Aluminium conductive paste for solar energy battery and preparation method thereof

A technology of solar cells and conductive pastes, which is applied in the manufacture of cables/conductors, conductive materials dispersed in non-conductive inorganic materials, circuits, etc., can solve the problems of leaking net storage performance, poor storage performance, etc., and achieve good storage performance and filling Effect of factor increase, good thixotropic properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

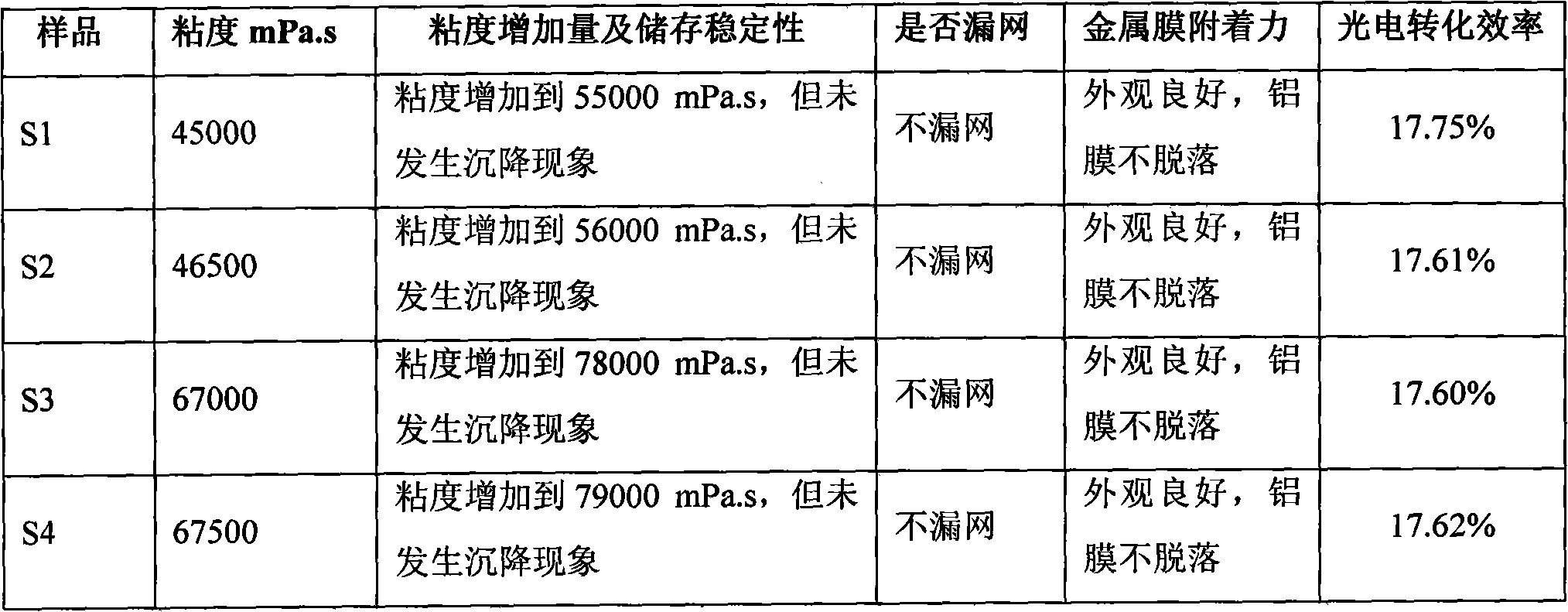

Examples

Embodiment 1

[0031] This example is used to illustrate the solar cell conductive paste disclosed in the present invention and its preparation method.

[0032] Step 1: Configuration of organic carrier

[0033] Based on the total weight of the organic vehicle to be prepared, get 30 parts by weight of terpineol, 54 parts by weight of dibutyl phthalate (DBP), mix uniformly, dissolve 16 parts by weight of ethyl cellulose In the above-mentioned mixed solvent, heat to 70°C to fully dissolve it, and stir evenly to obtain a uniform and clear organic vehicle A1.

[0034] Step 2: Preparation of Inorganic Binder

[0035] Get 68 parts by weight of bismuth oxide, 17 parts by weight of diboron trioxide, 7 parts by weight of silicon dioxide, 6 parts by weight of zinc oxide, and 2 parts by weight of aluminum oxide, join in a high-speed V-shaped mixer and mix for 20min, until uniform, an inorganic binder composed of oxide mixture powder is obtained.

[0036] Step 3: Preparation of solar cell conductive p...

Embodiment 2

[0040] This example is used to illustrate the solar cell conductive paste disclosed in the present invention and its preparation method.

[0041] Step 1: Configuration of organic carrier

[0042] Same as Example 1.

[0043] Step 2: Preparation of Inorganic Binder

[0044] Put the oxide mixture obtained in Step 2 of Example 1 into a porcelain crucible, put it into a silicon carbide rod furnace, heat it up to 500°C and keep it for 0.5 hours, then raise it to 1250°C, melt for 1 hour, water quench, and dry When the water content is less than 8%, use a crushing machine to crush it to 150 μm, and then put it into a ball mill tank to control the quality of the zirconia balls: material: deionized water = 2:1:0.5, tank speed 100 rpm, ball mill for 48 hours , filtered, and dried to obtain particle size D 50 It is a glass powder of about 2.5 microns.

[0045] Step 3: Preparation of solar cell conductive paste

[0046] Based on the total weight of the solar cell conductive paste requ...

Embodiment 3

[0049] This example is used to illustrate the solar cell conductive paste disclosed in the present invention and its preparation method.

[0050] Step 1: Configuration of organic carrier

[0051] Same as Example 1.

[0052] Step 2: Preparation of Inorganic Binder

[0053] Get 60 parts by weight of lead oxide, 25 parts by weight of boron trioxide, 5 parts by weight of silicon dioxide, 3 parts by weight of zinc oxide, 4 parts by weight of strontium oxide, 2 parts by weight of calcium oxide, 1 part by weight of Aluminum oxide was added to a high-speed V-type mixer and mixed for 20 minutes until uniform to obtain inorganic binder powder.

[0054] Step 3: Preparation of solar cell conductive paste

[0055] Based on the total weight of the solar cell conductive paste to be prepared, take 25 parts by weight of organic carrier A1 and place it in the stainless steel tank of the high-speed disperser, add 8.0 parts by weight of inorganic binder powder and 5.0 parts by weight under sti...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com