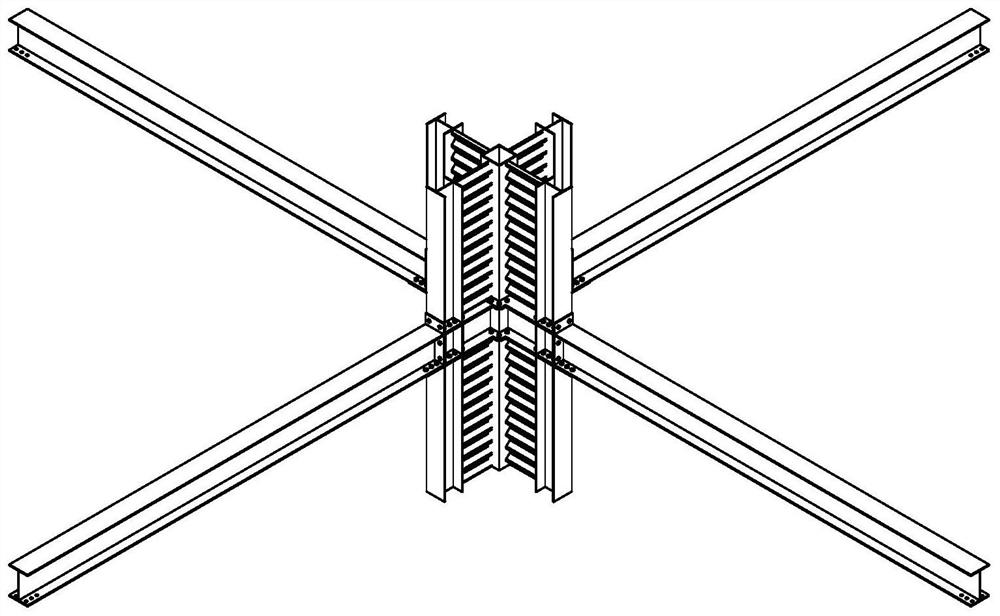

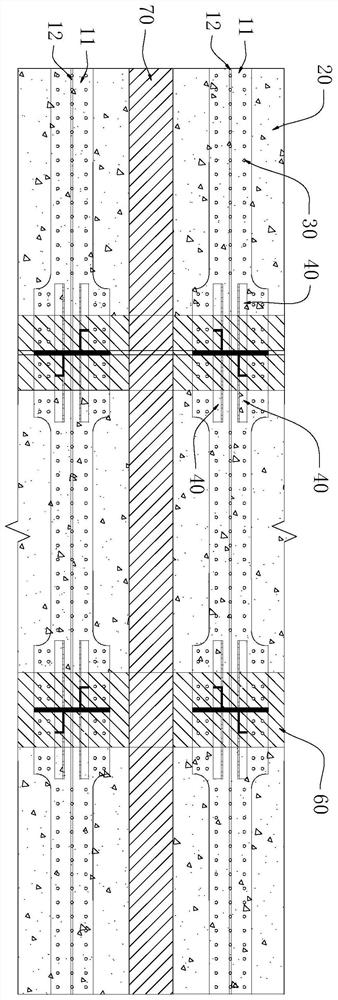

Assembly type steel structure special-shaped column frame structure system

PendingCN112302167AIncrease lateral stiffnessImprove seismic performanceStrutsPillarsEarthquake resistanceShaped beam

The invention discloses an assembly type steel structure special-shaped column frame structure system, and belongs to the technical field of structural engineering. The assembly type steel structure special-shaped column frame structure system involves a structure system, a roof panel system and an enclosure structure. The roof panel system is laid on steel beams of the structural system, the space between beam column vertical face frames of the structural system is filled with the enclosure system, the structural system adopts an assembly type steel structure special-shaped column frame system, and the corrugated plate anti-side special-shaped column comprises a square steel pipe column, a section steel column and a corrugated plate; and a connecting joint of the system is composed of a corrugated plate anti-side special-shaped column, an H-shaped beam with an end plate, a beam column-column connecting part with a protruding column and high-strength bolts. According to the assembly type steel structure special-shaped column frame structure system, the structure is flexible in arrangement and high in assembly efficiency, the protruding column and protruding beam problem can be reasonably solved, the bearing capacity and the anti-seismic property are higher compared with a traditional steel structure, and the application range is wider.

Owner:BEIJING UNIV OF TECH

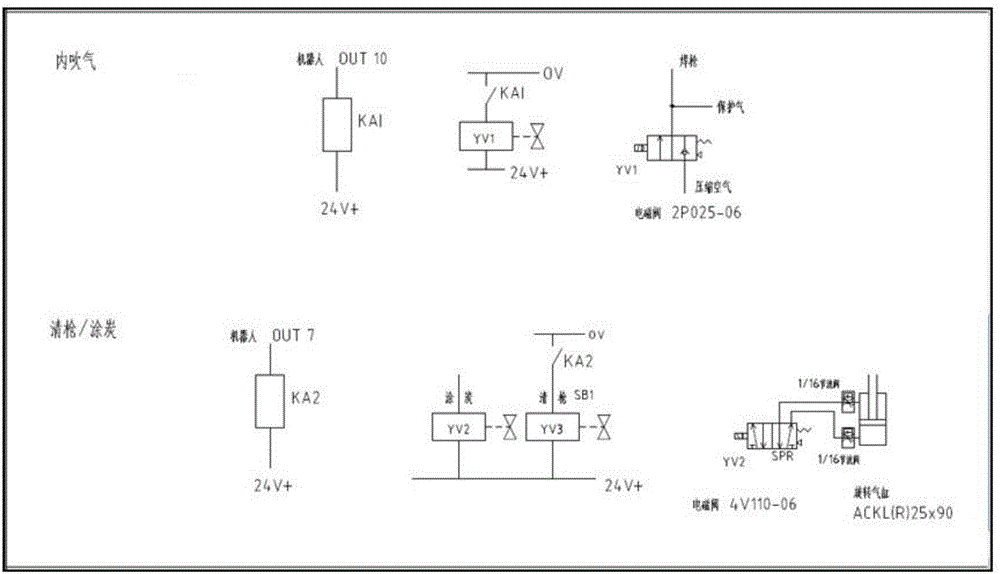

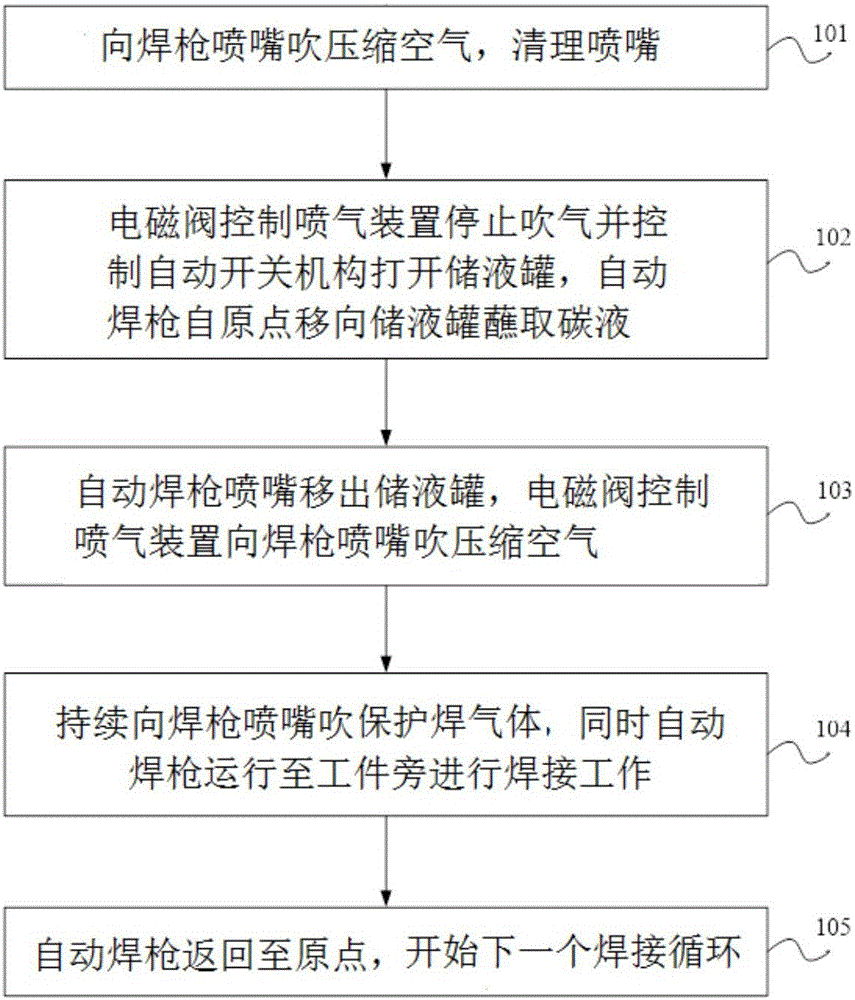

Anti-spatter welding method and system of automatic welding gun

InactiveCN106425059ANot easy to stickReduce chanceShielding gas supply/evacuation devicesSupport devices with shieldingSlagSpray nozzle

The invention discloses an anti-spatter welding method of an automatic welding gun. The anti-spatter welding method comprises the steps that high-pressure gas is sprayed to a spray nozzle of the welding gun, and the spray nozzle is cleaned; the spray nozzle of the welding gun is dipped in anti-spatter fluid; high-pressure gas and shielded welding gas are sprayed to the spray nozzle of the welding gun successively; and a workpiece is welded. Compared with the prior art, dipping of the anti-spatter fluid and gas blowing are combined, spattered molten drops can be isolated, the probability of adhesion between welding slag and the spray nozzle and adhesion between a contact tube and the inner wall of the contact tube is decreased, blockage of the spray nozzle and the contact tube of the welding gun is effectively avoided, and the purpose of preventing spatter of the spray nozzle and the contact tube of the welding gun is achieved; and in addition, a traditional gun cleaning device is not needed, the production cost is lowered, the service life of the contact tube is prolonged, the production time is saved, and high market value is achieved.

