A kind of steel flat angle welding method for ship hull structure

A technology of structural steel and welding methods, applied in welding equipment, arc welding equipment, manufacturing tools, etc., can solve the problems of low weld strength, unfavorable base metal corrosion protection, etc., to ensure welding quality, reduce ship construction period, eliminate Effect of Welding Stress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] Embodiment 1, comprises the following steps:

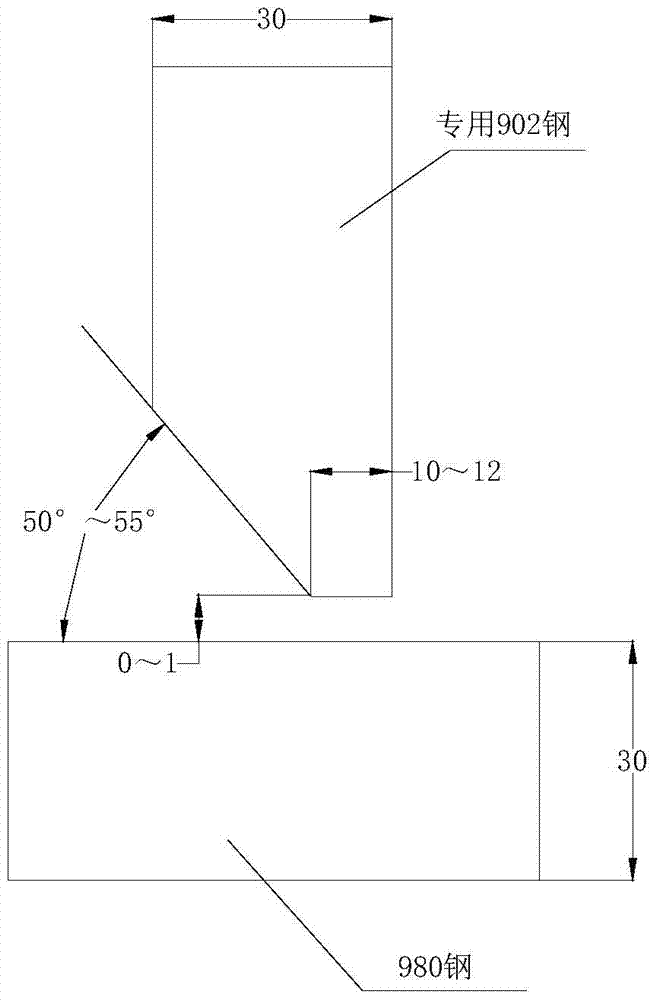

[0028] (1) Groove forming steps: such as figure 1 As shown, a single V-shaped bevel groove is formed on the corner joint of a special 902 steel workpiece with a thickness of 30mm, leaving a root of 10mm, and the angle of the bevel groove relative to the surface of the base part is 55°; The end face should remove water stains, oil stains, rust, hanging slag and other sundries that affect the welding quality;

[0029] (2) Preheating step: Corner joint the workpiece to be welded with the 30mm thick 980 steel base part to form a single V-shaped corner joint groove, the corner joint groove angle is 55°, and the angle joint groove gap is 0mm to 1mm; Then preheat the corner joint groove and the range of 150mm on both sides, and start welding when the preheating temperature reaches 130°C;

