Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

98results about How to "Satisfy production" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Silicon wafer chemical and mechanical polishing composition with high stability

InactiveCN102093820AWide applicabilityPracticalOther chemical processesPolishing compositions with abrasivesOrganic acidCompound (substance)

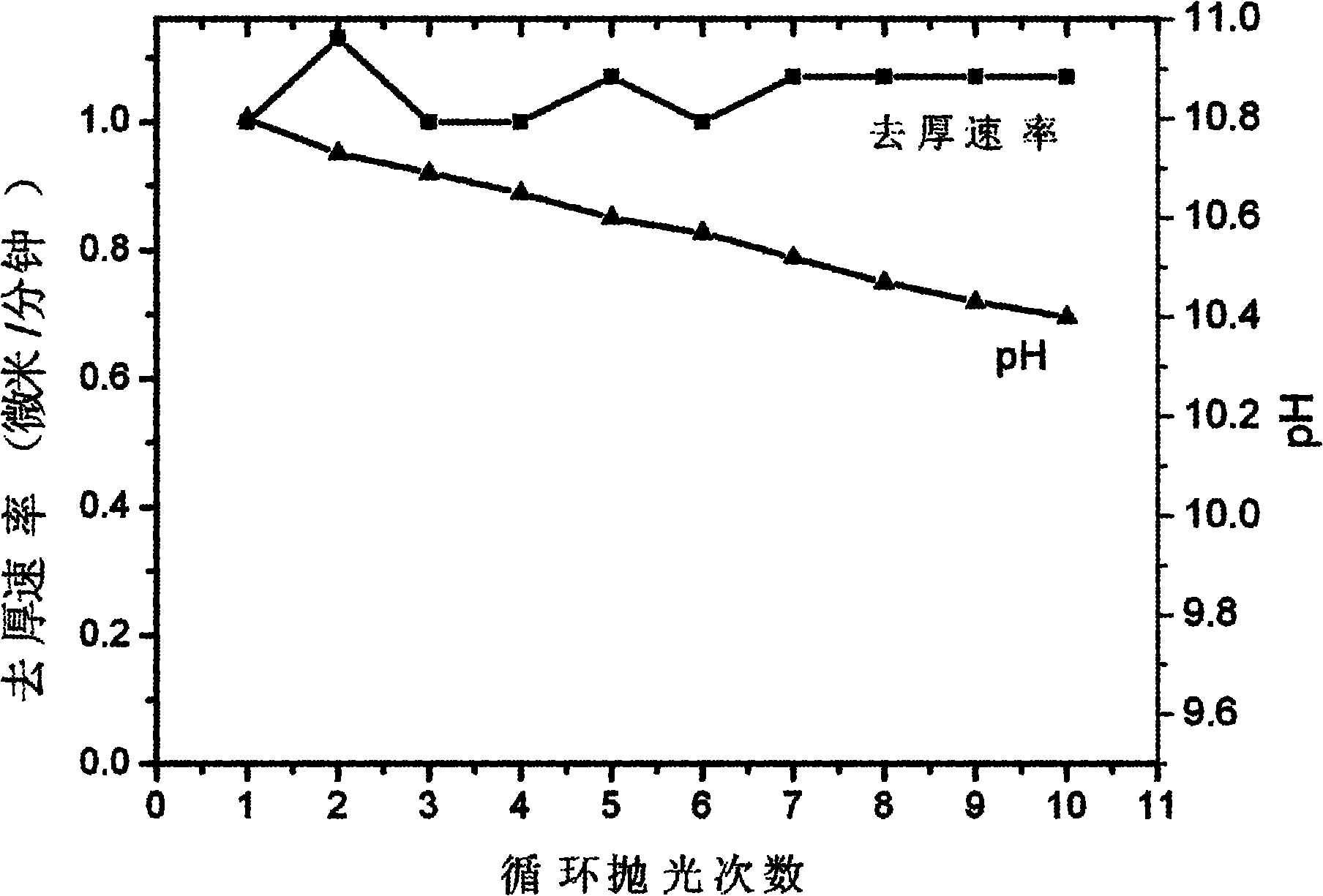

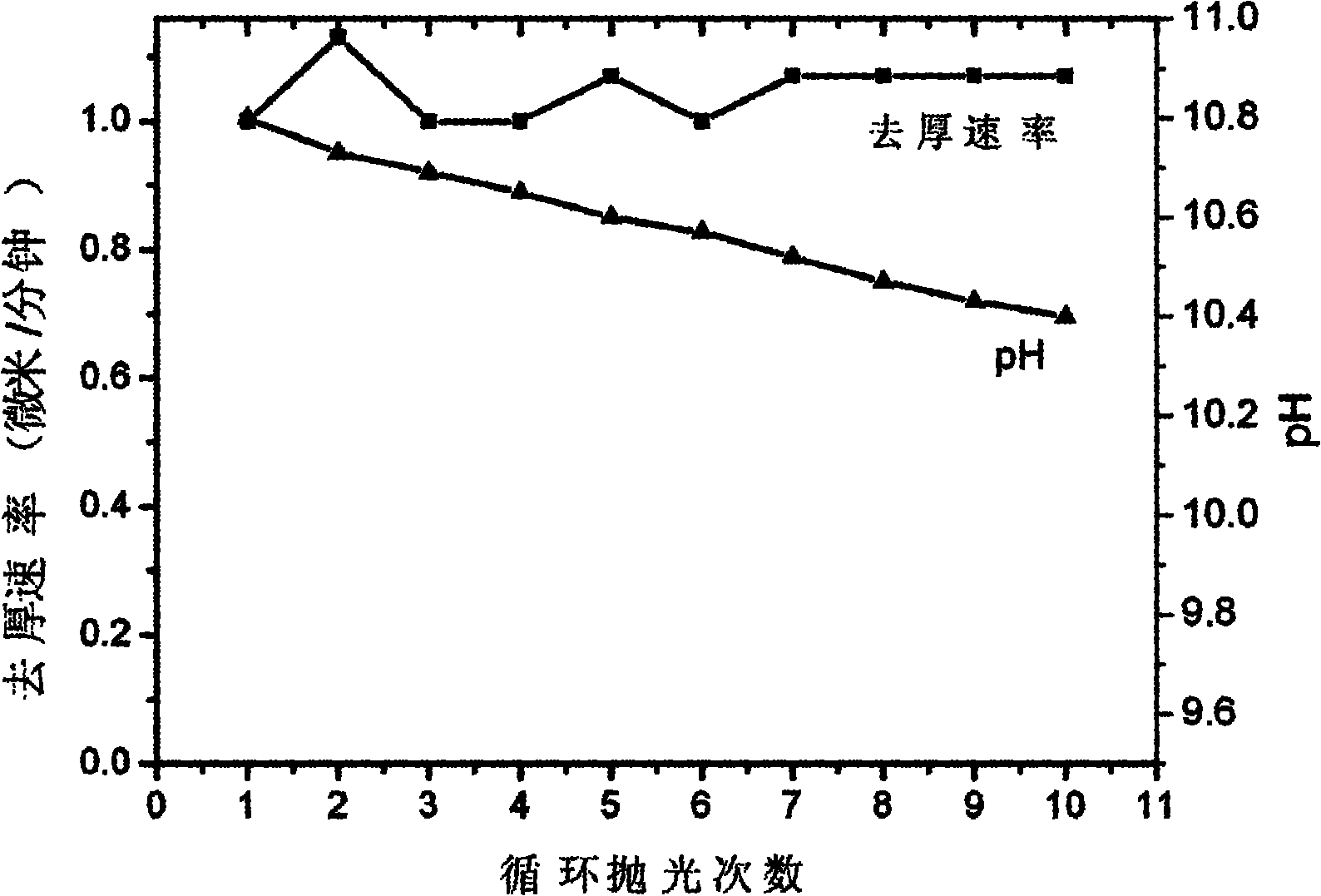

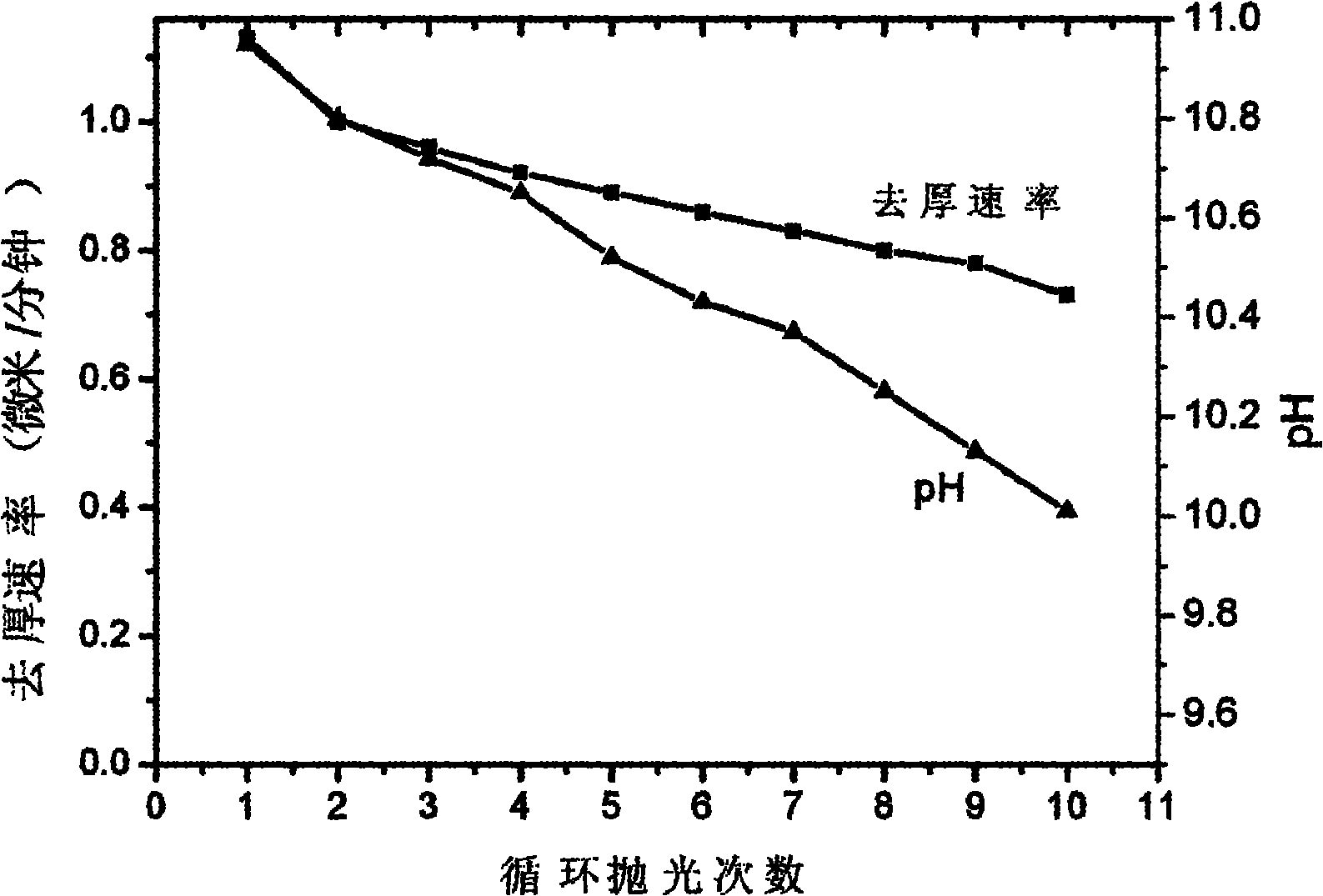

The invention discloses a silicon wafer chemical and mechanical polishing composition with high stability, belonging to the technical field of polishing compositions for roughlly polishing a semiconductor silicon substrate material. The polishing composition comprises the following components in percentage by weight: 0.5-50 percent of silicon dioxide abrasive particles, 0.01-10 percent of silicon-containing stabilizer, 0.01-20 percent of organic alkali corrosive, 0.01 -10 percent of organic acid chelating agent, 0.01-5.0 percent of other functional auxiliaries and the balance of deionized water. The polishing solution has a stabilization period of over 2 years, can perform repeated polishing or cyclic polishing, and has stable pH value and removal speed, wherein the number of cyclic polishing times can be up to 10. Meanwhile, the polishing composition has high silicon wafer removal rate up to over 1.0 mum / min, and the cyclic polishing removal rate in multiple times can be stable. The polishing solution is convenient to prepare and easy to use, has low cost, and is suitable for the rough polishing of silicon wafers of various types and sizes in the semiconductor industry.

Owner:TSINGHUA UNIV +2

Anti-sliding glaze, anti-sliding brick and preparation method thereof

The invention discloses an anti-sliding glaze which contains the following chemical components by weight percent: 42.8%-48.5% of SiO2, 19.1%-22.8% of Al2O3, 0.1%-0.2% of Fe2O3, 7.0%-9.5% of CaO, 2.5%-5.2% of MgO, 2.1%-8.6% of Na2O, 0.9%-4.1% of K2O, 1.1%-3.3% of ZnO and 2.8%-6.2% of ZrO2. The invention also discloses an anti-sliding ceramic tile and a preparation method for the anti-sliding ceramic tile. The anti-sliding ceramic tile disclosed by the invention can achieve an excellent anti-sliding effect after a layer of anti-sliding glaze is applied to the surface of the anti-sliding ceramic tile, the technology is simple and the cost is low.

Owner:DONGGUAN CITY WONDERFUL CERAMICS IND PARK

Aluminium foil material for tableware and manufacturing method of aluminium foil for tableware

InactiveCN101812616AHigh strengthReduce supersaturationMetal rolling arrangementsAluminum foilGrain growth

