Preparing method of nano beryllium powder

A nano and organic beryllium technology is applied in the field of preparation of nano beryllium powder, which can solve the problems of serious contact pollution of grinding equipment, difficulty in reducing the particle size of beryllium powder, complicated process equipment, etc., and achieves reduction of contact pollution, good sphericity, The effect of simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

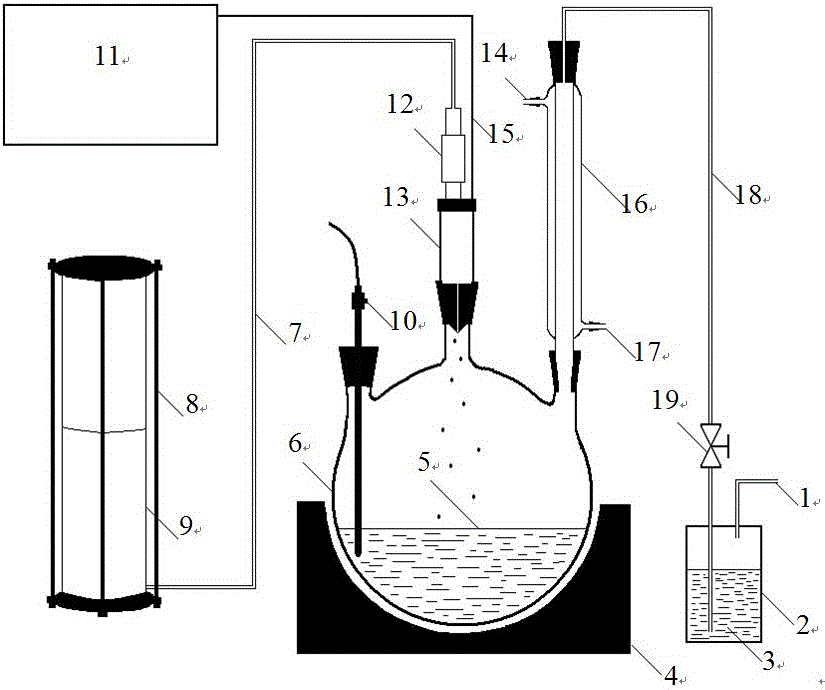

[0015] figure 1 It is a structural schematic diagram of the preparation device of the nano beryllium powder of the present invention.

[0016] The beryllium powder preparation process is carried out in a glove box. The gas in the glove box is high-purity argon (99.999%), the oxygen content is ≤10ppm, and the water content is ≤1ppm. The exhaust gas produced by the experiment is discharged to the beryllium laboratory filter tower. When entering the laboratory, wear a protective lab coat, a protective half mask, and latex gloves.

Embodiment 1

[0018] 1. Solvent purification

[0019] In this experiment, n-dodecane (Aladdin reagent, purity 99%, CAS: 112-53-8, boiling point 217°C) was used as the pyrolysis solvent. Before the solvolysis experiment, n-dodecane was purified by distillation to remove non-volatile impurities. Distillation under reduced pressure, the solvent temperature is about 128°C, the steam temperature is about 80°C, the distillation temperature is affected by the vacuum in the flask, the stirring speed is 1000 rpm, and the solvent after distillation is analyzed by ICP-MS. The test results show that , with no detectable metal impurities.

[0020] 2. Electronic thermometer calibration

[0021] The purified n-dodecane was added to the three-neck reaction flask 6, and the electronic thermometer was calibrated by the constant temperature (217°C) when n-dodecane boiled.

[0022] 3. Constant temperature of solvent

[0023] The temperature of the n-dodecane solvent was lowered to 203°C and maintained for ...

Embodiment 2

[0033] A micro-droplet controller is used to control the di-tert-butyl beryllium raw material to spray micro-droplets of picoliters to carry out pyrolysis reaction. Others are the same as in Example 1. Compared with Example 1, the particle size of the beryllium powder obtained in this experiment is smaller, but because the distribution speed of the organic beryllium liquid is too slow, the preparation rate of the beryllium powder is low.

PUM

| Property | Measurement | Unit |

|---|---|---|

| boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com