Owner:SHANGHAI FUJIYA HONGHU EXHAUST AIR SYST CO LTD

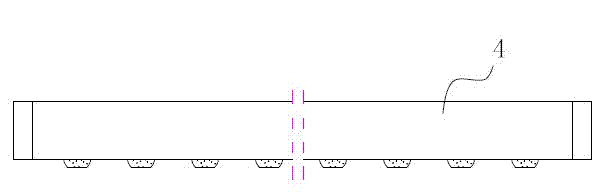

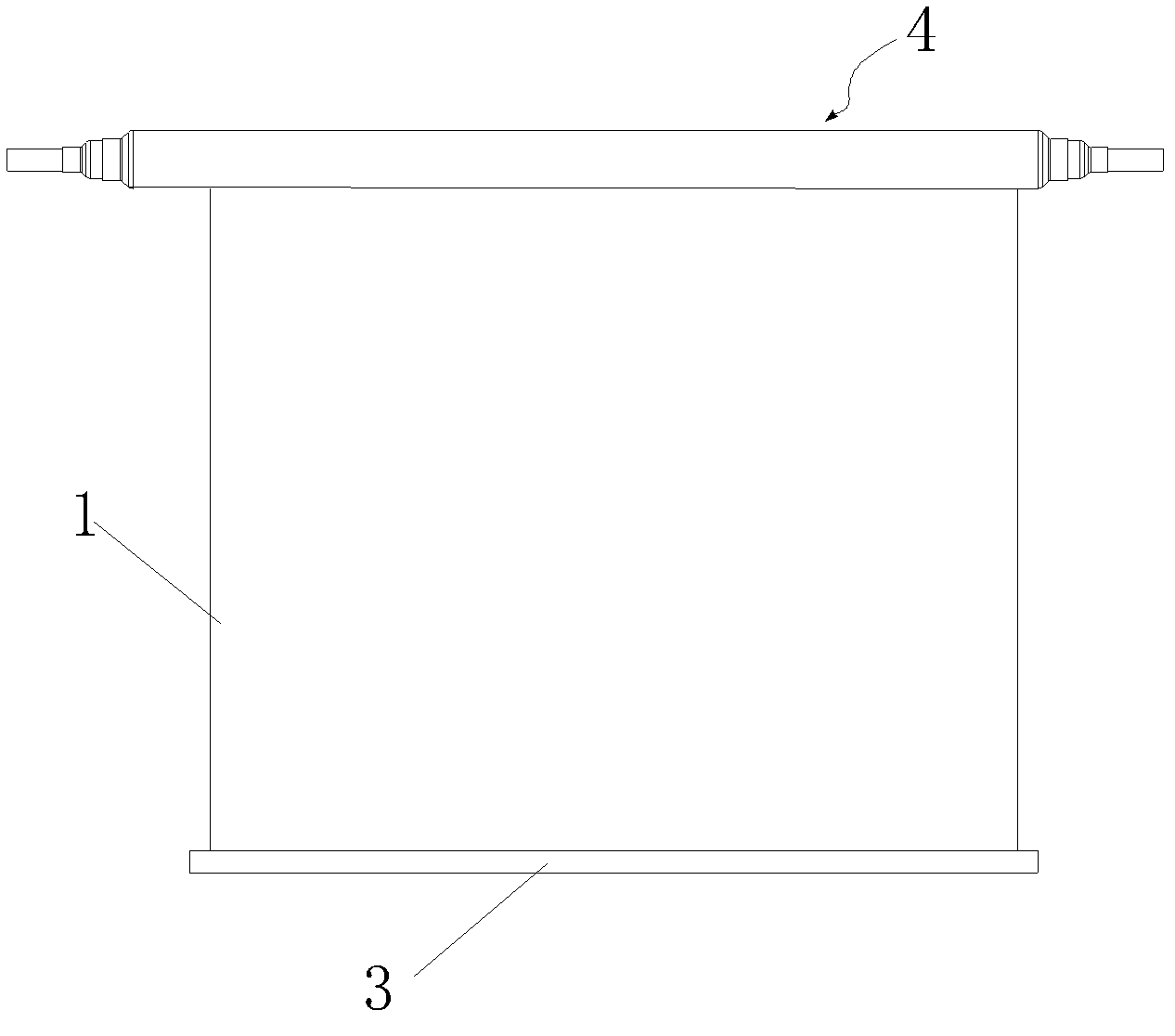

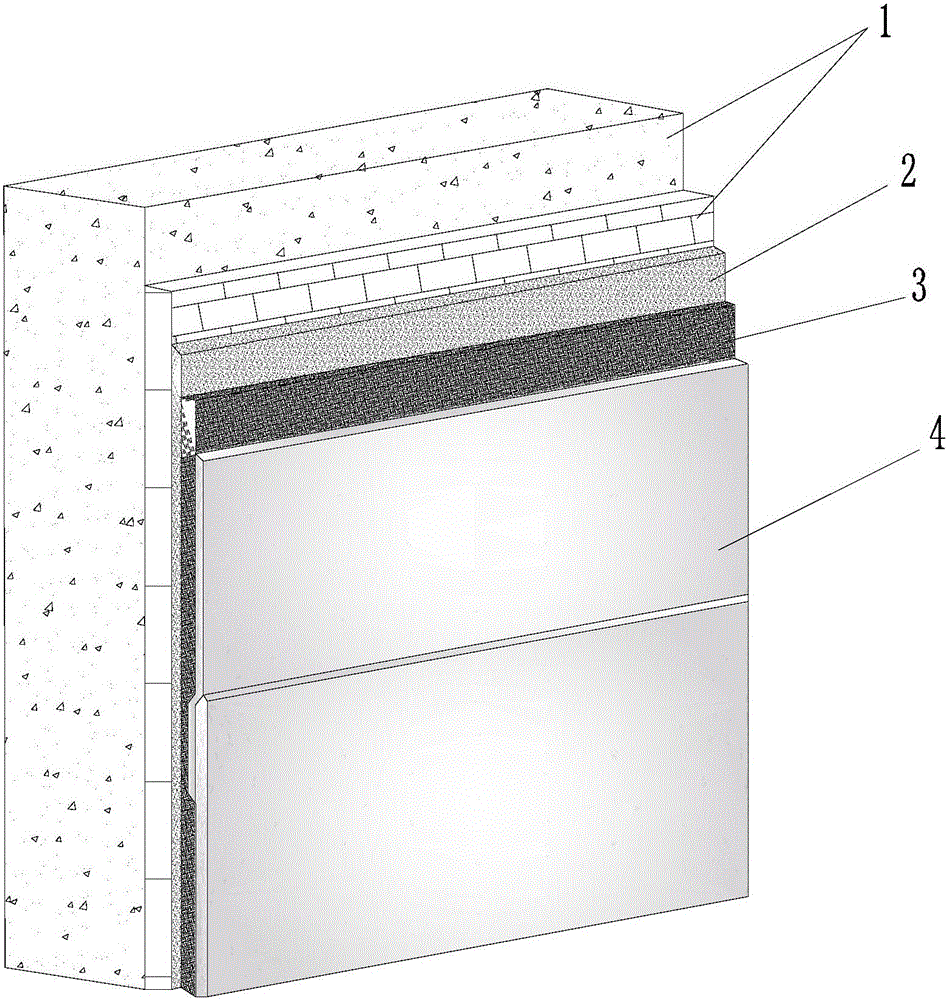

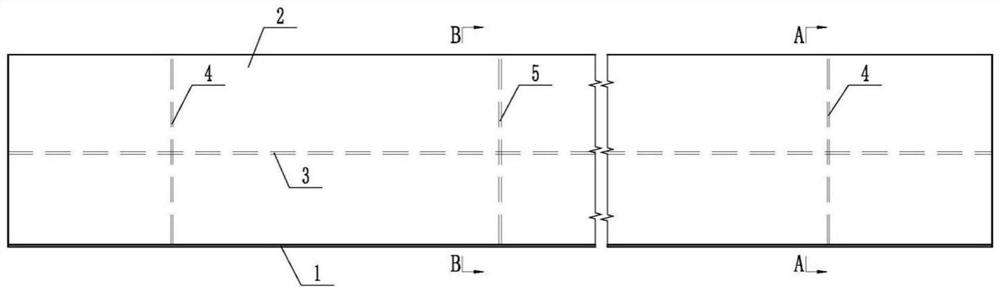

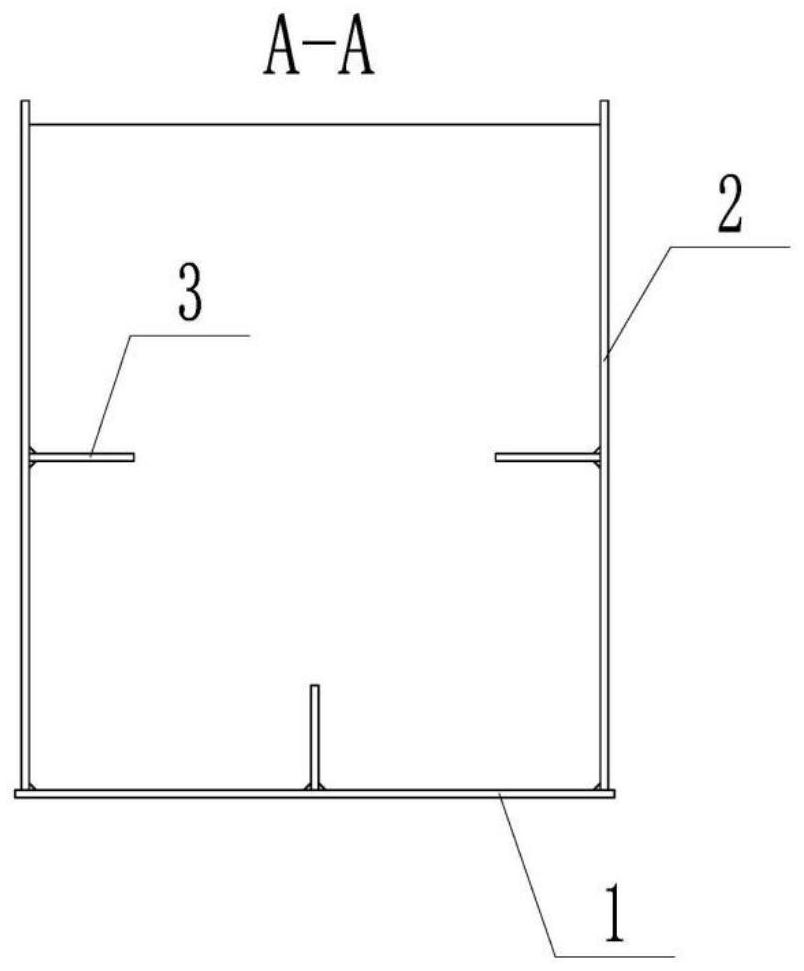

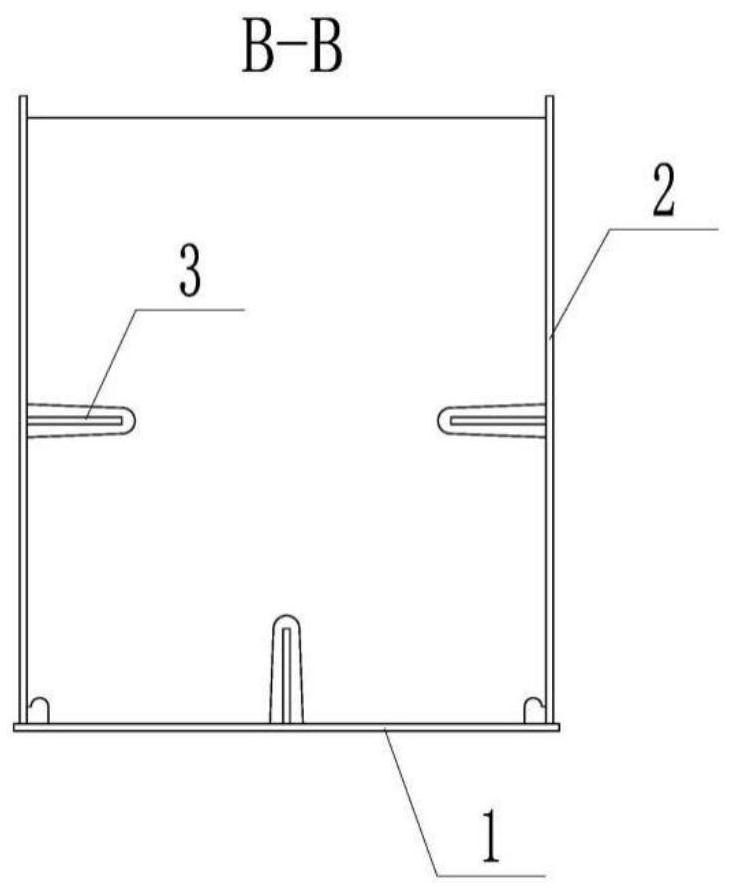

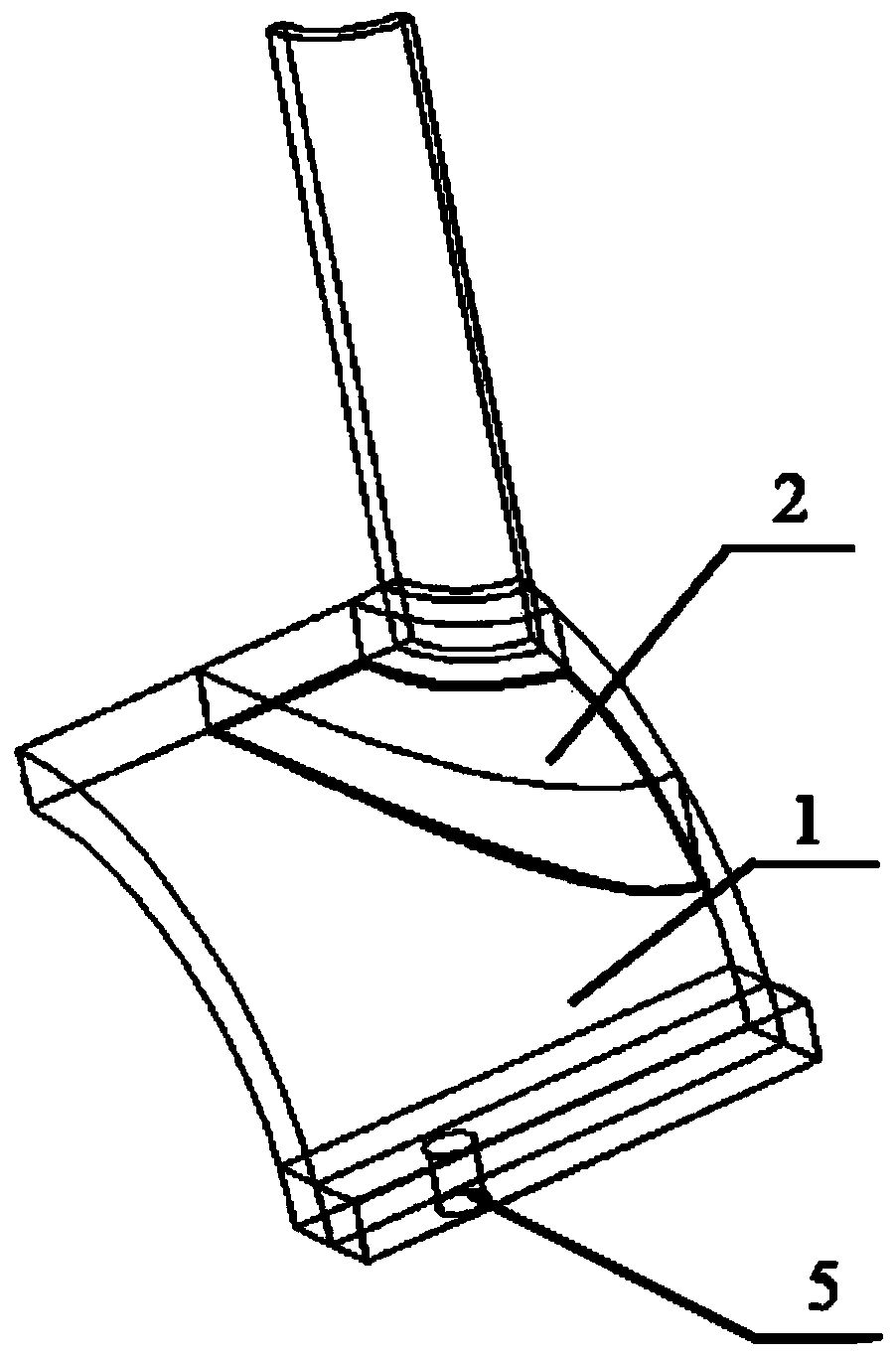

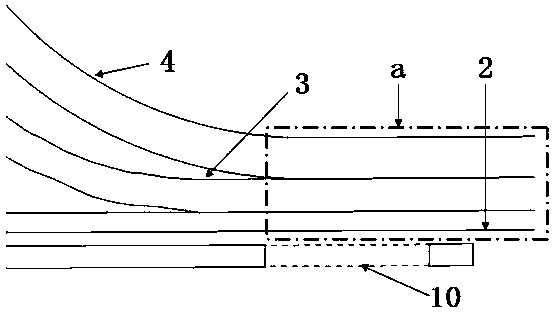

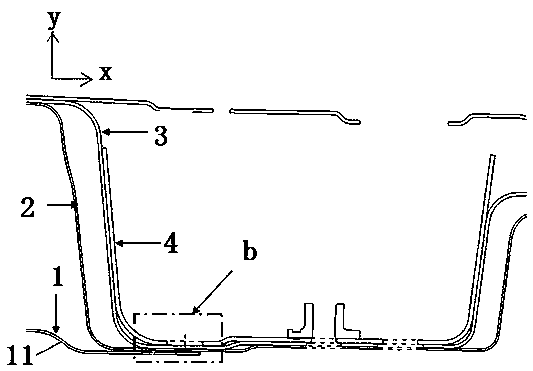

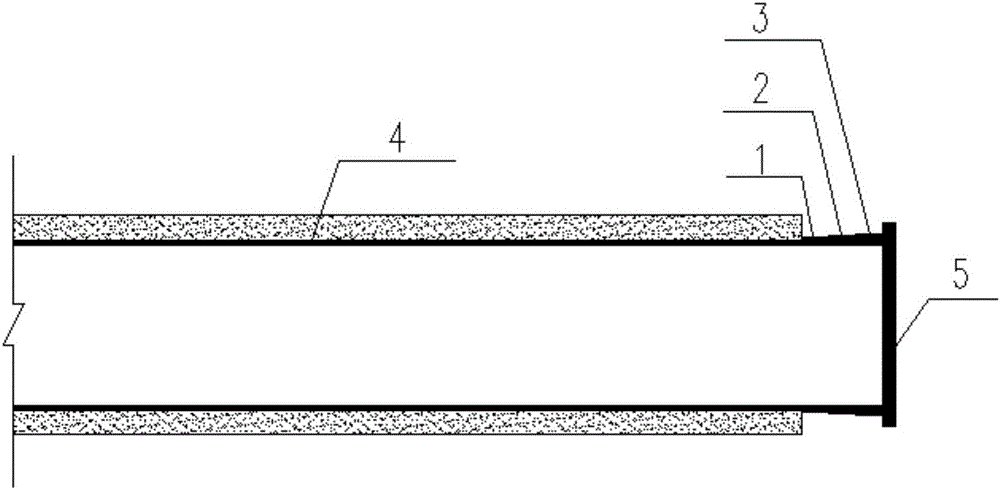

Anti-corrosion structure for chimney and construction method thereof

ActiveCN104989167AAvoid spot weldingAvoid Weld Quality IssuesTowersBuilding insulationsAdhesiveTitanium plate

The invention discloses an anti-corrosion structure for a chimney. The anti-corrosion structure comprises a first coat (2), an adhesive layer (3) and a titanium plate layer (4) which are arranged in sequence, wherein a chimney base (1) is coated with the first coat (2), and the titanium plate layer (4) adheres to the first coat (2) through the adhesive layer (3). The invention further discloses a construction method of the anti-corrosion structure for the chimney. The method comprises the steps of cleaning the chimney base, coating the cleaned chimney base with the first coat material, applying adhesive and sticking a titanium plate after the first coat material on the chimney base is solidified, and conducting inspection and repair. According to the method, the lapped titanium plate is directly stuck onto the structural layer of a chimney by means of the titanium plate adhesive. The method has the advantages that construction period is short, the requirement for the site construction environment is low, and the problem that titanium plate welding quality is poor due to poor construction site welding environment is solved.

