Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

74results about How to "Refining as-cast structure" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Composite metamorphic cast aluminum alloy and preparation method and application thereof

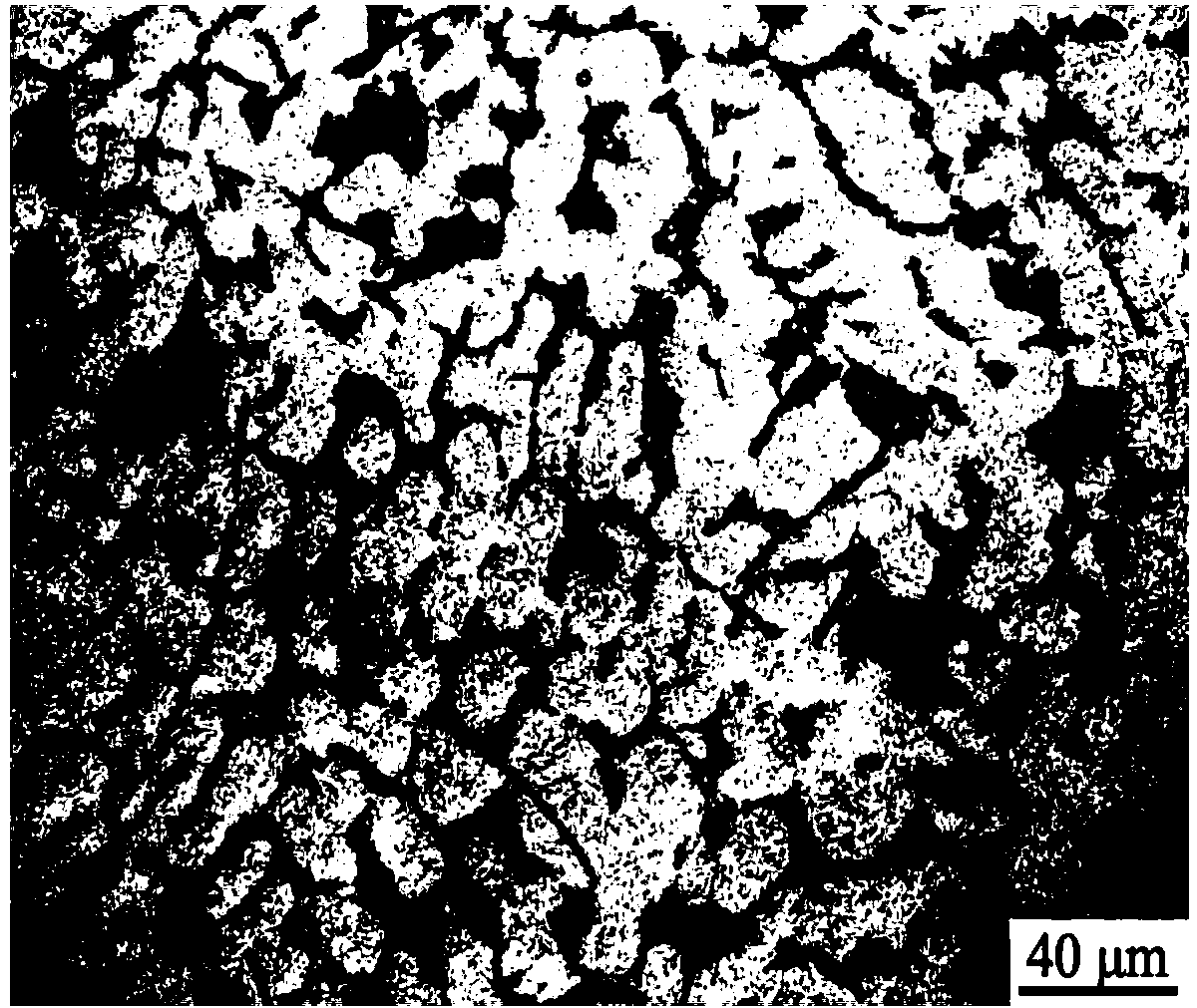

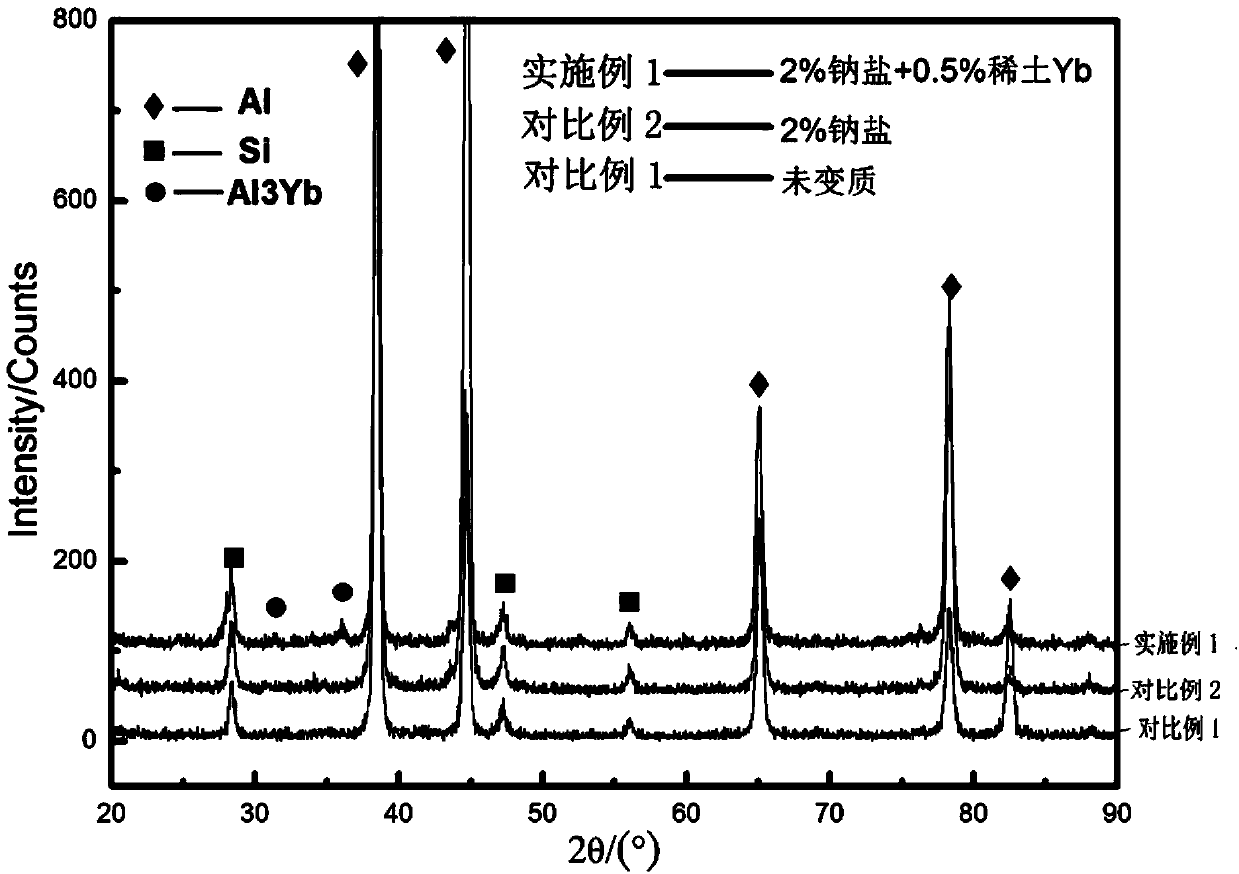

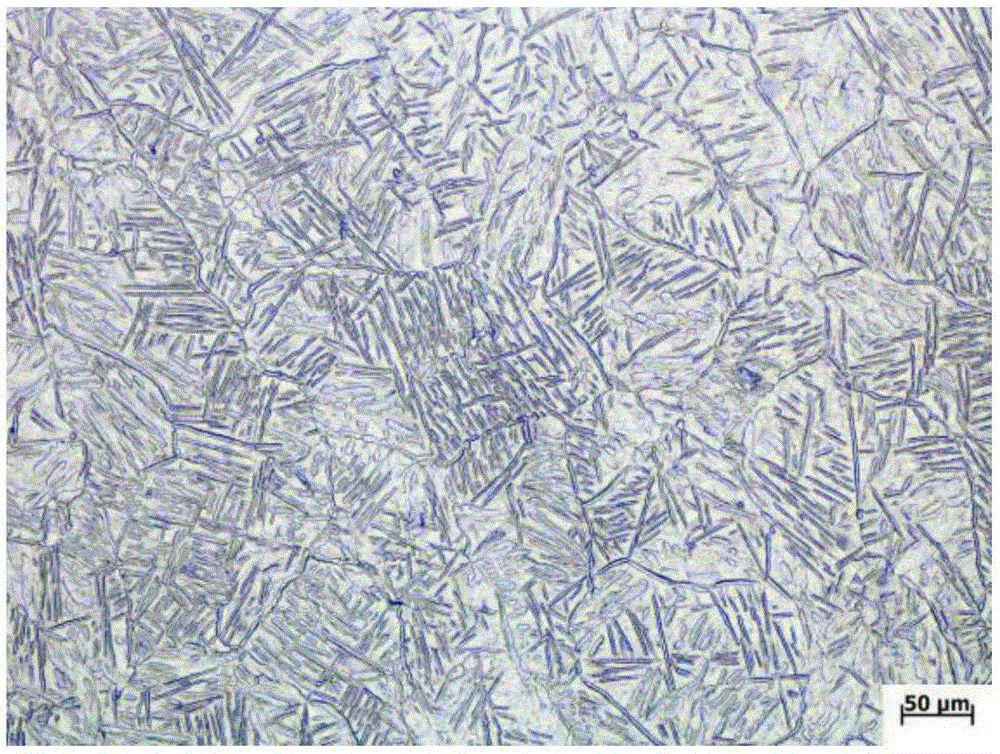

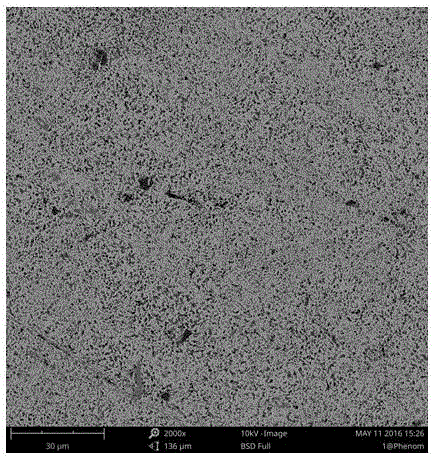

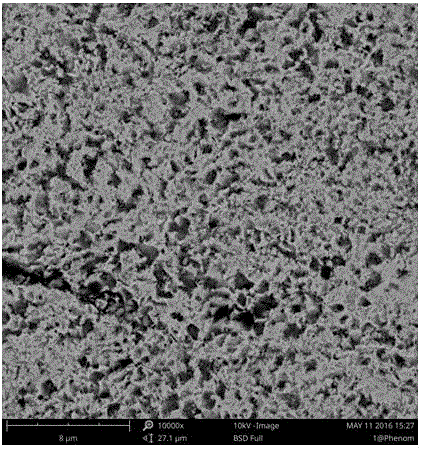

The invention provides a composite metamorphic cast aluminum alloy. The composite metamorphic cast aluminum alloy comprises, by weight, 8.0 % to 10.5 % of Si, 0.17 % to 0.3 % of Mg, 0.2 % to 0.5 % of Mn, 0.1 % to 1.0 % of Yb, 0.5 % to 3.0 % of sodium salt, less than 0.2 % of Fe, less than 0.1 % of Sn, less than 0.1 % of Cu and less than 0.05 % of Pb and the balance Al, wherein the Fe, the Sn, the Cu and the Pb are limited impurity elements. The invention further provides a preparation method and application of the composite metamorphic cast aluminum alloy. Due to metamorphism of the heavy rare earth element Yb and the alloying function, the casting-state structure of the alloy is significantly refined, strength and toughness of the alloy are improved, oxidation blending imported by the sodium salt metamorphism is reduced, and the compactness of a casting is improved.

Owner:ANHUI JIANGHUAI AUTOMOBILE GRP CORP LTD

High-perforance compression casting aluminium alloy

A aluminum alloy material consists of Si 9.5-11.5wt%, Cu 2.0-3.0wt%, Mg 0.3-0.4wt%, mixed rare earth RE 0.1-0.3wt%, Mn is less than or equal to 0.5, Zn is less than or equal to 1.0, Fe is less than or equal to 1.0, Al residue. The mixed rare earth RE consists of La 5-80wt%, Ce 5-40wt%, Nd 1-20wt%, Y 1-20wt%, Pr 1-20wt%. It achieves good flowing, mechanical and cutting machining performance.

