L415J steel welding matched flux-cored wire for coal slurry conveying pipe

A flux-cored welding wire, a practical technology, applied in the direction of welding medium, welding equipment, welding/cutting medium/material, etc., can solve the problems of undiscovered flux-cored welding wire, etc., and achieve good welding processability, uniform distribution, and uniform carbon distribution Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

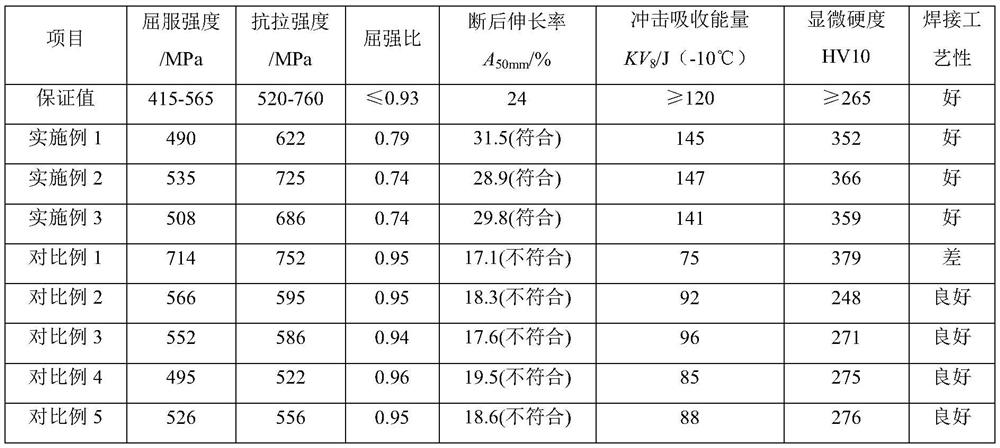

Examples

Embodiment 1

[0026] A kind of flux-cored welding wire matched with L415J steel welding for coal slurry conveying pipe, including sheath and flux core, the chemical composition and dosage of said flux core are calculated by mass percentage: 0.2% of hollow cage-like carbon microspheres, 4.2% of nano-bismuth powder, Nano beryllium powder 3.5%, manganese fluoride powder 1.2%, molybdenum powder 1.2%, chromium powder 1.6%, niobium powder 0.12%, vanadium powder 0.2%, titanium powder 0.16%, and the balance is FHT100·25 reduced iron powder.

[0027] The outer diameter of the hollow cage carbon microsphere is 300-360nm, the inner diameter is 220-280nm, and the mesopore diameter is 30-40nm.

[0028] The particle size of the nano-bismuth powder is 60nm-90nm.

[0029] The particle size of nano beryllium powder is 60nm-90nm.

[0030] Manganese fluoride powder, molybdenum powder, chromium powder, niobium powder, vanadium powder, titanium powder, and FHT100·25 reduced iron powder have a 100-mesh passing ...

Embodiment 2

[0035] A kind of flux-cored welding wire matched with L415J steel welding for coal slurry conveying pipe, including sheath and flux core, the chemical composition and dosage of the flux core are calculated by mass percentage: hollow cage-like carbon microspheres 0.28%, nano-bismuth powder 5.6%, Nano beryllium powder 4.9%, manganese fluoride powder 2.0%, molybdenum powder 1.5%, chromium powder 1.2%, niobium powder 0.18%, vanadium powder 0.15%, titanium powder 0.15%, and the balance is FHT100·25 reduced iron powder.

[0036] The outer diameter of the hollow cage carbon microsphere is 300-360nm, the inner diameter is 220-280nm, and the mesopore diameter is 30-40nm.

[0037] The particle size of the nano-bismuth powder is 60nm-90nm.

[0038] The particle size of nano beryllium powder is 60nm-90nm.

[0039] Manganese fluoride powder, molybdenum powder, chromium powder, niobium powder, vanadium powder, titanium powder, and FHT100·25 reduced iron powder have a 100-mesh passing rate ...

Embodiment 3

[0044] A kind of flux-cored wire used for welding L415J steel for coal slurry conveying pipe, including sheath and flux core, the chemical composition and consumption of the flux core are calculated by mass percentage: 0.24% of hollow cage-like carbon microspheres, 4.9% of nano-bismuth powder, Nano beryllium powder 4.2%, manganese fluoride powder 1.6%, molybdenum powder 1.45%, chromium powder 1.4%, niobium powder 0.2%, vanadium powder 0.12%, titanium powder 0.16%, and the balance is FHT100·25 reduced iron powder.

[0045] The outer diameter of the hollow cage carbon microsphere is 300-360nm, the inner diameter is 220-280nm, and the mesopore diameter is 30-40nm.

[0046] The particle size of the nano-bismuth powder is 60nm-90nm.

[0047] The particle size of nano beryllium powder is 60nm-90nm.

[0048] Manganese fluoride powder, molybdenum powder, chromium powder, niobium powder, vanadium powder, titanium powder, and FHT100·25 reduced iron powder have a 100-mesh passing rate o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Outer diameter | aaaaa | aaaaa |

| The inside diameter of | aaaaa | aaaaa |

| Mesopore diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com