Owner:BEIJING CPCEP ENERGY CONSERVATION & ENVIRONMENTAL PROTECTION TECH CO LTD

Automatic welding method for steel beam rod part groove-shaped structure

ActiveCN113070546ALess welding spatterWell-formed weldWelding accessoriesFillet weldStructural engineering

The invention discloses an automatic welding method for a steel beam rod part groove-shaped structure. The automatic welding method comprises the following steps that 1, transverse partition plates, a web plate, a bottom plate and stiffening ribs are assembled; 2, during welding, an arcing point is located at the bottom of a vertical welding seam of a middle partition plate and the web plate; 3, vertical fillet welds of the middle partition plate and the web plate are welded; 4, flat angle fillet welds of the middle partition plates and the bottom plate, and flat angle fillet weld of the web plate and the bottom plate are welded; 5, the previous step is repeated until all the middle partition plates are welded; 6, end partition plates are welded, and after arcing, vertical position fillet welds of the end partition plates at the lower sides of the web plate stiffening ribs and the web plate, elevation angle position and flat angle position fillet welds of the end partition plates and the web plate stiffening ribs, and vertical position fillet welds of the end partition plates at the upper sides of the web plate stiffening ribs and web plate are welded; 7, welding flat angle fillet welds of the web plate and the bottom plate, flat angle fillet welds of the end partition plates and the bottom plate and vertical fillet welds of the end partition plates and the bottom plate stiffening ribs are welded; and 8, the previous step is repeated until all the end partition plates are welded to other panels. The method can be used for welding a groove-shaped portion of a rod part, and the welding seam quality can be greatly improved.

Owner:中铁宝桥(扬州)有限公司 +1

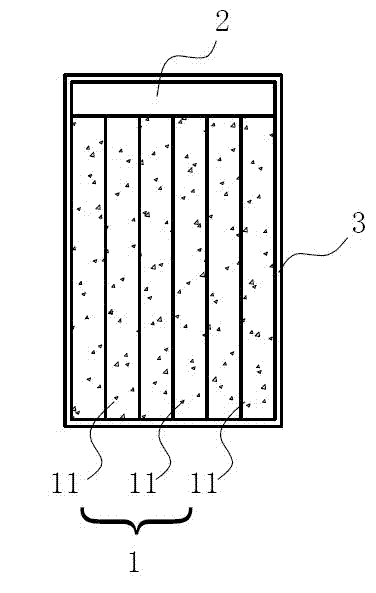

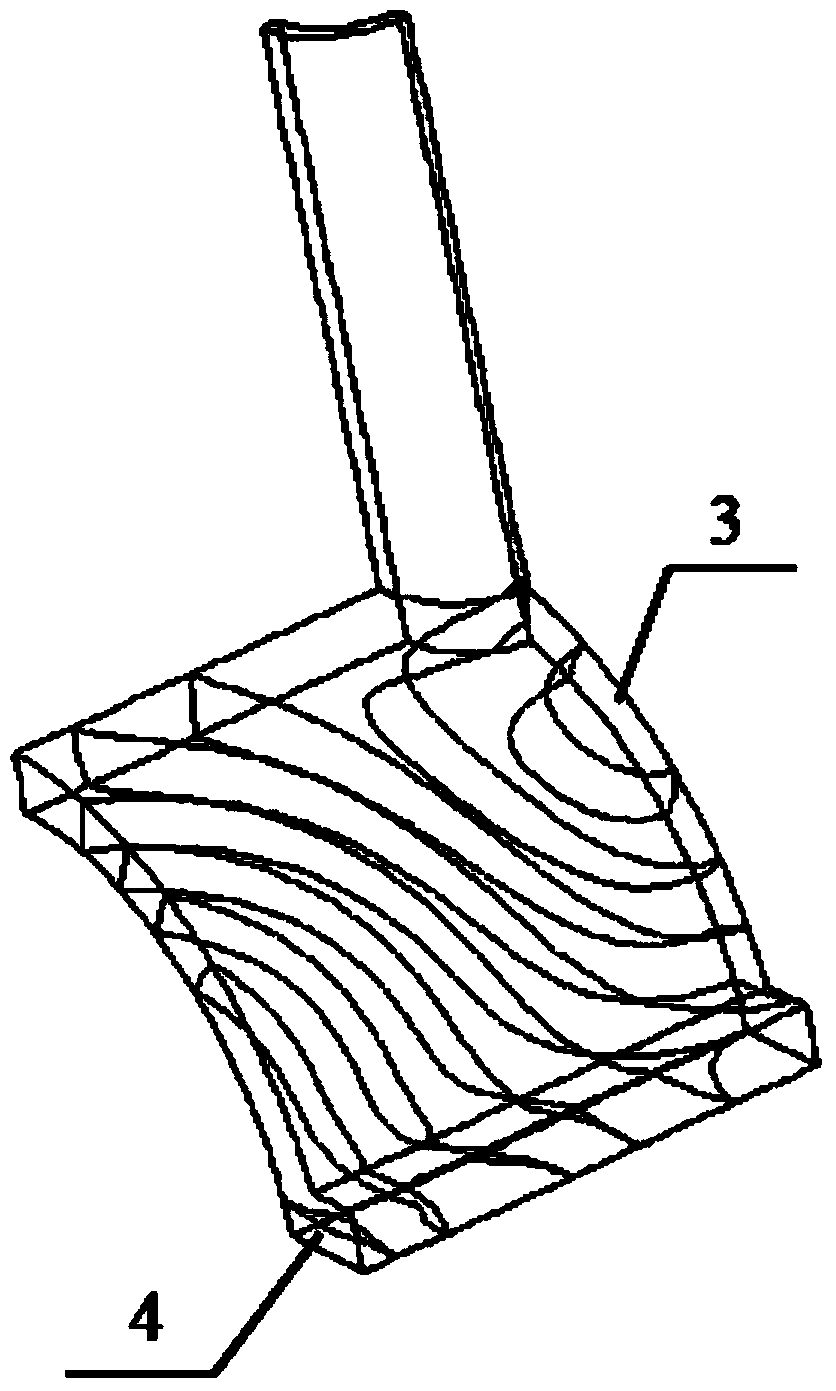

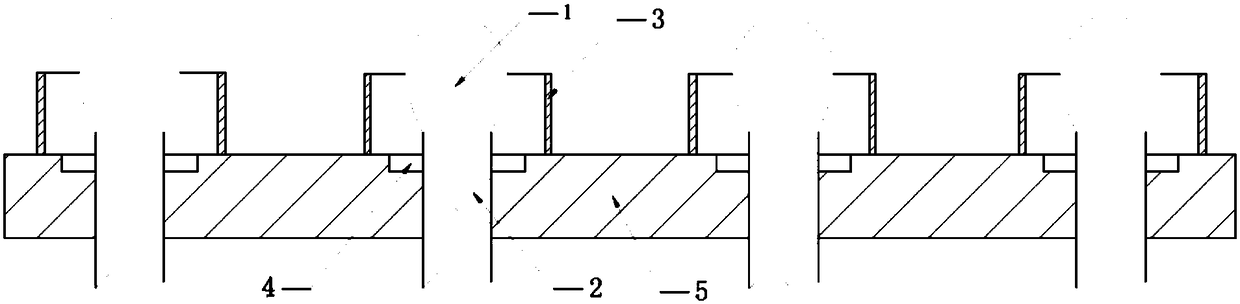

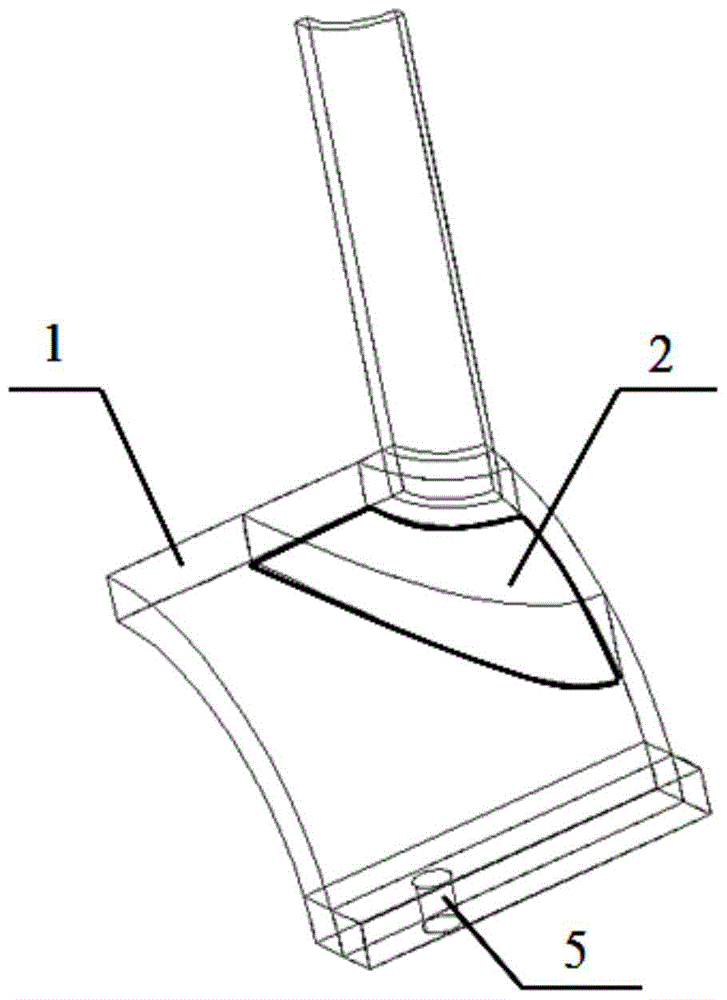

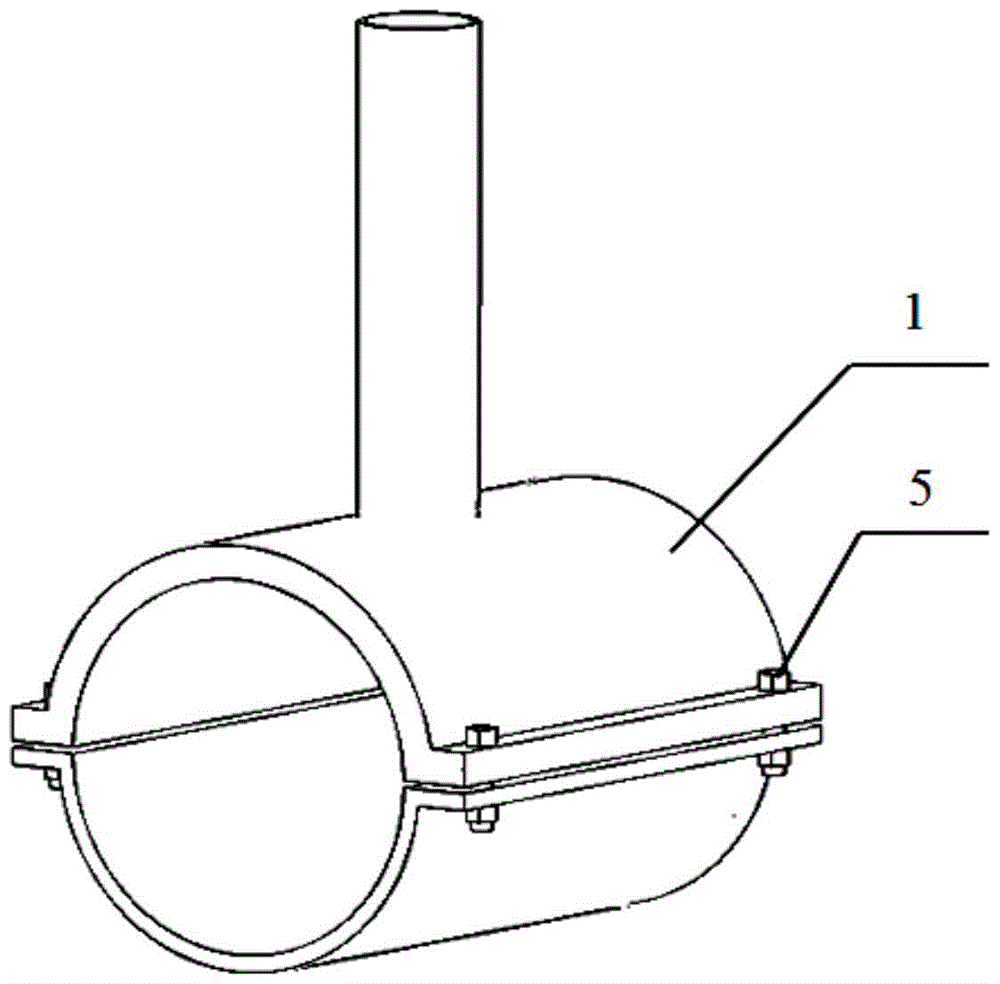

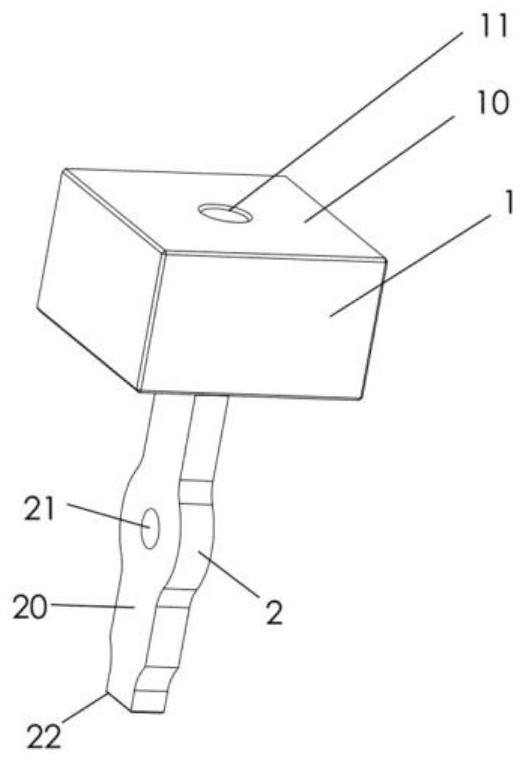

Novel saddle-shaped pipe fitting and connecting and fixing method thereof in electric fusion welding process

InactiveCN104191115AReduce scrap rateAvoid Weld Quality IssuesWelding/cutting auxillary devicesAuxillary welding devicesPipe fittingEconomic benefits

The invention relates to plastic pipeline welding technologies, and provides a novel saddle-shaped pipe fitting and a connecting and fixing method of the novel saddle-shaped pipe fitting in the electric fusion welding process. The body of the novel saddle-shaped pipe fitting is a saddle-shaped arc body, a branch pipe is arranged on the arc body, and the positions, on the two sides of the branch pipe, on the arc body are respectively provided with at least one boss. At least one screw hole is formed in one side of each boss, and a meshing structure is arranged on the other side of each boss. The structure of the saddle-shaped pipe fitting is improved, the lower half portion of an original saddle-shaped pipe fitting is omitted, a set of flexible binding belts is adopted for pretightening, the pressure of a fusion area in the welding process of the saddle-shaped pipe fitting is kept fully and stably, the welding quality problem caused by the insufficient pressure of the fusion area under the existing welding condition is solved, the rejection rate of saddle-shaped pipe fitting welding products is reduced, the production and manufacturing cost is saved, and economic benefits are improved.