Owner:CHONGQING UNIV

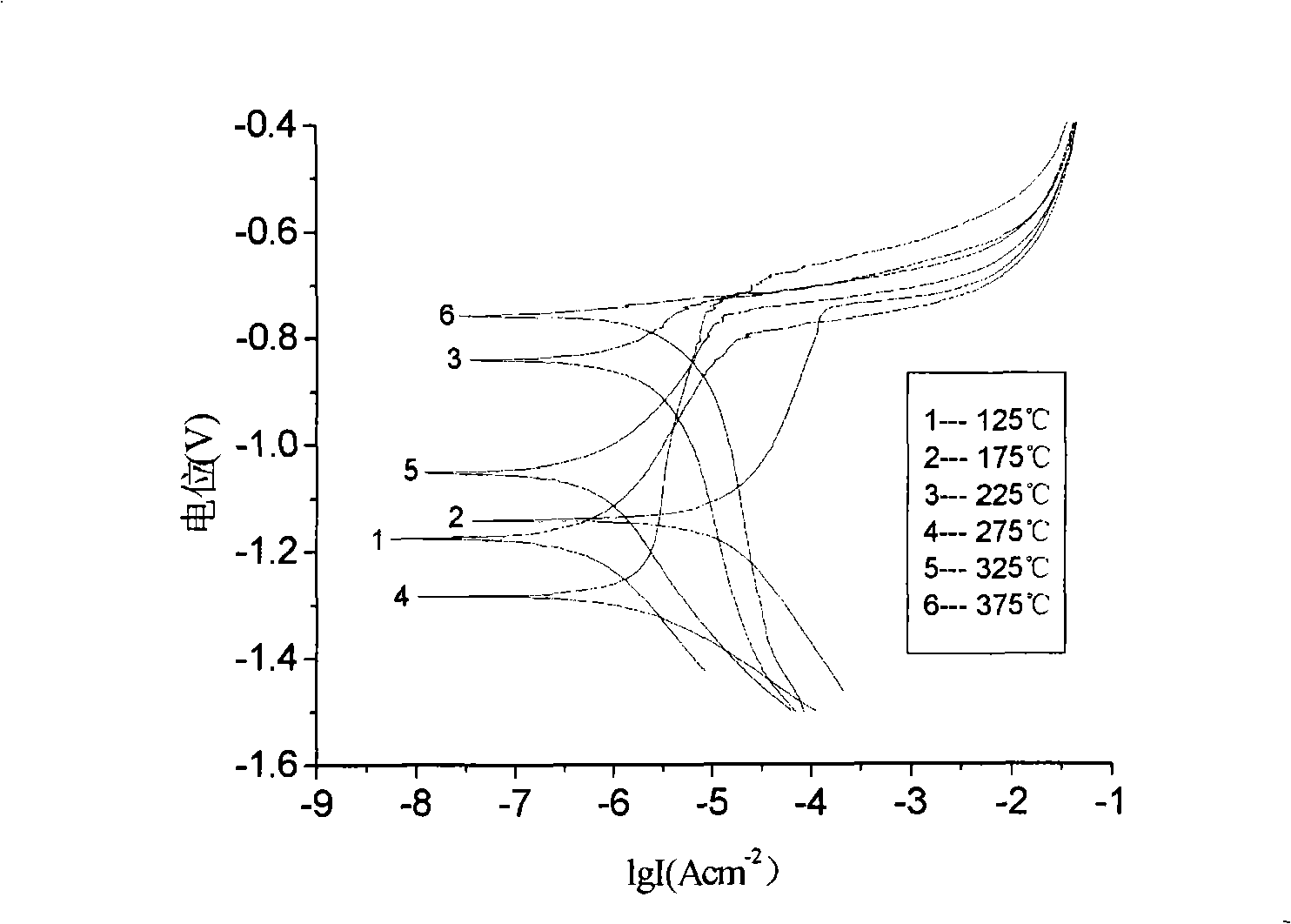

Thermal treatment process for erbium-containing aluminum-magnesium-manganese wrought aluminium alloy

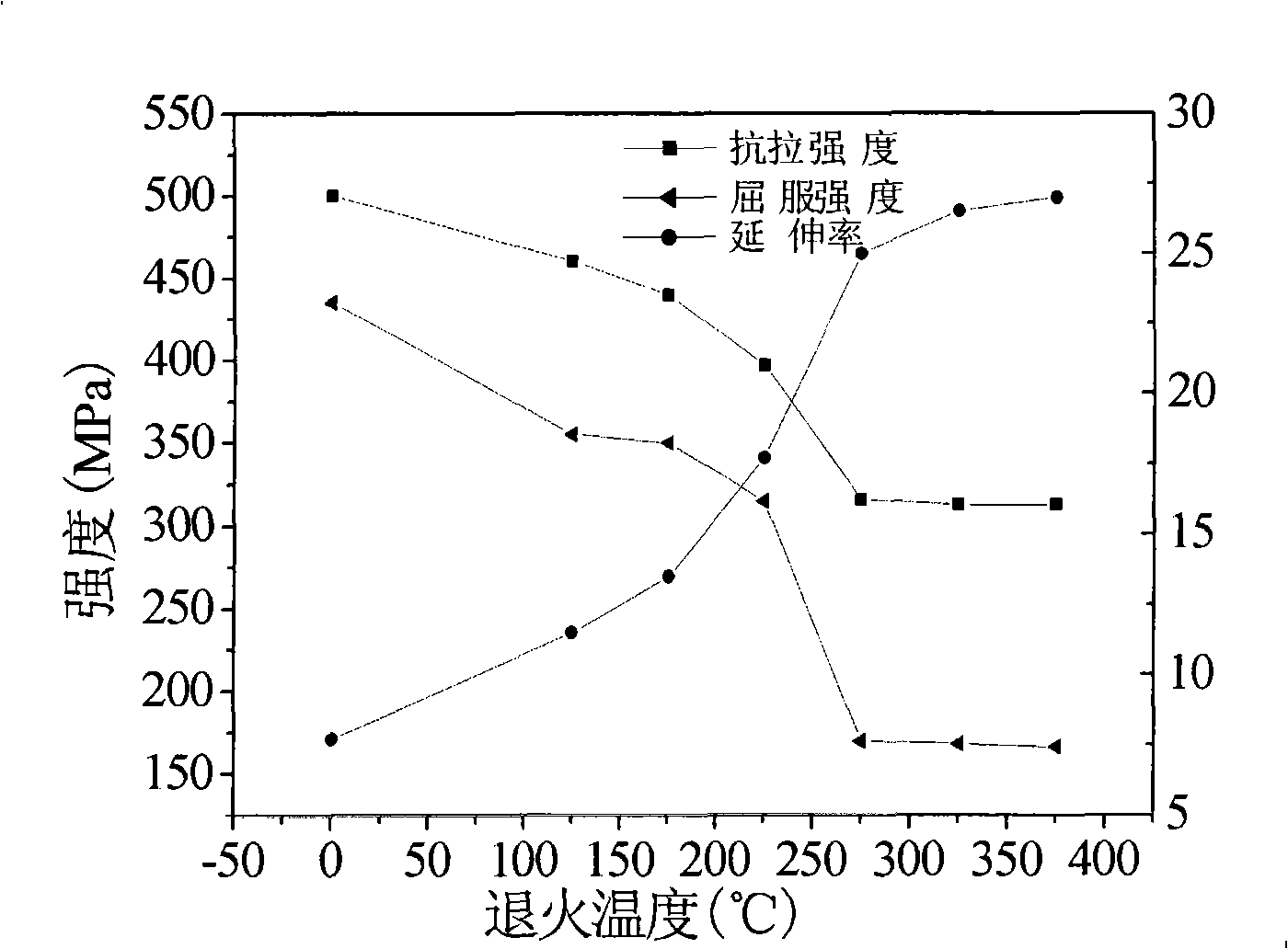

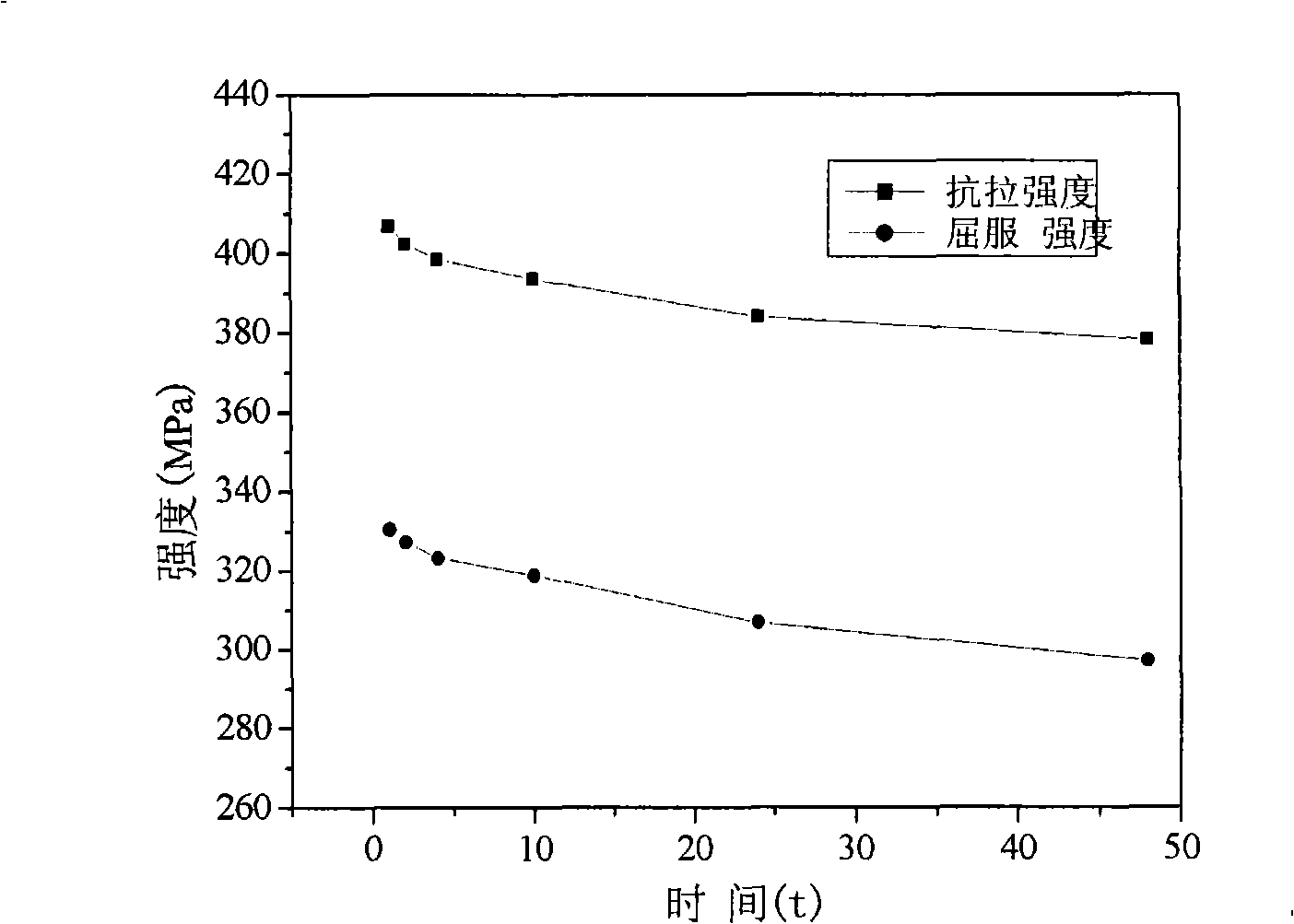

The thermal treatment process for an aluminum-magnesium-manganese wrought aluminum alloy containing erbium belongs to the filed of metal alloys. The existing aluminum alloy thermal treatment process has the problems of strength reducing, corrosion resisting performance reducing after long term use, etc. The invention aims at providing the thermal treatment process for an aluminum-magnesium-manganese cold-rolled sheet containing erbium, which is realized by homogenizing annealing, hot rolling, cold rolling, stabilizing annealing and other process steps, wherein the stabilizing annealing process comprises the steps that, a cold-rolled sheet is annealed at the temperature of 100-400 DEG C and insulated for 1-48h; the annealing temperature and the insulating time are preferably 125-250 DEG C and 1-8h respectively. The thermal treatment process of the invention ensures the alloy to acquire excellent corrosion resisting performance under the condition that the high plasticity of the aluminum-magnesium-manganese cold-rolled sheet containing erbium is kept at a higher level; the treated alloy can be used for a long time with basically constant performance, and the service range of the alloy is wide.

