Method for improving ductility of casting beryllium aluminum alloy

A technology of beryllium aluminum alloy and elongation rate, which is applied in the field of improving the elongation rate of cast beryllium aluminum alloy, can solve the problems of casting beryllium aluminum alloy difficult to meet customer needs, low product strength, low elongation rate, etc., to achieve elongation increase and casting defects Effect of improving and increasing strength and elongation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

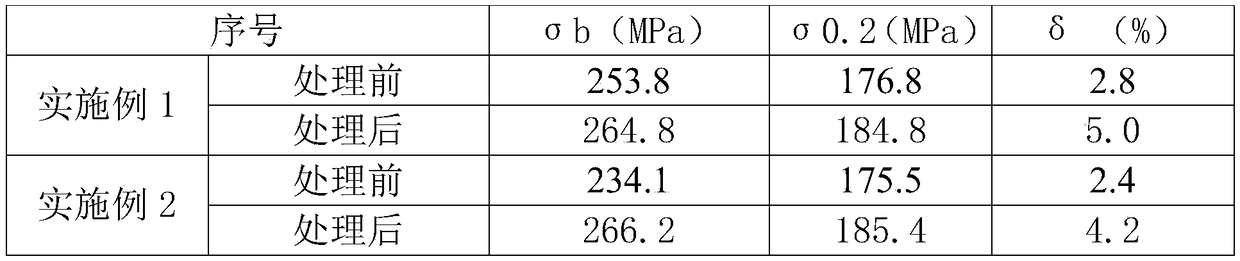

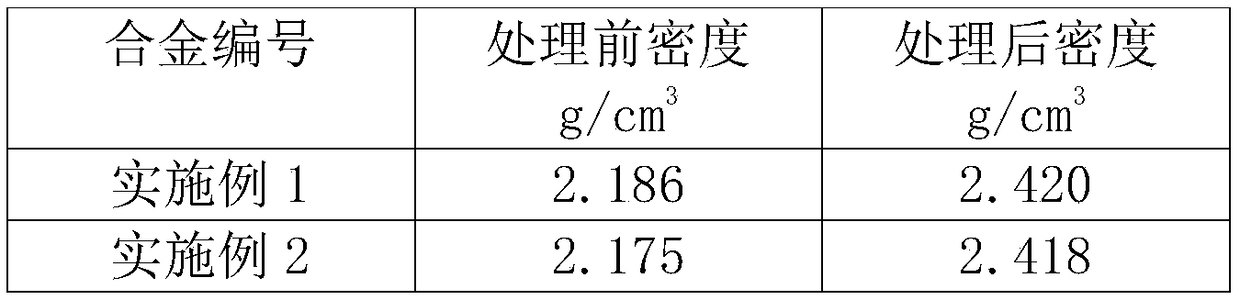

Embodiment 1

[0016] Take the beryllium aluminum alloy casting and put it into the isostatic pressure furnace, fill the initial pressure, raise the temperature at 3°C / min to 500°C and keep it warm for 30 minutes, then continue to raise the temperature to 585°C at the same rate. At this time, the pressure in the furnace is 115MPa. After 150 minutes, cool down to 200°C at 5°C / min, and turn off the power to cool down.

Embodiment 2

[0018] Take the beryllium aluminum alloy casting and put it into the isostatic pressure furnace, fill it with the initial pressure, raise the temperature at 5°C / min to 500°C and keep it warm for 30 minutes, then continue to raise the temperature to 600°C at the same rate. At this time, the pressure in the furnace is 130MPa. After 1750 minutes, cool down to 200°C at a rate of 3°C / min, and turn off the power to cool down.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com