Bolting-welding mixed-connection segmented prefabricated assembly type composite beam and construction method thereof

A segmented prefabrication and assembly technology, which is applied in the direction of erecting/assembling bridges, bridges, bridge parts, etc., can solve the problems of small spans of bridges, improve bridge spans, avoid welding quality problems, and reduce pressure area Increased effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

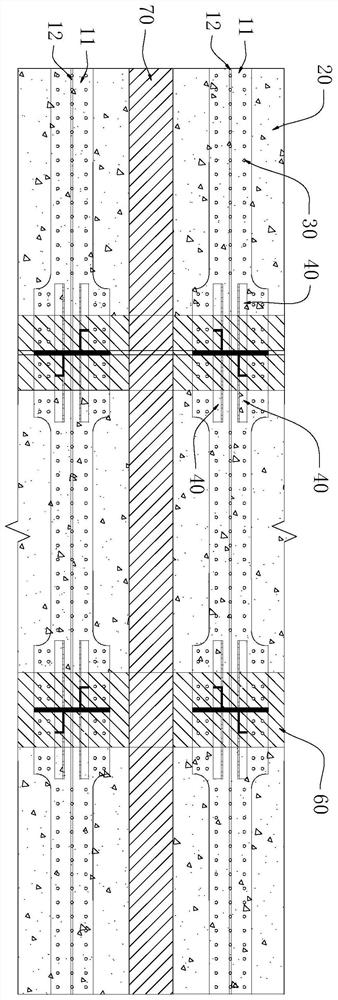

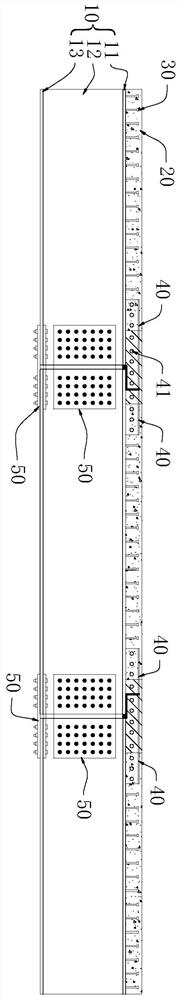

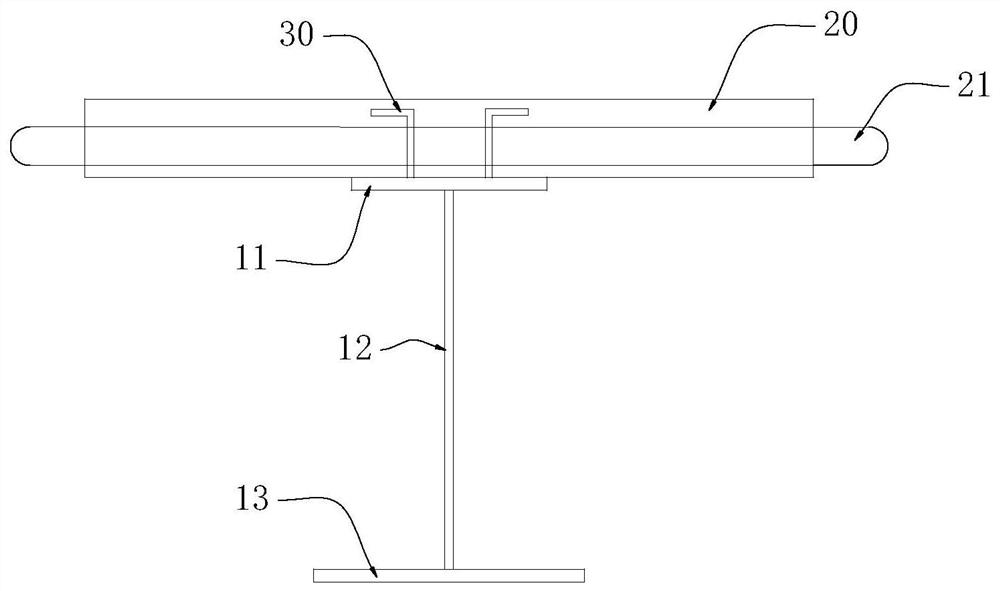

[0032] refer to Figure 1 to Figure 5 , the present invention is a segmented prefabricated composite beam with bolted and welded joints, including several prefabricated main beam sections, longitudinal connecting sections and transverse connecting sections, and adjacent prefabricated main beam sections are connected by longitudinal connecting sections to form a target span The main girder structure, adjacent main girder structures are connected by transverse connecting sections to form a bridge span structure.

[0033] Specifically, the prefabricated main girder segment includes a steel beam 10, a concrete slab 20, and several shear connectors 30, the steel beam 10 includes a top plate 11, a bottom slab 13, and a web 12 connected between the top slab 11 and the bottom slab 13, and the concrete slab 20 is located above the top plate 11, one end of several shear connectors 30 is poured and fixed in the concrete slab 20, and the other end is welded and fixed on the top plate 11. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com