The invention relates to an aluminium foil material for tableware and a manufacturing method of aluminium foils for the tableware, belonging to the technical field of manufacture of aluminium alloy materials and the aluminium foils. The aluminium foil material comprises the following components in percentage by weight: 0.2-0.30% of Si, 1.40-1.50% of Fe, 0.05% of Cu, 0.50-0.60% of Mn, 0.05% of Mg, 0.01% of Cr, 0.05% of Zn, 0.05% of Ti, and the balance of Al, wherein the components are smelted into an alloy. The manufacturing method of the aluminium foils for the tableware comprises the following steps of: a, smelting; b, casting; c, uniform annealing; d, cold rolling; e, foil rolling; and f, finished product annealing. The invention can prevent an aluminium coil from generating grain growth during the uniform annealing and also has better machining property and easy rolling.

Owner:JIANGSU DINGSHENG NEW MATERIAL JOINT STOCK CO LTD

Method for producing glucose and cellobiose using cellulose complex enzyme

InactiveCN101603065AIncrease saccharification rateSatisfy productionMicroorganism based processesFermentationFiberConcentrations glucose

A method for producing glucose and cellobiose using cellulose complex enzyme is the technology using the cellulose complex enzyme as a catalyst and realizing the high saccharification rate conversion of cellulose by adding cellulose enzyme activator at the optimized stirring speed. Glucose concentration can reach 150g / L after using cellulose enzymatic hydrolysis, and the method is a cellulose saccharification production technology with economic feasibility. With the technology used, low cost, low usage of enzyme and high saccharification rate can be realized, and the productions of cellulose alcohol and biochemical products (lactic acid, succinic acid and the like) are satisfied. In the whole technology, no beta-glucosaccharase is added additionally, no sugar concentrating device is added, and the technology is simple, the equipment cost is low and the industrialized prospect is good.

Owner:CHINA THREE GORGES UNIV

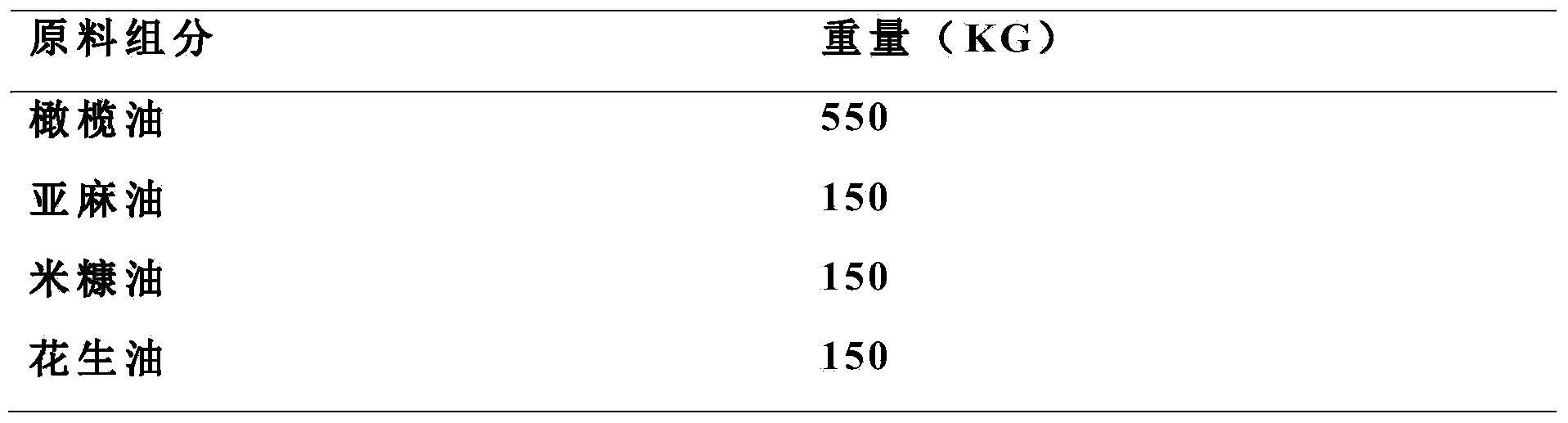

Omega formula olive blending oil

InactiveCN103719304AReasonable proportionSolve the problem of unsuitable tasteEdible oils/fatsPerilla oilRapeseed

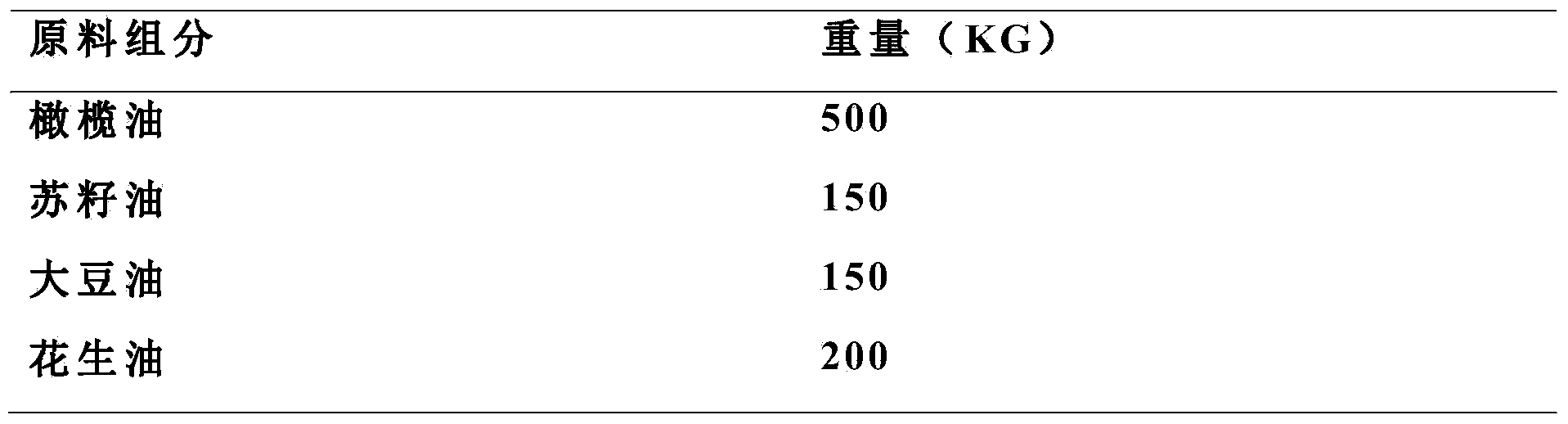

The invention discloses omega formula olive blending oil. The omega formula olive blending oil is characterized in that the olive blending oil is composed of following raw materials in percentage by weight: 20%-75% of olive oil, 15%-75% of a first blending raw material and 2%-50% of a second blending raw material, wherein the first blending raw material is selected from one or any combination of corn germ oil, peanut oil, sunflower seed oil, sesame oil, cottonseed oil, safflower oil, safflower seed oil, corn oil, soybean oil and canola oil; the second blending raw material is selected from one or any combination of seal oil, algal oil, rice bran oil, linseed oil, flax stem oil, flaxseed oil, grape seed oil, camellia oil, rapeseed oil, colleseed oil, walnut oil, zanthoxylum oil, perilla oil and deep sea fish oil.

