Simple method for chromizing small-axis parts and special chromizing agent thereof

A technology for chromizing and parts, which is applied to the simple field of chromizing small shaft parts, can solve the problems of high cost of chromizing process, uneven chromizing layer, and high chromizing temperature, avoid coarse grains, simple equipment, and improve the efficiency of chromizing. The effect of wear and corrosion resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

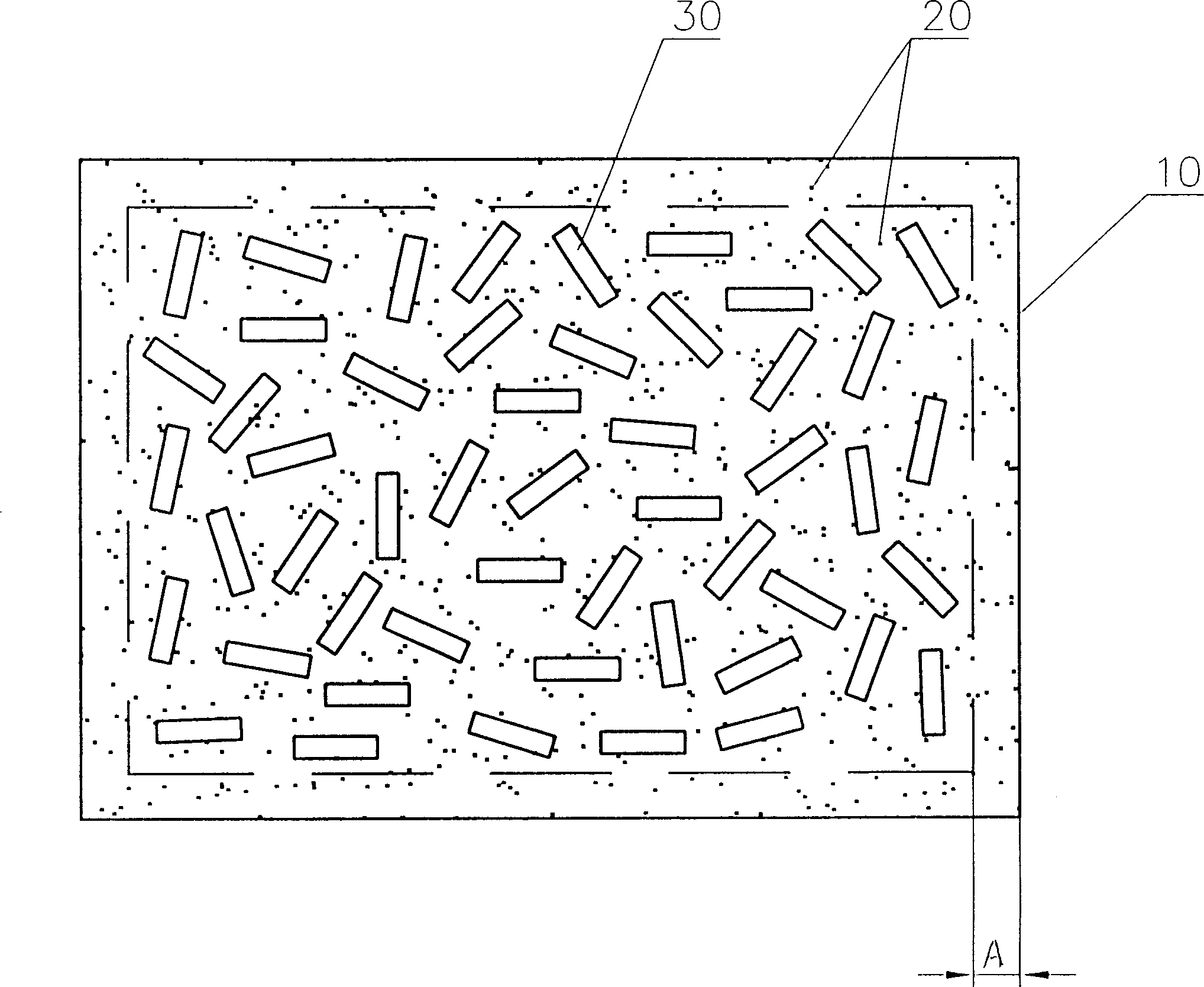

[0023] Chromizing treatment of small shaft parts with a diameter of φ2mm and a length of 9mm, the specific steps and process conditions are as follows:

[0024] (1) Stir the small shaft and the chromizing agent uniformly in a weight ratio of 1:2.75 and then put them into the chromizing tank 10 . (2) Mix the refractory mud with ordinary water glass, adjust it into a semi-thick shape, tightly seal the chromizing tank cover, evenly paste the gaps in the cover, and then put the tightly sealed chromizing tank into a high-temperature box-type resistance furnace, According to the size of the furnace, it can be evenly filled, and 3-5 chromizing tanks can be placed. Close the furnace door, and then seal the furnace door with aluminum silicate. (3) Sectional heating and heat preservation: heat up to 200°C and hold for 1 hour; heat up to 400°C and hold for 2 hours; heat up to 450°C and hold for 1 hour; heat up to 600°C and hold for 1 hour; heat up to 800°C ℃, holding time 1 hour. (4) C...

Embodiment 2

[0026] Carry out chromizing treatment to diameter φ 2.4mm, the small shaft part of length 6.25-11mm, its concrete steps are identical with embodiment 1, difference is:

[0027] The mixing ratio of the small shaft and the chromizing agent in step (1) is 1:2 by weight.

[0028] Chromizing treatment temperature and time in step (4): heating up from 800° C. to 920° C. and keeping the temperature for 11 hours to obtain a chromium carbide layer with a thickness of 7-18 μm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| microhardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com