Owner:ZHEJIANG UNIV +1

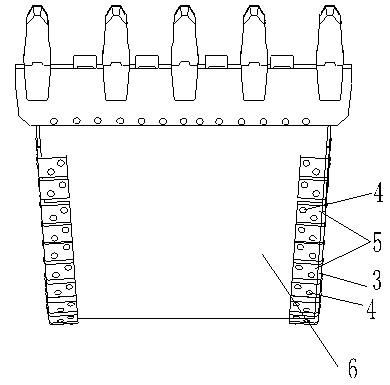

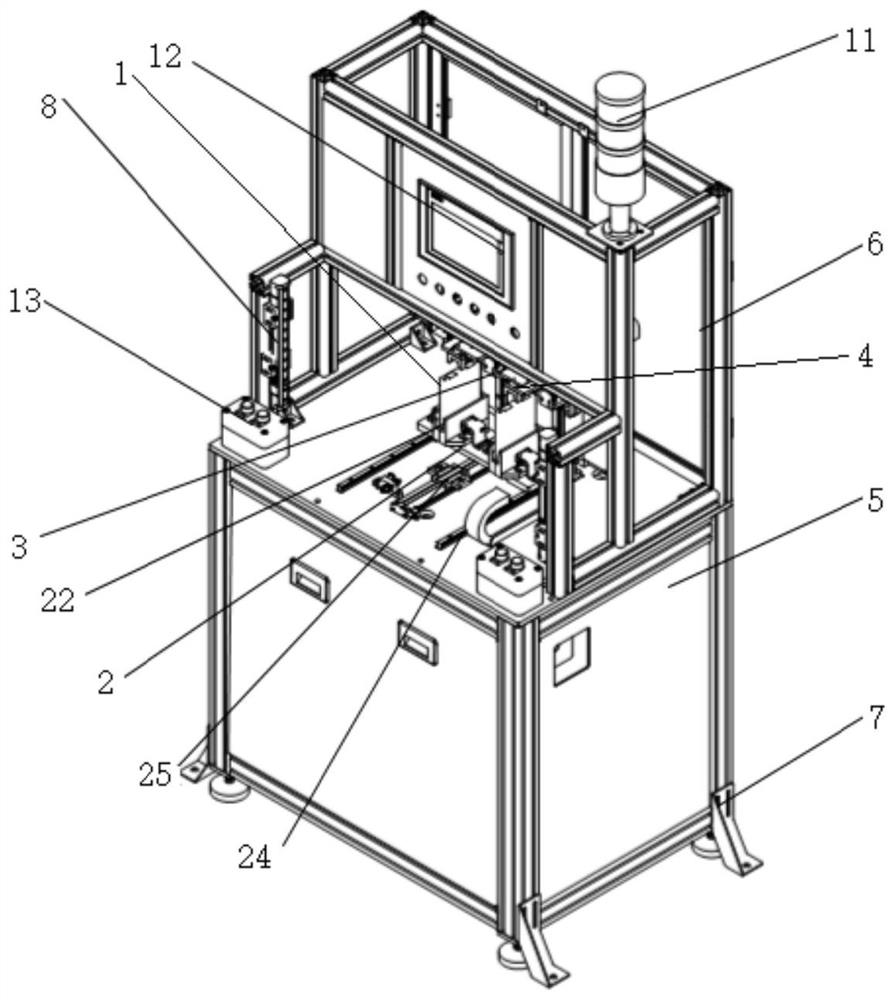

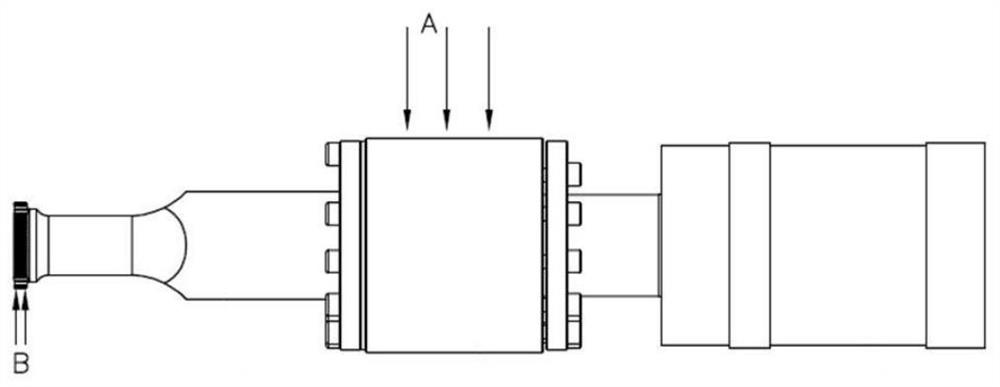

Anode steel claw welding system

PendingCN109434342AImprove welding efficiencyImprove welding qualityWelding/cutting auxillary devicesAuxillary welding devicesCrucibleButt joint

The invention discloses an anode steel claw welding system. The anode steel claw welding system comprises a fusion welding transformer, a controller, a three-dimensional movement mechanism, a consumable electrode plate, a crystallizer, a slagging transformer, a crucible, a carbon rod lifting mechanism and a carbon rod; after claw legs and a cross beam are placed in a preset position of a lower crystallizer, the controller controls a sliding door type frame to move, an upper crystallizer and the lower crystallizer are in matched butt joint, and a welding port reaches a preset position; then, the controller controls the three-dimensional movement mechanism to move to drive the consumable electrode plate to penetrate through the corresponding welding port, and gaps exist between the consumable electrode plate and the bottom and the inner wall of the welding port; and the controller controls the carbon rod lifting mechanism to move to drive a carbon rod to move, so that a solid fluxing agent contained in the crucible is molten. The molten liquid fluxing agent is poured into the welding port to complete automatic welding of the anode steel claw, the welding efficiency is high, the welding quality is good, the welding cost can be effectively reduced, and the problem of welding quality caused by individual operation differences in manual welding is avoided.