Owner:美格尔橄榄油业(苏州)有限公司 +1

Container foil material and method for manufacturing container foil

InactiveCN102409200AHigh strengthSatisfy productionMetal rolling arrangementsPunchingUltimate tensile strength

The invention relates to a manufacture method of an aluminum alloy material, concretely relates to a container foil material and a method for manufacturing a container foil. The alloy of the container foil material comprises the following compositions by weight percentage: 0.20-0.26% of Si, 0.42-0.50% of Fe, 0.05% of Cu, 0.15-0.20% of Mn, 0.01% of Mg, 0.1% of Zn, 0.04% of Ti and the balance of Al. According to the invention, the content of Fe and Si are re-allocated by the material on the basis of a 8011 alloy, and certain Mn element is added, so that the material intensity can be raised, and the material has good processing performance and is easy to roll. The detection of the material shows that the when aluminum foil thickness is 0.05-0.06mm, the tensile strength is 120-160MPa, the elongation percentage is greater than or equal to 12% and the cupping value is greater than or equal to 5.0. The material of the invention has good punching performance, and can be used for producing various aviation tableware.

Owner:JIANGSU DINGSHENG NEW MATERIAL JOINT STOCK CO LTD

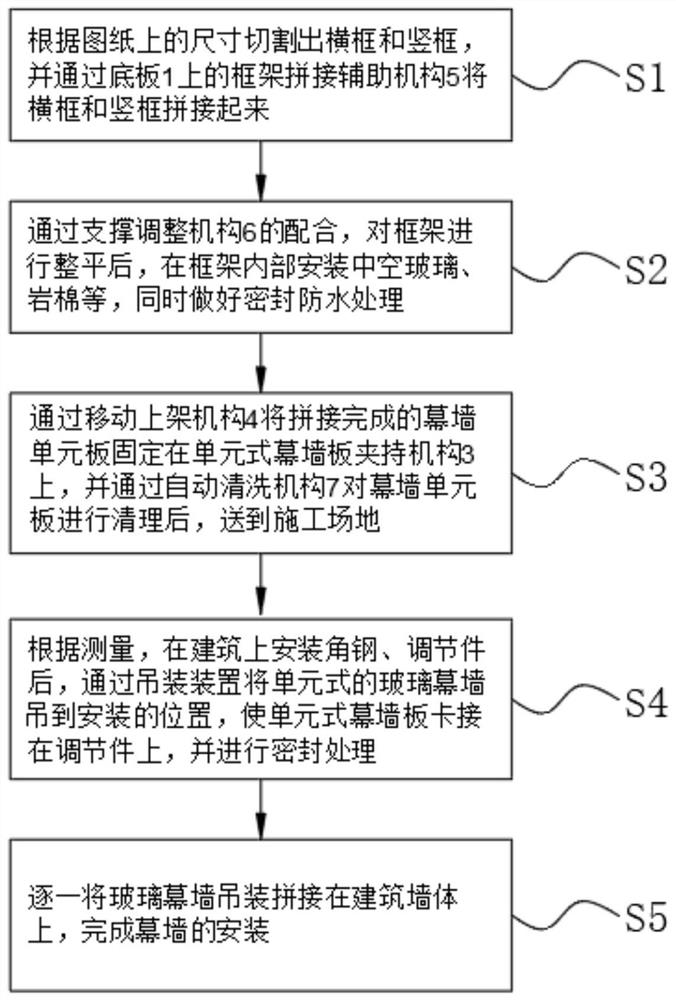

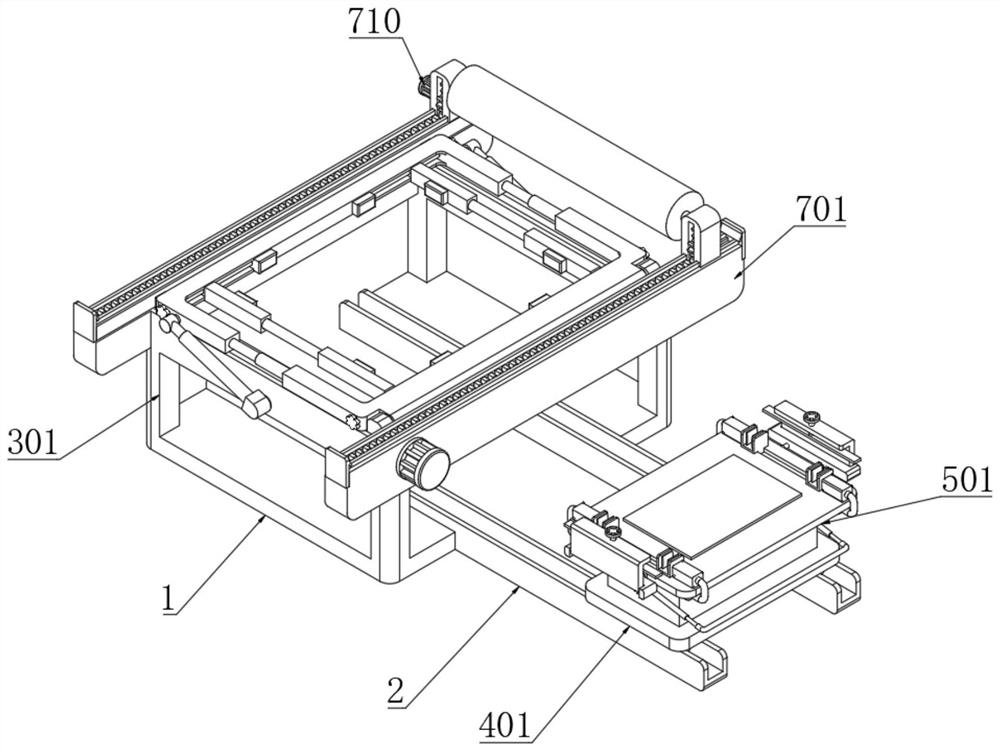

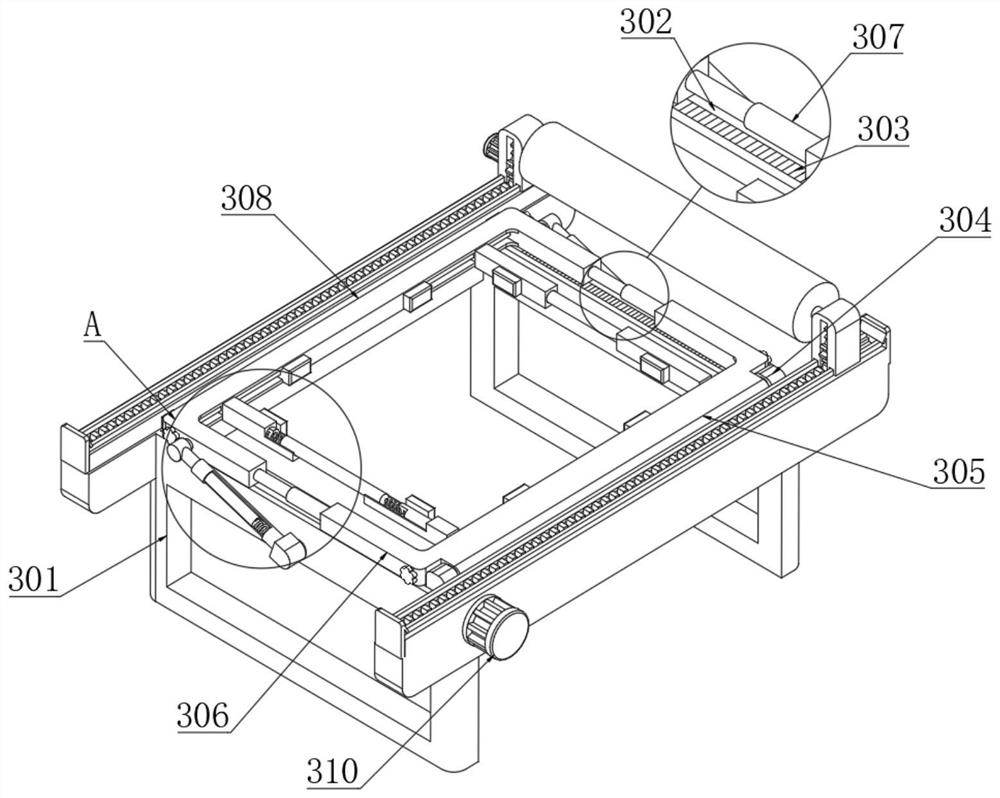

Installation method of spliced building curtain wall

InactiveCN112431336AScientific and reasonable structureEasy to useWallsWork holdersFixed frameEngineering

Owner:罗显容

Smelting method for stainless steel material

ActiveCN104962800AUnique methodIngredients have no effectProcess efficiency improvementElectric arc furnaceSS - Stainless steel

The invention relates to a smelting method, in particular to a smelting method for a stainless steel material. The smelting method comprises the following steps: preparing materials, carrying out EAF (electric arc furnace) smelting, carrying out LF (low frequency) furnace primary smelting, carrying out VOD furnace smelting and carrying out LF furnace re-smelting. The smelting method disclosed by the invention is unique, improves the quality of molten steel, reduces the production cost and solves the problem of smelting various molten steel in the same EAF furnace by the enterprises.

Owner:KOCEL STEEL

Seabuckthorn leaf instant tea and preparation method

The present invention relates to a seabuckthorn leaf instant tea, it is a seabuckthorn instant tea powder made up by utilizing water extract of seabuck thorn leaf through the processes of drying and blending. Its preparation method includes the following steps: making the seabuckthorn leaf undergo the processes of steaming to retain its green colour, rolling and stir-drying, soaking in boiling water, extracting, filtering, concentrating, drying, blending and forming to obtain the product which can be directly drunk, and can be mixed with auxiliary materials of fruit juice and sugar for drinking so as to meet requirements of different consumers. In its processing course the impurities of scales, heavy metal, sand and pesticide residue can be completely removed with tea dregs, so that it is a pure clean beverage.

