Anti-spatter welding method and system of automatic welding gun

An automatic welding and anti-splash technology, which is applied in the cleaning and maintenance of welding torch consumables, welding torches, anti-spatter methods and systems, and can solve the difficulties in realizing automatic control of welding production lines, inability to realize automatic induction spraying of welding torches, and increasing labor intensity of operators, etc. problem, to achieve the effect of isolating droplet splash, saving production time and high market value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0044] Take the production of 18,446 pieces of cold-end assembly of the "Volkswagen" Lavida model as an example (the program has been preset and turned on):

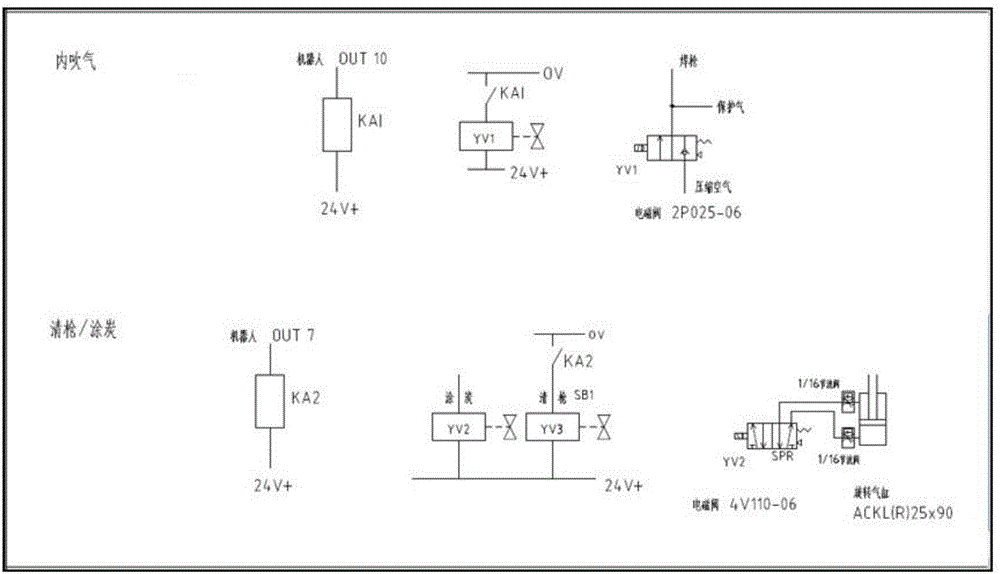

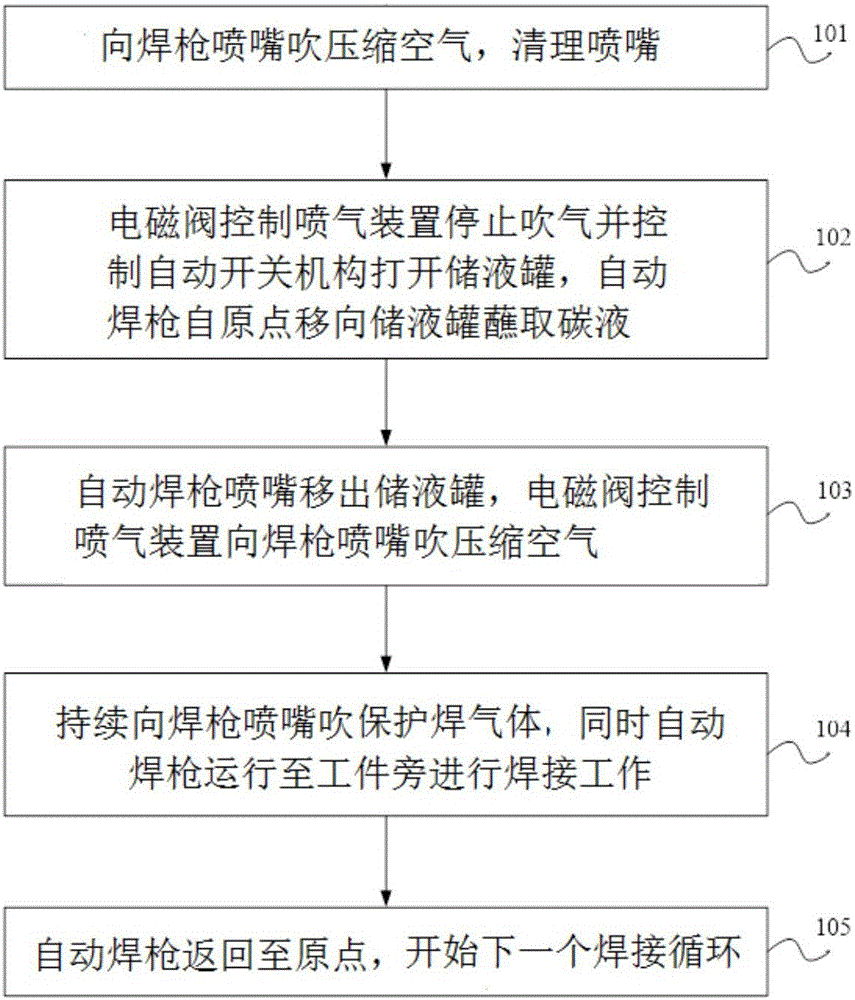

[0045] Step1, spray compressed air into the nozzle of the welding torch, and the compressed air flows through all parts of the torch head of the welding torch—including the barrel (gooseneck), contact nozzle seat, shunt, contact nozzle, nozzle, etc.; the automatic welding torch moves to the wire brush Clean the nozzle. At this time, the automatic welding torch and wire brush cooperate to complete the cleaning of small splashes;

[0046] Step2, the solenoid valve controls the air injection device to stop the air injection and controls the automatic switch mechanism to open the liquid storage tank, and the automatic welding torch moves to the liquid storage tank to dip in the carbon liquid;

[0047] Step3, the automatic welding torch nozzle moves out of the liquid storage tank, the solenoid valve controls the air injection...

Embodiment 2

[0052] The difference between this embodiment and Embodiment 1 lies in the production of 21,340 "Volkswagen" POLO GP hot-end assemblies, and the cost saving of consumables is shown in Table 1.

Embodiment 3

[0054] The difference between this embodiment and Embodiment 1 lies in the production of 23,460 automobile MPI HE hot end assemblies, and the cost saving of consumables is shown in Table 1.

[0055] Table 1

[0056]

[0057] Validation period: October 9, 2015 to November 30, 2015.

[0058] It can be seen from Table 1 that the anti-spatter welding method of the automatic welding torch provided by the present invention can effectively prevent the generation of spatter, reduce the consumption of contact tips, and continuously reduce the production cost, which has a high application prospect.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thermal resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com