Owner:内蒙古世星新材料科技有限公司

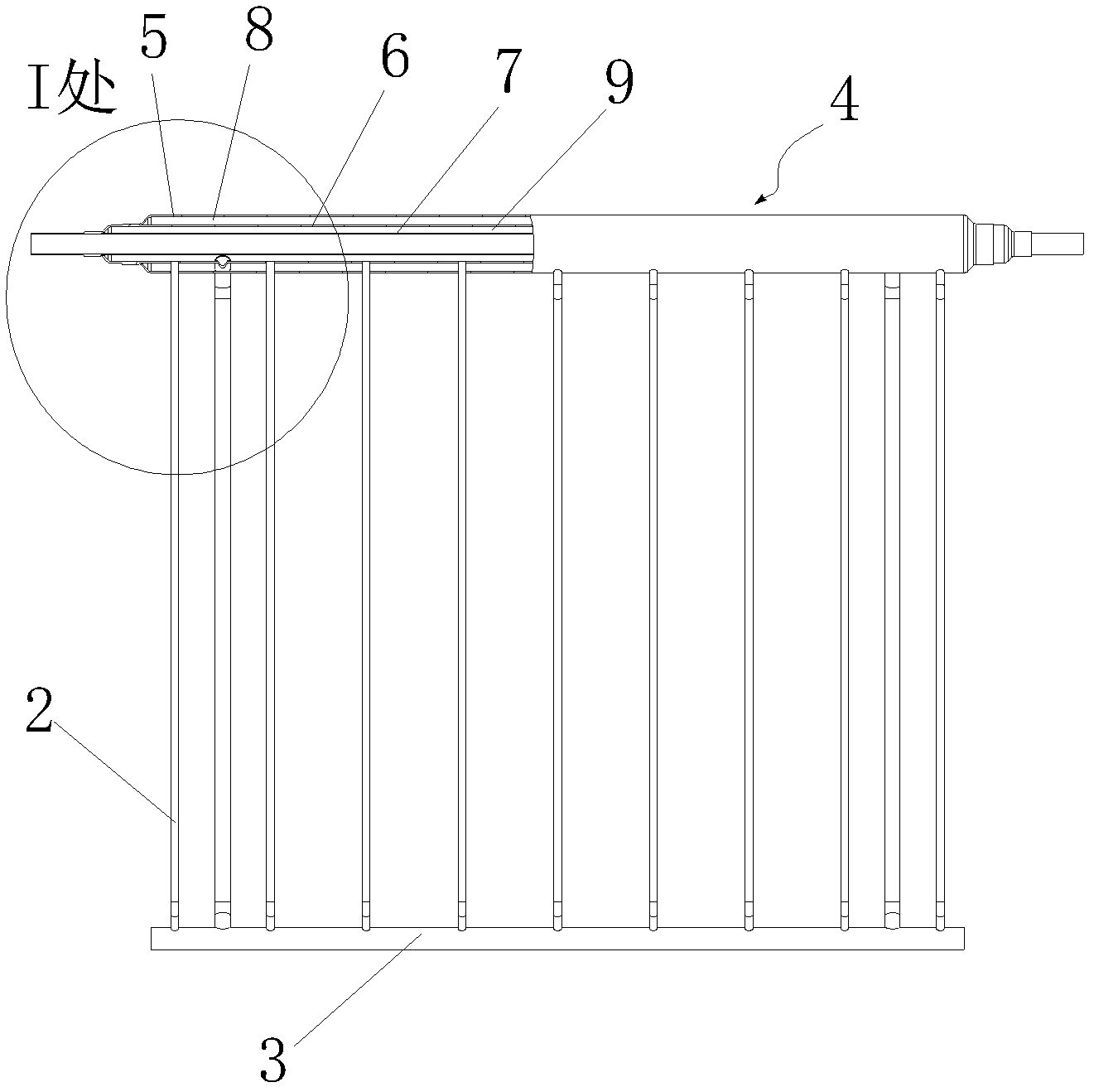

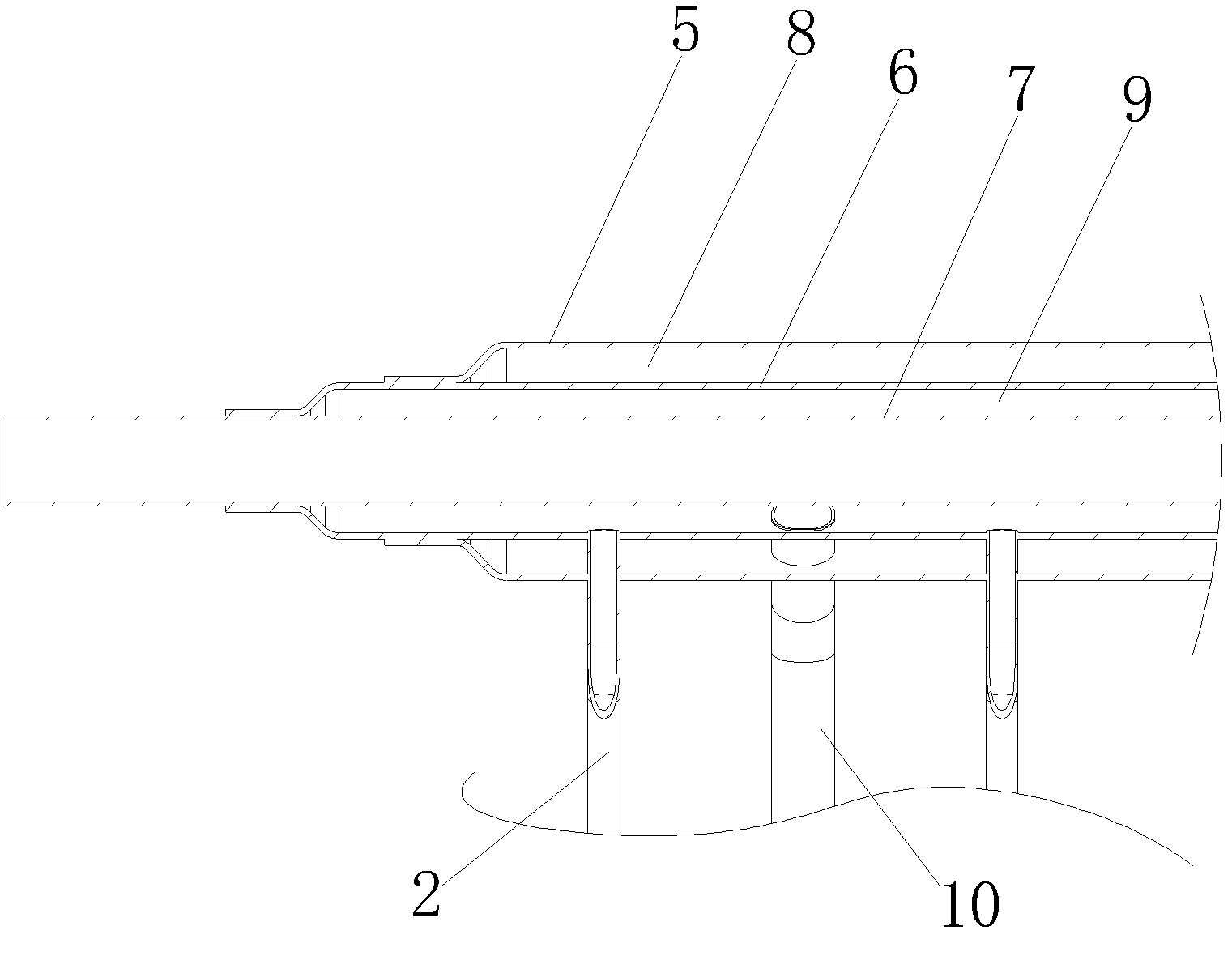

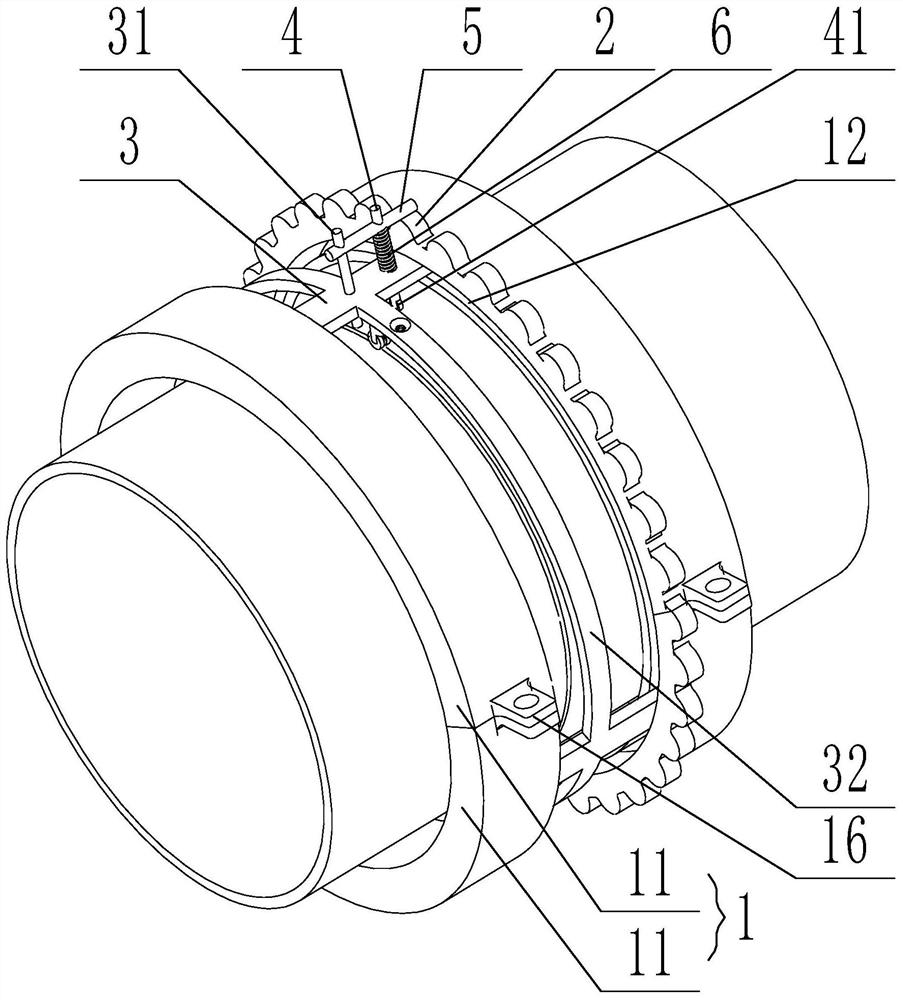

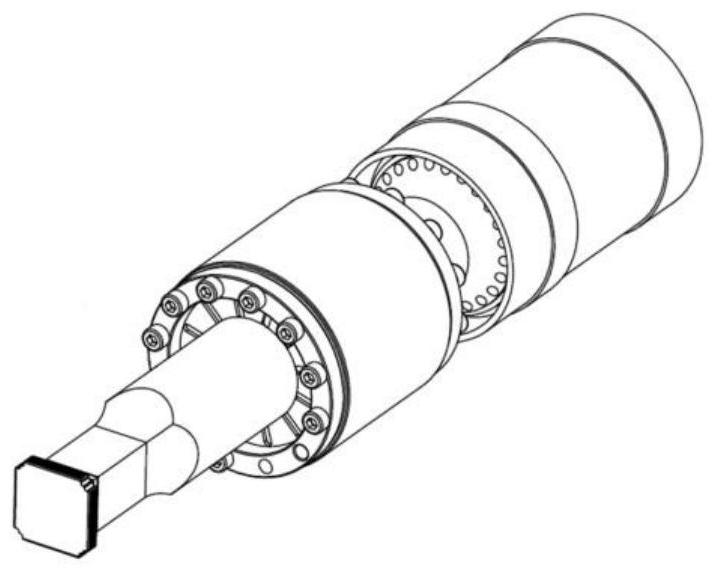

Automatic sealing type pipe-pipe welding machine head

ActiveCN113070555AAvoid harmAvoid problems that require constant adjustment of postureWelding accessoriesElectric machineryPipe welding

The invention discloses an automatic sealing type pipe-pipe welding machine head, and belongs to the technical field of automatic welding equipment. The automatic sealing type pipe-pipe welding machine head comprises two fixing rings which are coaxially arranged left and right, a plurality of semi-cylinders, a cambered plate, a vertical rod, a cross rod and a tension spring, wherein annular grooves are formed in the opposite surfaces of the two semicircular rings, the plurality of semi-cylinders are uniformly fixed on the outer wall of the right side fixing ring around the axis of the right side fixing ring, the two ends of the cambered plate are slidably connected with the annular grooves in the left side and the right side, a middle hole and a vertical hole are formed in the cambered plate in the thickness direction, the vertical rod penetrates through the vertical hole, the bottom of the vertical rod is in shaft connection with a roller, a roller fixing shaft is connected with an output shaft of a motor, the motor is fixed to the vertical rod, the top of the vertical rod penetrates through the middle of the cross rod, and the right end of the cross rod abuts against the outer arc face of the semi-cylinder, and the tension spring is arranged on the vertical rod in a penetrating mode. According to the automatic sealing type pipe-pipe welding machine head, welding without wire feeding is carried out, manual labor is replaced, damage to the body of a worker is avoided, and the welding efficiency is improved.

Owner:合肥九州龙腾科技成果转化有限公司

A kind of steel flat angle welding method for ship hull structure

ActiveCN105195858BHigh strengthAvoid crackingArc welding apparatusWelding/soldering/cutting articlesHull structureStructural engineering

The invention relates to a flat-angle welding method for hull structural steel, and belongs to welding methods for hull structural steel. The problems that an existing flat-angle welding method for hull structural steel is bad for base material corrosion prevention, and weld joints are low in strength are solved. The flat-angle welding method includes the steps of groove forming, preheating, front face welding, postweld treatment on the front face, back gouging, back face welding and postweld treatment on the back face. Machining is easy, welding deformation is effectively reduced, flat-angle welding for the hull structural steel is smoothly achieved and passes a weldability test and welding procedure qualification, labor efficiency can be improved, welding materials, electric energy and labor hour can be saved, the production cost is reduced, the shipbuilding cycle is shortened, and the blank of welding ship structural steel and forged steel in China is filled up.

Owner:WUCHANG SHIPBUILDING IND

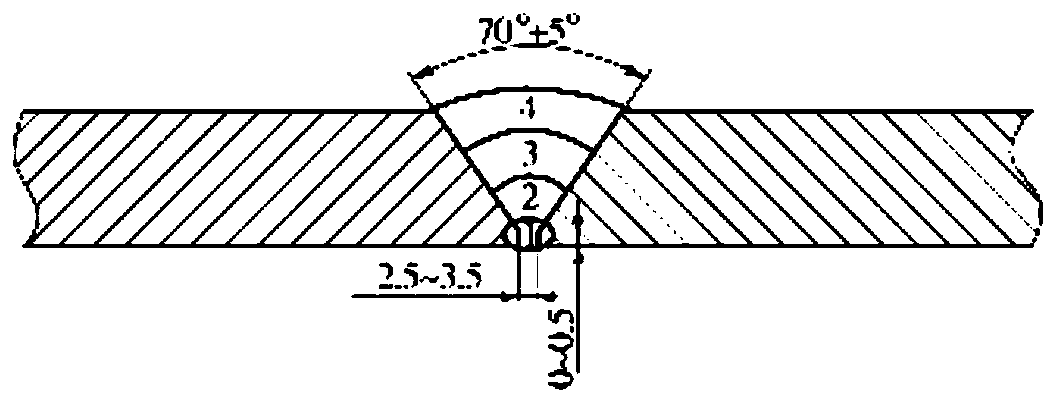

Welding method of nickel-base alloy steel pipeline

The invention discloses a welding method of a nickel-base alloy steel pipeline. A groove of a pipeline to be welded is treated, the angle of the groove of the pipeline to be welded is 70-75 degrees, the poor mobility of material liquid metal is avoided, the groove of the pipeline to be welded and the outer surface of the pipeline to be welded are polished and cleared, the situation that an oxidization layer exists on a weld opening is prevented, then after the pipeline is located and fixed, argon is adopted for protecting the groove of the pipeline to be welded, layering welding is adopted, and the situation that due to the improper welding temperature, as a result, metal grain of weld seams is thick and large, and the mechanical performance and corrosion resisting performance of the weldseams are lowered. According to the method, the scheme is reasonable, the data is reliable and explicit, the problem of 800 H welding quality can be effectively solved, the welding quality is improved, a left gas blocking baffle, a right gas blocking baffle and the inner wall of the pipeline to be welded are utilized for forming a sealing structure, then multiple gas output holes in a gas conveying pipe are utilized for inflating argon into the weld opening, the stable argon environment atmosphere is provided for welding, the device is simple in structure, and stability of the welding environment is ensured.

Owner:SCEGC EQUIP INSTALLATION GRP COMPANY

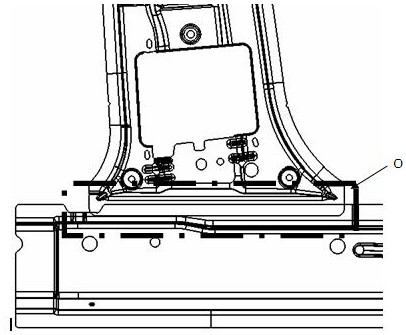

Connecting structure of stiffening beam and side wall assembly on front wheel cover

ActiveCN108423077AReduce stressAvoid solder jointsSuperstructure connectionsSingle vehicleHinge angle

The invention provides a connecting structure of a stiffening beam and a side wall assembly on a front wheel cover, which solves the problem of CO2 welding spot breaking or part metal plate cracking in a traditional structure, improves the safety of a bicycle body and the satisfaction degree of a customer, and lowers the manufacturing cost of a bicycle. The connecting structure comprises a front wheel cover stiffening beam, a side wall outer plate, a column-A lower stiffening plate and a column-A upper hinge stiffening plate which are sequentially fit from outside to inside, wherein the column-A lower stiffening plate and the column-A upper hinge stiffening plate are connected through spot welding to form a column-A lower stiffening plate assembly; the column-A upper hinge stiffening plateis provided with a welding through hole; and the front wheel cover stiffening beam, the side wall outer plate and the column-A lower stiffening plate assembly are connected together and are connectedby virtue of spot welding through the welding through hole by using welding tongs.

Owner:CHERY AUTOMOBILE CO LTD

Multi-pin connection assembly

InactiveCN109301539AAvoid Weld Quality IssuesGuaranteed installation reliabilityCoupling device connectionsSoldered/welded conductive connectionsEngineeringMechanical engineering

The invention discloses a multi-pin connector assembly. The multi-pin connector assembly comprises a multi-pin connector and a PCB matched with the multi-pin connector; the top ends of the pins of themulti-pin connector pass through positioning holes in the PCB and extend to the back of the PCB; and an annular tin blocking sleeve is arranged around each of the pins on the back of the PCB. According to the multi-pin connection assembly of the invention, the pins are less prone to the problems of tin adhesion, tin inadequacy and tin bead scattering during welding. The multi-pin connector assembly has the advantages of great universality and good effect. With the multi-pin connector assembly adopted, all the welding quality problems of the multi-pin connector can be solved, the installationreliability of the connector is ensured, and thus, the stability and safety of products can be ensured.

Owner:ZHENGZHOU YUNHAI INFORMATION TECH CO LTD

The bottoming method of MIG welding in pipeline welding

The invention relates to a priming method for melting pole MIG welding in pipeline welding and belongs to the technical field of pipeline welding. During welding, V-shaped welding grooves are oppositely formed in butt-joint end faces of two pipes to be welded respectively, the bottom gap of the V-shaped grooves is 3 mm to 5 mm, the angle of the groove on one side is 30 degrees to 35 degrees, semi-automatic melting pole MAG welding equipment is adopted as a welding machine for priming welding, and mixed gas of argon and carbon dioxide is adopted as protection gas and comprises, by volume, 95% of argon and 5% of carbon dioxide. The method adopts the common semi-automatic melting pole MAG welding equipment to achieve an MIG welding effect, the construction cost can be reduced, the construction efficiency is improved, and welding defects in conventional operation methods are avoided.