Owner:SHANXI UNIV

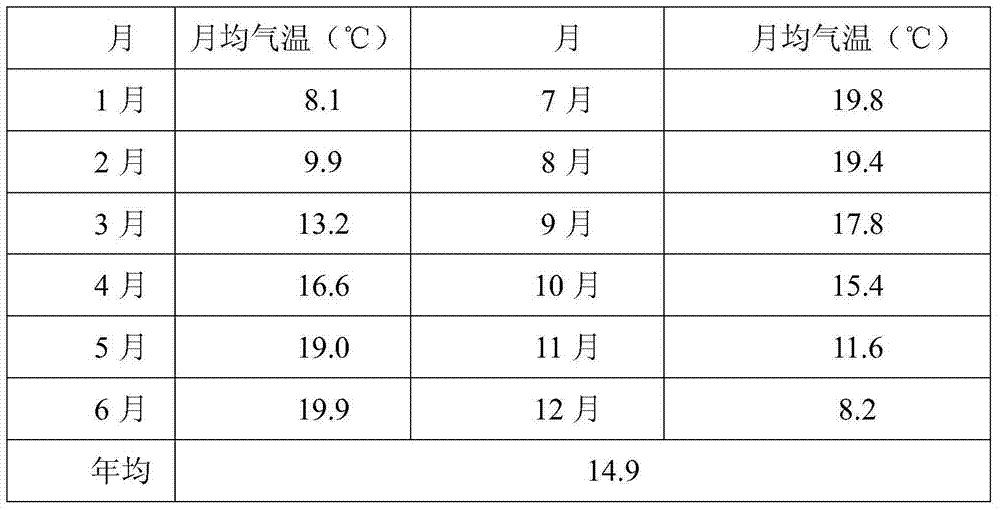

Method for producing short-day strawberry flowering seedlings in central region of Yunnan province

ActiveCN104115732AIncrease costImprove reproductive efficiencyCultivating equipmentsSoilless cultivationFragariaBEACH STRAWBERRY

The invention discloses a method for producing short-day strawberry flowering seedlings in the central region of Yunnan province. The method comprises the steps of variety selecting, stock plant field planting curing, seedling breeding and short-day flowering processing. The short-day strawberry variety with the properties that the number of flowers in simple inflorescence is more than 20, the flowering time of a single flower in the same inflorescence is scattered, and the flowering time of the simple inflorescence lasts for one or more months is selected; the stock plant field planting curing, the seedling breeding and short-day flowering processing are carried out in the central region of Yunnan province with the altitude ranging from 1,600 meters to 1,900 meters; a nutrient solution including 100-150 milligrams per liter of N, 20-25 milligrams per liter of P and 80-100 milligrams per liter of K is used for watering the seedlings during the stock plant curing period, the seedlings are processed for 10 hours in the short day and processed for 30-35 days under the natural temperature condition, and flower bud differentiation is achieved in more than 90 percent of seedlings. The flowering cost is low, the flowering seedling supply time is early, 30-40 seedlings can be harvested in each stock plant in the middle ten days of June, the fresh autumn short-day strawberries can be produced, and normal winter and spring fresh strawberry production can be guaranteed.

Owner:FLOWER RES INST OF YUNNAN ACAD OF AGRI SCI +1

High strength and high elastic oil resistant rubber

The invention relates to high strength and high elastic oil resistant rubber. The oil resistant rubber has high strength, good elasticity and wide temperature range while the strength and oil resistance can be ensured. The rubber comprises the following components in parts by weight: 100 parts of hydrogenated nitrile-butadiene rubber, 10-20 parts of heat stabilizer, 10-15 parts of plasticizer, 10-25 parts of reinforcing agent, 1-2 parts of vulcanizing agent, 1-5 parts of crosslinking aid and 2-5 parts of peroxide vulcanizing agent. The oil resistant rubber of the invention uses hydrogenated nitrile-butadiene rubber to replace common nitrile-butadiene rubber, uses nanometer reinforced material as auxiliary material and also adopts a special vulcanizing system. hydrogenated nitrile-butadiene rubber has good oil resistance; as the hydrogenated nitrile-butadiene rubber has a highly saturated structure, the hydrogenated nitrile-butadiene rubber has good heat resistance, good chemical resistance, excellent ozone resistance and higher compression set resistance; and the hydrogenated nitrile-butadiene rubber is also characterized by high tensile strength, high elongation at break, high tearing resistance, wear resistance and the like. The rubber of the invention can be used to produce the oil resistant air dome, solve the breakage phenomenon and save the production cost.

