Rare earth armor steel and manufacture method thereof

A manufacturing method and armor steel technology, applied in the field of rare earth armor steel and its manufacture, can solve the problems of high cost of alloying elements, poor economy, low-temperature toughness of materials and negative impact on formability, etc., to improve atmospheric corrosion resistance, refine As-cast structure, effect of inhibiting further corrosion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

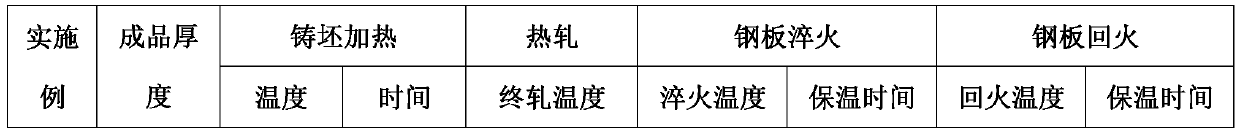

[0044] Embodiment: According to the composition requirements of the rare earth armor steel of the present invention, the present invention provides corresponding manufacturing methods, and the smelting process includes converter blowing, LF refining (Ladle Furnace, ladle refining furnace), RH vacuum treatment (RH: Ruhrstahl-Heraeus-Vacuum Degassing, vacuum cycle degassing refining), slab continuous casting, slab hot delivery, slab heating, controlled rolling, controlled cooling, hot rolling coiling-finishing or medium plate hot straightening-cooling bed cooling-shearing Cutting, final heat treatment of plates. The steelmaking-continuous casting process includes hot metal desulfurization and slag removal pretreatment, top-bottom combined blowing converter blowing, tapping alloying, LF refining, and slab continuous casting. Desulfurization by spraying lime powder into the molten iron ladle, and then mechanically removing slag with a slag removal car. The temperature of the molte...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com