Owner:PANGANG GRP ENG TECH

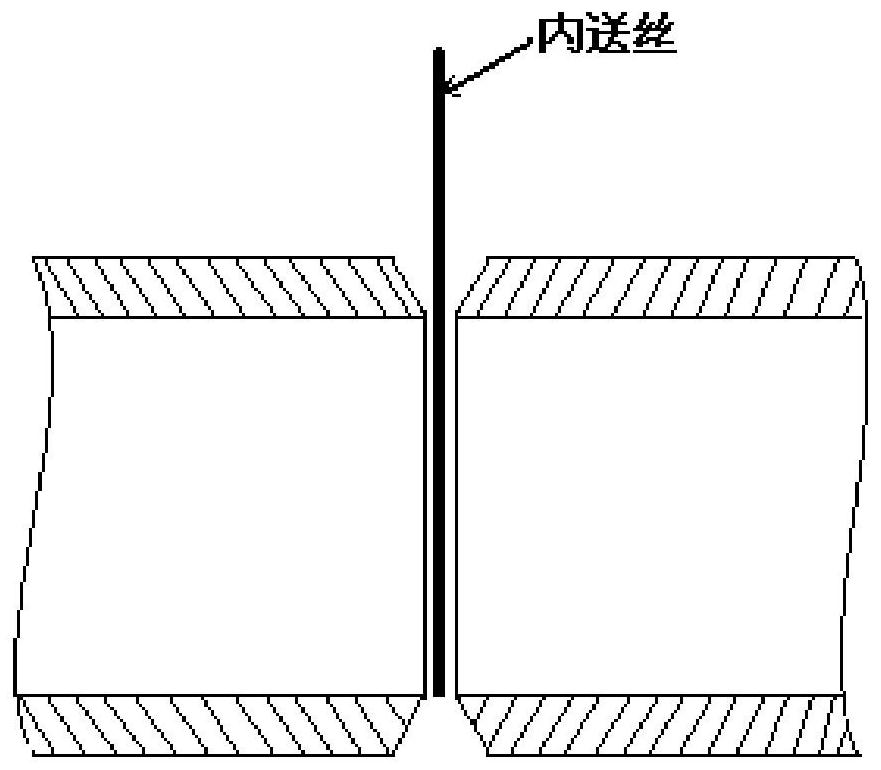

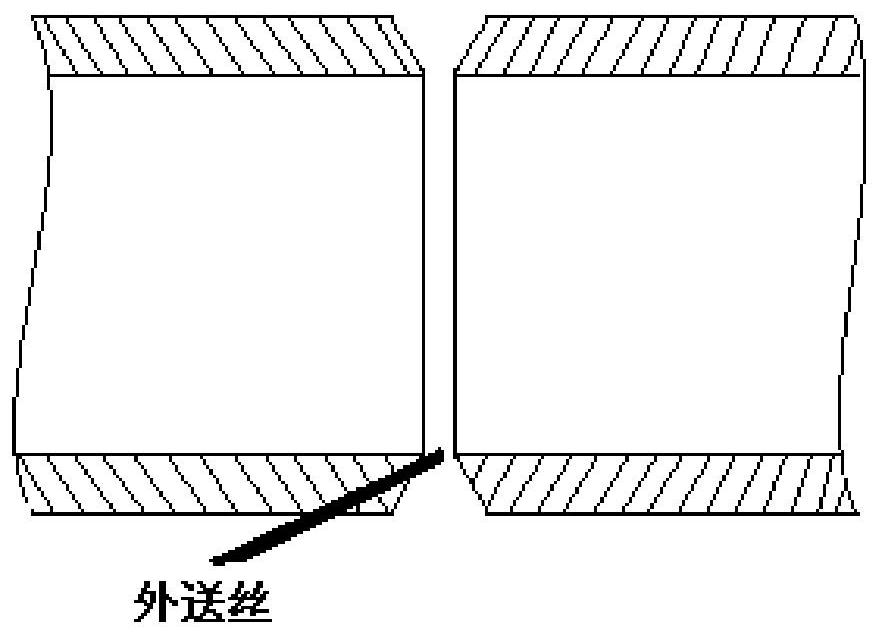

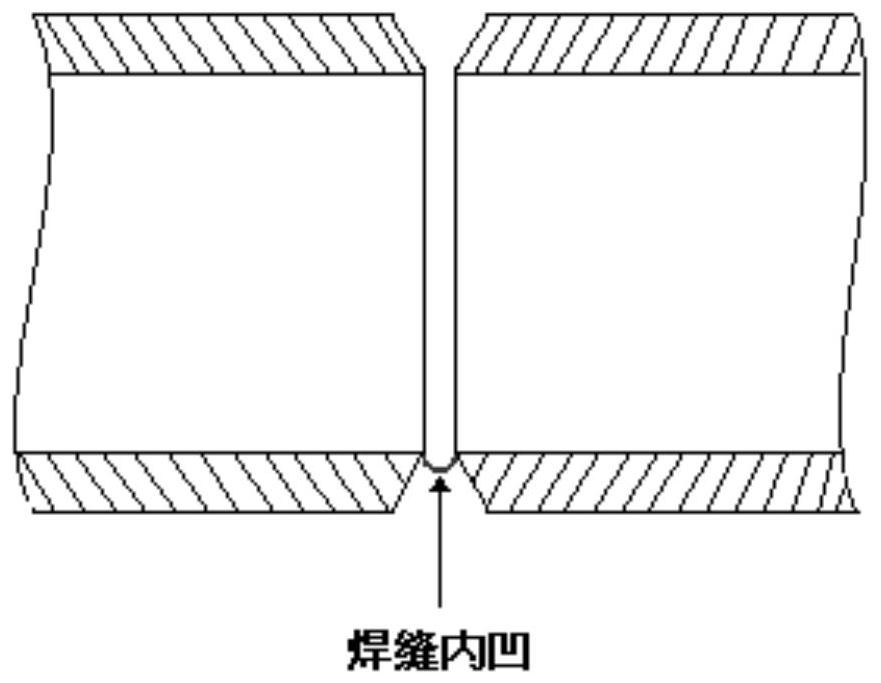

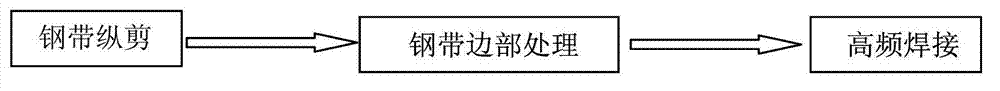

Steel strip edge processing method for high-frequency welded pipe and welded pipe production process

InactiveCN102886647AAlleviate overheatingAvoid scratchesHigh frequency current welding apparatusChemical treatmentHeat-affected zone

The invention provides a steel strip edge processing method for a high-frequency welded pipe and a welded production process adopting the processing method. The steel strip edge processing method for the high-frequency welded pipe comprises the following step of: performing mechanically or chemically processing the welded area and heat-affected area of a steel strip edge to be subjected to high-frequency welding or a specified area with an edge processing requirement to remove burr, scale cinder and adhered contaminants from the processed area. By the method, the welded area of the steel strip edge of the high-frequency welded pipe can be kept clean, the temperature of the welded area is uniformly and rationally distributed, the quality stability of the high-frequency welded pipe is improved, and the quality of a welding seam is greatly improved.

Owner:CHINA IRON & STEEL RES INST GRP +1

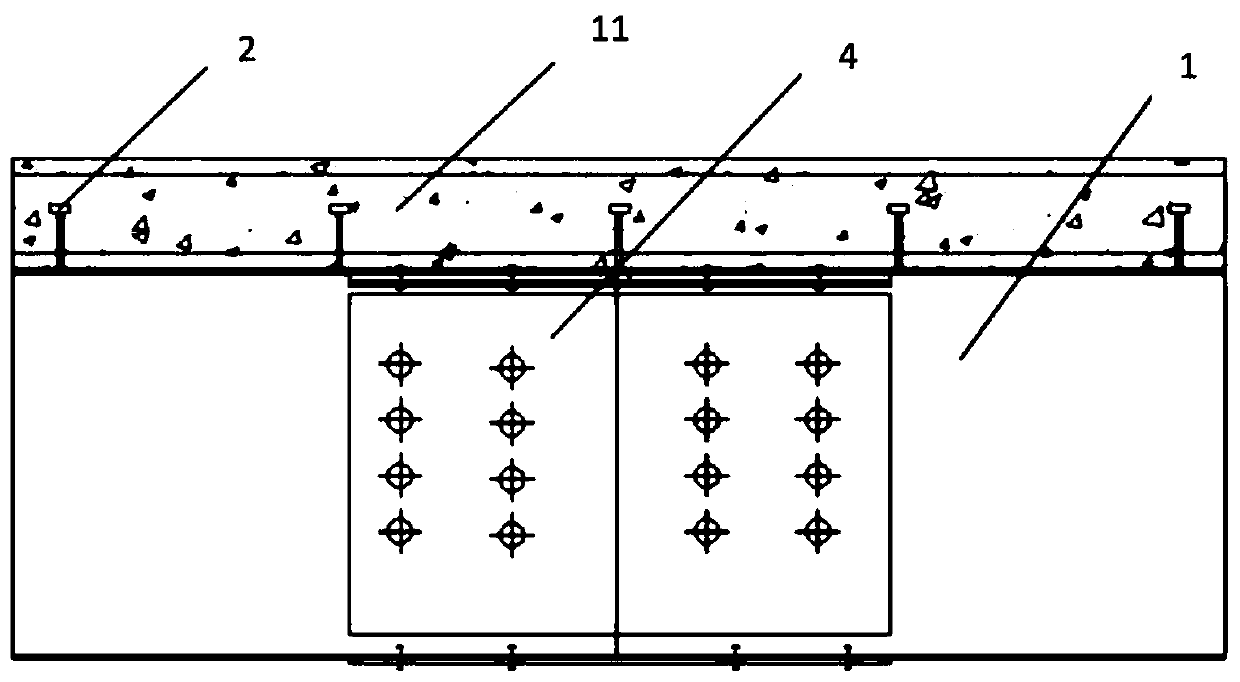

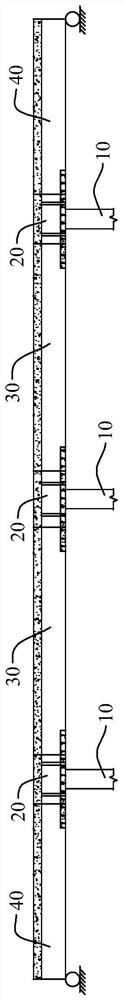

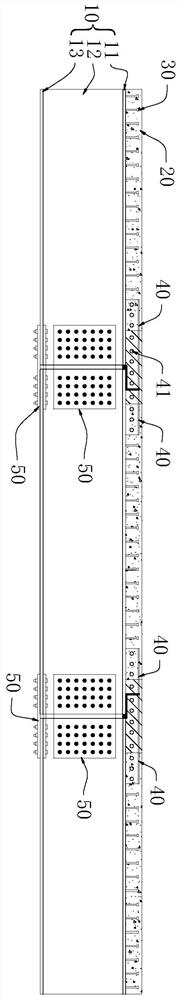

Fabricated steel-concrete combined rigid frame bridge and construction method thereof

PendingCN112458877AReduce steel consumptionReduce building heightBridge structural detailsBridge erection/assemblyArchitectural engineeringRebar

The invention discloses a fabricated steel-concrete combined rigid frame bridge and a construction method thereof. The fabricated steel-concrete combined rigid frame bridge comprises a plurality of prefabricated main beam sections, pier columns, prefabricated cross beams, longitudinal connecting sections and transverse connecting sections, and the prefabricated cross beams are arranged above the pier columns and are provided with slotted holes; exposed steel bars are arranged above the pier columns and are inserted into the slotted holes, and high-strength concrete grout is poured into the slotted holes to achieve connection of the prefabricated cross beams and the pier columns; and the prefabricated cross beams are connected with the prefabricated middle beam sections and the prefabricated end sections through bolting and welding, the prefabricated steel-concrete combined rigid frame bridge is convenient to prefabricate, transport and construct, the structural advantages of the steel-concrete combined beam can be brought into full play, and industrial production, segmented transportation and prefabricated construction can be achieved.

Owner:GUANGZHOU MUNICIPAL ENG DESIGN & RES INST CO LTD

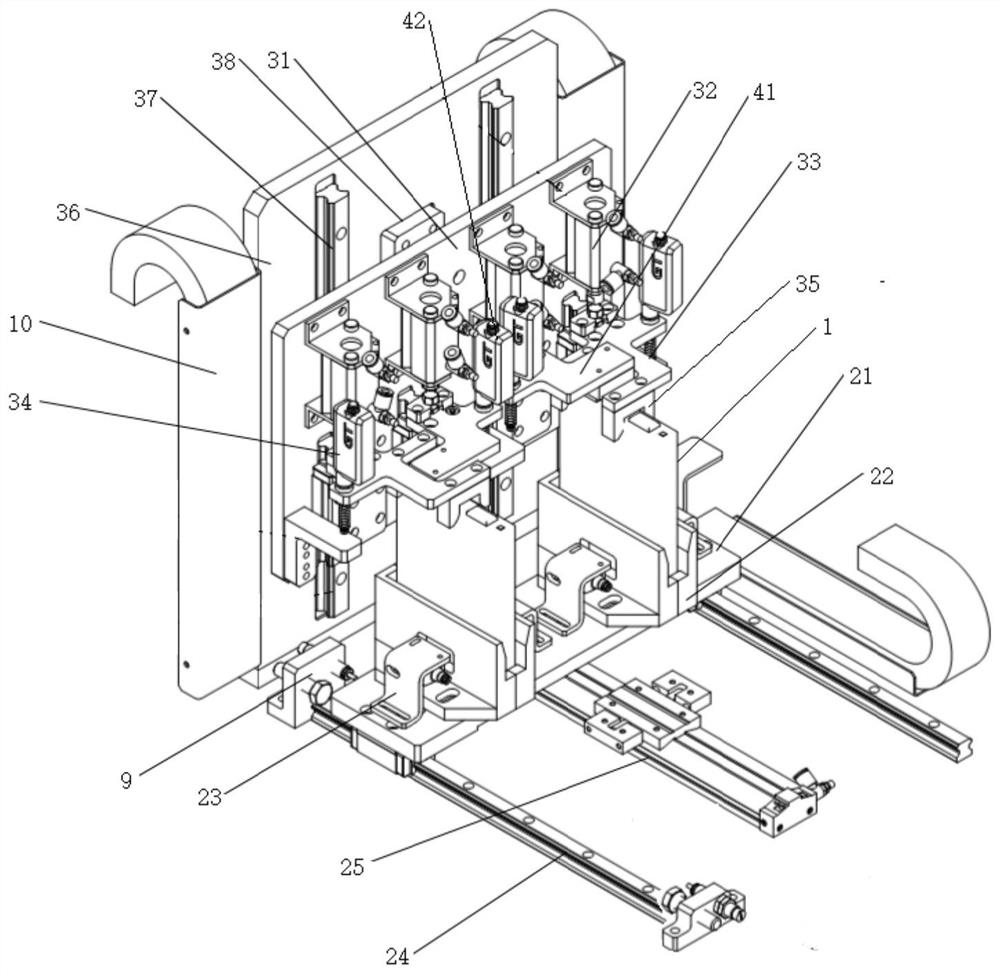

Battery cell height measuring device

PendingCN112857237AAvoid Weld Quality IssuesImprove efficiencyUsing optical meansReal time displayElectrical and Electronics engineering

The invention discloses a battery cell height measuring device. The device comprises a battery cell fixing mechanism used for fixing a battery cell, a pole detection mechanism used for detecting the height from the pole face of the battery cell to the bottom of the battery cell and a cover plate detection mechanism used for detecting the height from the cover plate face of the battery cell to the bottom of the battery cell, one end of the battery cell is fixed to the battery cell fixing mechanism, and the other end of the battery cell is propped against the pole detection mechanism and the cover plate detection mechanism. The battery cell height measuring device can automatically measure the height from the pole face of the battery cell to the bottom of the battery cell, and the measured value can be displayed on a display screen in real time; meanwhile, the height from the cover plate surface of the battery cell to the bottom of the battery cell is automatically measured, the measured value is displayed in real time, and the problems that the welding quality of a PACK module is poor due to height inconsistency and the module is not firmly bonded with glue of a battery shell are solved.