Owner:JIANGSU YANGZHOU HELI RUBBER PROD

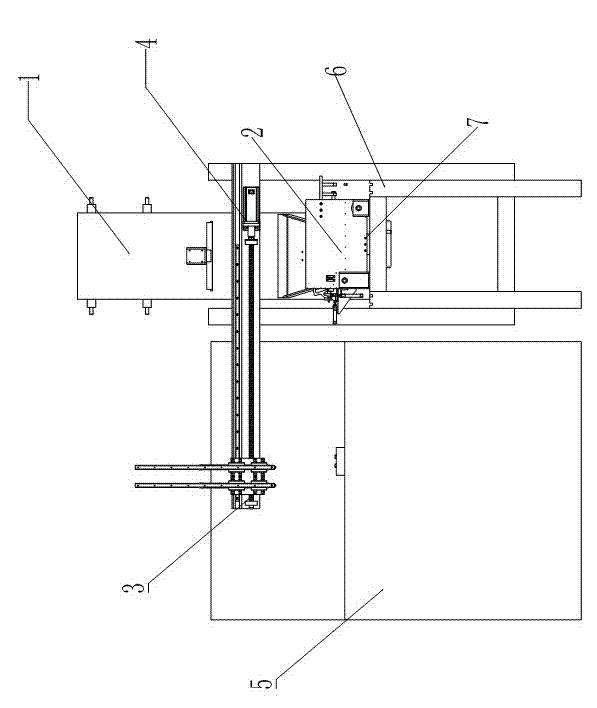

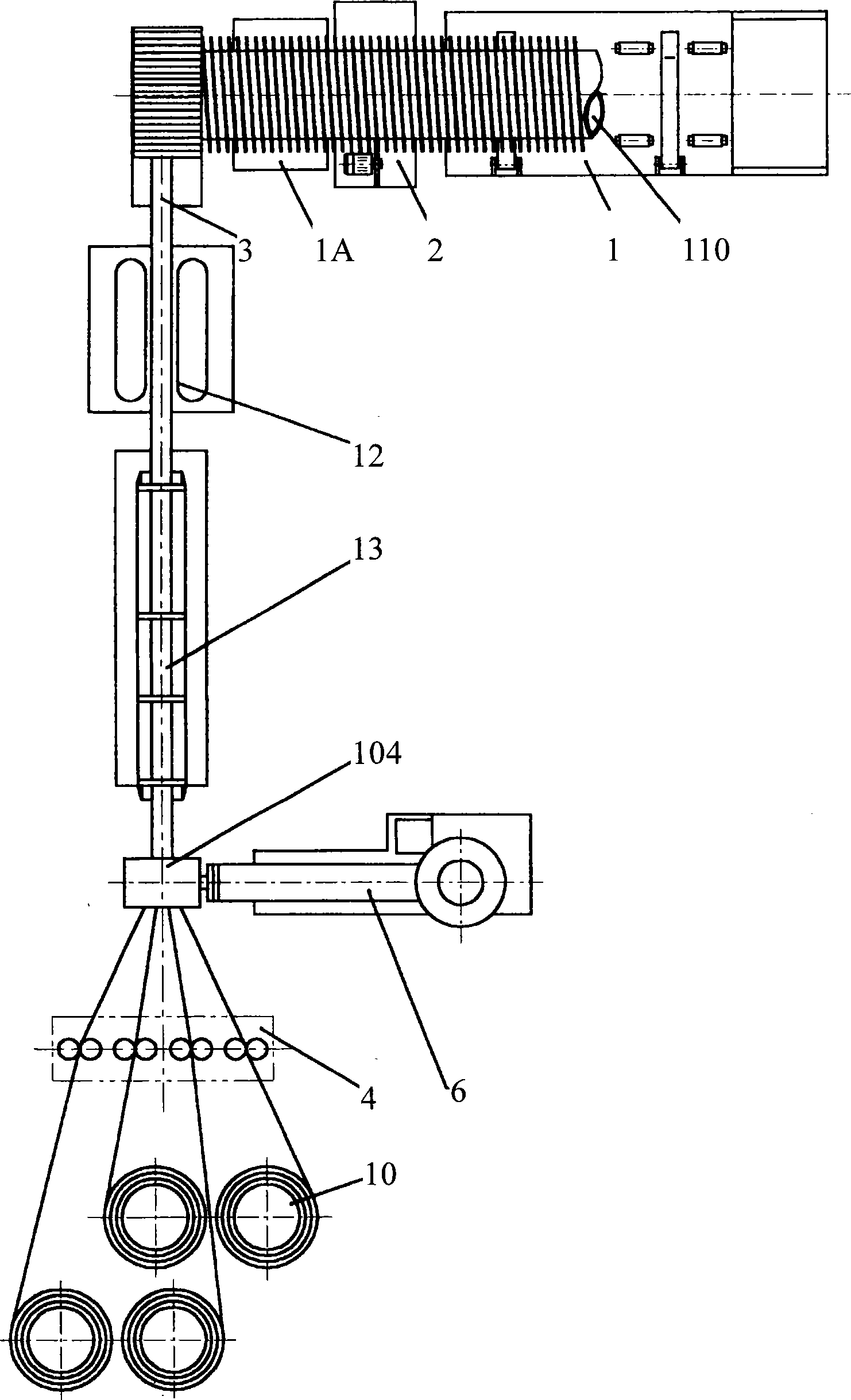

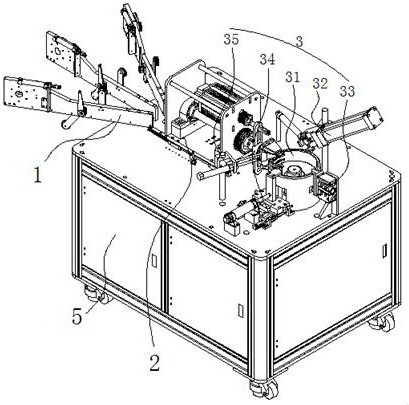

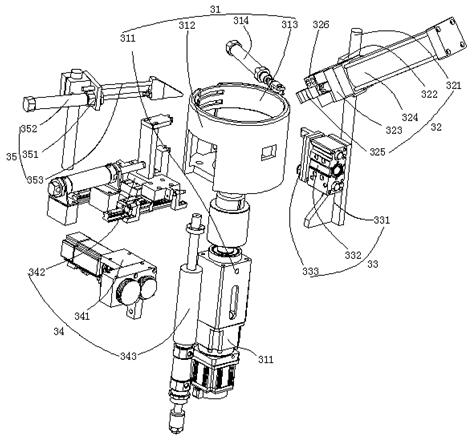

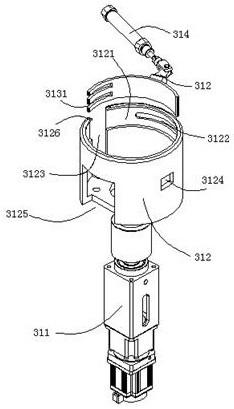

Feed device for toothbrush hair-planting

The invention provides a feed device for toothbrush hair-planting. The feed device comprises a toothbrush separating machine, a toothbrush shaking machine, a location detection module, a positioning cylinder, a vibration motor, a rotating cylinder, a manipulator and an electrical control system. The toothbrush separating machine discharges a plurality of toothbrushes one by one in a separating mode, and the toothbrush shaking machine receives the toothbrushes which are discharged one by one in the separating mode. The location detection module detects locations of the received toothbrushes, when the toothbrushes are in standard locations, the positioning cylinder locates the toothbrushes. When the deviation between the toothbrushes and the standard locations is within a preset range, the vibration cylinder acts, and then stops until the toothbrushes are located in the standard locations. The manipulator grabs the located toothbrushes into a toothbrush hair-planting machine, and the electrical control system automatically controls every component to continuously work. Compared with the prior art, the feed device adjusts locations of the toothbrushes through the vibration motor and the rotating cylinder, can reduce workload of staff, and improves work efficiency.

Owner:LIANYUNGANG BEIZILE INFORMATION TECH

A method of preparing a reactive-sintered silicon carbide ceramic product

A method of preparing a reactive-sintered silicon carbide ceramic product is disclosed. The method includes (1) a step of preparing slurry, namely a step of adding slurry materials into a material mixing slurry preparing device, and fully stirring the slurry materials to prepare grouting slurry; (2) a step of injecting the slurry to a porous resin mold, and molding to obtain a green body; (3) a step of putting the green body into a drying oven to obtain a dried green body; and (4) a step of subjecting the dried green body to siliconizing reactive sintering in a high-temperature vacuum sintering furnace, performing siliconizing under vacuum conditions with the highest temperature being 1350-1750 DEG C, maintaining the temperature for 0.5-5 h, and cooling a product to obtain a finished product. According to the method, the occupied space of devices in the method is low, the production efficiency is high, automatic production can be achieved, the molded product has advantages of high density, good uniformity, and the like, raw materials are nontoxic, the drying efficiency is high, the production cycle is short, a cost is greatly reduced, product uniformity is better, produced products are more diversified, and the method can achieve production of large-size special-shape complex products.