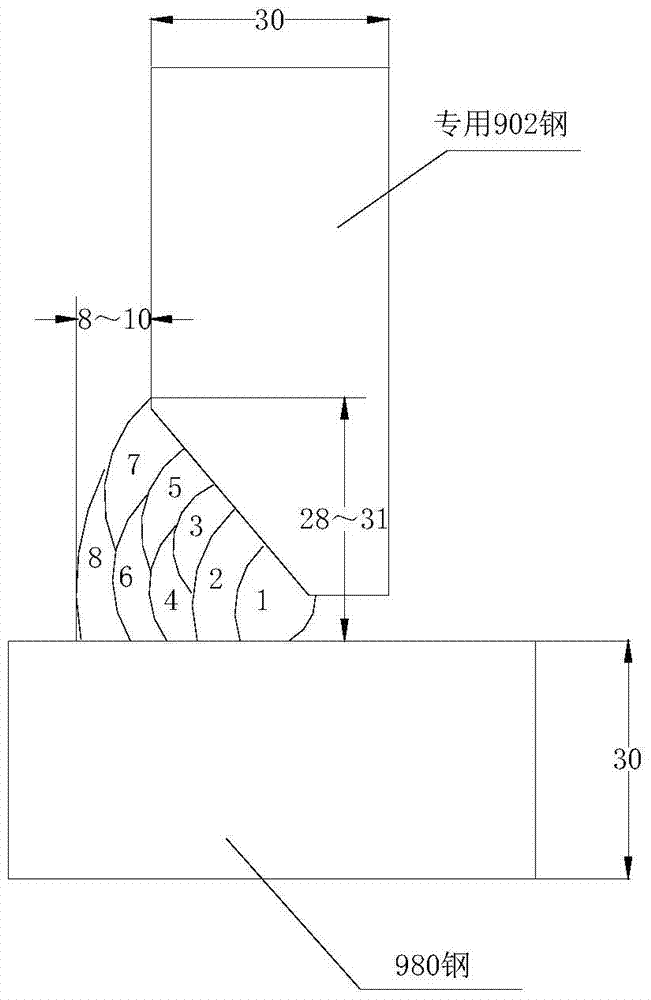

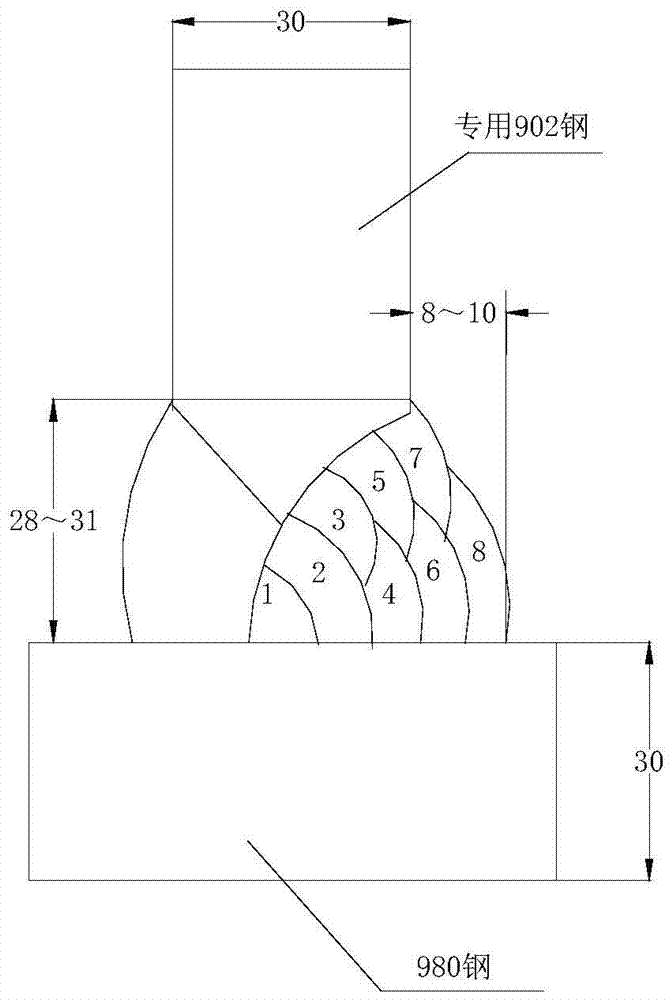

[0030] (3) Front welding step: as shown in Figure 2(A), 5 layers and 8 passes of manual arc welding are used to fill the bevel groove of the ...

Embodiment 2

[0035] Embodiment 2, is exactly the same as the step of embodiment 1, and difference is only in the process parameter in each step:

[0036] In the step of forming the bevel, the root is 12mm, and the bevel angle of the bevel is 50°;

[0037] In the preheating step, the corner joint groove angle is 50°, the corner joint groove gap is 0 mm to 1 mm, and the preheating temperature reaches 100 ° C to start welding;

[0038] In the front welding step, the temperature between passes is controlled at 100°C during welding.

[0039] In the post-welding treatment step of the front side, the heating temperature reaches 250°C, and the heat preservation time is 2 hours;

[0040] In the root cleaning step on the back side, the preheating temperature reaches 100°C;

[0041] In the back welding step, the temperature between the passes is controlled at 100°C during welding;

[0042] In the post-soldering treatment step of the back surface, the heating temperature reaches 250° C. and the tem...

PUM

| Property | Measurement | Unit |

|---|---|---|

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com