Owner:HEFEI GUOXUAN HIGH TECH POWER ENERGY

Transition joint for connection of thin-walled lining steel pipeline and blind plate

The invention discloses a transition joint for connection of a thin-walled lining steel pipeline. The transition joint comprises a first pipe part, a second pipe part and a third pipe part, wherein the first pipe part, the second pipe part and the third pipe part are sequentially welded. The first pipe part is welded and fixed to the pipeline. The third pipe part is fixed to a blind plate. The inner diameters of the first pipe part, the second pipe part and the third pipe part are all the same as the inner diameter of the pipeline. The wall thicknesses of the first pipe part, the second pipe part and the third pipe part are sequentially increased, a step structure is formed, the wall thickness of the first pipe part is larger than that of the pipeline, and the outer diameter of the third pipe part is smaller than that of the blind plate. Compared with the prior art, the transition joint for connection of the thin-walled lining steel pipeline and the blind plate has the following beneficial effects that by means of the transition joint, the weld joint quality problem generated due to the fact that an existing thin-walled steel lining pipe and the blind plate are directly welded is solved, the problem that the medium running pressure cannot be borne is solved, the welded junction quality is ensured, meanwhile, the welded junction stress is uniform, and therefore the pipeline can bear the medium running pressure.

Owner:TIANJIN PIPELINE ENG GROUP

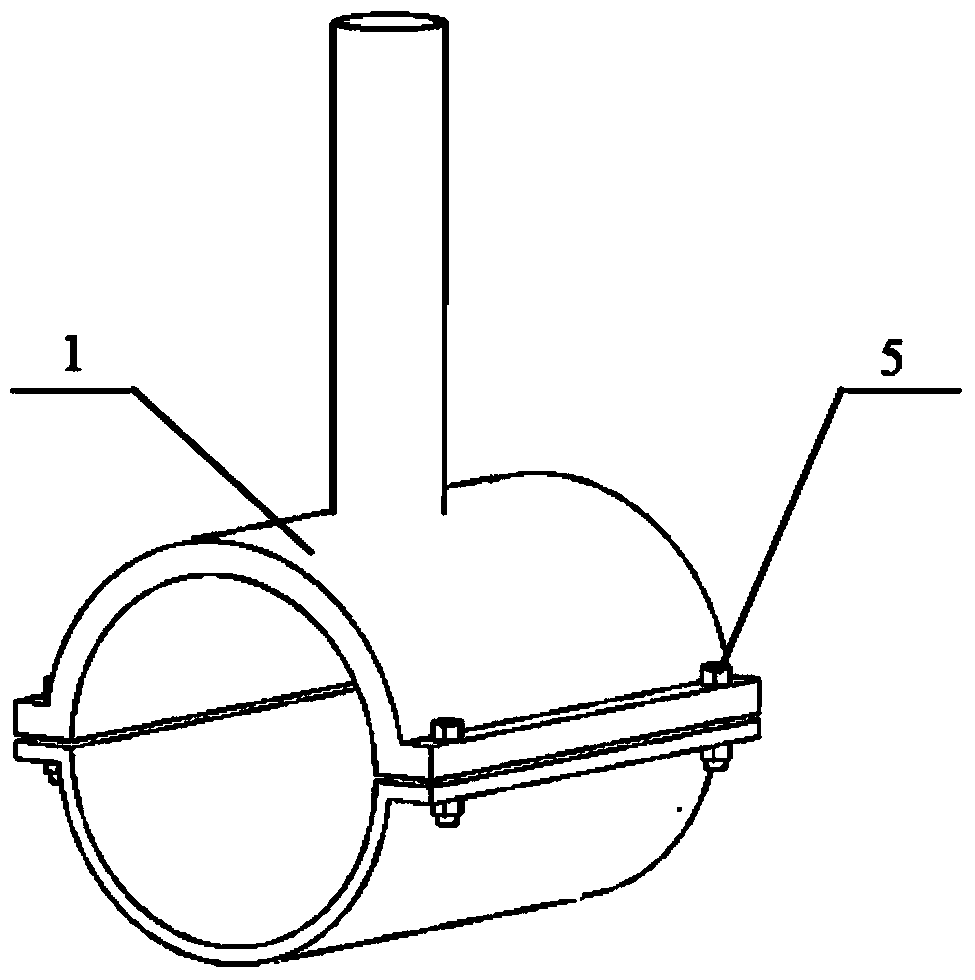

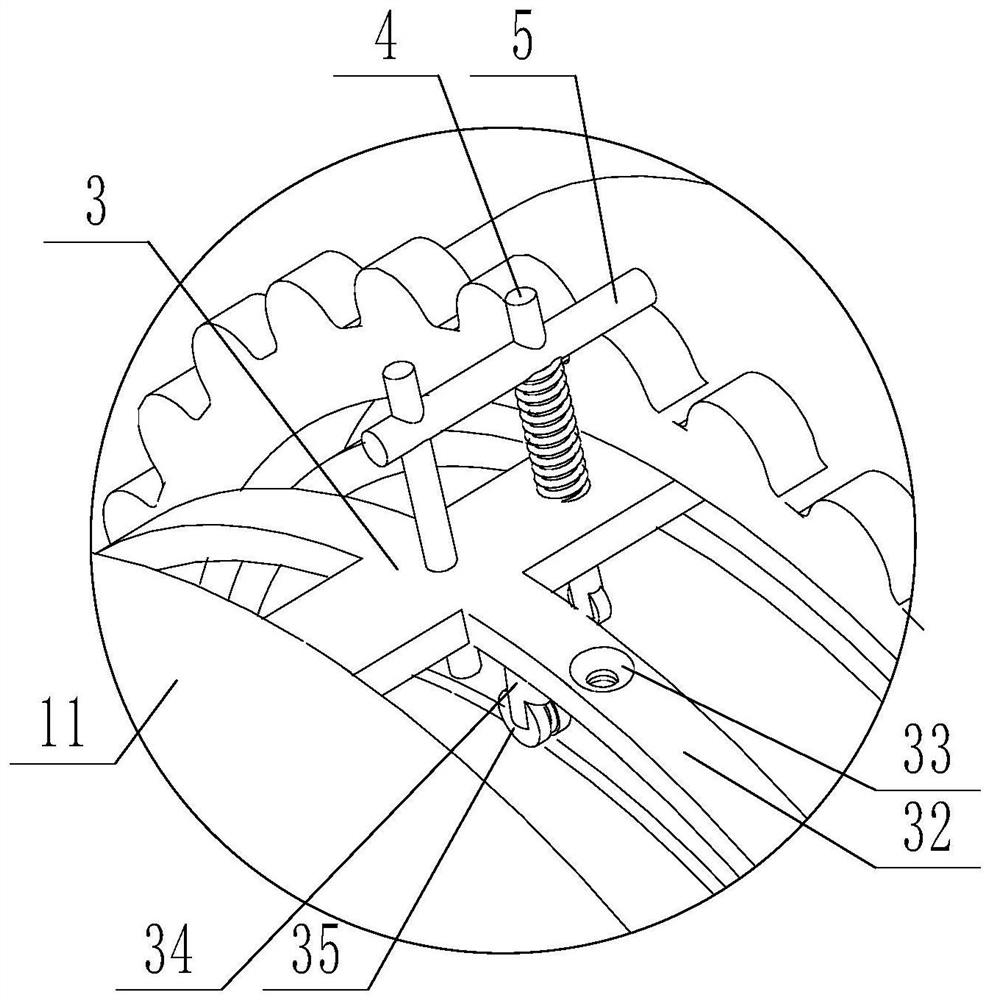

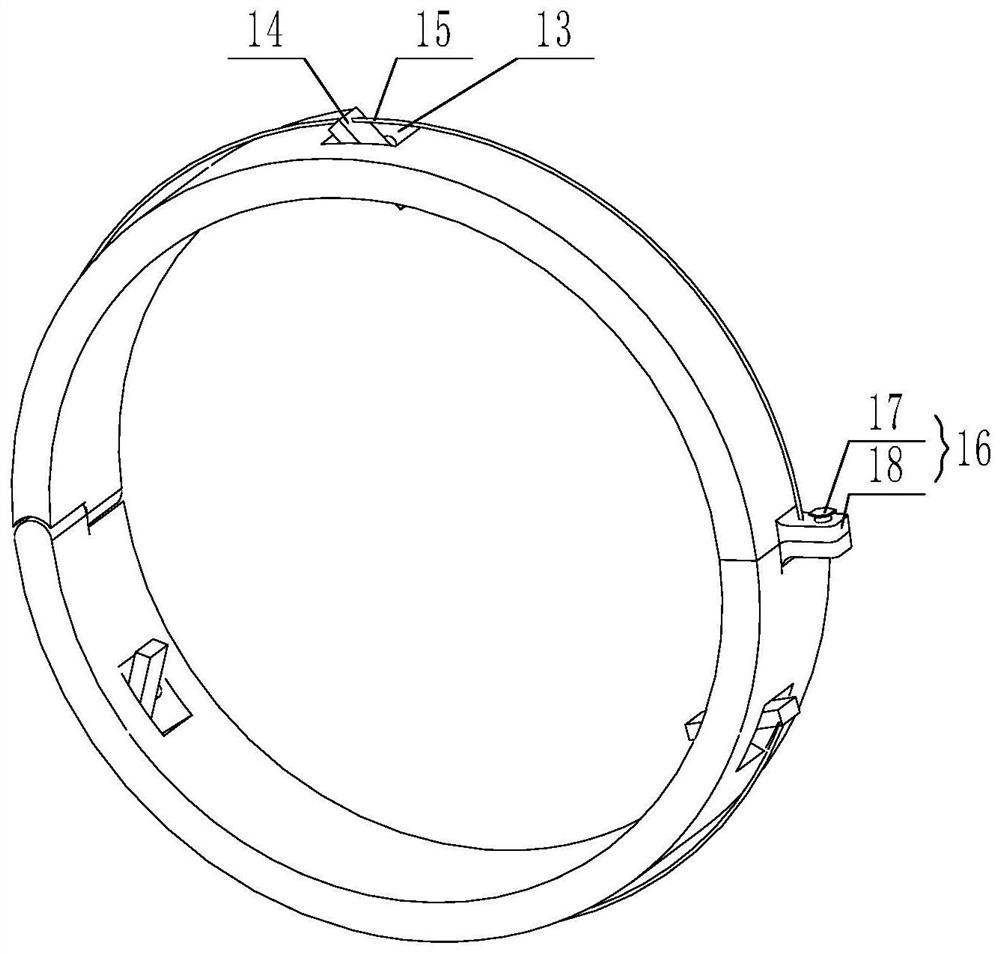

Connection Fixing Method and Strip Clamp for Saddle-shaped Pipe Fittings by Electric Fusion Welding

InactiveCN104385569BReduce scrap rateAvoid Weld Quality IssuesTubular articlesBand shapePipe fitting

The invention relates to a plastic pipe welding technology, and aims at providing a connection fixing method during electrofusion welding of a saddle-shaped pipe fitting and a band-shaped clamp thereof. The connection fixing method during electrofusion welding of the saddle-shaped pipe fitting comprises the steps: putting the saddle-shaped pipe fitting on a main pipe, getting at least two band-shaped clamps and respectively installing at two sides of the a branch pipe of the saddle-shaped pipe fitting, and after welding is finished, dismounting the band-shaped clamps. One joint at one end of the main body of the band-shaped clamp is provided with a strip-shaped groove, the one joint at the other end is provided with a clamping mechanism and a spring, and the position of the clamping mechanism is provided with a pressure sensor and a minisize electronic display which are in mutual connection. By increasing the extra clamps for further clamping, the stable maintenance of the pressure of a fusion zone in the welding process of the saddle-shaped pipe fitting is fully guaranteed, the welding quality problem caused by insufficiency of the fusion-zone pressure under conventional welding conditions is solved, the rejection rate of the saddle-shaped pipe fitting product is reduced, and the economic benefit is improved.

Owner:ZHEJIANG UNIV +1

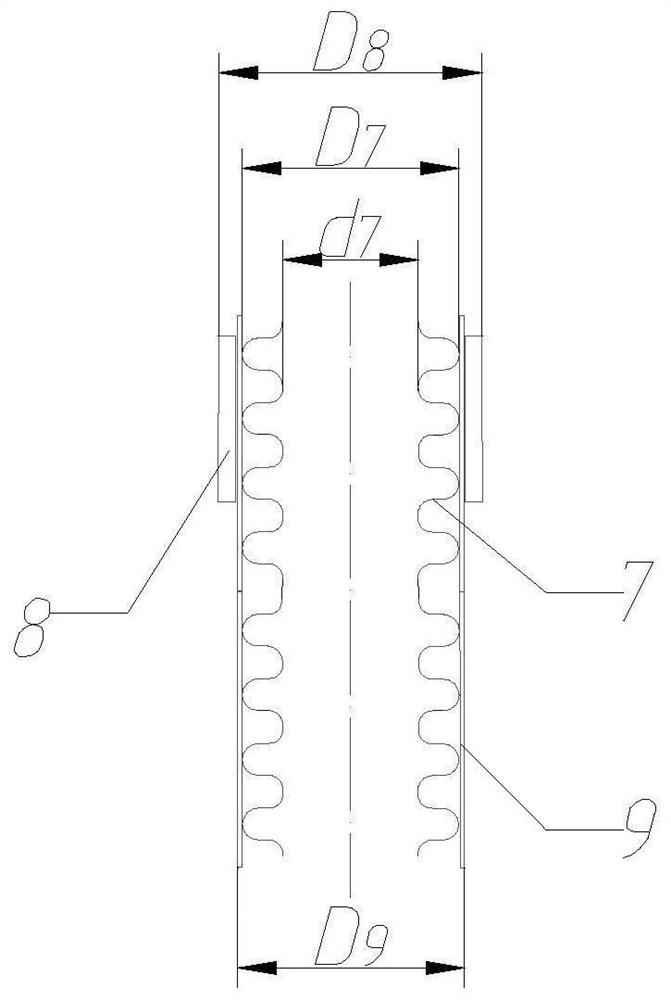

A corrugated metal hose net sleeve compression ring locking device and method

ActiveCN112388196BEnsure Assembly ConsistencyHigh strengthWelding/cutting auxillary devicesAuxillary welding devicesEngineeringMetal hose

A corrugated metal hose net sleeve compression ring locking device and method, including a mold handle, the mold handle is fixedly connected to the upper mold frame, the upper mold frame is fixedly connected to the upper mold through the first guide column, and the upper mold frame is connected to the upper mold There is a first elastic element between them, and the outer side of the upper mold frame is fixedly connected with the upper end of the wedge; the lower slope of the wedge is matched with the outer slope of the slider, and the inner side of the slider is fixedly connected with the replaceable lower mold of the split mold, and the slider and the lower There is a fixed limit plate on the top of the mold, and the outer side of the limit plate cooperates with the inner side of the wedge; the slider is placed on the radial guide positioning device, and the outer side of the radial guide positioning device cooperates or is fixedly connected with the inner side of the baffle; the upper part of the inner side of the baffle and The outer side of the lower end of the wedge is matched, the second elastic element and the end cover are arranged on the outer side of the baffle in turn, and the second guide post passes through the end cover and the baffle to be fixedly connected with the slider; the existing end faces of the three parts are changed by adjustable plastic deformation , Obtain enough plastic deformation to make these three parts fit closely, ensure the assembly consistency of the bellows, net sleeve, and net sleeve compression ring, and achieve the effect of the head.