Owner:NINGBO VULCAN TECH CO LTD

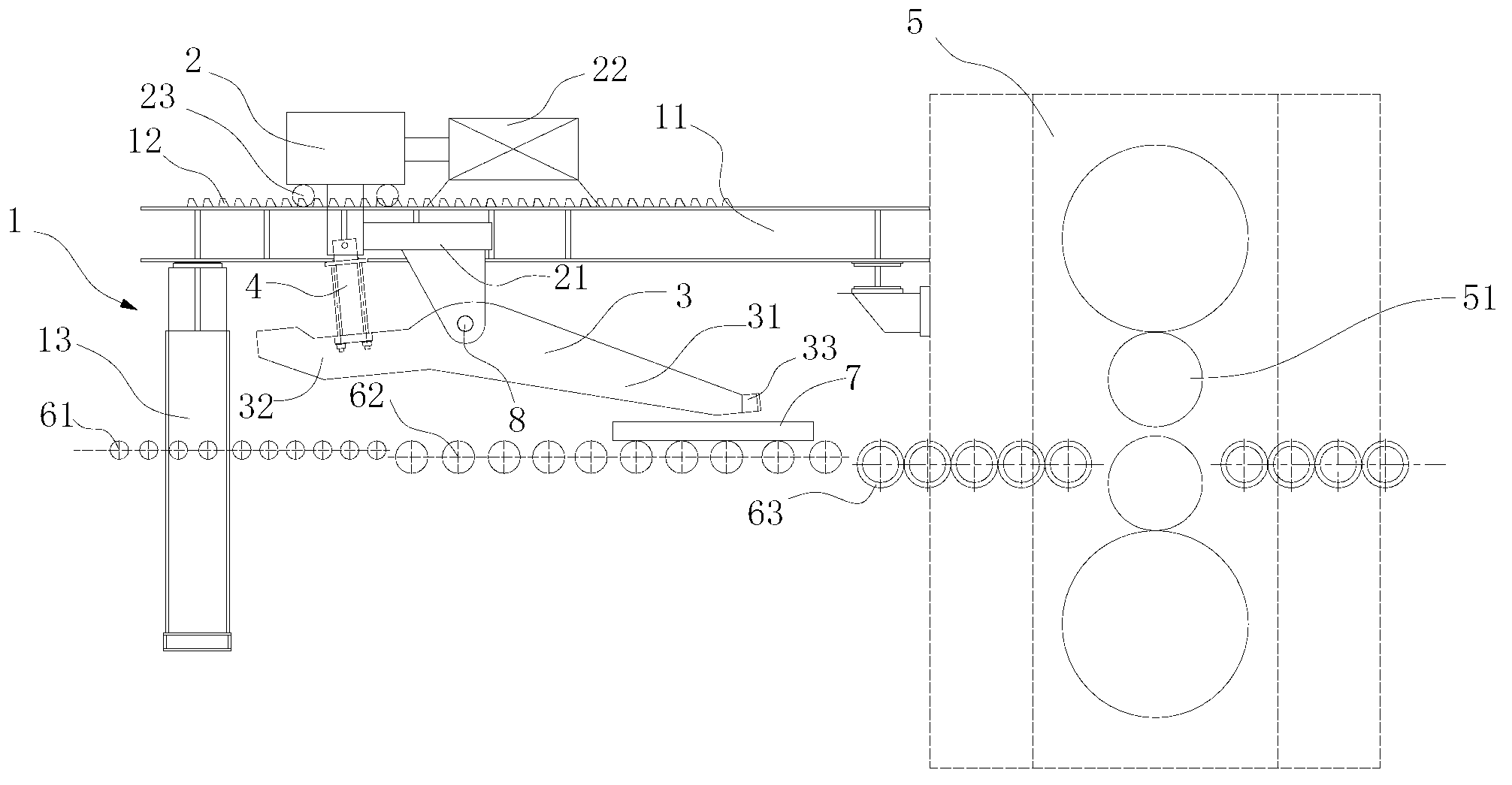

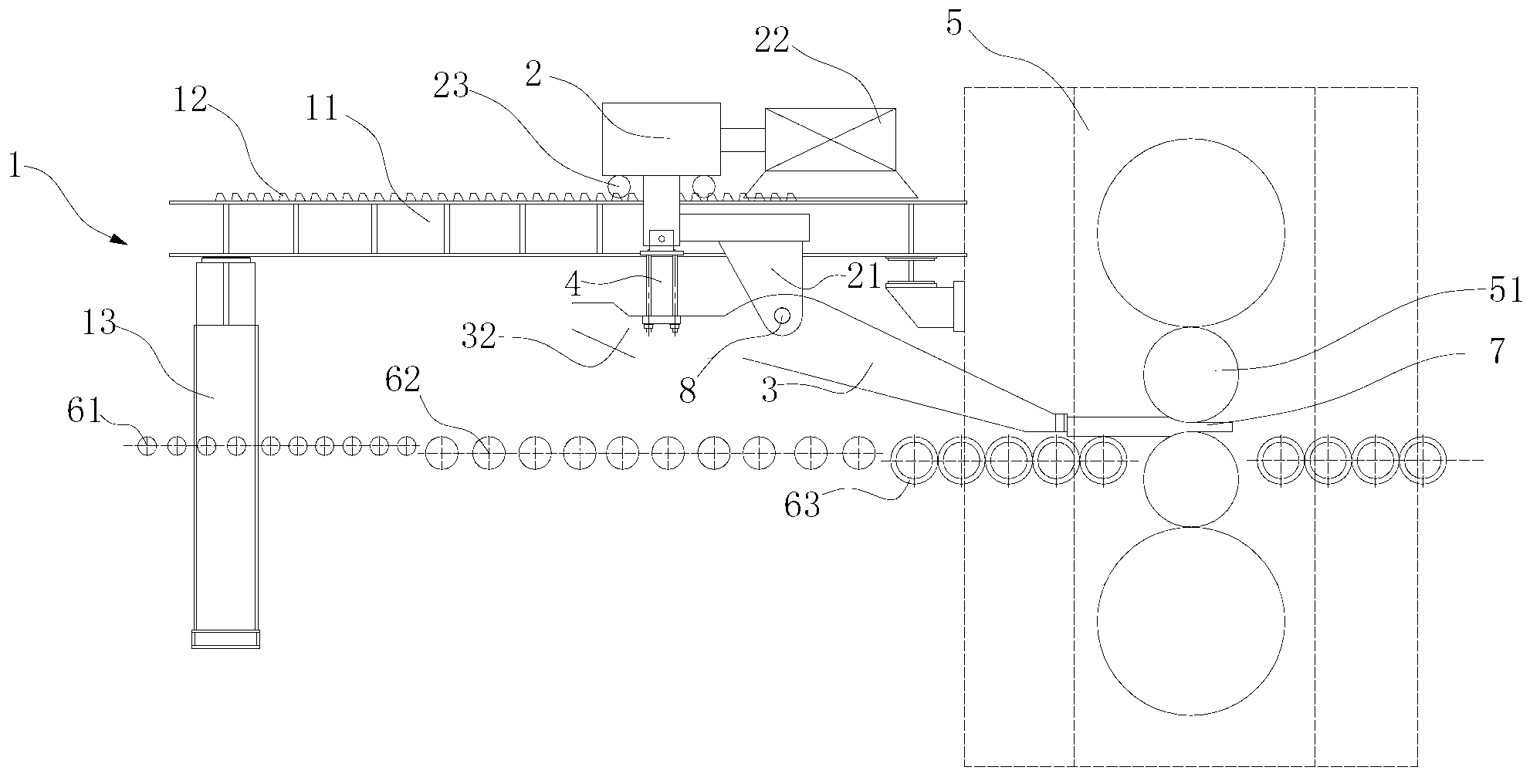

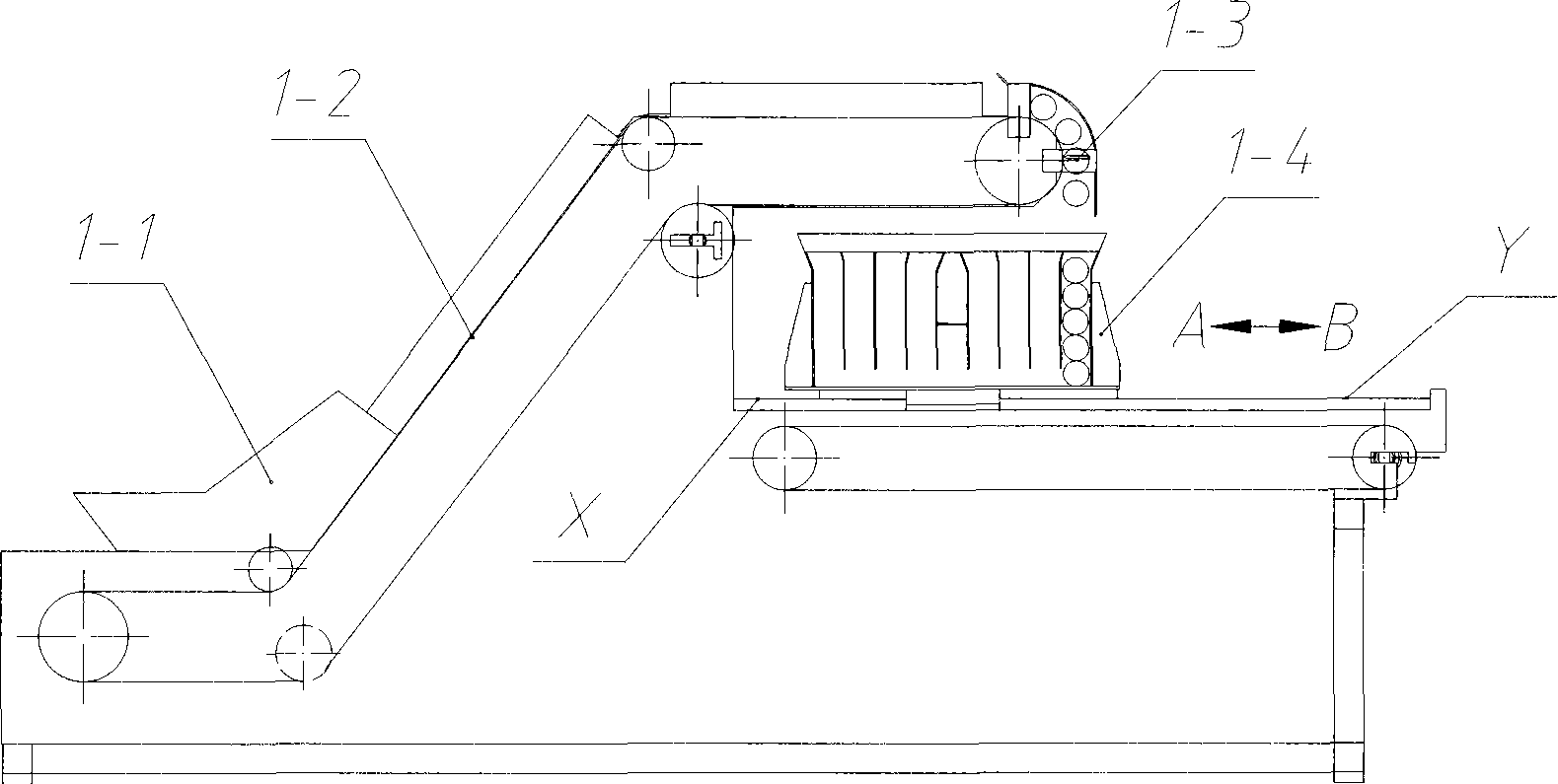

Winding-pipe production device

InactiveCN101456253AReduce transportation linksLow transportation costTubular articlesControl systemEngineering

The invention relates to a wound pipe production device. The production device comprises a belt supplying part, a pipe production part, a control system and a movable foundation, wherein the control system and the movable foundation are connected with a driving mechanism of the belt supplying part and the pipe production part. The pipe production part comprises a feeding device, a winding device, a pipe cutting device and a support, wherein the feeding device, the winding device, the pipe cutting device and the support are arranged on the movable foundation. The winding device, the pipe cutting device and the support are arranged sequentially in a matching mode. The feeding device and the winding device are arranged in a matching mode to realize feeding along a cutting direction. The wound pipe production device can be delivered to a site where pipes are used for on-site production, thereby saving pipe transpiration and pipe transportation cost. The wound pipe production device is flexible in structure, can use compound belts as raw material to product pipes, carry out complete belt production and pipe production, use steel strips and plastic raw materials to produce pipes and produce wound pipes of various pipe diameters.

Owner:HUAHAN SCI & TECH

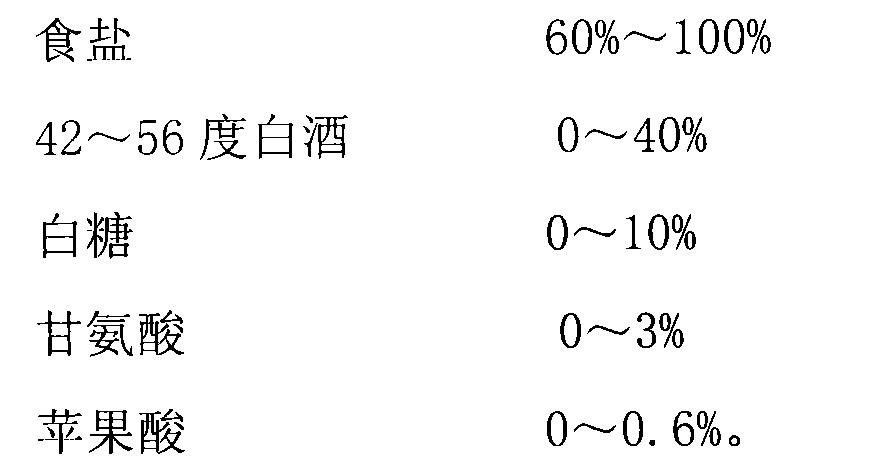

Method for rapidly and integrally pickling salted egg yolk

The invention relates to a method for rapidly and integrally pickling salted egg yolk, which is characterized by comprising the following steps of: fully mixing an egg yolk with a pickling agent in a pickling container; pickling; and carrying out heating concentration, maturing, oil pulverization and moulding treatment on the mixture to obtain the salted egg yolk. In the oil pulverization step, the mature salted egg yolk is subjected to grinding and pulverizing treatment. The pickling agent comprises the following components in percentage by weight: 60-100 percent of salt, 0-40 percent of white spirit, 0-10 percent of white sugar, 0-3 percent of glycine and 0-0.6 percent of malic acid. The invention has the advantages of large-scale production of salted egg yolk, simple production operation, high productivity and uniform quality, high oil pulverization performance and perfume and pure taste of the pickled salted egg yolk.

