Method for preparing vacuum hot-pressed beryllium material with diameter greater than 300 mm and beryllium material

A technology of vacuum hot pressing and beryllium materials, which is applied in the field of beryllium materials, can solve the problems of high cost, low pressing efficiency, and low pressing force, and achieve the effects of low pressing cost, high pressing efficiency, and improved material density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] Step 1: Prepare beryllium powder with a beryllium content of 99.4% by weight, an average particle size of 14 μm, and a total impurity content of 0.5% by weight.

[0025] Step 2: Put the beryllium powder into a mold for baking and then put it into a vacuum hot pressing furnace for pressure sintering;

[0026] The baking temperature is 180°C; baking for 10 hours.

[0027] Process conditions of pressure sintering: vacuum 1×10 -2 Pa began to heat up, the heating rate was 145°C / h, the holding temperature was 1140°C, and the holding pressure was 25MPa / cm 2 , The heat preservation time is 2 hours.

[0028] Step 3: Cooling the pressure-sintered beryllium powder to room temperature and demolding, to obtain a vacuum hot-pressed beryllium material with a diameter of 310 mm.

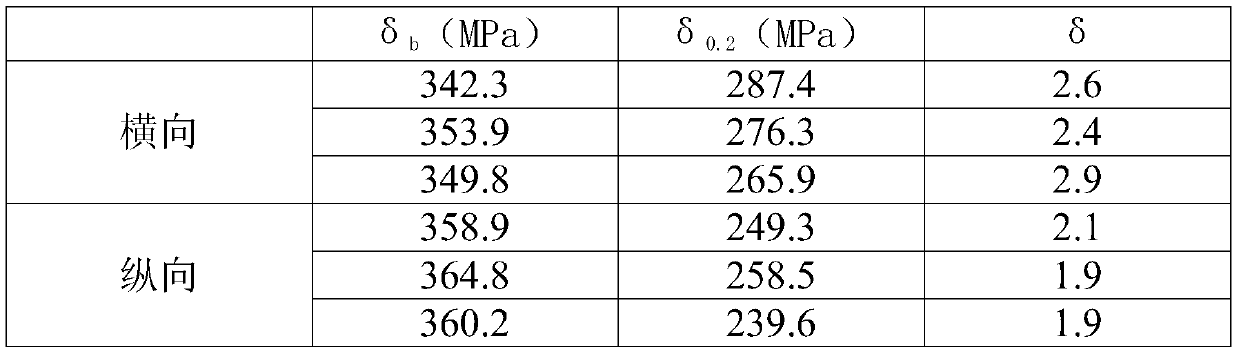

[0029] The performance parameters of the vacuum hot-pressed beryllium material with a diameter of 310 mm prepared in this embodiment are shown in the following table:

[0030]

Embodiment 2

[0032] Step 1: Prepare beryllium powder with a weight content of 99.8%, an average particle diameter of 10 μm, and a total weight content of 0.1% of impurities.

[0033] Step 2: Put the beryllium powder into a graphite mold with an inner diameter greater than 300mm and bake, then put it into a vacuum hot pressing furnace for pressure sintering;

[0034] The baking temperature is 200°C; the baking time is 15 hours.

[0035] The process conditions of pressure sintering are: vacuum 2×10 -2 Pa began to heat up, the heating rate was 100°C / h, the holding temperature was 1150°C, and the holding pressure was 18MPa / cm 2 , The heat preservation time is 8 hours.

[0036] Step 3: Cooling the pressure-sintered beryllium powder to room temperature and demolding, to obtain a vacuum hot-pressed beryllium material with a diameter of 350 mm.

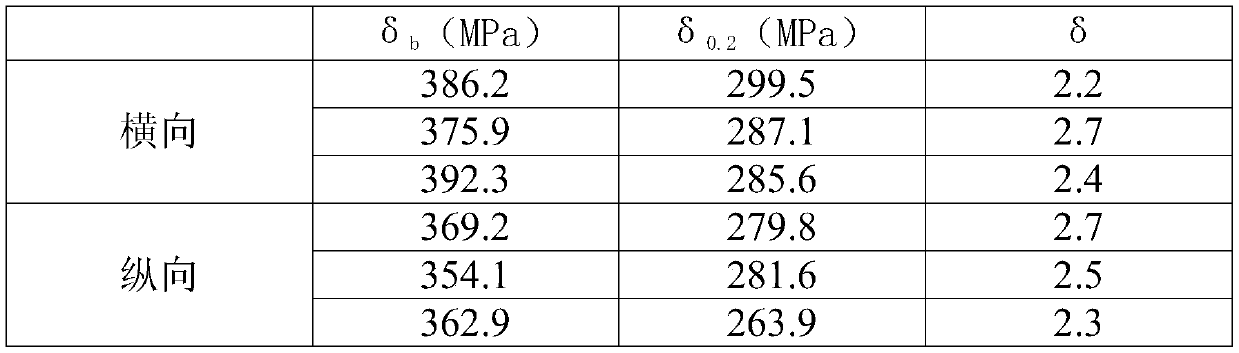

[0037] The performance parameters of the 350mm diameter vacuum hot-pressed beryllium material prepared in this embodiment are shown in the following table:

[0038]...

Embodiment 3

[0040] Step 1: Prepare beryllium powder with a beryllium content of 99.5% by weight and an average particle size of 11 μm.

[0041] Step 2: Put the beryllium powder into a graphite mold with an inner diameter greater than 300mm and bake, then put it into a vacuum hot pressing furnace for pressure sintering;

[0042] The baking temperature is 220°C; the baking time is 13 hours.

[0043] The process conditions of pressure sintering are: vacuum 3×10 -2 Pa began to heat up, the heating rate was 140°C / h, the holding temperature was 1100°C, and the holding pressure was 22MPa / cm 2 , Heat preservation and pressure keeping time 6 hours.

[0044] Step 3: Cooling the pressure-sintered beryllium powder to room temperature and demolding, to obtain a vacuum hot-pressed beryllium material with a diameter of 330 mm.

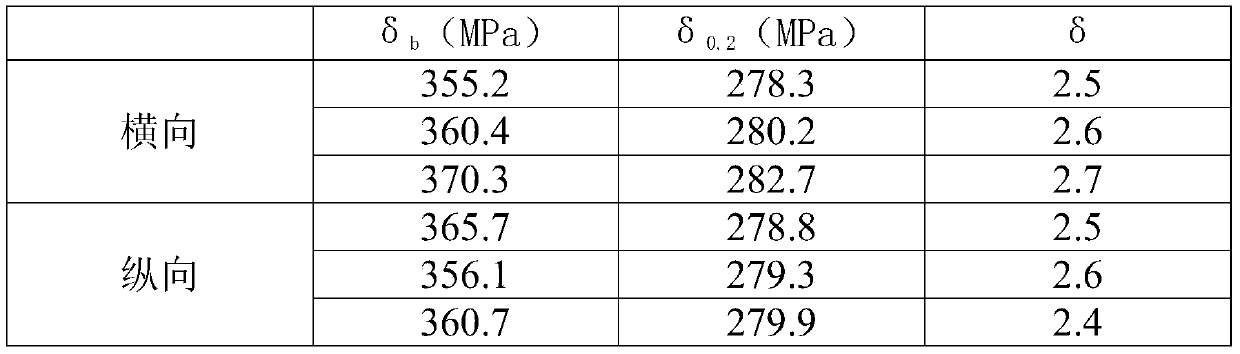

[0045] The performance parameters of the vacuum hot-pressed beryllium material with a diameter of 330 mm prepared in this embodiment are shown in the following table:

[0046]

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| ultimate tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com