Owner:XI AN JIAOTONG UNIV

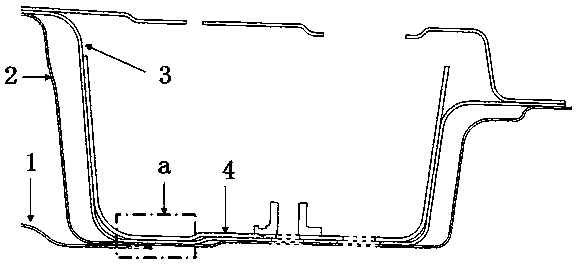

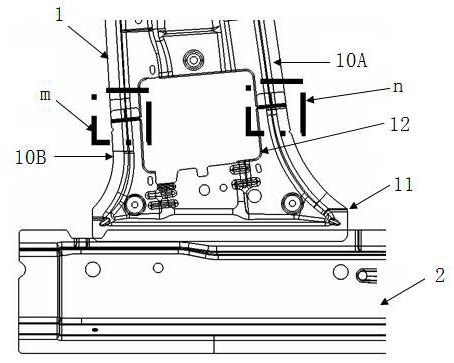

A segmented b-pillar inner panel structure and its welding method

ActiveCN107792195BSolve structural problems that cannot be achieved by spot weldingAvoid Weld Quality IssuesSuperstructure subunitsSuperstructure connectionsSpot weldingBoard structure

The invention provides a sectional type B column inner plate structure. The structural problem that in a traditional structural design, spot welding cannot be achieved in the welding process of an integral type B column inner plate and a threshold inner plate can be solved. The sectional type B column inner plate structure comprises a B column inner plate body, the bottom of the B column inner plate body is an overlap edge used for being connected with the threshold inner plate, a safety belt emergency locking retractor via hole is formed in the position, close to the overlap edge, of the lower end of the B column inner plate body, the critical point lies in the fact that the B column inner plate body is disconnected on the two sides of the safety belt emergency locking retractor via holeto form a sectional structure including a B column inner plate body upper section and a B column inner plate body lower section, and the B column inner plate body upper section and the B column innerplate body lower section are connected in a spot-welded mode through an overlap edge structure.

Owner:CHERY AUTOMOBILE CO LTD

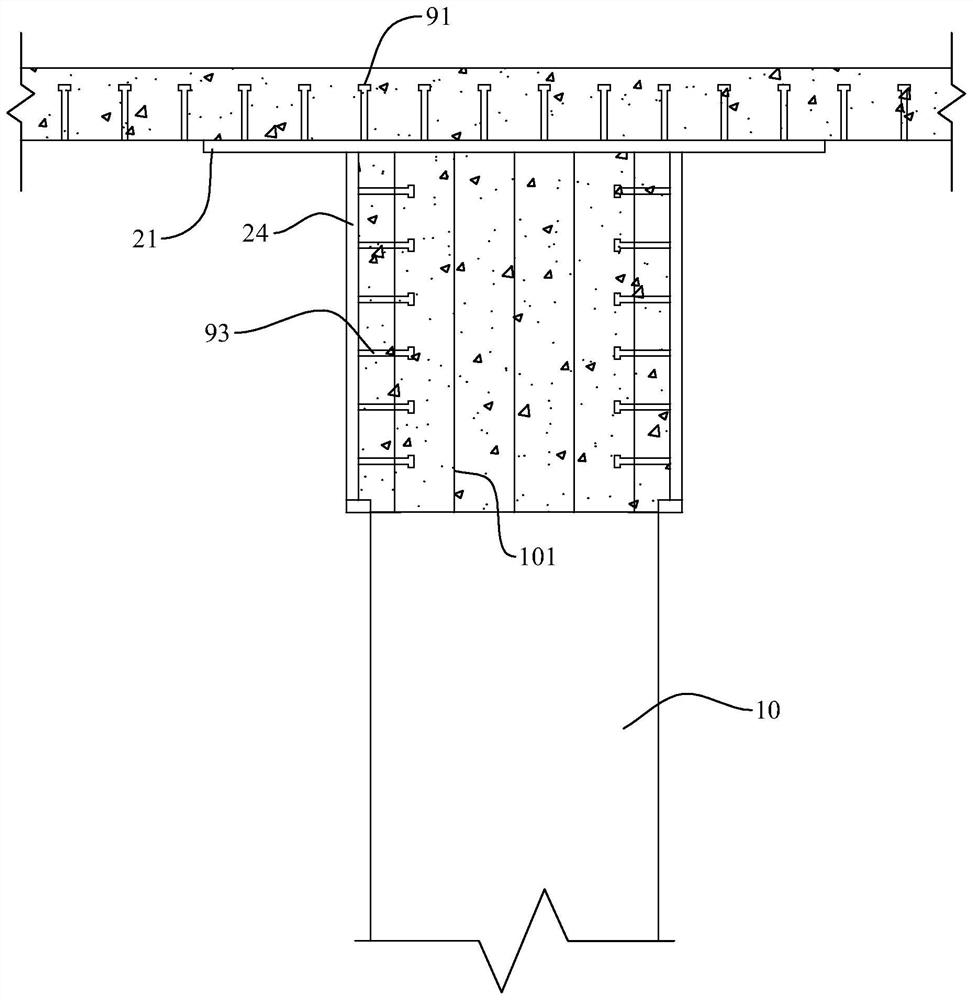

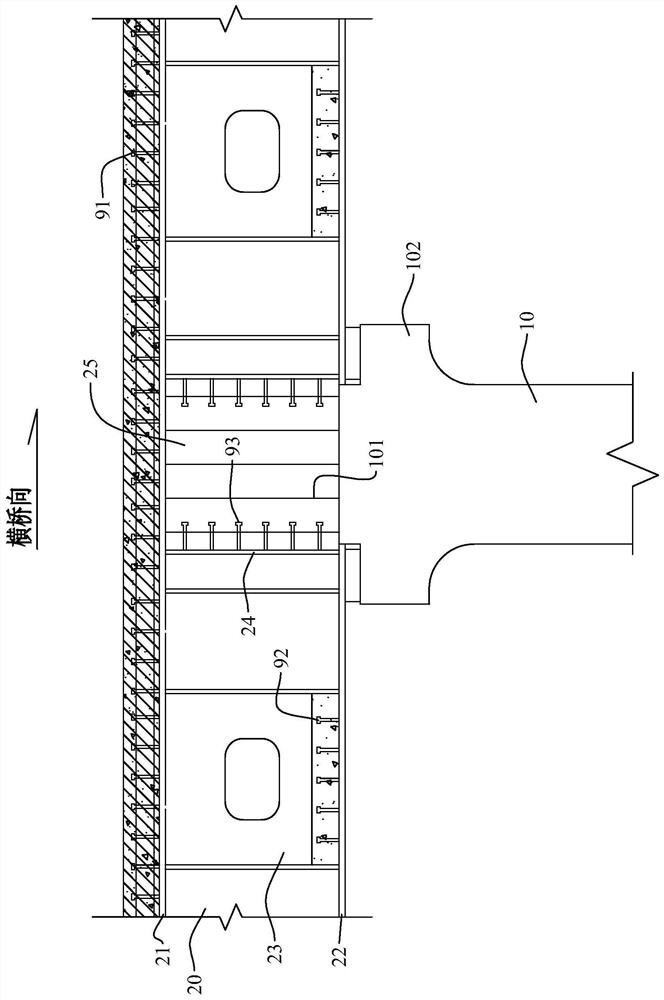

Bolting-welding mixed-connection segmented prefabricated assembly type composite beam and construction method thereof

PendingCN112458879AGive full play to structural advantagesIncrease spanBridge structural detailsBridge erection/assemblyButt weldingButt joint

The invention discloses a bolting-welding mixed-connection segmented prefabricated assembly type composite beam and a construction method thereof. The composite beam comprises prefabricated main beamsegments, the adjacent prefabricated main beam segments are connected through longitudinal connecting segments to form main beam structures, and the adjacent main beam structures are connected throughtransverse connecting segments to form a bridge span structure; each prefabricated main beam segment comprises a steel beam, a concrete slab and a shear connector, and each steel beam comprises a topplate, a bottom plate and a web; and adjacent top plates are welded in a butt joint mode, adjacent bottom plates and webs are connected in a fastened mode through bolts after being welded in a butt joint mode, longitudinal connecting steel components are arranged on the top plates, and adjacent longitudinal connecting steel components are welded in a butt joint mode. The longitudinal connecting steel components are provided with round holes, first reinforcing steel bars penetrate into the round holes, second reinforcing steel bars extend out of the periphery of the concrete slabs, and longitudinal connecting segment wet joints are cast in situ between the first reinforcing steel bars and the second reinforcing steel bars; and transverse connecting segment wet joints are cast in place between the adjacent concrete slabs; the segmental prefabricated reinforced concrete composite beam is convenient to transport and hoist; and bolt welding mixed connection is adopted, overhead welding ofthe bottom plate is avoided, and construction is convenient.

Owner:GUANGZHOU MUNICIPAL ENG DESIGN & RES INST CO LTD

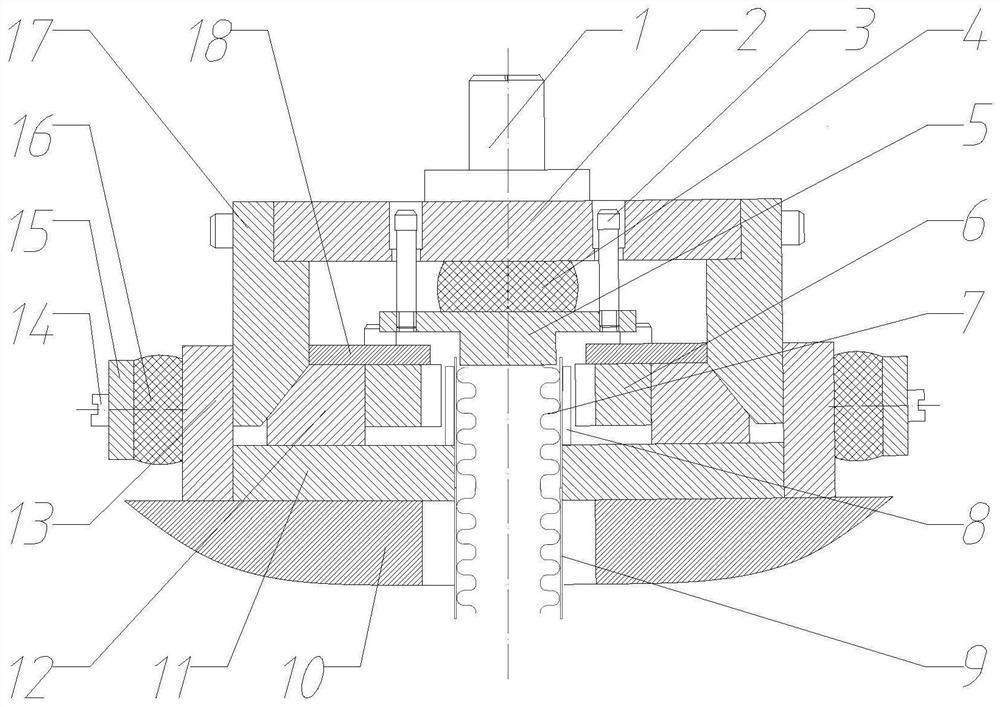

Ultrasonic metal welding tool head

PendingCN113059261AUniform pressurePrecision weldingNon-electric welding apparatusUltrasound energyMaterials science

The invention discloses an ultrasonic metal welding tool head. The ultrasonic metal welding tool head comprises a welding piece and an external fixing piece. One end of the welding piece is connected with one end of the external fixing piece. The other end of the external fixing piece is provided with an external fixing face so that the ultrasonic metal welding tool head can be fixed to a movement assembly. The movement assembly is used for providing pressure. The other end of the welding piece is provided with a welding face used for welding. When the ultrasonic metal welding tool head is used for welding, the welding piece is located under the external fixing piece, the movement assembly applies pressure to the external fixing piece so that a molten welding object can be solidified and formed, and welding is achieved. The ultrasonic metal welding tool head has the beneficial effect that the welding quality problem caused by uneven stress of the welding face of the welding object and uneven ultrasonic energy is solved.

Owner:KEPU ULTRASONIC ELECTRONICS TECHCAL

Corrugated metal hose net cover pressing ring locking device and method

ActiveCN112388196AEnsure Assembly ConsistencyHigh strengthWelding/cutting auxillary devicesAuxillary welding devicesStructural engineeringIndustrial engineering

The invention discloses a corrugated metal hose net cover pressing ring locking device and method. The corrugated metal hose net cover pressing ring locking device comprises a die handle which is fixedly connected to an upper die frame, wherein the upper die frame is fixedly connected to an upper die through a first guide column, a first elastic element is arranged between the upper die frame andthe upper die, and the outer side of the upper die frame is fixedly connected to the upper end of a taper wedge; the lower end slope of the taper wedge is matched with the outer side slope of the slide block, the inner side of the slide block is fixedly connected to a replaceable split die lower die, a limiting plate is fixedly connected above the slide block and the lower die, and the outer sideof the limiting plate is matched with the inner side of the taper wedge; the slide block is placed on a radial guide positioning device, and the outer side of the radial guide positioning device is matched with or fixedly connected to the inner side of a baffle plate; the upper portion of the inner side of the baffle plate is matched with the outer side of the lower end of the taper wedge, and a second elastic element and an end cover are sequentially arranged on the outer side of the baffle plate; a second guide column passes through the end cover and the baffle plate, and is fixedly connected to the slide block; existing end face shapes of the three parts can be changed by regulating and controlling plastic deformation, so that enough plastic deformation is obtained; the three parts aretightly attached, so that assembling consistency of the corrugated tube, the net cover and the net cover pressing ring is guaranteed, and the end sealing effect is achieved.

Owner:XI AN JIAOTONG UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com