Beryllium coarse powder crushing device and production method for beryllium coarse powders using same

A crushing device and coarse powder technology, which is applied in the field of beryllium coarse powder crushing device, can solve the problems of equipment without beryllium material crushing, and achieve the effect of short cycle and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

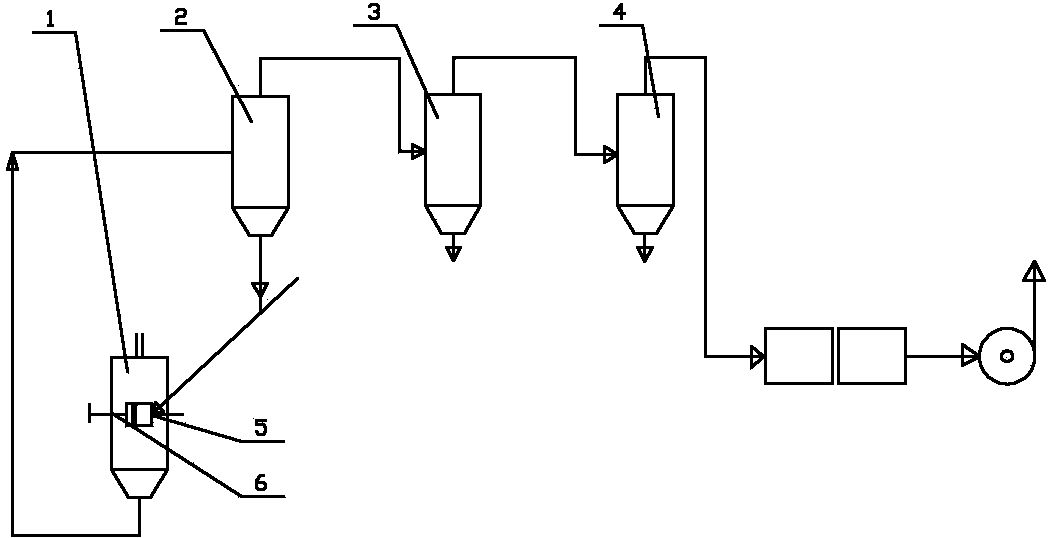

[0017] The crushing device for beryllium coarse powder of the present invention comprises a disc mill 1, a gravity classifier 2 and a cyclone classifier 3 connected together in sequence, wherein the disc mill 1 includes a conical shell and a fixed fixed device installed in the conical shell. Disk 5 and moving disk 6, fixed disk 5 and moving disk 6 are two grindstones of equal size, fixed disk 5 is also called stator, and moving disk 6 is also called rotor, and is made of cemented carbide. The stator and rotor are aligned in parallel, beryllium shavings or powder pass through the stator and rotor, and are ground into powders that meet the requirements under the high-speed rotation of the rotor. The upper end of the conical shell is connected with an air intake system (specifically connected through the air inlet opened at the upper end of the conical shell). When the wind force is constant, the grinding rate can be controlled by controlling the current. A cold water circulation...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com