Owner:BEIJING UNIV OF AGRI

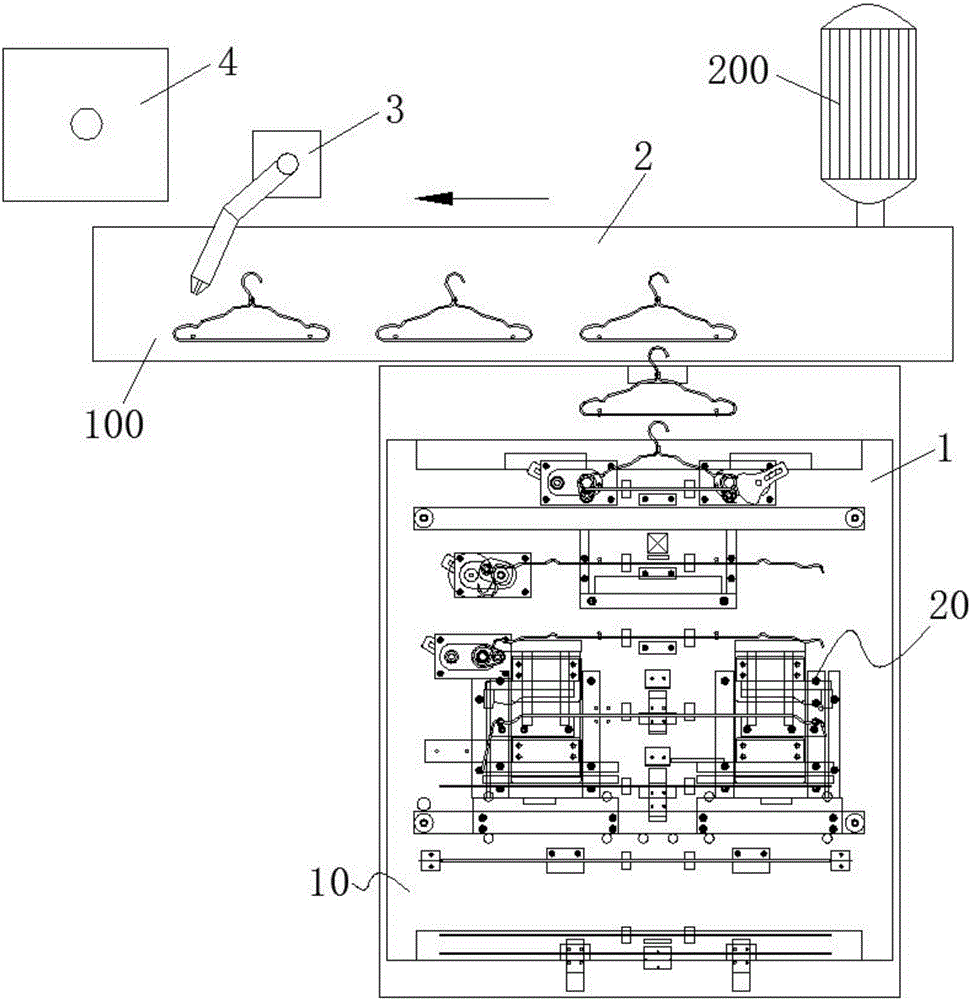

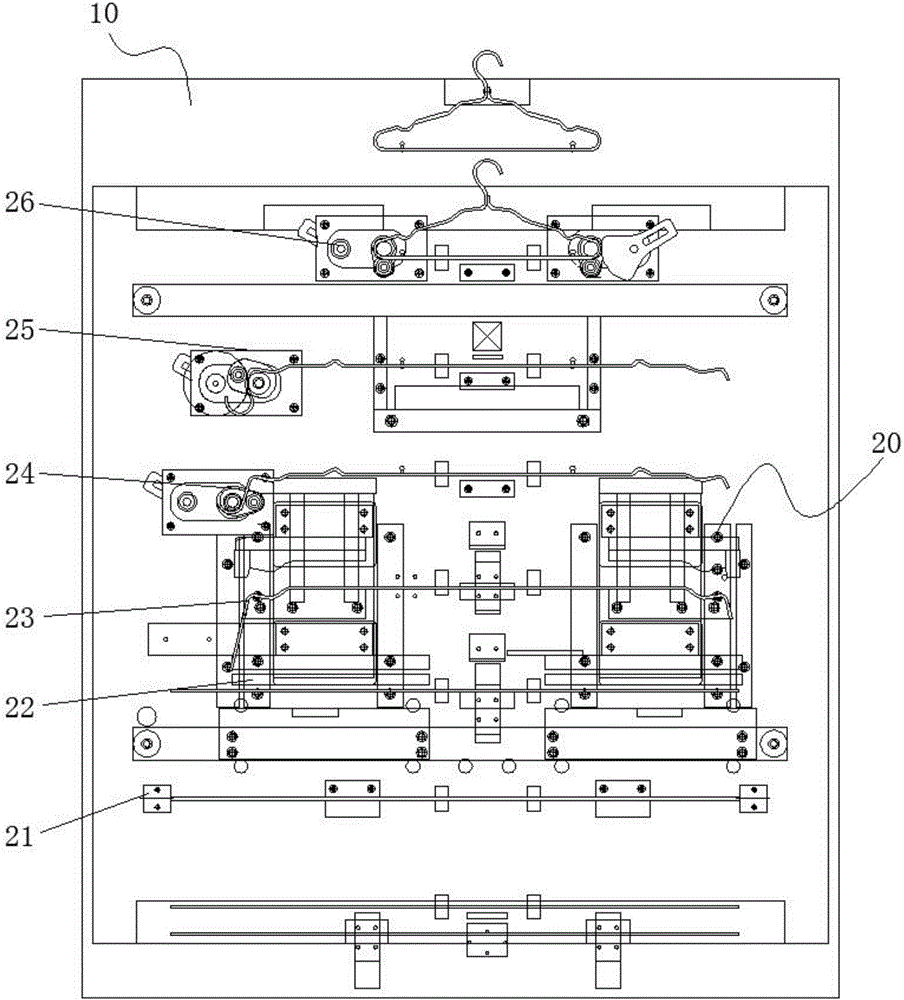

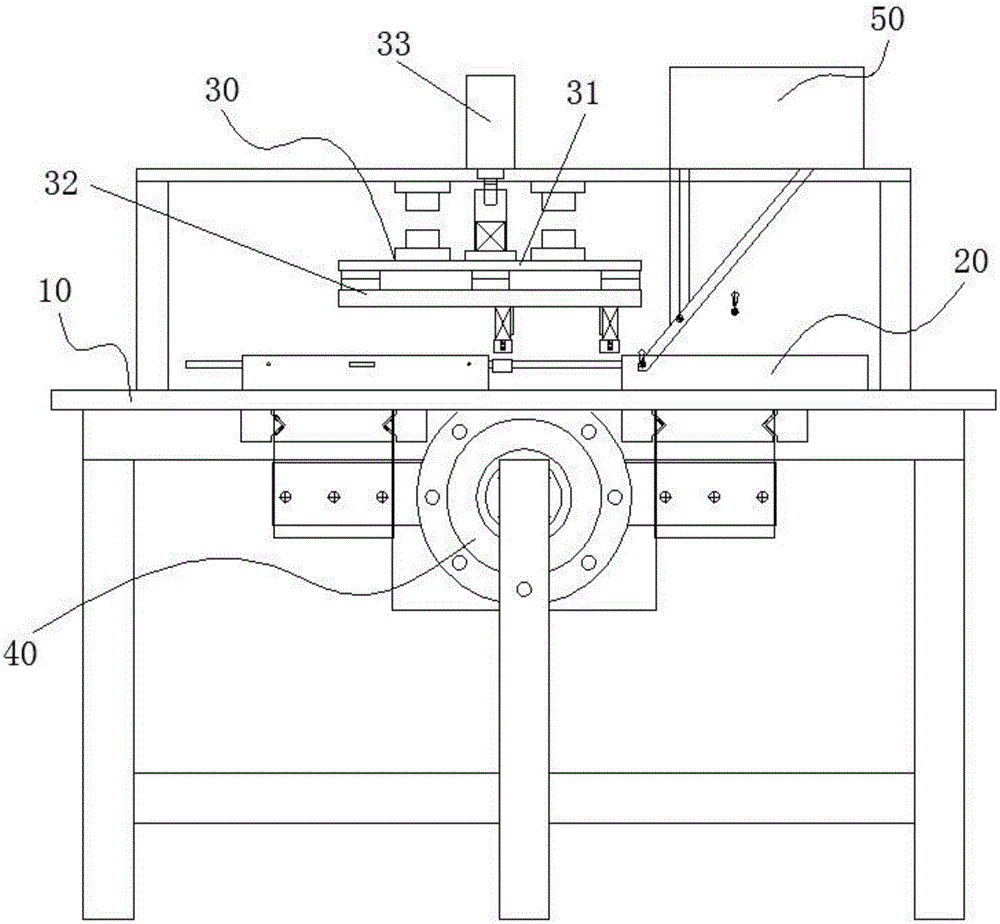

Automatic hanger machining device

ActiveCN105964840ASatisfy productionIncrease the level of automationWire articlesWork in processEngineering

The invention discloses an automatic hanger machining device. The automatic hanger machining device comprises a bending forming machine, a conveying mechanism, an automatic picking machine and a stapling machine. The conveying mechanism is arranged between the bending forming machine and the automatic picking machine. The stapling machine is arranged on one side of the automatic picking machine. The bending forming machine is used for bending raw materials to form semi-finished hangers. The conveying mechanism is used for conveying the semi-finished hangers to the position of the automatic picking machine from the bending forming machine. The automatic picking machine is used for picking up the semi-finished hangers on the conveying mechanism and placing the semi-finished hangers on the stapling machine to be stapled. According to the automatic hanger machining device, due to the fact that the bending forming machine, the conveying mechanism, the automatic picking machine and the stapling machine are arranged, integrated hanger producing and machining are achieved, complex hanger production can be achieved, the automation level of the automatic hanger machining device is high, and the production efficiency is obviously improved.

Owner:台山市万力达金属制品科技有限公司

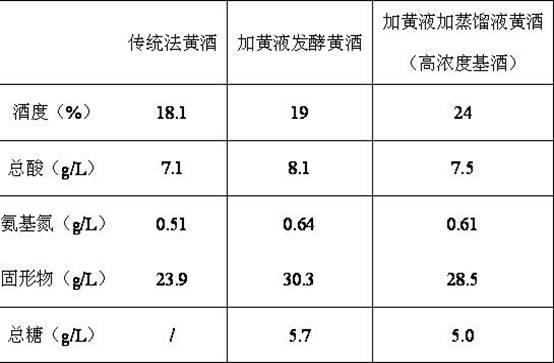

Brewing method of high-concentration yellow rice wine

ActiveCN102154074ASatisfy productionSave spaceAlcoholic beverage preparationBiotechnologyDistillation

The invention discloses a brewing method of a high-concentration yellow rice wine, comprising the brewing processes of: immersing raw materials (rice), steaming, pre-fermenting, post-fermenting, squeezing, distilling 20-50% (Vol) of squeezed wine, separating bulk wine into distillate and yellow liquid having high alcoholic strength through distillation, adding the yellow liquid in the pre-fermenting process, carrying out wine decocting and sterilizing treatment on the 20-50% (Vol) of squeezed wine, then uniformly mixing with the distillate, and aging together to finally form a high-concentration yellow rice wine (bulk wine) base wine. The brewing method of the stable-quality high-concentration yellow rice wine has the advantages of labor and material resource saving, brewing space saving, production efficiency improvement, convenience for aging and meets the requirement of large-scale industrial production.

Owner:JIANGSU ZHANGJIAGANG BREWING

High-elastic environment-friendly rubber sheet for teaching head and manufacturing process thereof

The invention discloses a high-elastic environment-friendly rubber sheet for a teaching head and a manufacturing process thereof, which relates to a product in the plastic field. The product comprises 80-100 parts of imported polyvinyl chloride (PVC) paste resin raw material, 100-150 parts of dioctyl phthalate, 2-4 parts of composite liquid stabilizer and 0.1-1 part of environment-friendly toner, and is molded by adopting a slush molding process. The manufacturing process comprises the following steps: grinding the toner; stirring; filtering; carrying out vacuum defoamation; and carrying out slush molding treatment. The slush molding treatment mainly comprises the following steps: putting a mold into a rubber heating furnace at 260-280 DEG C to be heated for 5-10s; then, taking out the mold, filling slurry, and standing for 10-15s; pouring the non-gelatinous slurry into a recovery tank; putting the mold into the rubber heating furnace again to be heated for 30-40s; taking out the mold, putting the mold into cooling water, and standing for 20-30s; and after the mold is cooled, taking the mold out of the water, and taking out burrs. The product integrates the characteristics of environment protection, flexibility, high elasticity and is convenient to use, uses more elastic materials, has stronger self-regulating property and wide application range, and can be used by a user conveniently.

