Metal beryllium powder for 3D printing and preparation method and application thereof

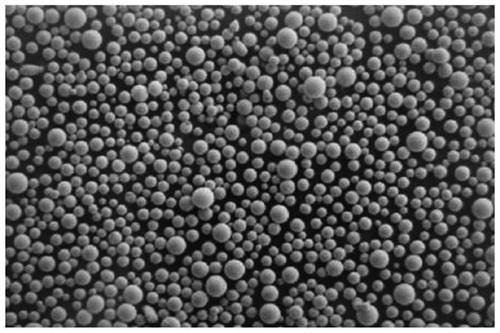

A 3D printing, metal beryllium technology, applied in the field of metal beryllium powder preparation, can solve the problems of unreasonable particle size distribution, limited application of metal beryllium, low bulk density, etc., and achieves good fluidity, low oxygen content, and good sphericity. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0027] In an exemplary embodiment of the present invention, the preparation method of metal beryllium powder for 3D printing may comprise the following steps:

[0028] Put the metal beryllium rod into the plasma arc melting rotary atomization device, draw a vacuum and control the vacuum degree in the device (that is, the vacuum degree in the vacuum chamber) at 5×10 -3 Below Pa, further, it can be 3×10 -3 Pa~5×10 -3 Pa. Excessively high vacuum in the extraction device will prolong the production preparation time of the equipment and reduce work efficiency. If the vacuum in the extraction device is too low, more inert gas needs to be flushed to replace and remove oxygen, which is uneconomical.

[0029] Then a mixed inert gas is fed into the device to ensure that the oxygen content in the atomization chamber (ie vacuum chamber) is below 3ppm, and the plasma arc is turned on under the protection of the inert gas to melt the front end of the metal beryllium rod to form a liquid f...

example 1

[0054] Process metal beryllium rods containing 98.2% beryllium and 97% relative density (see Table 1 for the main components) into Ф50×700mm raw beryllium rods, and remove oxides and impurities on the surface of the raw material beryllium rods.

[0055] Put the raw material beryllium rods from which surface oxides and impurities have been removed into the arc rotating electrode device, and vacuumize to 3×10 -3 Pa.

[0056] Then feed a mixed inert gas into the device. When the oxygen content in the atomization chamber is guaranteed to be lower than 3ppm, the arc is turned on under the protection of the inert gas, and the power of the arc melting is controlled by adjusting the working current to control the melting of the metal beryllium rod. Speed, among them, the working current output is 1800A, and the arc length is 70mm.

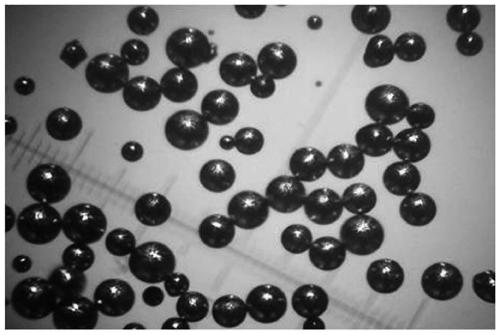

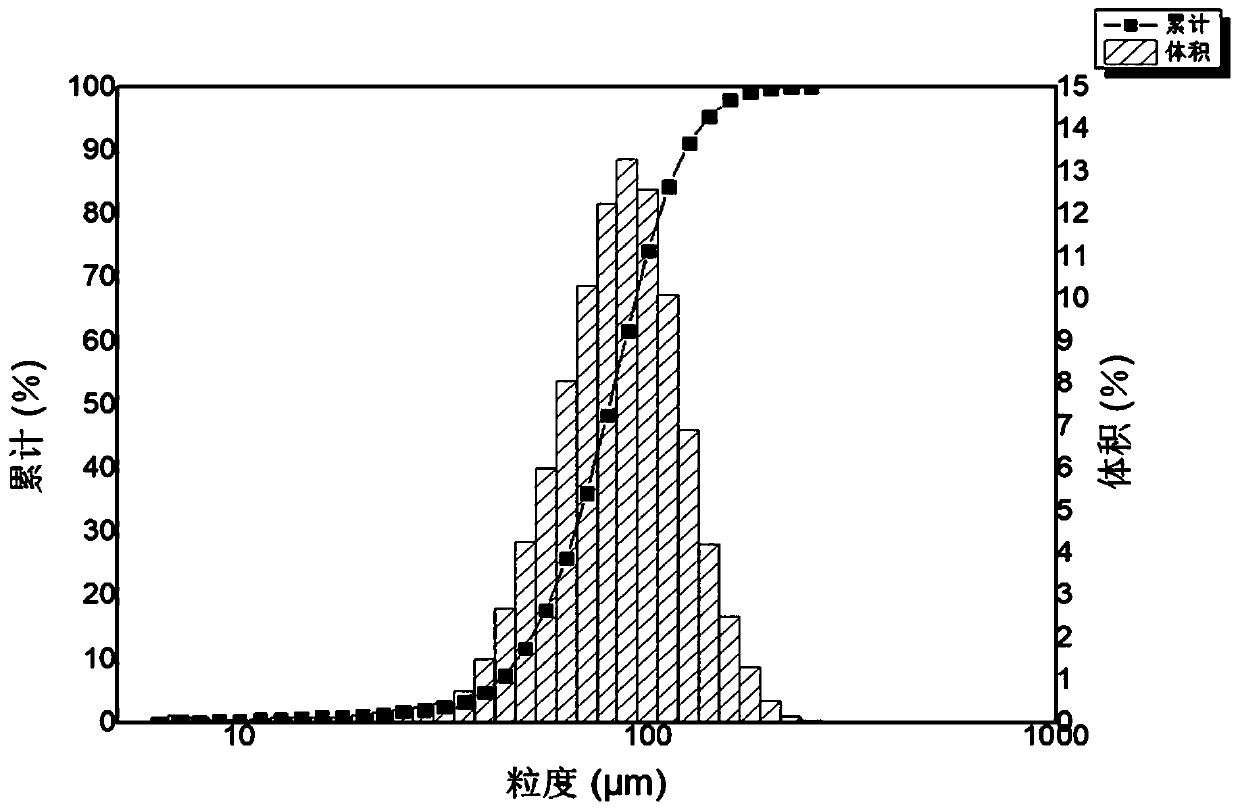

[0057] The raw material beryllium rod is rotated at a speed of 16000rpm. The front end of the raw material beryllium rod is melted by the arc to form a l...

example 2

[0066] Take metal beryllium rods with a beryllium content greater than 99.1% and a relative density greater than 97% (see Table 3), process them into raw material beryllium rods with a diameter of Ф100×350mm, and remove oxides and impurities on the surface of the raw material beryllium rods.

[0067] Put the raw material beryllium rods from which surface oxides and impurities have been removed into the arc rotating electrode device, and vacuumize to 3×10 -3 Pa.

[0068] Then feed a mixed inert gas into the device to ensure that the oxygen content in the atomization chamber is lower than 3ppm, and open the arc under the protection of the inert gas, and control the melting speed and operating current of the metal beryllium rod by controlling the power of the arc melting and the size of the working current Output 2800A, arc length 45mm.

[0069] The raw material beryllium rod is rotated at a speed of 26000rpm. The end surface of the raw material beryllium rod is melted into a li...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com