Welding method of nickel-base alloy steel pipeline

A welding method and alloy steel technology, applied in welding equipment, arc welding equipment, metal processing equipment, etc., can solve the problems of fast cooling speed of weld metal, easy formation of debris in weld seam, poor fluidity of molten pool metal, etc., to achieve Reduce mechanical properties and corrosion resistance, avoid welding temperature discomfort, reliable and clear data

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention is described in further detail below in conjunction with accompanying drawing:

[0029] The purpose of the present invention is to provide a nickel-based alloy steel pipe welding method to solve the problem of poor fluidity of the molten pool metal and easy formation of a refractory oxide film (NiO) on the surface during welding of nickel-based alloy steel, resulting in poor penetration and poor weldability. The seam is easy to form thermal cracks and pores.

[0030] A nickel-based alloy steel pipeline welding method, comprising the following steps:

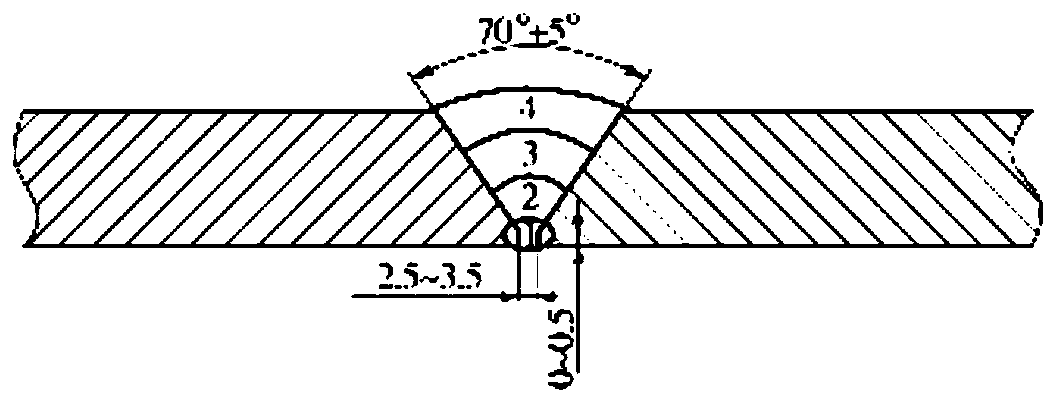

[0031] Step 1. Process the groove of the pipeline to be welded, and obtain the groove angle of the pipeline to be welded at 70° to 75°, such as figure 2 shown;

[0032] Step 2. Grinding and cleaning the groove of the pipeline to be welded and the outer surface of the pipeline to be welded, and positioning and fixing;

[0033] Step 3. Use argon gas to protect the groove of the pipeline to be welded...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com