Owner:BEIJING UNIV OF TECH

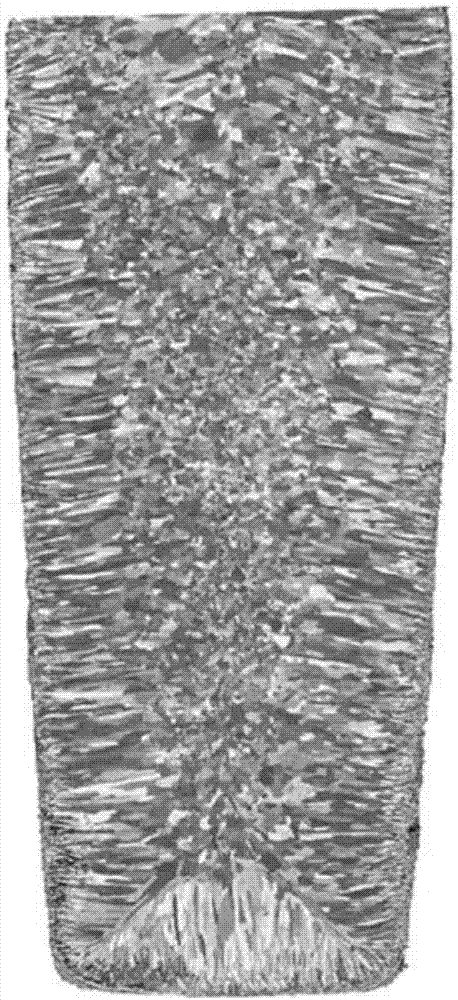

Near-alpha titanium alloy with high dynamic performance and preparation method of near-alpha titanium alloy

The invention discloses a near-alpha titanium alloy with high dynamic performance. The near-alpha titanium alloy is composed of, by mass percent, 5.0%-6.8% of Al, 1.5%-2.4% of Zr, 1.0%-1.9% of Mo, 1.5%-2.5% of V, 0.05%-0.30% of Fe, 0.05%-0.14% of O, and the balance Ti. The sum of the mass percents of the components is 100%. The invention further discloses a preparation method of the titanium alloy. The as-cast structure of a large cast ingot is refined and the microcosmic uniformity of cast ingot components is improved through a purification and high-homogeneity smelting method; and meanwhile, as the content of Al and the content of O are controlled, it is guaranteed that the WSTi6211F titanium alloy has enough strength, the plasticity and the toughness of the WSTi6211F titanium alloy are greatly improved, and the purpose of improving the dynamic performance of the titanium alloy is achieved in combination with a high-temperature homogenizing treatment and cyclic forging process.

Owner:西部超导材料科技股份有限公司

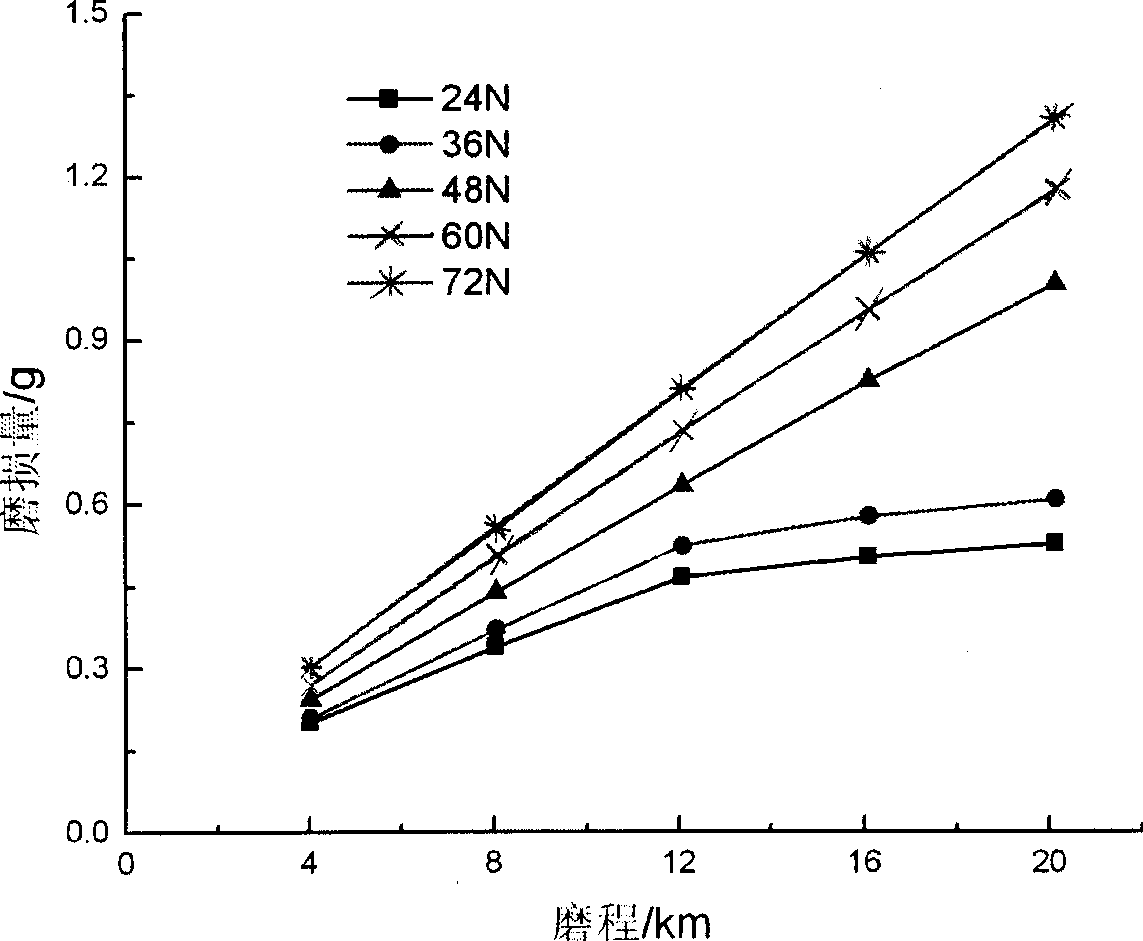

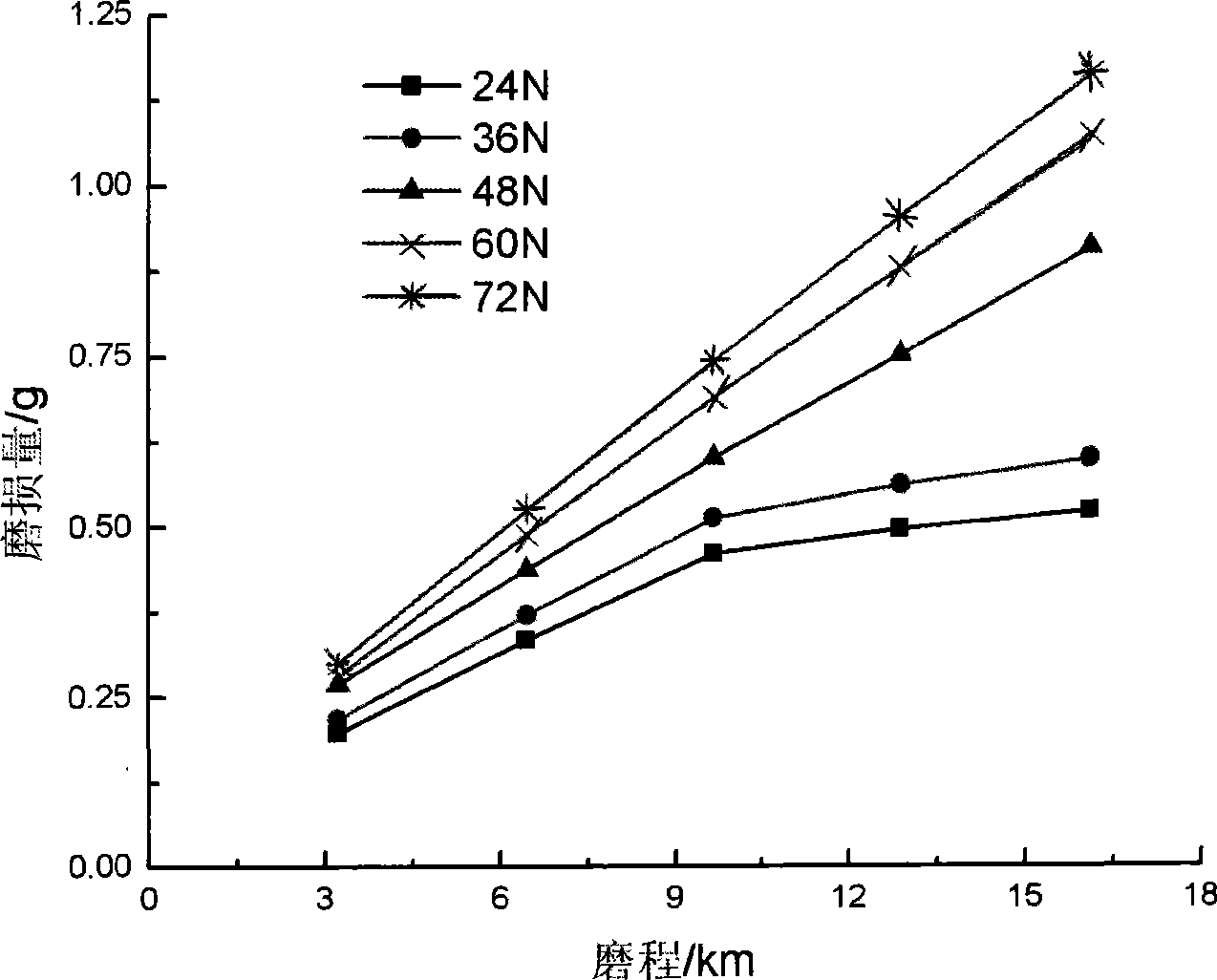

Environmental self-lubricating wear-resistant copper alloy and preparation method thereof

