All vegetable oil high-speed planographic printing ink

A lithographic printing and vegetable oil technology, applied in inks, household appliances, applications, etc., can solve the problems of rising raw material cost, poor printing, small flow, etc., to achieve excellent environmental protection, fast drying on paper, and stable on-machine effects.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

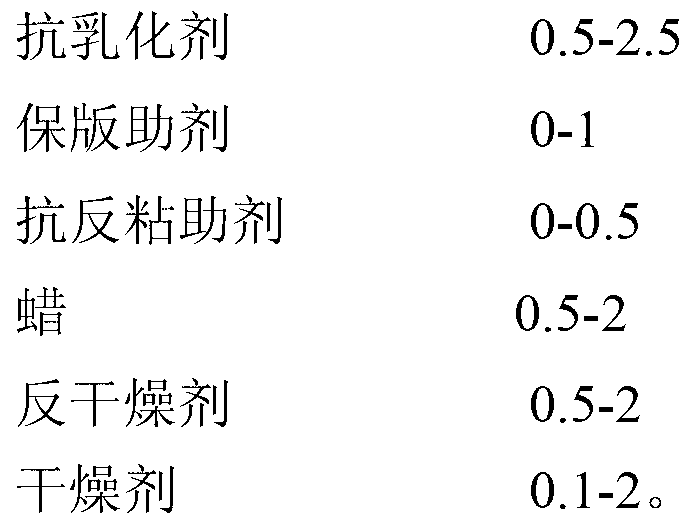

[0055] Please refer to Table 1 for the composition of the all-vegetable oil high-speed lithographic printing ink of the present invention.

[0056] Table 1: Vegetable oil high-speed lithographic ink formula of the present invention

[0057] raw material name

yellow

red

blue

black

Binder A

20-80

20-80

20-80

20-80

Binder B

0-50

0-50

0-50

0-50

Binder C

0-30

0-30

0-30

0-30

Binder D

0-10

0-10

0-10

0-10

paint

10-20

10-20

10-20

10-20

Auxiliary

1.6-12

1.6-12

1.6-12

1.6-12

0-15

0-15

0-15

0-15

[0058] According to the plant high-speed lithographic ink formula in Table 1, the pigments used were selected, and four monochrome ink formulas of yellow, red, blue, and black were designed. The specific compositions are shown in Table 2.

[0059] Table 2: Monochrome Ink Formulations

[0060]...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tackiness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com