Solder ring for magnetron cathode assembly, method for producing solder ring for magnetron cathode assembly and molybdenum end cap connecting with solder ring

A magnetron cathode and manufacturing method technology, applied in the field of powder metallurgy manufacturing, can solve problems such as poor uniformity, affecting the welding quality of molybdenum end caps and magnetron coils, achieve high yield, solve welding quality problems, and reduce production costs Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

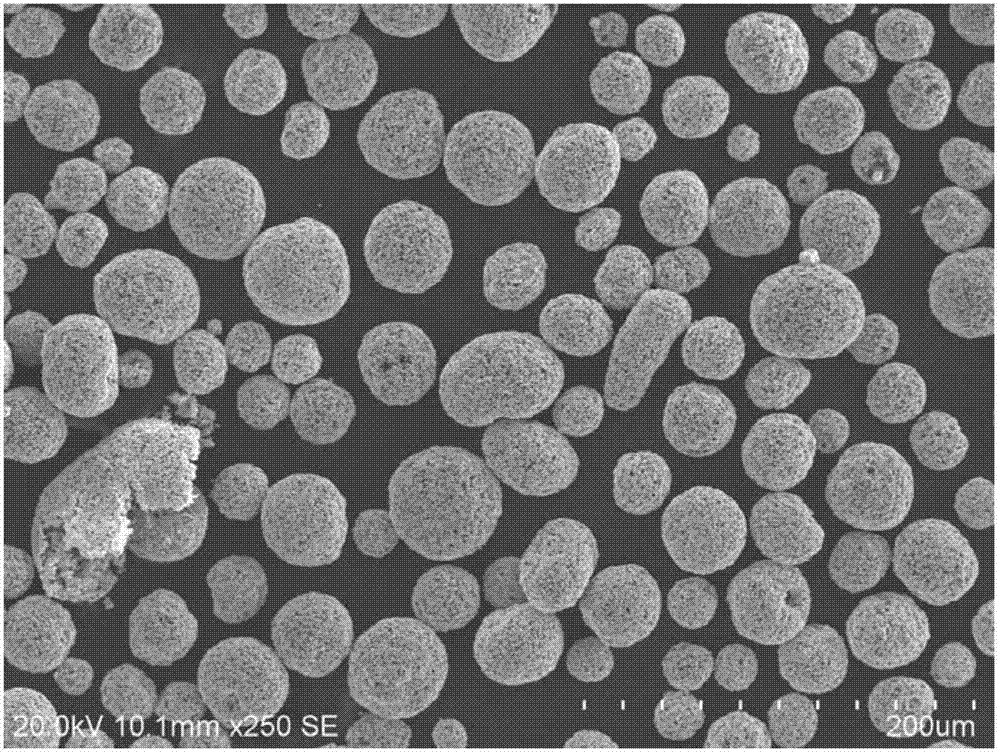

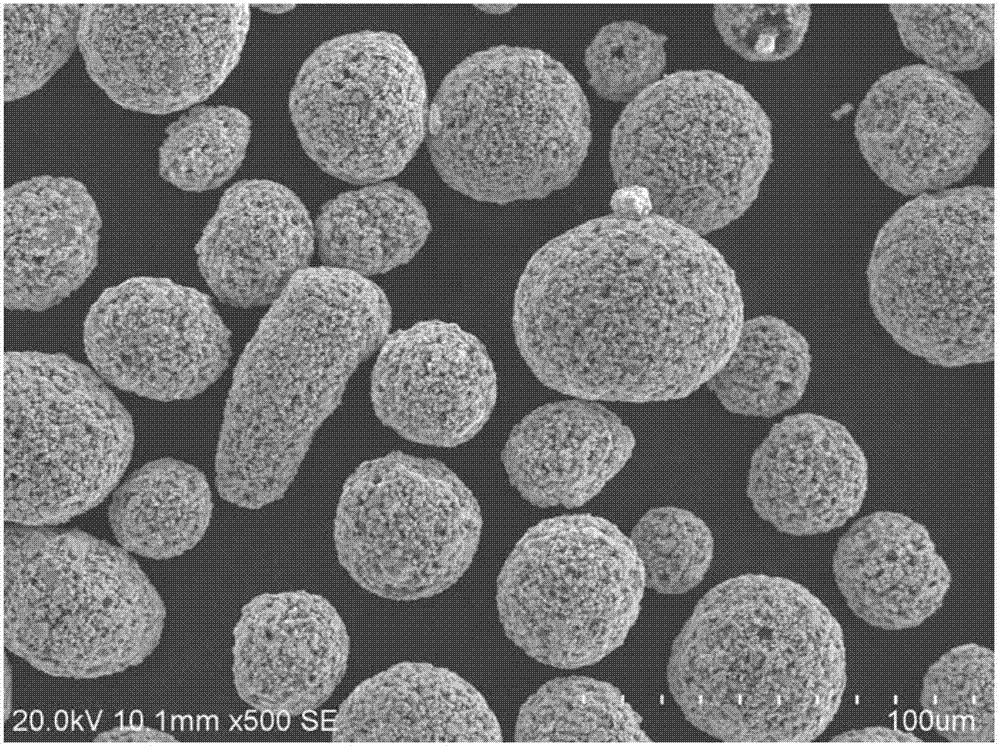

[0037] (1) Weigh polyvinyl alcohol and polyethylene glycol in a weight ratio of 5:1, add distilled water, stir and dissolve to obtain a forming agent system, and the concentration of the forming agent system is 0.02~0.1g / mL; according to 10:60:10 Weigh ruthenium powder, molybdenum powder and nickel powder in a weight ratio to obtain a metal powder system and pour it into a ball mill jar, add grinding balls and the above-mentioned forming agent system, and carry out wet ball milling for 20 hours to obtain a slurry, wherein the grinding balls and metal The weight ratio of the powder system is 3:1, and the weight ratio of the metal powder system and the forming agent system is 7:1; the slurry is transported to a centrifugal atomizing disc for atomization, drying and granulation to obtain granulated powder, which is The scanning electron microscope image of the granulated powder is as follows figure 1 and figure 2 The above-mentioned granulated powder is respectively sieved thro...

Embodiment 2

[0041] (1) Weigh polyvinyl alcohol and polyethylene glycol in a weight ratio of 10:1, add distilled water, stir and dissolve to obtain a forming agent system solution, and the concentration of the forming agent system solution is 0.02~0.1g / mL; according to 30:40 Weigh ruthenium powder, molybdenum powder and nickel powder in a weight ratio of 40 to obtain a metal powder system and pour it into a ball-milling jar, add a grinding ball and the above-mentioned forming agent system solution, and carry out wet ball milling for 10 hours to obtain a slurry, wherein grinding The weight ratio of the ball to the metal powder system is 6:1, and the weight ratio of the metal powder system to the solution of the forming agent system is 3:1; the slurry is transported to a centrifugal atomizing disc for atomization, drying and granulation to obtain a Granular powder; pass the above-mentioned granulated powder through 80-mesh and 400-mesh sieves respectively to obtain solder powder; put the abov...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com