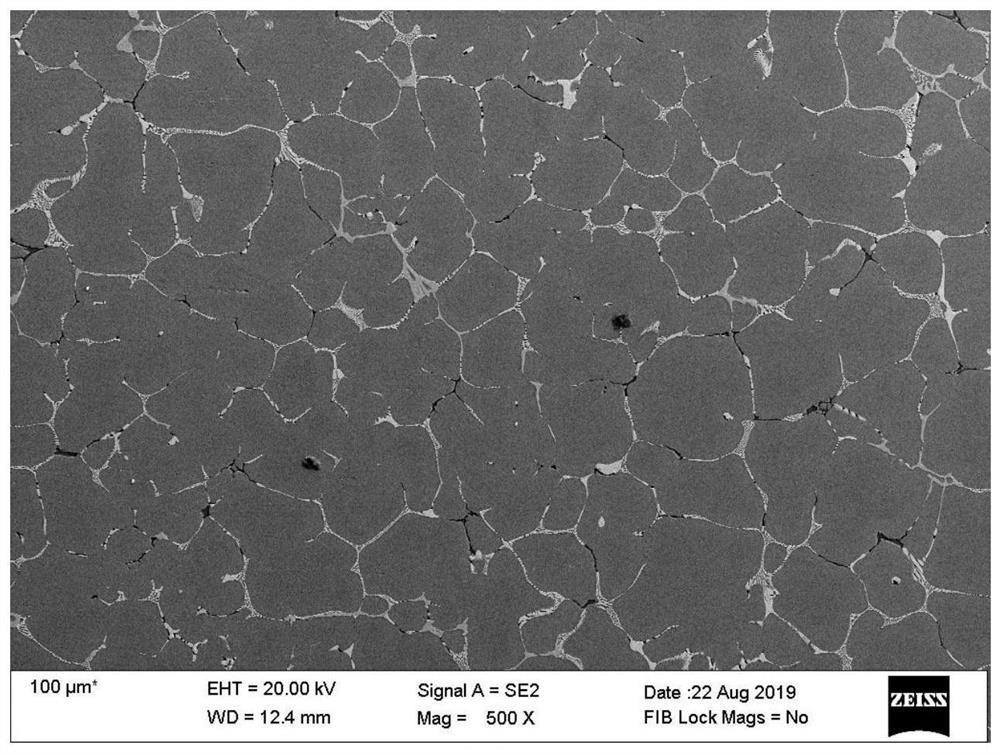

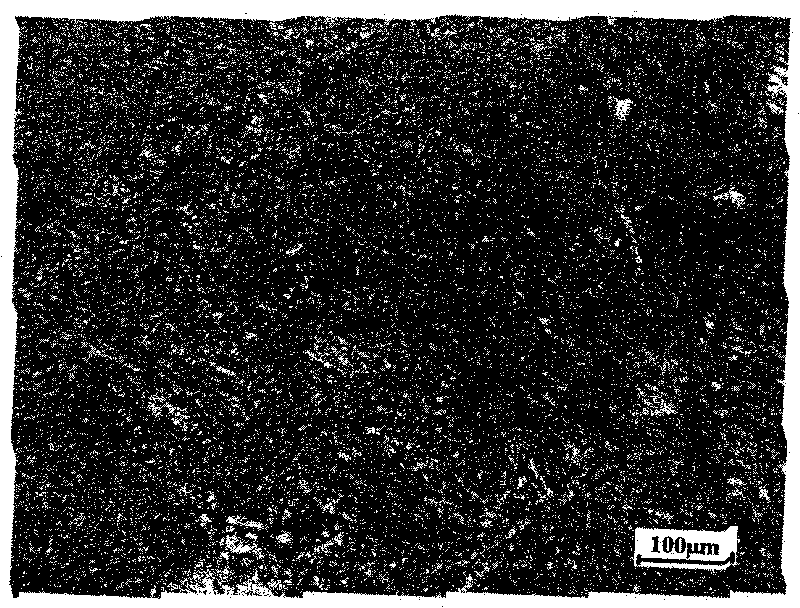

The invention discloses environmental self-lubricating wear-resistant copper alloy, comprising the following components by mass percent: 5-13% of Sn, 2-9% of Ni and / or Co, 2-11% of Bi, 0.05-0.3% of Zr, 0.05-0.5% of RE, the balance of Cu and inevitable impurities, wherein the content of the impurity is smaller than or equal to 0.3%, the RE is Ce-La misch metal. Meanwhile, the preparation method of the environmental self-lubricating wear-resistant copper alloy is disclosed. The environmental self-lubricating wear-resistant copper alloy has the advantages that the conventional wear-resistant copper alloy containing lead is replaced, and the environmental self-lubricating wear-resistant copper alloy is the wear-resistant copper alloy material with environment-friendly and self-lubricating effects. The alloy solidification molding process is interfered by adopting a strong pulsed electromagnetic physical field in the manufacturing process, the as-cast segregation and loosening of the obtained environmental self-lubricating wear-resistant copper alloy are significantly reduced, the alloy is fine and even in as-cast structure, and high in density, the hardness of the molded casting is greater than 70HB, the tensile strength is greater than 230MPa, and the alloy density is greater than 8.7g / cm<3>. The environmental self-lubricating wear-resistant copper alloy has good overall performance, the preparation method is good in stability, and low in cost, the preparation process is green and free of pollution, and industrialization is easily achieved.

Owner:镇江金鑫有色合金有限公司 +2

Preparation method of TC17 titanium alloy flat square section bar

ActiveCN103143660ARefining as-cast structureAddressing inhomogeneityMetal-working apparatusIngotWork in process

The invention provides a preparation method of a TC17 titanium alloy flat square section bar. The preparation method comprises the following steps that (1) a riser and an ingot bottom of a TC17 titanium alloy cast ingot are cut off, and surface defects are removed; (2) billet forging is performed on the TC17 titanium alloy cast ingot, and primary forging stocks are obtained; (3) first middle forging is performed on the primary forging stocks, and first middle forging stocks are obtained; (4) second middle forging is performed on the first middle forging stocks, and second middle forging stocks are obtained; (5) sawing is performed on the second middle forging stocks, then forming forging is performed, and a semi-finished flat square section bar is obtained; and (6) heat treatment is performed on the semi-finished flat square section bar, and the TC17 titanium alloy flat square section bar with the length of 850 mm to 1600 mm, the width of 132 mm and the thickness of 65 mm to 100 mm is obtained. The preparation method has the advantages of integral technical scheme, strong process controllability, uniformity in product texture and shape, excellent overall performance, high batch stability and high yield and is suitable for large-scale industrial production.

Owner:WESTERN TITANIUM TECH

Copper-chromium-zirconium alloy and preparation method thereof

Copper-chromium-zirconium alloy is characterized by being prepared from the following raw materials in percent by weight: 0.2-1.2% of chromium, 0.05-0.2% of zirconium, 0.06-0.10% of magnesium, 0.05-0.5% of scandium and the balance of copper. The invention further provides a preparation method of the copper-chromium-zirconium alloy. The preparation method sequentially comprises the following steps:(1), proportionally preparing copper, chromium, zirconium, magnesium and scandium elements, performing vacuum smelting, and performing split casting to obtain a casting blank; (2), performing homogenizing treatment and hot extrusion on the casting blank to obtain a bar blank; (3), performing solid solution treatment to the bar blank; (4), performing cold deformation processing on the bar blank obtained after the solid solution treatment; (5), performing aging treatment to a material obtained after the cold deformation processing to obtain the needed copper-chromium-zirconium alloy. The copper-chromium-zirconium alloy has high tensile strength, high electrical conductivity and high elongation and has relatively high high-temperature tensile strength and excellent comprehensive performance.

Owner:GUANGDONG HUAXING HEAT EXCHANGE EQUIP CO LTD +1

High-strength Mg-Li-Al-Y-Ca alloy and preparation method thereof

InactiveCN106521274AImprove mechanical propertiesThe processing technology is easy to operateHigh intensityMetal

The invention belongs to the technical field of metal materials and relates to a high-strength Mg-Li-Al-Y-Ca alloy and a preparation method thereof. The alloy is prepared from components in percentage by weight as follows: 4wt%-12wt% of Li, 2wt%-6wt% of Al, 1wt%-3wt% of Y, 0.5wt%-1.5wt% of Ca and the balance of Mg and impurity elements including Si, Fe, Cu and Ni, and the total quantity of the impurity elements is smaller than 0.02wt%. The alloy is prepared with the method comprising steps as follows: (1) material baking, (2) material addition, (3) casting, (4) plastic deformation, and (5) heat treatment technology. Certain mass of Y elements and certain mass of Ca elements are added to a Mg-Li-Al alloy, a strengthening phase having the high heat stability is introduced into an alloy solidification structure; meanwhile, the solidification structure is promoted to be refined; and the high-strength Mg-Li-Al-Y-Ca alloy has the relatively low density and the excellent mechanical property through plastic deformation and the heat treatment technology.

Owner:JIANGSU UNIV OF TECH

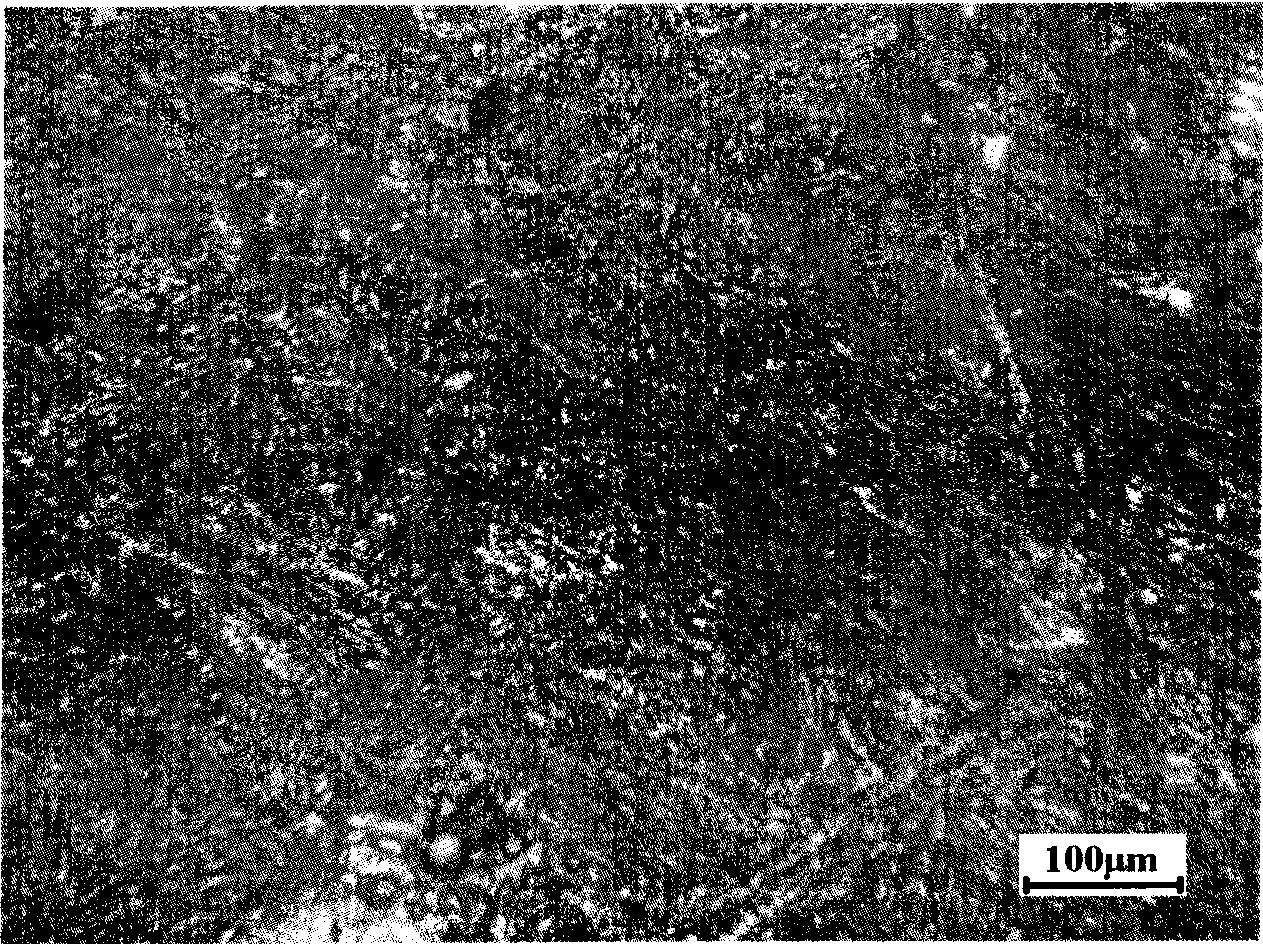

Low-alloy abrasion-proof and corrosion resistant steel and method for producing the same

InactiveCN101423916AStrong resistance to seawater corrosionImprove corrosion resistanceElectric furnaceProcess efficiency improvementWear corrosionWear resistant

The invention relates to low alloy wearing resistance corrosion resistance steel which is suitably used in the ocean mud-sand wearing and corrosive environment, which is produced by the following steps: Mn-Si-Cr-Mo system non-carbide bainite alloy steel is taken as research basis, the carbon content and other alloy element contents are properly adjusted, elements of Al, Nb and rare earth contributing to improving the corrosion resistance of the alloy steel are added for modification, and the Mn-Si-Cr-Mo-Al system non-carbide bainite steel is formed by the progression quenching heat treatment process, so that the low alloy wearing resistance corrosion resistance steel is obtained. The steel has good obdurability, wearing resistant and corrosion resistant comprehensive performance and welding repair performances, and can be used to solve the problem of repairing worn blades of a centrifugal pump of a ship, and can also be applied to other ocean wearing resistance welding parts.

Owner:HOHAI UNIV +1

Magnesium-zinc-zirconium-yttrium-magnesium alloy

InactiveCN101812620AImprove heat deformation plasticityReduce extrusion deformation resistanceHeat deflection temperatureYttrium

The invention provides a magnesium-zinc-zirconium-yttrium-magnesium alloy which comprises the following components in percentage by weight: 2.0-4.0% of zinc, 0.2-0.5% of zirconium and 0.9-5.8% of yttrium and the balance magnesium and impurity. The invention improves optional heat deflection temperature range of the alloy by controlling zinc content in the magnesium-zinc-zirconium series magnesium alloy and adding yttrium element with a proper proportion; higher deflection temperature is favorable for improving the heat deflection plasticity of magnesium alloy and improving extrusion rate; and meanwhile, alloy crystalline grain is refined by the action that high melting point second phase containing yttrium prevents crystalline grains from growing in the heat extrusion deformation recrystallization process so as to obtain magnesium alloy with moderate strength and favorable plasticity. The magnesium-zinc-zirconium-yttrium-magnesium alloy with the optimal proportion has the room-temperature tensile strength of 279 MPa, yield strength of 184 MPa and elongation percentage of 28%.

