Operational Neutron Source

a neutron source and operation technology, applied in nuclear engineering, nuclear elements, greenhouse gas reduction, etc., can solve the problems of large design area, insufficient control of neutron flux, and large neutron generation in the core, so as to improve the reliability of the operation and improve the failure-free operation of the neutron source.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

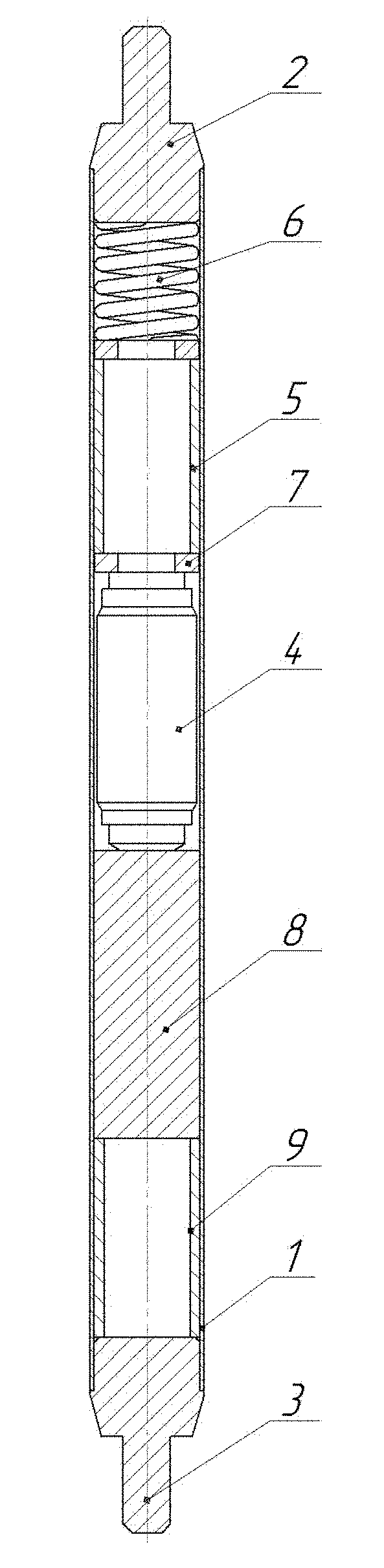

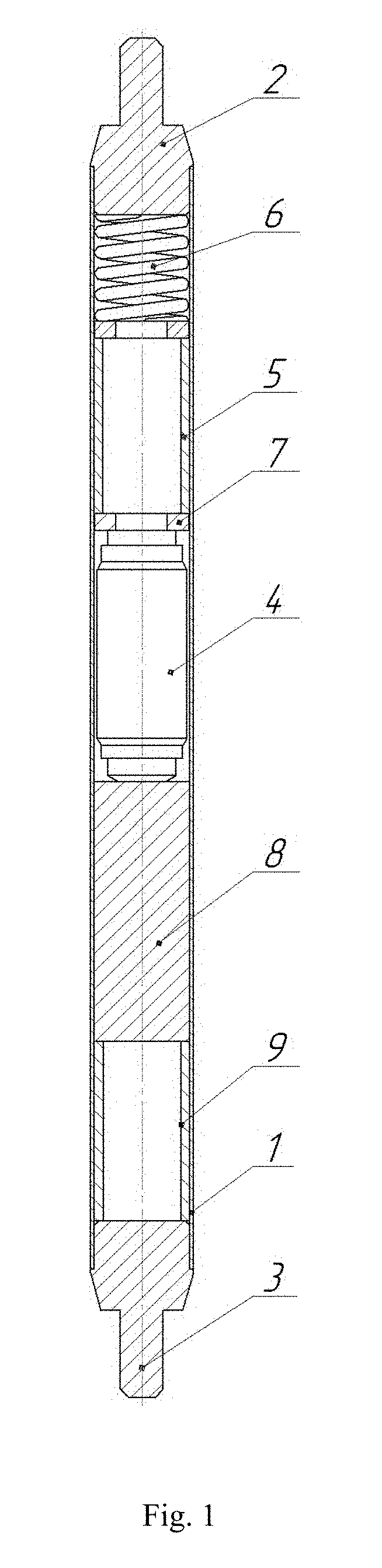

[0027]The container-type operational neutron source has an enclosure 1 made of martensite-ferrite grade steel with a diameter of 12 mm in the smooth part, and the wall thickness of 0.4 mm, with four spiral ribs located on the outer side of the enclosure. The diameter along the ribs is 13.5 mm, the rib winding pitch is 750 mm. (Not shown in the drawing)

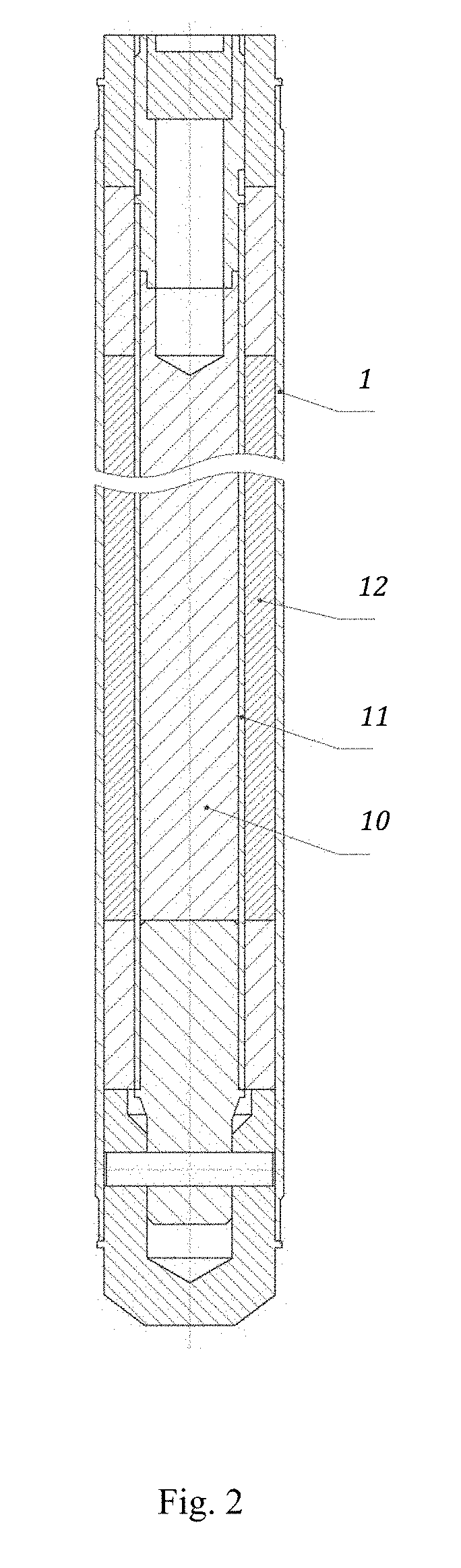

[0028]The enclosure houses an ampule 4 with active elements: antimony and beryllium. The active components are located in separate antimony and beryllium cavities of coaxial design.

[0029]An upper gas collector is located above the ampule 5, which serves as a compensation volume collecting gaseous fission products. The gas collector 5 is pressed against the ampule through washers 7 with a spring 6.

[0030]At the bottom, the ampule is supported by a reflector 8 and a bottom gas collector 9.

[0031]The neutron source enclosure inner cavity is filled with helium to ensure heat transfer.

[0032]The neutron source enclosure is sealed with two shan...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com