Closed runner flat-plate solar heat collector plate core

A flat-panel solar energy and heat collector technology, applied in solar thermal power generation, solar thermal devices, heating devices, etc., can solve problems such as pipeline welding or connection quality problems, complicated installation process, leakage of heat transfer medium, etc., to avoid pipeline The effect of welding or connection quality problems, expanding the scope of application, and reducing the amount of maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The following are the best examples of the plate core of the closed channel flat solar heat collector of the present invention, and do not limit the scope of protection of the present invention.

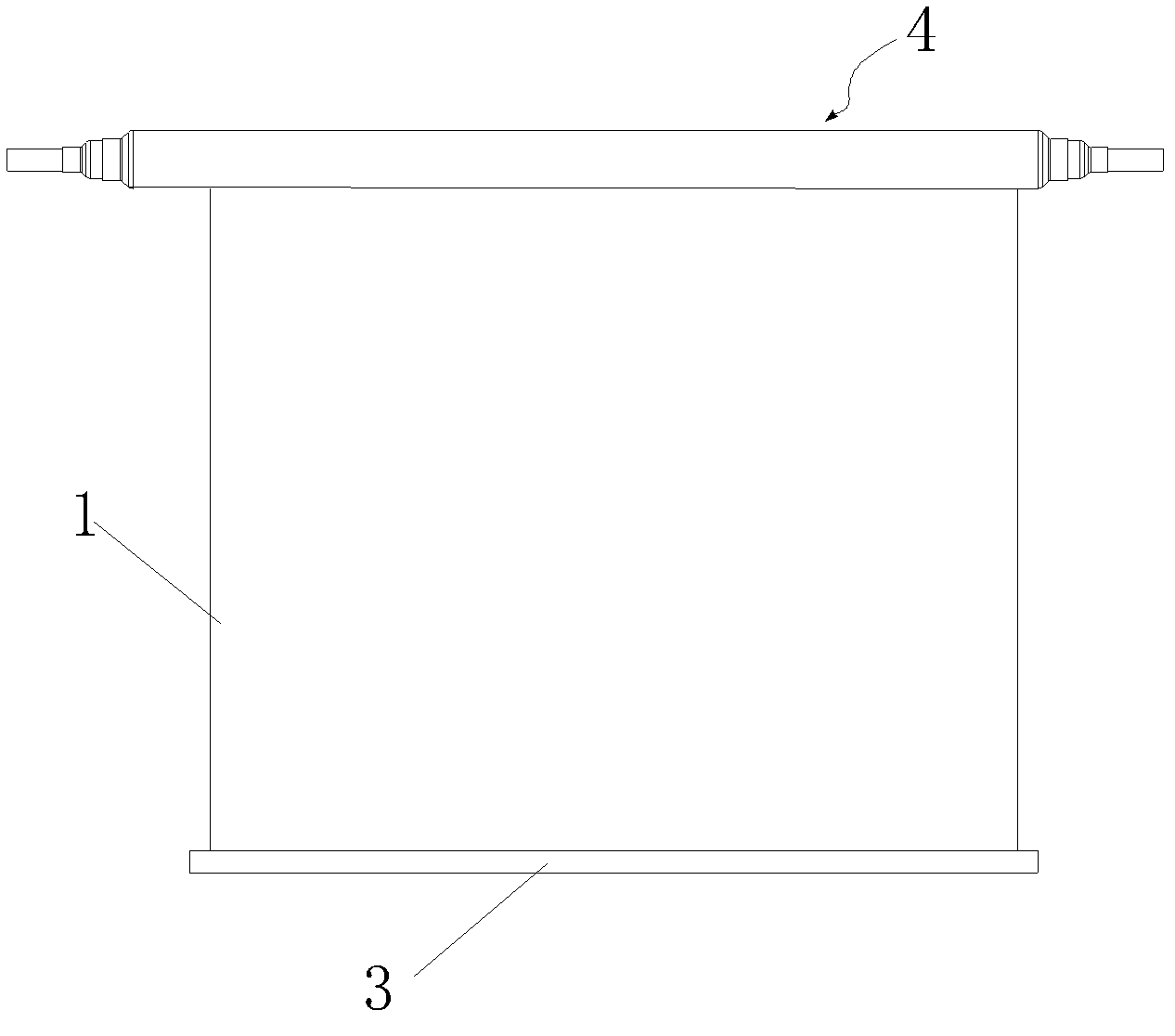

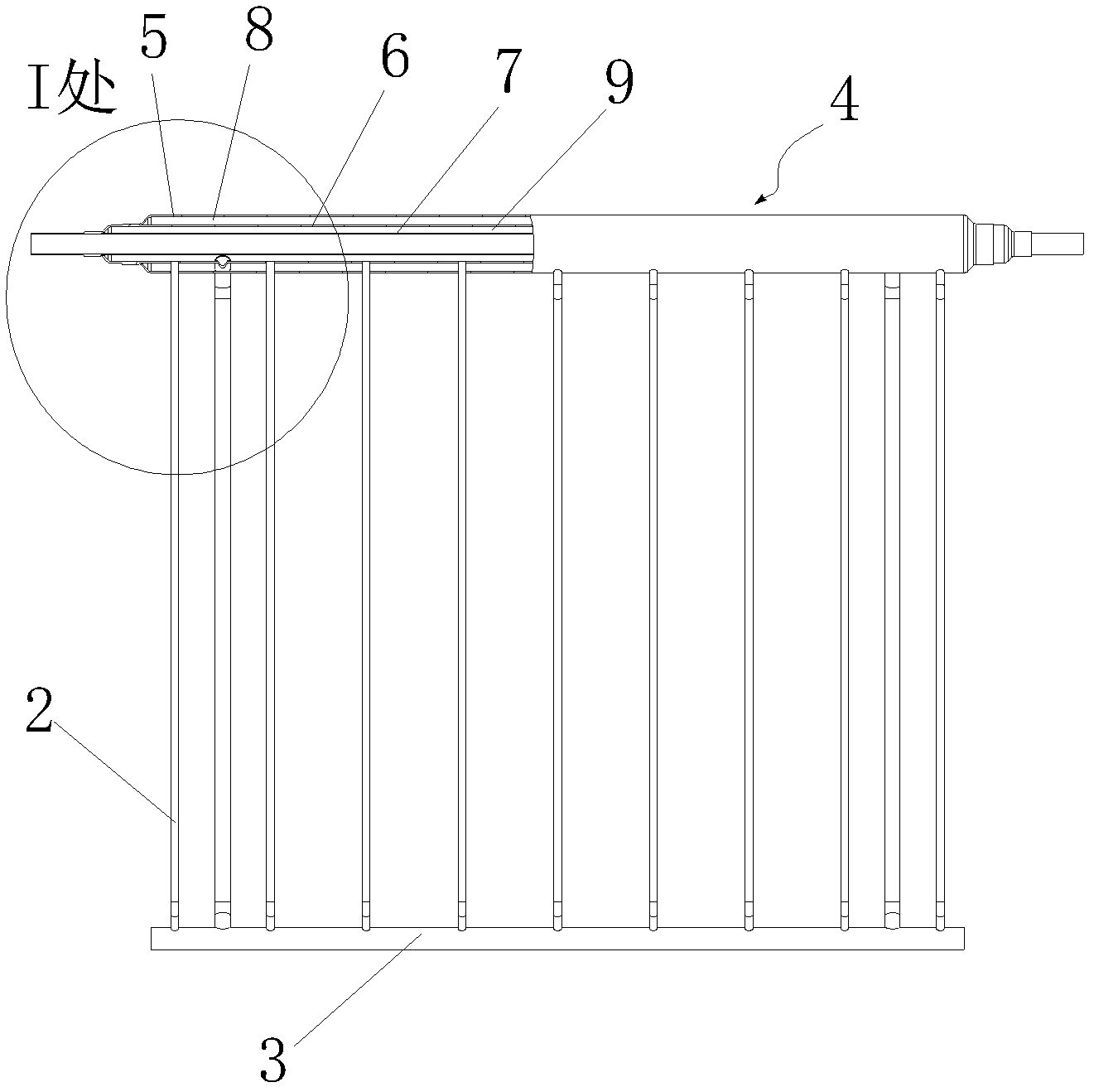

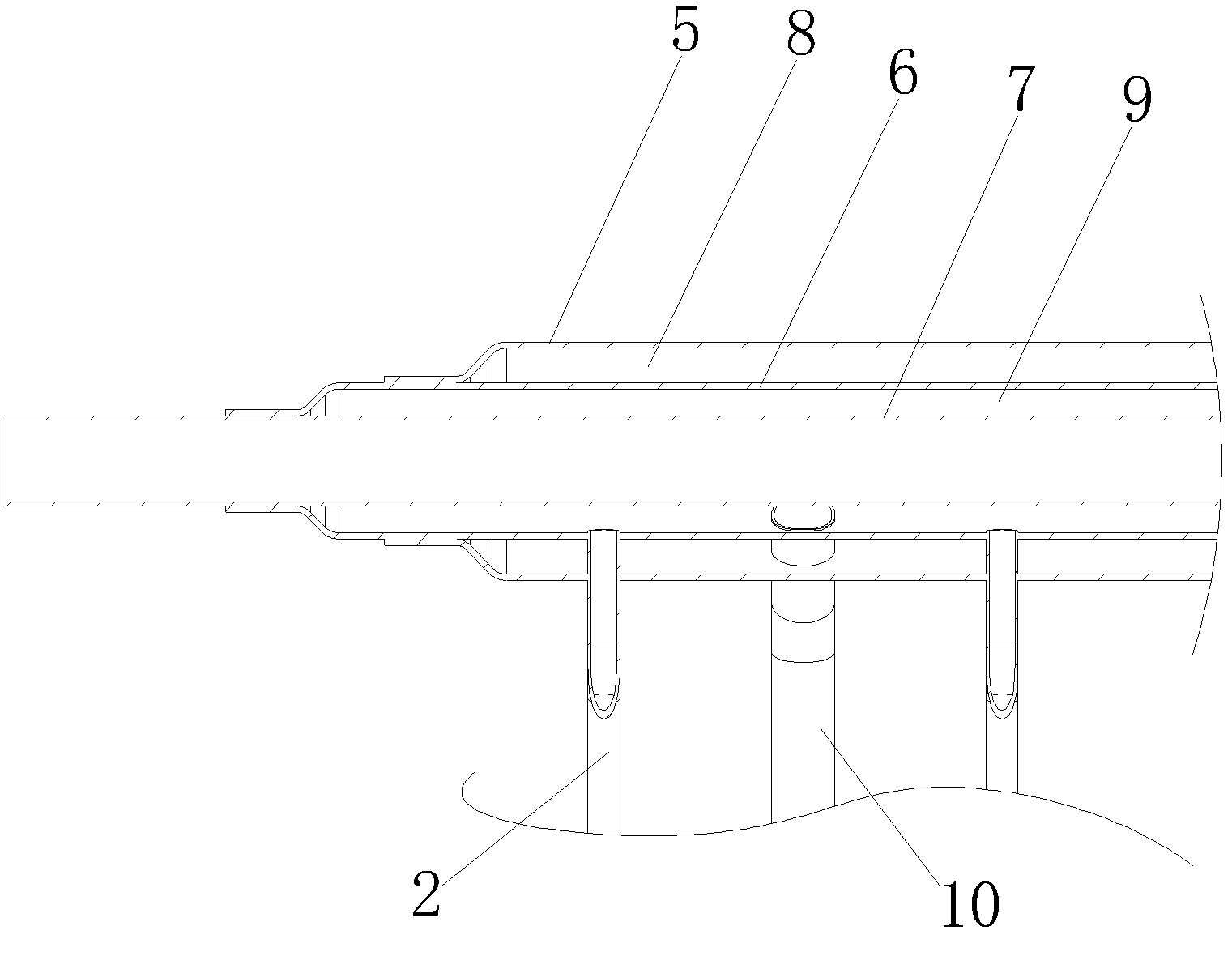

[0013] refer to figure 1 , figure 2 , image 3 , Figure 4 , providing a closed channel flat plate solar collector plate core, including a heat absorbing plate 1, a number of pipes 2 installed on the back of the heat absorbing plate 1, installed at one end of the heat absorbing plate 1 and connected with the several The header pipe 3 connected to one end of the root row pipe 2 also includes a sleeve-type vacuum heat-preservation heat exchange device 4 installed on the other end of the heat-absorbing plate 1. 5. The heat transfer medium sleeve 6 set in the vacuum insulation sleeve 5 and the heated medium straight-through pipe 7 sleeved in the heat transfer medium sleeve 6 are composed of the vacuum insulation sleeve 5 and the heat transfer medium sleeve 6. A vacuum insulat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com