Owner:CHONGQING UNIV

Super-strength aluminum alloy section

The invention discloses a super-strength aluminum alloy section. The super-strength aluminum alloy section comprises, by mass, 6%-10% of zinc, 0.1%-3% of copper, 1%-3% of magnesium, 0.5%-1% of silicon, 0.3%-0.6% of manganese, 0.03%-0.05% of scandium, 0.02%-0.04% of zirconium, 0.02%-0.04% of erbium, 0.03%-0.05% of lanthanum, 0.01%-0.03% of yttrium, 0.01%-0.03% of cerium, 0.03%-0.06% of titanium, 0.08%-0.1% of boron and the balance aluminum. By means of the super-strength aluminum alloy section, the comprehensive mechanical property of the aluminum alloy section is improved while it is guaranteed that an aluminum alloy has the super strength.

Owner:ANHUI LANT ALUMINUM

Technological method for improving equiaxed crystal ratio of bistable ferrite stainless steel continuous casting billets

The invention provides a technological method for improving the equiaxed crystal ratio of bistable ferrite stainless steel continuous casting billets. The technological method comprises the steps of aprimary melting furnace, AOD, VOD, LF and continuous casting. According to the technological method provided by the invention, the equiaxed crystal ratio of the bistable ferrite stainless steel continuous casting billets is improved largely, and the cold machining and molding performances of ferrite stainless steel as well as the surface quality of products are improved; and the problems of nozzle clogging and blockage caused by TiN and TiOx generated by adding excessive Ti in the continuous casting technological process are solved effectively.

Owner:UNIV OF SCI & TECH BEIJING

Method for improving plasticity of cast Al-Li alloy

The invention relates to a method for improving the plasticity of cast Al-Li alloy. The method includes the steps that alloying elements capable of forming Al3M particles of the L12-type structure with Al are added in the casting process of the cast Al-Li alloy; and the alloying elements include at least two of Zr, Sc, Er and Yb. Through combined addition of the alloying elements capable of forming the Al3M particles of the L12-type structure with the Al in the cast Al-Li alloy, the alloy as-cast structure can be refined obviously, the alloy can be promoted to separate out coherency Al3M particles in the solid solution process, the precipitation density of composite particles Al3(M and Li) in the cast Al-Li alloy is increased ultimately, and thus alloy plasticity is improved. By adoption of the method, the cast Al-Li alloy can be further subjected to short-time 'preageing' treatment at a low temperature before solid solution, the number of the Al3M particles in an alloy matrix can be further increased, and the alloy plasticity is improved.

Owner:SHANGHAI JIAO TONG UNIV

6XXX-series aluminum alloy and preparation method thereof

The invention provides 6XXX-series aluminum alloy, and belongs to the technical field of metal alloy. The 6XXX-series aluminum alloy is prepared from the following element components in percentages byweight: 0.8-1.5% of Mg, 1.5-3.0% of Si, 0.2-0.5% of Cu, 0.2-0.5% of Mn, 0.1-0.15% of Cr, 0.15-0.4% of Y, 0.1-0.3% of Zr, 0.05-0.15% of Sr, 0.01-0.04% of Ti, less than or equal to 0.1% of Zn, less than or equal to 0.5% of Fe, less than or equal to 0.05% of single impurities, less than or equal to 0.15% of total impurities and the balance of Al. By an as-cast structure of yttrium-zirconium refinedaluminum alloy, fine grains can be strengthened; and by excessive Si, the hardness and strength of the aluminum alloy are improved. From embodiments, the hardness of the aluminum alloy is 129 HBW, thetensile strength is 411 MPa, the yield strength is 348 MPa, and the ductility is 15%.

Owner:CENT SOUTH UNIV

Magnesium lithium alloy, preparation method thereof and preparation method for magnesium lithium alloy plate

The invention discloses magnesium lithium alloy, a preparation method thereof and a preparation method for magnesium lithium alloy plate. The magnesium lithium alloy is composed of 10-15% of Li, 3-6% of Al, 0.3-2.0% of Sr, 0.05-1.0% of Sc, 0.05-0.5% of Zr, less than or equal to 0.005% of impurity element Fe, less than or equal to 0.002% of Ni, less than or equal to 0.02% of Cu and rest of Mg by weight. By means of the Sr and Sc, the heat resistance of the magnesium lithium alloy is improved, the problem of the beta-phase magnesium lithium alloy that the mechanical property of the alloy is lowered obviously due to over-aging is overcame effectively, and moreover, the dendritic crystal growth is hindered because Al3Sc is enriched on a solid-liquid interface, and accordingly the cast structure of the alloy is thinned; after the alloy is solidified, most of the Al3Sc phase is distributed at the crystal boundary, so that the crystal boundary can be pinned greatly, and the yield strength and the tensile strength of the alloy are obviously improved.

Owner:ANHUI JIANGHUAI AUTOMOBILE GRP CORP LTD

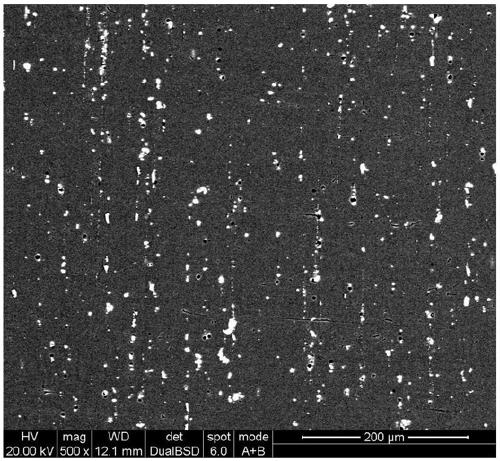

Low-cost titanium alloy and preparation method thereof

The invention discloses a low-cost titanium alloy and a preparation method thereof. In the titanium alloy, titanium is used as a main body element, and an alpha stable element B and a beta stable element Fe are used as alloy elements. The titanium alloy is composed of 0.5-5 wt.% of Fe, 0.05-0.2 wt.% of B, and the balance of titanium and inevitable impurities. The preparation method comprises the following steps: adding raw materials into an argon-introduced cold crucible levitation melting furnace according to the designed alloy component proportion, repeatedly melting to obtain a cast ingot, carrying out cogging forging on the cast ingot at the temperature of higher than the phase transformation point, sampling the forged alloy, carrying out heat treatment, and finally, carrying out structure and performance characterization. The titanium alloy provided by the invention has the advantages of uniform alloy components, fine structure, high tensile strength (up to 750-850 MPa), high elongation percentage (10-15%) and low cost, and can substitute partial high-price titanium alloys in some fields.

Owner:NANJING UNIV OF TECH

Ultrahigh-strength soluble magnesium alloy as well as preparation method and application thereof

ActiveCN110106416AImprove solid solubilityIncrease supersaturationFluid removalIngotUltimate tensile strength

The invention relates to an ultrahigh-strength soluble magnesium alloy. The ultrahigh-strength soluble magnesium alloy comprises the following components of, in percentage by mass, 6.0-10.0wt% of Sm,0.05-0.2wt% of Sc, 0.2-1.4wt% of Zn, 0.2-0.5wt% of Ag, 0.5-2.0wt% of Cu, 0.5-1.2wt% of Ni, 0%-0.1% of impurity elements and the balance Mg. The preparation method comprises the following steps that the raw materials are mixed according to proportion, the mixture is smelted and refined to obtain melt, the melt is subjected to casting to obtain a cast ingot, the cast ingot is subjected to homogenization treatment on to obtain a blank, the blank is extruded to obtain a forming part, and the forming part is subjected to aging strengthening treatment to obtain the magnesium alloy. The tensile strength of the magnesium alloy is greater than or equal to 520 MPa, and the dissolution rate of the magnesium alloy in 3% KCl solution at 93 DEG C is 52-94 mg * cm <-2> h<-1>.

Owner:重庆昱华新材料科技有限公司

Component design and preparation method for zinc-aluminum alloy pipe

The invention discloses a component design and preparation method for a zinc-aluminum alloy pipe. The zinc-aluminum alloy pipe comprises, by weight, 36.00%-69.00% of zinc, 31.00%-64.00% of aluminum, 0.01%-1.00% of copper, 0.01%-1.00% of magnesium, 0.01%-1.0% of tin, 0.01%-1.00% of silver, 0.01%-2.00% of titanium, 0.01%-0.50% of boron, 0.01%-0.70% of cerium and 0.01%-0.20% of praseodymium, and the sum of the weight percentage is 100%. The obtained zinc-aluminum alloy pipe can be used for manufacturing a mold and a pipe fitting in a complex shape and used for manufacturing a delay element in the civil explosive industry according to the component and performance differences, so that an existing lead-antimony alloy pipe which is severe in environmental pollution and toxicity is replaced; and meanwhile, zinc-aluminum alloy is light in proportion and cheaper than a copper alloy material, the cost can be obviously reduced, and the zinc-aluminum alloy pipe can be widely used in metallurgy, mines, light industry, food, chemical industry, printing, mechanical equipment and other fields.

Owner:FUZHOU UNIVERSITY

Grain-refined manganese-lithium alloy and method for manufacturing same

The invention discloses grain-refined manganese-lithium alloy and a method for manufacturing the same. The manganese-lithium alloy comprises, by mass, from 11.0% to 15.0% of Li, form 1.0% to 3.0% of Al, from 0.1% to 0.5% of La, lower than or equal to 0.3% of impurities and the balance manganese. The method for manufacturing the grain-refined manganese-lithium alloy includes heating a formula amount of the pure manganese, a formula amount of the pure lithium, a formula amount of the pure aluminum and a formula amount of manganese-lanthanum master alloy under conditions of vacuumizing and feeding of inert gas until the temperature reaches 720 DEG C to obtain alloy; preserving heat at the temperature of 700 DEG C after the alloy is completely melted, and allowing the alloy to stand for 15 minutes; and pouring melted alloy liquid in molds to obtain as-cast manganese-lithium alloy. The grain-refine manganese-lithium alloy contains rare earth La, structures of grains of the grain-refine manganese-lithium alloy are fine and uniform, the strength and the plasticity are improved, and the grain-refine manganese-lithium alloy is excellent in follow-up processing property, low in production cost and suitable for industrial large-scale production.

Owner:CHONGQING UNIV

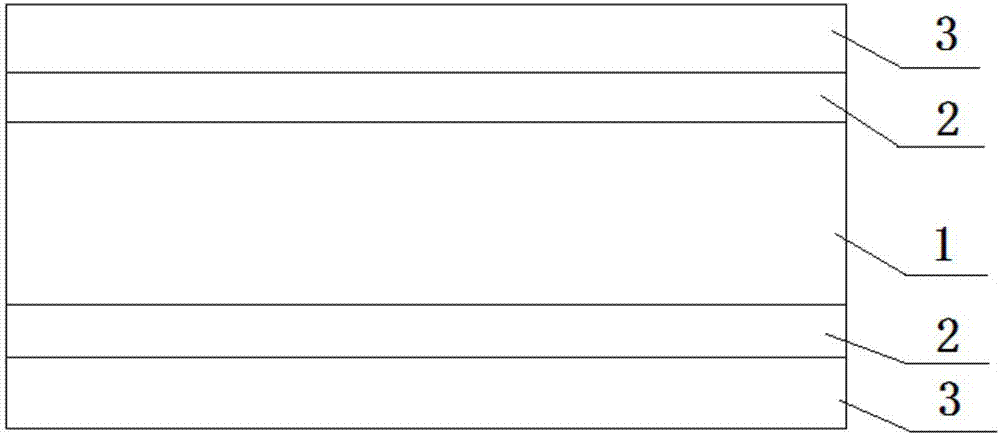

Five-layer aluminum alloy composite board and composite method

InactiveCN107881370AHigh strengthHigh hardnessLamination ancillary operationsLaminationAlloy compositeImpurity

The invention relates to a five-layer aluminum alloy composite board and a composite method. The structure of the composite board is 4xxx / 3003mod1 / 3003mod2 / 3003mod1 / 4xxx, wherein the 3003mod2 comprises the components of not greater than 0.15% of Si, not greater than 3.0% of Fe, 0.5%-0.8% of Cu, 1.3-1.85% of Mn, 0.05-0.15% of Ti, and the balance Al and inevitable impurities of which the total amount is less than 0.15%, and the 3003mod1 comprises the components of 0.45-0.8% of Si, 0.1-0.6% of Fe, 1.3-1.8% of Mn, 2.0-3.0% of Zn, 0.05-0.15% of Zr, and the balance Al and inevitable impurities of which the total amount is less than 0.15%. According to the five-layer aluminum alloy composite board and the composite method, the components and the structure are improved, and therefore the purpose of protecting a core material can be achieved, the strength of an alloy can be improved, meanwhile, the post-weld strength of the material can be improved, in addition, the composite method is simple and easy to realize, and the obtained five-layer aluminum alloy composite board is low in cost.

