Connection Fixing Method and Strip Clamp for Saddle-shaped Pipe Fittings by Electric Fusion Welding

A technology of electrofusion welding and fixing method, which is applied in the direction of tubular articles, other household appliances, household appliances, etc., can solve the problem that the pressure in the melting zone cannot be well maintained, and can solve the problem of insufficient pressure in the melting zone, reduce the scrap rate, The effect of improving economic efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

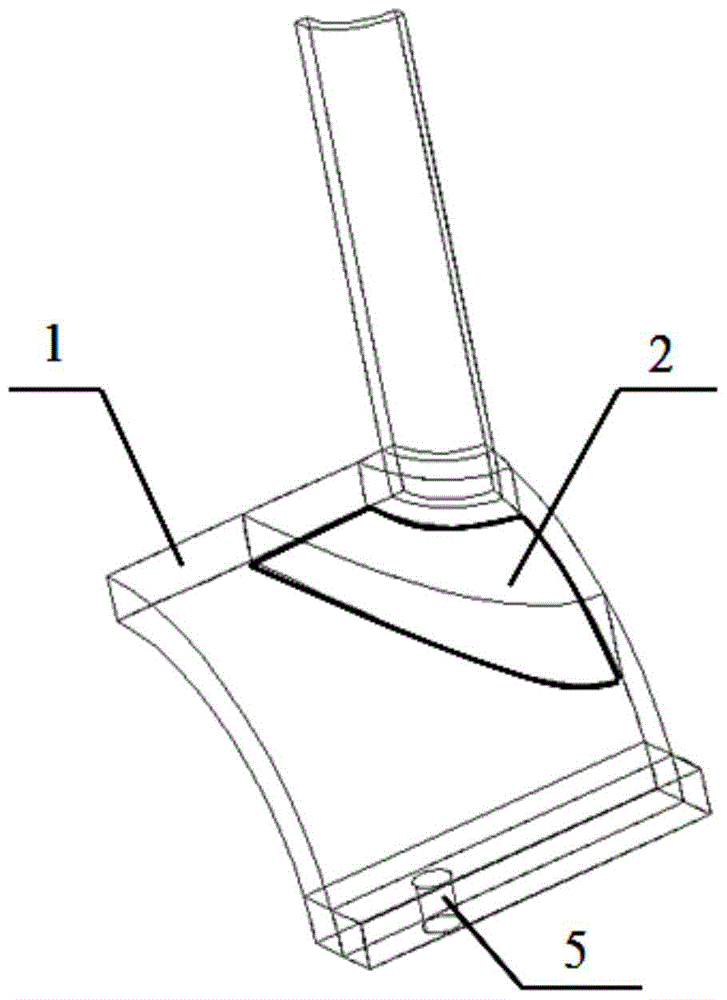

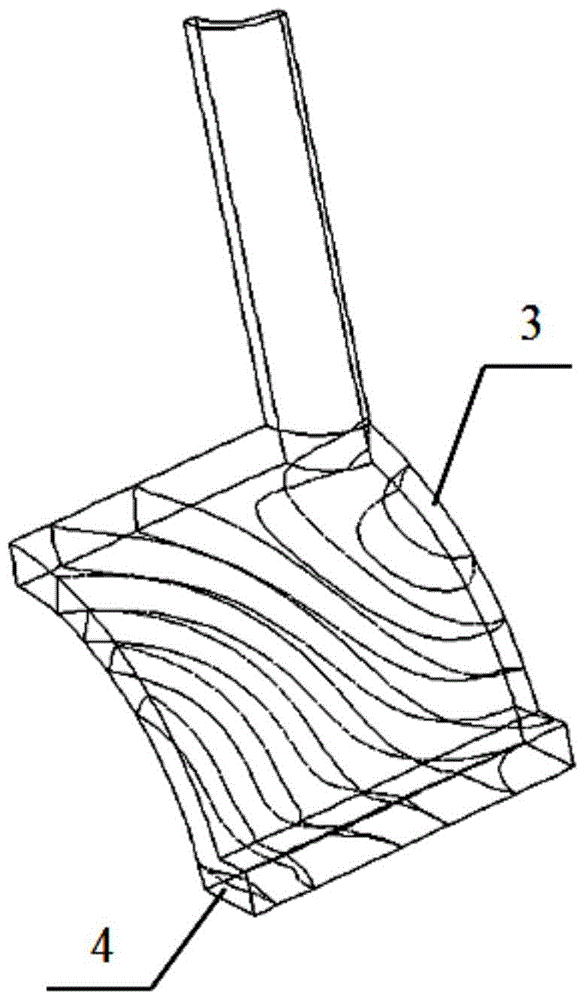

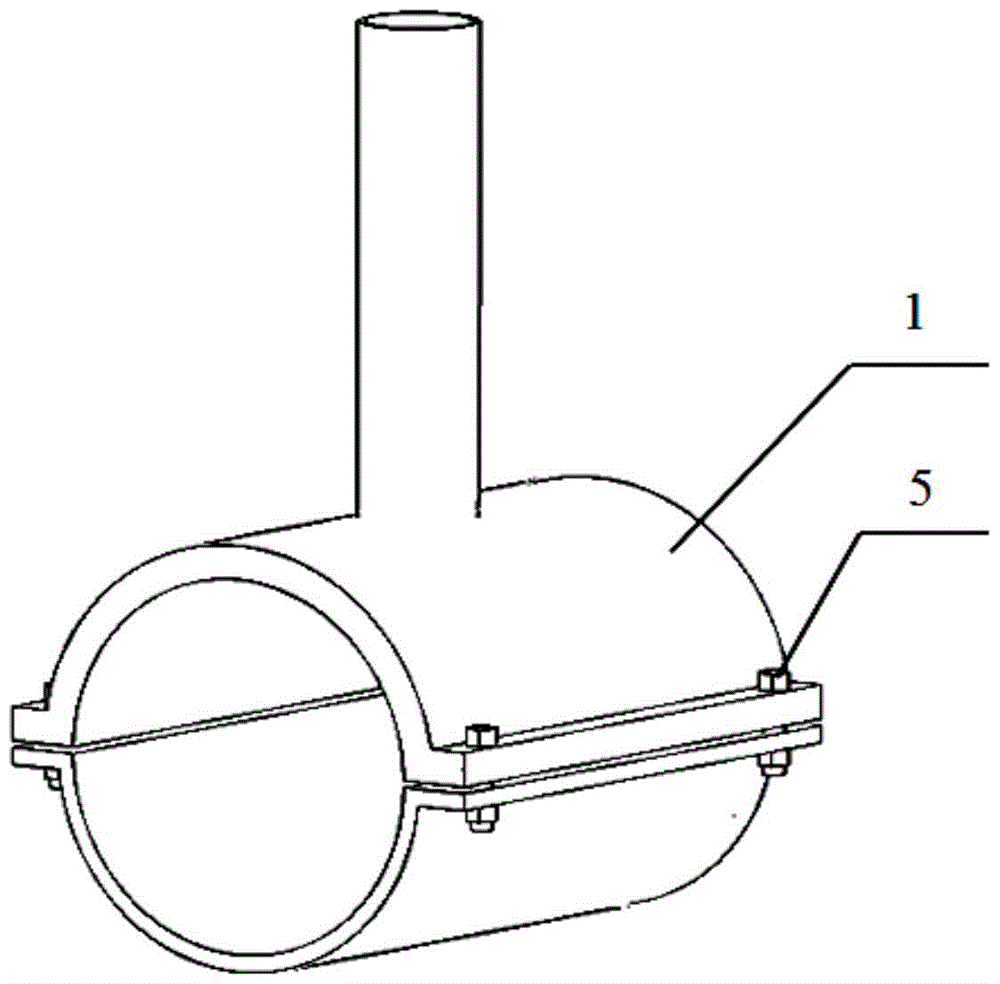

[0039] image 3 Shown is the electric fusion welding assembly drawing of the above-mentioned saddle-shaped pipe fitting 1 (the main pipe is not drawn). Before the electric fusion welding, the saddle-shaped pipe fitting 1 is placed on the main pipe, and the connecting bolts 5 on both sides are tightened; Figure 4 A set of belt clamps shown clamps the entire saddle-shaped pipe fitting 1, one side of the clamp is in close contact with the outer wall of the branch pipe on the saddle-shaped pipe fitting 1, and the pre-tightening force in the clamp is adjusted to an ideal value according to the requirements of pipe fittings of different specifications , so that the pipe fittings fit tightly with the main pipe before welding. The specific installation process of the clamp is as follows: hoop the main body 7 of the strip clamp on the saddle-shaped pipe 1, the clamping head 11 will be stuck in the strip groove 66, and the pressure sensor 9 will transmit the real-time pre-tightening fo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com