Rod-shaped structure Zn2GeO4 material as well as preparation method and application thereof

A rod-like structure and uniform technology, applied in structural parts, chemical instruments and methods, inorganic chemistry, etc., can solve the problems of low Coulombic efficiency, poor cycle stability, poor rate performance, etc., to achieve improved cycle performance, not easy to reunite, long The effect of diameter ratio

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] The rod-like structure Zn of this example 2 GeO 4 The preparation method of the material, the steps are as follows:

[0035] (1) Slowly add 52 mg (0.5 mmol) of GeO to 10 mL of water 2 , 0.6057g (5mmol) of Tris, and stir evenly until a homogeneous and transparent Ge-Tris solution is formed.

[0036](2) Add 10 mL of diethylenetriamine, 10 mL of water, and 189 mg (1 mmol) of Zn(NO) to the Ge-Tris solution prepared in step (1) under stirring. 3 ) 2 , stir to prepare 50 mL of reaction solution, put the reaction solution into the reaction kettle, place it in a 200 ℃ oven, react for 10 h, naturally cool to room temperature, centrifuge, wash with distilled water, and put the solid obtained from the reaction into 70 ℃ Dry in the oven, that is.

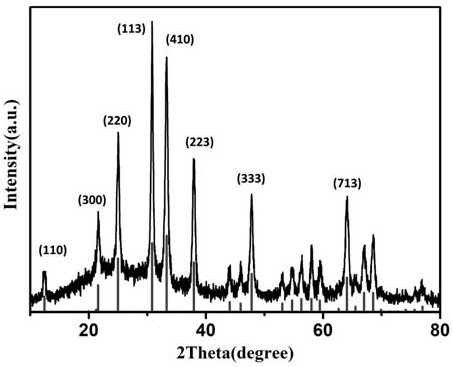

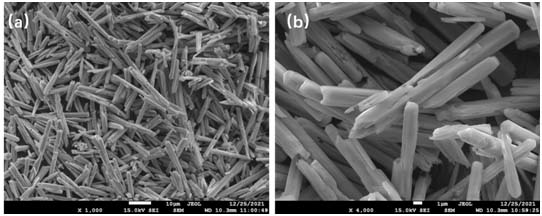

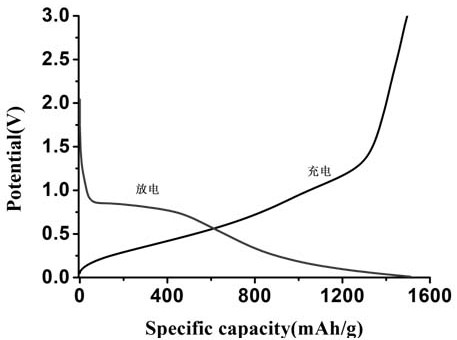

[0037] ①Physical phase test: the rod-shaped Zn prepared in this example 2 GeO 4 The material is tested by XRD, such as figure 1 It can be seen from the figure that in the XRD pattern of Zn 2 GeO 4 The diffraction peaks of all c...

Embodiment 2

[0040] The rod-like structure Zn of this example 2 GeO 4 The preparation method of the material includes the following steps:

[0041] (1) Slowly add 10.5 mg (0.1 mmol) of GeO to 10 mL of water 2 , 0.2423 g (2 mmol) of Tris and stirred until a homogeneous and transparent solution was formed.

[0042] (2) Add 10ml of diethylenetriamine and 10ml of water, 37.8mg (0.2mmol) of Zn(NO) to the solution prepared in step (1) under stirring. 3 ) 2 , stir to prepare 50ml of reaction solution, put the reaction solution into the reaction kettle, place it in a 180°C oven, react for 10h, naturally cool to room temperature, centrifuge, wash with distilled water, and put the solid obtained from the reaction into 70°C Drying in an oven to obtain rod-shaped Zn 2 GeO 4 Material.

Embodiment 3

[0044] The rod-like structure Zn of this example 2 GeO 4 The preparation method of the material includes the following steps:

[0045] (1) Slowly add 52.3 mg (0.5 mmol) of GeO to 10 mL of water 2 , 1.2114 g (10 mmol) of Tris and stirred until a homogeneous and transparent solution was formed.

[0046] (2) Add 10ml of diethylenetriamine and 10ml of water, 183mg (1mmol) of Zn(CH) to the solution prepared in step (1) under stirring. 3 COO) 2 , stir to prepare 50ml of reaction solution, put the reaction solution into the reaction kettle, place it in a 220°C oven, react for 5h, naturally cool to room temperature, centrifuge, wash with distilled water, and put the solid obtained from the reaction into 70°C Drying in an oven to obtain rod-shaped Zn 2 GeO 4 Material.

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com