Owner:YINBANG CLAD MATERIAL

2XXX series aluminum alloy and preparation method thereof

ActiveCN112626401AImproves strength and hardnessReduce industrial costMetal-working apparatusMetal alloySolution treatment

The invention relates to a 2XXX series aluminum alloy and a preparation method thereof, and belongs to the technical field of non-ferrous metal alloys. The problems of low strength and poor toughness of the 2XXX series aluminum alloy in the prior art are solved. The 2XXX series aluminum alloy comprises the following chemical components in percentage by mass: 3.9-4.5 percent of Cu, 0.5-1.0 percent of Mg, 0.5-1.2 percent of Mn, 0.3-0.8 percent of Si, 0.1-0.2 percent of Zr, less than or equal to 0.1 percent of Ti, less than or equal to 0.4 percent of Fe, less than or equal to 0.1 percent of Zn, less than or equal to 0.05 percent of single impurity, less than or equal to 0.15 percent of total impurity and the balance of Al. The preparation method of the 2XXX series aluminum alloy comprises the steps that 1, pure Al, an Al-Cu intermediate alloy, an Al-Mg intermediate alloy, an Al-Si intermediate alloy, an Al-Mn intermediate alloy and an Al-Zr intermediate alloy are weighed according to the mass percent of all the elements to serve as raw materials; 2, the raw materials are refined to obtain an aluminum alloy smelting solution, and cast into a cast ingot; and 3, the cast ingot is sequentially subjected to homogenization, forging and pressing, solution treatment and aging treatment, and the 2XXX series aluminum alloy is obtained. The strength and toughness of the 2XXX series aluminum alloy are improved.

Owner:ADVANCED MFG TECH CENT CHINA ACAD OF MASCH SCI & TECH +2

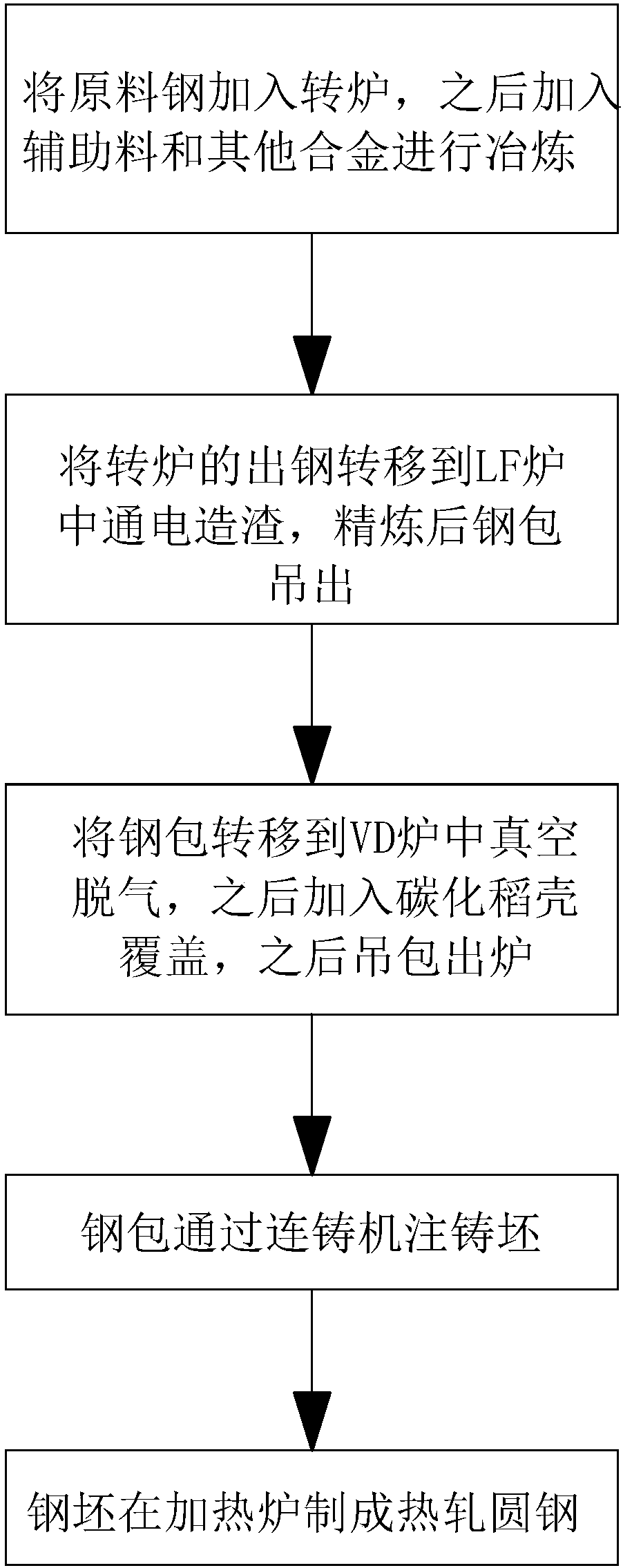

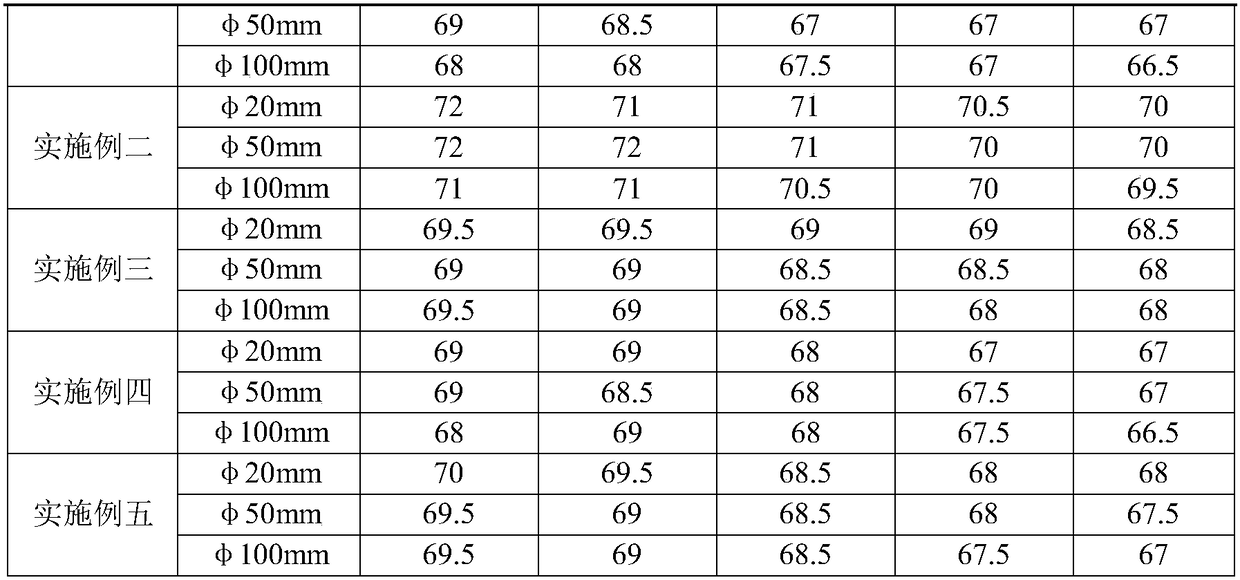

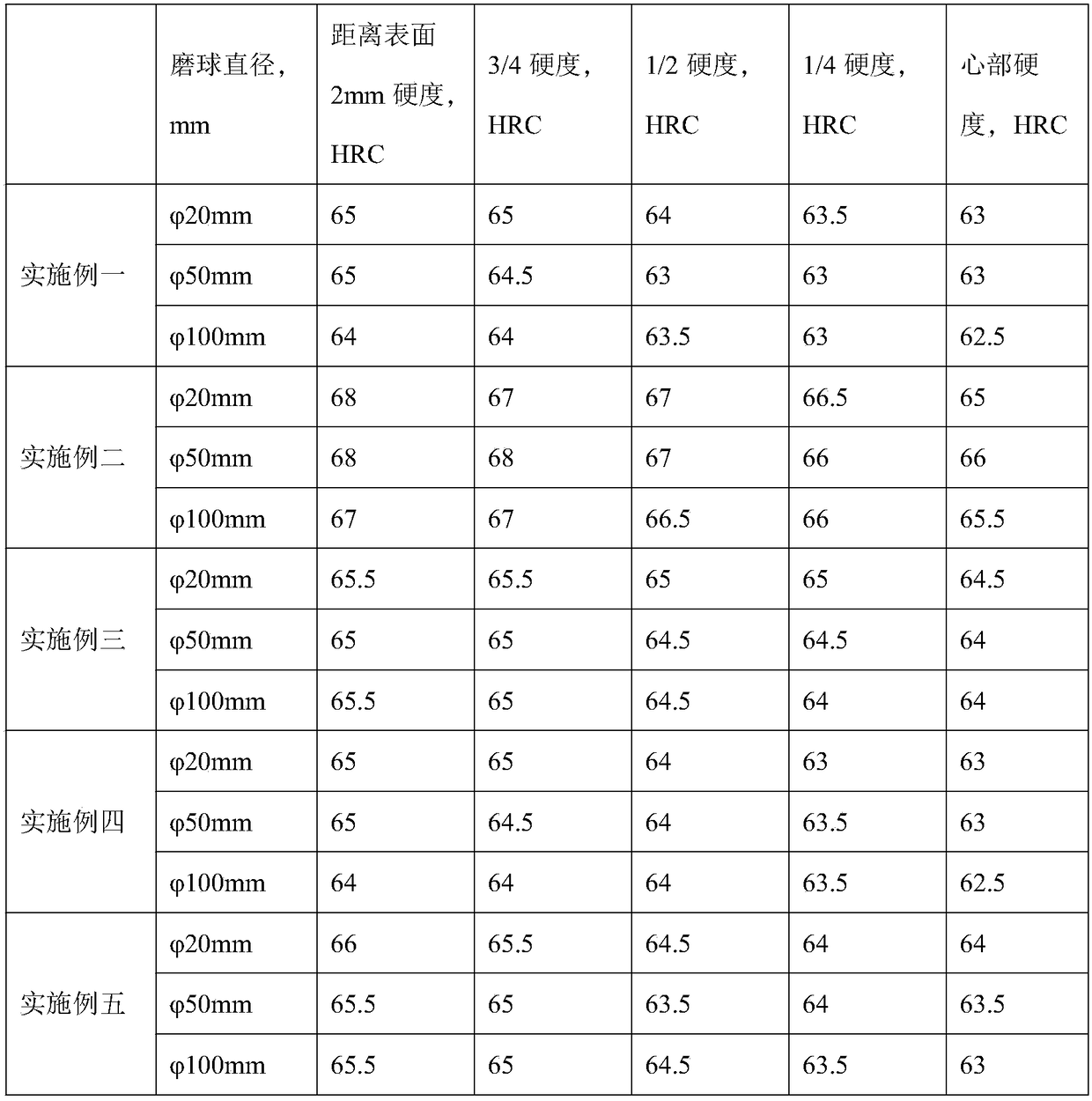

Hot-rolled round steel for high-carbon-manganese-chromium grinding ball and manufacturing method thereof

The invention provides hot-rolled round steel for a high-carbon-manganese-chromium grinding ball. The hot-rolled round steel is prepared from the following components: 0.72 to 0.82 percent of C, 0.17to 0.35 percent of Si, 0.70 to 0.90 percent of Mn, 0.010 to 0.030 percent of P, 0.010 to 0.030 percent of S, 0.50 to 0.70 percent of C, 0.20 to 0.30 percent of In, 0.10 to 0.20 percent of Ag, 0.15 to0.25 percent of Cu, 0.080 to 0.100 percent of Ga, 0.20 to 0.26 percent of Ni, 0.10 to 0.14 percent of Zn, 0.14 to 0.16 percent of Sn and the balance of Fe and unavoidable impurities. The round steel provided by the invention contains relatively high elements including carbon, manganese, tin and the like and can be obtained by refining a casting-state structure of steel, so that the prepared grinding ball has relatively great rigidity; when an object with relatively great rigidity is ground, good wear resistance can be ensured; meanwhile, the round steel also contains the chromium element withrelatively high content, so that the round steel has a relatively strong corrosion-resisting capability and the round steel is suitable for being used in various fields for grinding.

Owner:TIANJIN RONGCHENG UNITED IRON & STEEL GRP CO LTD

Low-alloy abrasion-proof and corrosion resistant steel and method for producing the same

InactiveCN101423916BImprove corrosion resistanceFix fixesElectric furnaceProcess efficiency improvementWear corrosionWear resistant

The invention relates to low alloy wearing resistance corrosion resistance steel which is suitably used in the ocean mud-sand wearing and corrosive environment, which is produced by the following steps: Mn-Si-Cr-Mo system non-carbide bainite alloy steel is taken as research basis, the carbon content and other alloy element contents are properly adjusted, elements of Al, Nb and rare earth contributing to improving the corrosion resistance of the alloy steel are added for modification, and the Mn-Si-Cr-Mo-Al system non-carbide bainite steel is formed by the progression quenching heat treatment process, so that the low alloy wearing resistance corrosion resistance steel is obtained. The steel has good obdurability, wearing resistant and corrosion resistant comprehensive performance and welding repair performances, and can be used to solve the problem of repairing worn blades of a centrifugal pump of a ship, and can also be applied to other ocean wearing resistance welding parts.

Owner:HOHAI UNIV +1

Rare earth armor steel and manufacture method thereof

The invention provides rare earth armor steel and a manufacture method thereof. Alloyed rare earth elements are distributed in an iron-based structure of the armor steel, the alloyed rare earth elements are one or multiple of the three elements, namely, cerium Ce, lanthanum La and yttrium Y, the content of the alloyed rare earth elements is controlled at 0.005 wt% to 0.080 wt% through a steelmaking feeding rare earth wire process, and through the common effect of the alloyed rare earth elements and other alloyed elements, the armor steel with the tensile strength being 1700-2200 MPa, the Brinell hardness being HB480 to HB600 and the corrosion resistance being the corrosion rate, not larger than 1.65 g / (m<2>.h), of a 96 h periodic infiltration corrosion test. The corrosion resistance is notinferior to that of 09CuPCrNiA steel. The 09CuPCrNiA steel is equivalent to ASTM A242(COR-TEN A) steel or Japan SPA-H steel or China Q355GNH steel, and therefore better application of the rare eartharmor steel to personal and armored vehicle bullet protection and bullet protection projects of fixed or movable structures is facilitated.

Owner:国研(淮安)新材科技有限公司

Wear-resistant steel and production process thereof

ActiveCN108315645AImprove wear resistanceHigh strengthProcess efficiency improvementWear resistantUltimate tensile strength

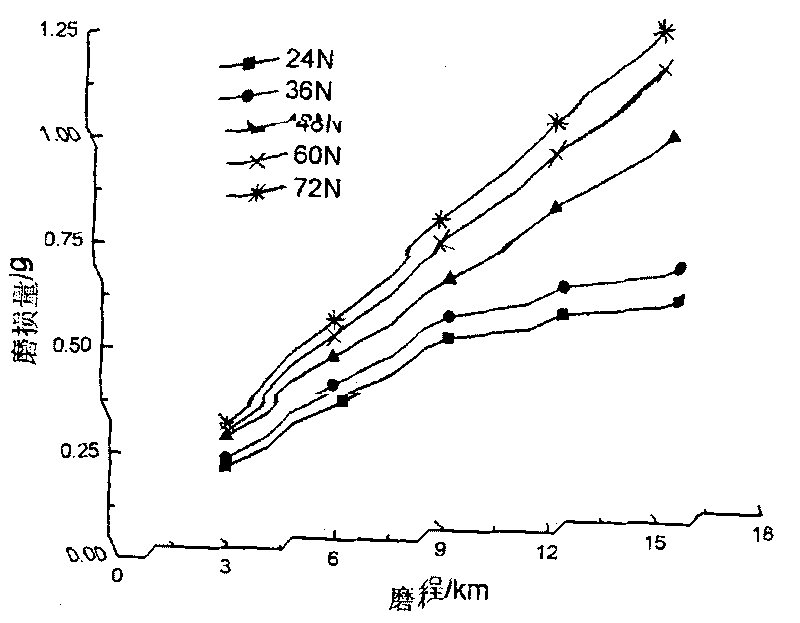

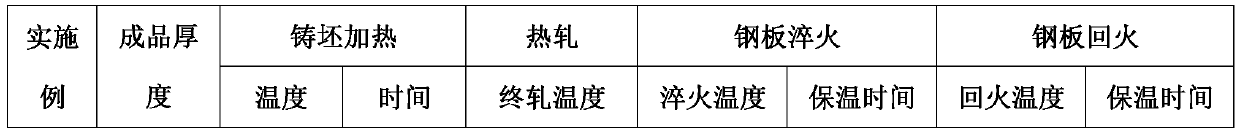

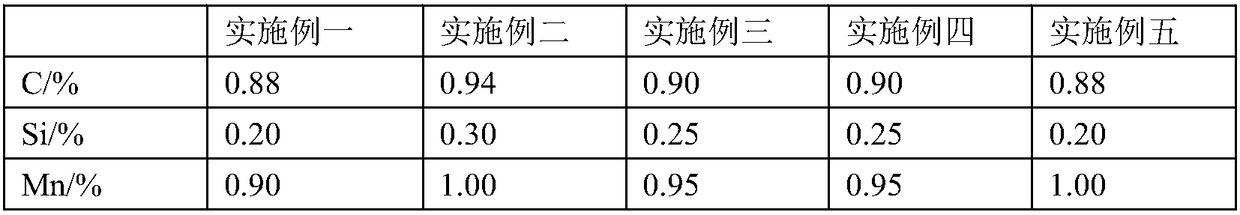

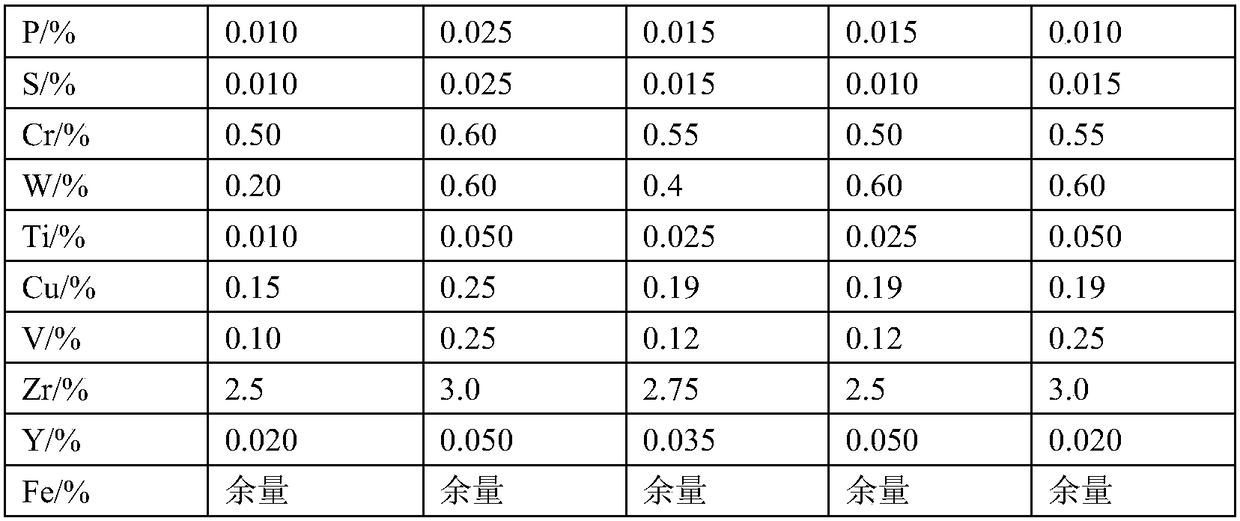

The invention relates to wear-resistant steel and belongs to the technical field of metal smelting. The wear-resistant steel is prepared from the following components in percent by mass: 0.88-0.94% ofC, 0.20-0.30% of Si, 0.90-1.00% of Mn, 0.50-0.60% of Cr, 0.20-0.60% of W, 0.10-0.25% of V, 2.50-3.00% of Zr, 0.010-0.050% of Ti, 0.020-0.050% of Y, less than or equal to 0.025% of P, less than or equal to 0.025% of S, less than or equal to 0.25% of Cu and the balance of Fe and inevitable impurities. The wear-resistant steel has the beneficial effects that the problems of low strength and poor wear resistance of the existing low-carbon wear-resistant steel is solved; the wear-resistant steel is finer in crystal and fuller in internal density, and a grinding ball prepared by the wear-resistantsteel is larger in hardness and good in wear resistance.

Owner:天津荣程联合钢铁集团有限公司

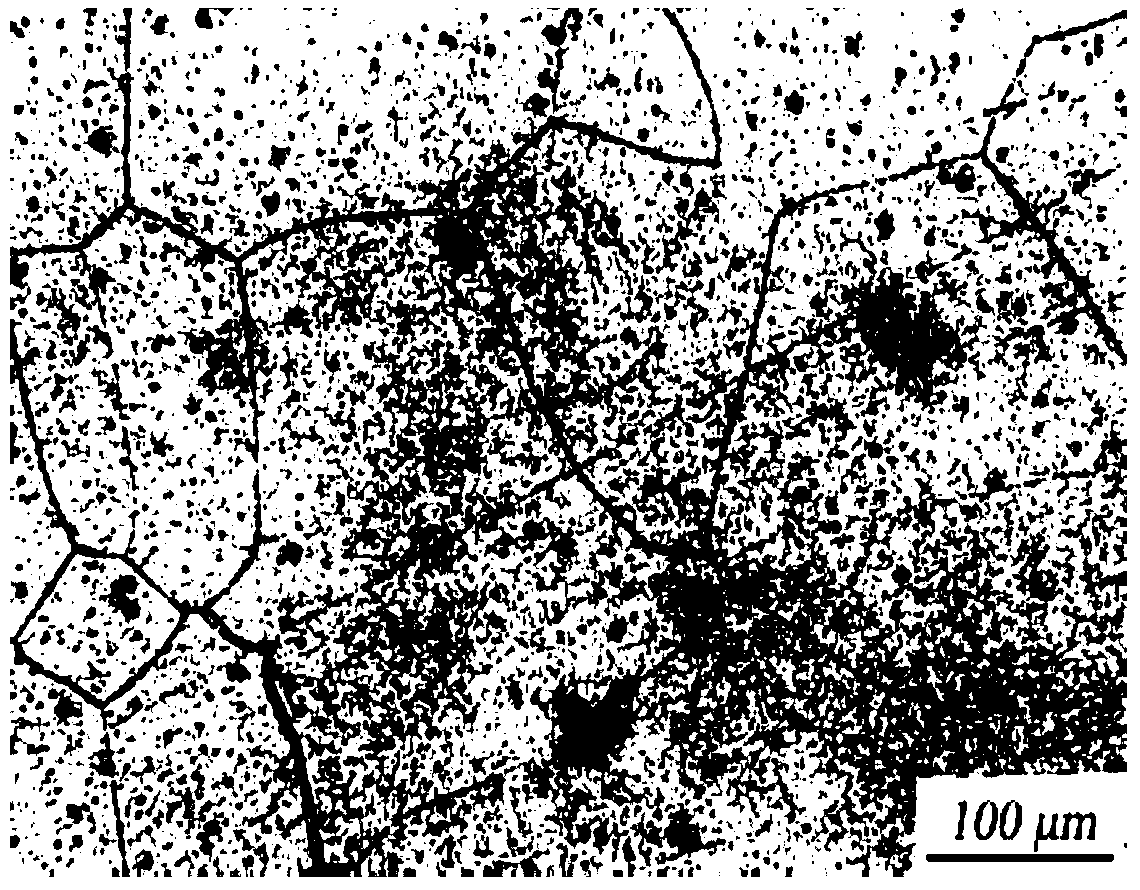

Rare earth oxide modified copper-nickel-silicon alloy material and preparation method and application thereof

InactiveCN106011535APromote formationGuaranteed tensile strengthMagnetic circuit characterised by magnetic materialsSilicon alloyRare earth

The invention belongs to the technical field of high-performance copper alloy materials, and discloses a rare earth oxide modified copper-nickel-silicon alloy material and a preparation method and application thereof. All the components include, by weight percentage, 1.1%-4.1% of nickel, 0.1%-2.1% of silicon, 0.01%-1.2% of rare earth oxide, and the balance copper and unavoidable impurities, wherein the rare earth oxide is strontium lanthanum manganese oxide (the atomic ratio of strontium is 0.01-0.29, and the atomic ratio of lanthanum is 0.01-0.59), and a vacuum induction smelting method is adopted. Part of the rare earth oxide in the rare earth oxide modified copper-nickel-silicon alloy material focuses in front of a solid-liquid interface, constitutional supercooling is caused, the cast structure is refined, and the dendrite arm spacing is reduced. Part of fine rare earth oxide particles enter grains to serve as heterogeneous nucleation points, and formation of isometric crystal is promoted. The rare earth oxide has a doping effect, thereby playing a role as modificator and affecting the separating-out number and distribution of a second phase. Finally, on the premise of guaranteeing the tensile strength of the cast alloy, the elongation is greatly improved, and the cast alloy has good plasticity.

Owner:SHANDONG UNIV +1

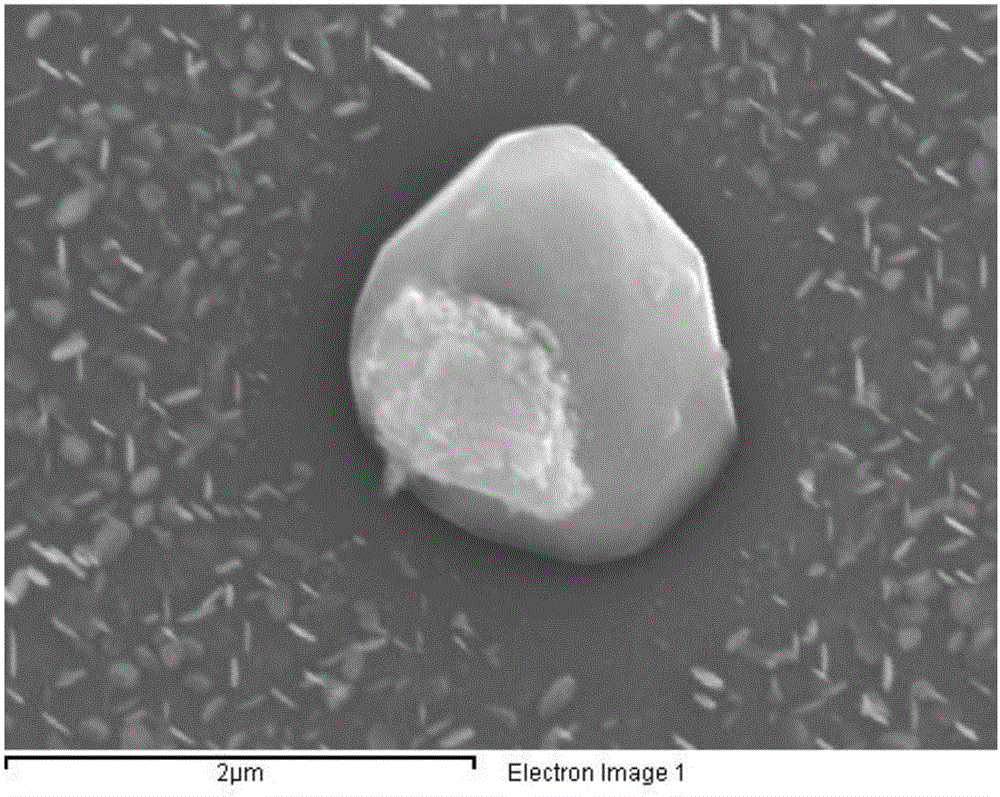

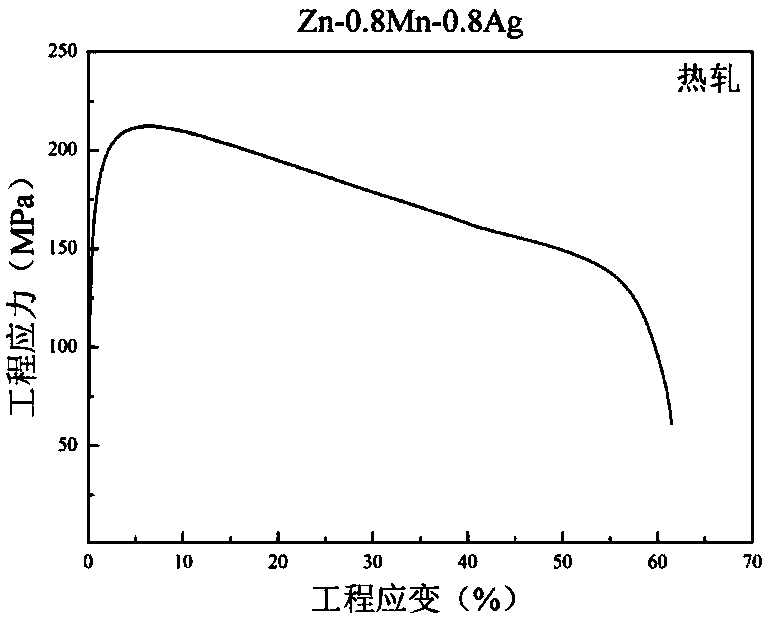

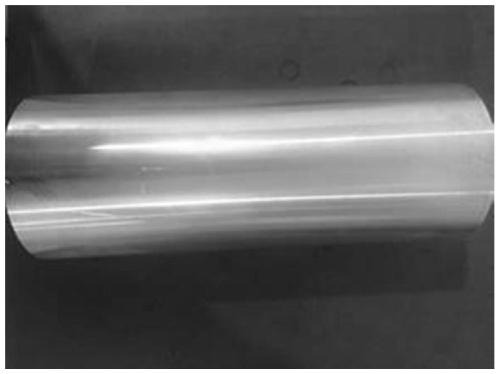

A low-alloyed Zn-Mn-Ag or Zn-Mn-Ca alloy and a preparing method thereof

The invention discloses a low-alloyed Zn-Mn-Ag or Zn-Mn-Ca alloy and a preparing method thereof, and belongs to the technical field of component designing and preparation of non-ferrous metal alloy materials. The provided zinc alloy includes, by mass, (1) 0.1-5% of Mn and 0.05-5% of Ag, with the balance being Zn; or (2) 0.1-5% of Mn and 0.02-2% of Ca, with the balance being Zn. An as-cast alloy manufactured through vacuum smelting is rolled or extruded to achieve plastic deformation, thus optimizing the alloy structure and allows the alloy to have good comprehensive mechanical performance. Therolling step includes four process routes. The extruding step includes one process route. The prepared deformed Zn-Mn-Ag or Zn-Mn-Ca alloy can be adopted as instrument and apparatus shells, decorative products, models, electrical appliance components, and the like. In addition, the alloy has mechanical performance needed for biomedical implant materials, can be degraded in vivo, has excellent cytocompatibility and can be implanted into animals or humans as a biomedical material.

Owner:UNIV OF SCI & TECH BEIJING

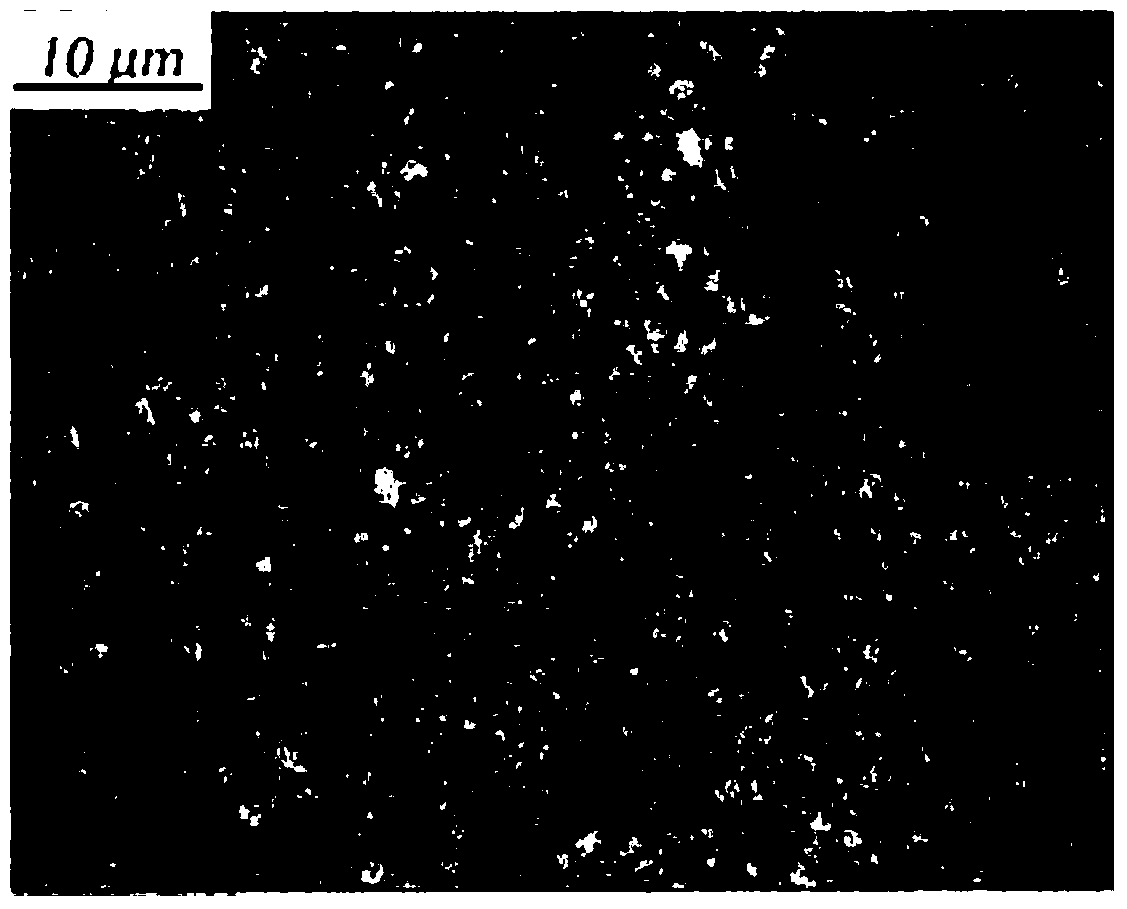

Al-Zn-Mg-SC series aluminum alloy powder for metal 3D printing and preparation method thereof

InactiveCN111440975AUniform chemical composition of powderGrain refinementAdditive manufacturing apparatusUltimate tensile strengthAluminium alloy

The invention discloses a preparation method of Al-Zn-Mg-SC series aluminum alloy powder for metal 3D printing. The preparation method comprises the steps of batching, vacuum melting, casting, homogenization treatment, ingot surface post-treatment and pulverizing. The invention also discloses the aluminum alloy powder prepared by the method. The aluminum alloy powder is used for 3D printing of a workpiece, and the tensile strength of the prepared workpiece is 500-550 MPa, the yield strength is 450-505 MPa, and the elongation is 9%-12%. The metal 3D printing aluminum alloy powder meeting high-strength part printing requirements is prepared, the chemical components are uniform, and the grain sizes basically range within 40-60 micrometers.

Owner:HUNAN ORIENTAL SCANDIUM

Steel special for abrasion-resistant grinding ball and preparation method of steel

The invention provides steel special for an abrasion-resistant grinding ball. The steel special for the abrasion-resistant grinding ball comprises 0.88%-0.94% of C, 0.20%-0.30% of Si, 0.90%-1.00% of Mn, no more than 0.025% of P, no more than 0.025% of S, 0.50%-0.60% of Cr, 0.010%-0.050% of Ti, 0.20%-0.30% of In, no more than 0.25% of Cu, 0.080%-0.100% of Ga, 0.20%-0.26% of Ce, 0.10%-0.14% of Zn, 0.14%-0.16% of Sn, and the balance Fe and inevitable impurities. By adoption of the technical scheme, crystals of the steel are fine, and the internal density of the steel is high; the grinding ball prepared from the steel is high in hardness and good in abrasion resistance; and the steel special for the abrasion-resistant grinding ball is low in production cost and suitable for being used for grinding in various fields.

Owner:天津荣程联合钢铁集团有限公司

A kind of copper chromium zirconium alloy and preparation method thereof

Copper-chromium-zirconium alloy is characterized by being prepared from the following raw materials in percent by weight: 0.2-1.2% of chromium, 0.05-0.2% of zirconium, 0.06-0.10% of magnesium, 0.05-0.5% of scandium and the balance of copper. The invention further provides a preparation method of the copper-chromium-zirconium alloy. The preparation method sequentially comprises the following steps:(1), proportionally preparing copper, chromium, zirconium, magnesium and scandium elements, performing vacuum smelting, and performing split casting to obtain a casting blank; (2), performing homogenizing treatment and hot extrusion on the casting blank to obtain a bar blank; (3), performing solid solution treatment to the bar blank; (4), performing cold deformation processing on the bar blank obtained after the solid solution treatment; (5), performing aging treatment to a material obtained after the cold deformation processing to obtain the needed copper-chromium-zirconium alloy. The copper-chromium-zirconium alloy has high tensile strength, high electrical conductivity and high elongation and has relatively high high-temperature tensile strength and excellent comprehensive performance.

Owner:GUANGDONG HUAXING HEAT EXCHANGE EQUIP CO LTD +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com