Owner:HENAN REBECCA HAIR PRODS TNC +2

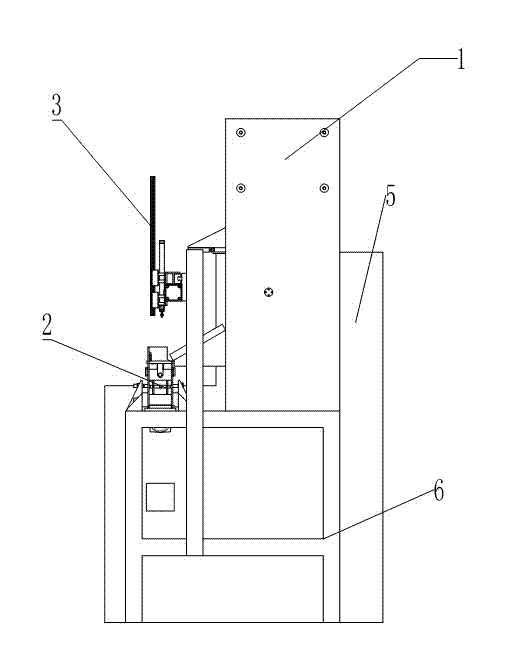

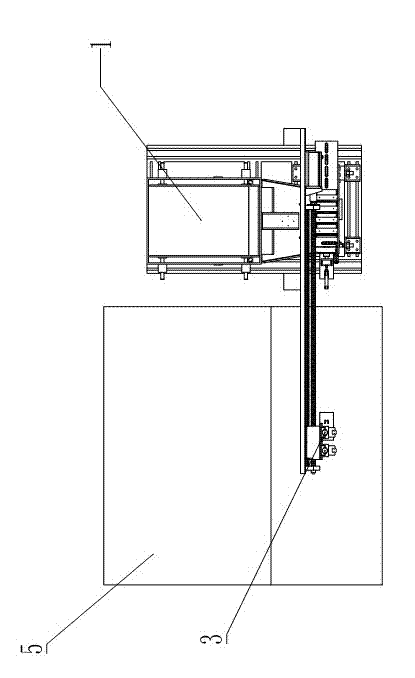

Forced rolling mill feed device

ActiveCN103252362AOperational securityEasy to operateMetal rolling arrangementsWorking environmentUltimate tensile strength

The invention discloses and provides a forced rolling mill feed device. According to the forced rolling mill feed device, labor intensity of workers can be reduced, and mechanical feeding can be achieved. The forced feed device comprises a supporting machine base, a translation trolley and a lifting frame. A suspension frame is arranged on the supporting machine base, the translation trolley is arranged on the suspension frame of the supporting machine base, the lifting frame is connected on the translation trolley through a lifting device, and the lifting frame is located below the suspension frame of the supporting machine base. The forced rolling mill feed device is adopted to feed rolling pieces, the labor intensity can be effectively reduced, energy consumption is reduced, production efficiency is improved, and the production rhythm is accelerated. The forced rolling mill feed device can also be applied to the field of rolling and producing rare and refractory metal pieces, volatilization of the rare and refractory metal pieces can be effectively reduced, pollution to the environment is reduced, and working environment of the workers is improved.

Owner:CHINA ERZHONG GRP DEYANG HEAVY IND

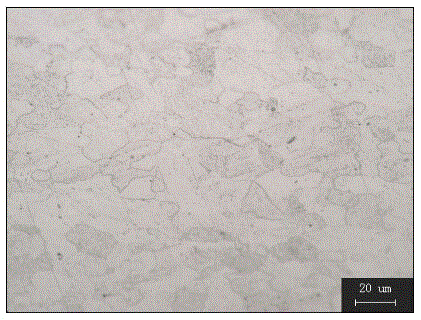

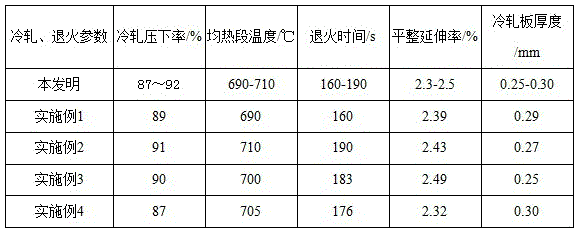

Cold-rolled tinning base plate for chemical bucket and manufacturing method thereof

The invention relates to a cold-rolled tinning base plate for a chemical bucket and a manufacturing method thereof. The technical problems that an existing cold-rolled tinning base plate for the chemical bucket is high in strength, low in percentage elongation after fracture and prone to cracking in the manufacture-forming process of the chemical bucket are solved. The cold-rolled tinning base plate for the chemical bucket provided by the invention comprises, by weight, 0.002%-0.004% of C, 0-0.03% of Si, 0.31%-0.40% of Mn, 0-0.015% of P, 0-0.015% of S, 0.04%-0.06% of Alt, 0.065%-0.075% of Ti, and the balance Fe and inevitable impurities. The cold-rolled tinning base plate is mainly used for the packaging fields of chemical tanks, aerial fog tanks and the like.

Owner:SHANGHAI MEISHAN IRON & STEEL CO LTD

Preparation method of copper-containing metal composite oxide photocatalytic material

ActiveCN104445356ADoes not involve emissionsReduce usageCopper oxides/halidesElectric arc furnaceOxygen

The invention discloses a preparation method of a copper-containing metal composite oxide photocatalytic material. The preparation method comprises the following steps: putting copper and zirconium into a vacuum electric arc furnace, performing vacuum pumping, then charging argon, starting smelting, keeping for 60-90 seconds after copper and zirconium are smelted, cooling to obtain an alloy molten ingot, turning over, repeating for 4 to 6 times, putting the alloy molten ingot into rapid melt quenching and melt spinning equipment, performing vacuum pumping, then charging argon, performing smelting by adopting a magnetic induction heating mode to form a melt after completely melting, opening an air pressure valve, spraying the melt on the surface of a copper roller which rapidly rotates to obtain a continuous amorphous alloy ribbon, and putting the amorphous alloy ribbon into a ceramic cup, wherein the ceramic cup comprises a ceramic base, the ceramic base is connected with a ceramic cup cover, the ceramic cup cover is provided with an air inlet hole, an observation view window and a graphite electrode, and the ceramic base is in sliding connection with an ignition graphite electrode; and connecting one end of the amorphous alloy ribbon with the graphite electrode, charging oxygen, then pushing the ignition graphite electrode to the amorphous alloy ribbon, and enabling the ignition graphite electrode to be in contact with the amorphous alloy ribbon to generate electric sparks for igniting an alloy strip material.

Owner:SOUTHEAST UNIV

High-manganese steel continuous casting method

The invention provides a high manganese-steel continuous casting method. The high manganese steel comprises the following components by weight percentage: 0.21% to 0.25% of C, 4.5% to 5.5% of Mn, 0.2%to 0.3% of Si, 0.2-0.3% of Si, less than 0.008% of P, less than 0.002% of S, 0.015% to 0.04% of Al, and balance of Fe and inevitable impurity elements. The continuous casting method is characterizedin that the second cooling section is divided into two modes for water supply, the first mode adopts a weak cold water line, the specific water quantity is 0.15-0.25 L / kg, and the second mode is thatthe nozzles of the last two sections of a casting machine are closed. The method solves the production of high manganese steel which has a large total alloy amount and strong crack sensitivity duringthe continuous casting of large billet in the conventional process.

Owner:ANGANG STEEL CO LTD

Automatic clamping machine for civilian explosion medium package explosive cartridge

The invention relates to a civilian explosive package scroll automatic clip feeder, which is composed of a hopper, a belt conveying mechanism, two sets of power mechanisms, two sets of explosive clip mechanisms, an explosive dropping shielding plate, an optical fiber sensor, a guide rod, a connecting plate, a sideboard and a rack; the hopper and the explosive dropping shielding plate are arranged on the sideboard of a belt conveyor of the belt conveying mechanism; the optical sensor is arranged on the explosive dropping shielding plate; the slide blocks of the two sets of explosive clip mechanisms are respectively sleeved on two guide rods; both ends of each guide rod are fixed on the connecting plate connected with the sideboard; the guide rods, the sideboard and the connecting plate are arranged on the rack as a whole; and the slide blocks of each set of explosive clip mechanism are connected with the synchronous belt of one set of power mechanism. The invention has fast conveying speed, with the number of the clip-fed explosive scrolls reaching 540 to 600 per minute; each explosive clip is composed of a respective conveying system and is independent to others, free from mutual impact; the explosive clips can be continuously operated and never stop; and the entire device has smart and compact structure, as well as good stability.

Owner:WUHAN RENTIAN PACKAGING TECH

Preparation method of immobilized microbial formaldehyde degradation preparation

InactiveCN106350502AGood removal effectSatisfy productionGas treatmentDispersed particle separationHydrogenSulfite salt

The invention discloses a preparation method of an immobilized microbial formaldehyde degradation preparation, belonging to the technical field of formaldehyde degradation. The preparation method comprises the following steps: mixing kitchen waste with active sludge, then mixing with a prepared culture medium, and culturing; after the culture, sequentially adding a formaldehyde solution, a sodium sulfide solution, a sodium sulfite solution and a sodium hydrogen sulfite solution, and performing aeration and acclimation culture; after the culture, picking out the vigorously growing bacteria for purification and enrichment culture to obtain bacterial liquid capable of degrading formaldehyde; and sterilizing wormcast and solidifying the bacterial liquid to obtain the immobilized microbial formaldehyde degradation preparation. In the invention, the bacteria after culture and acclimation are immobilized in a carrier, the obtained preparation can thoroughly decompose formaldehyde, the formaldehyde removal rate is high, and secondary environmental pollution is avoided during the purification and degradation.

Owner:吴迪

Method for producing surface compound cutter billet by horizontal electro-slag surfacing

The preparation method for cutter surface complex billet in this invention belongs to level electro-slag surfacing technique. It has been used to renewing and repairing for crank axle, roller and mould of waste and old, but the complex steel used to cutter requires large overlay welding area, clear interface, even thickness and high adhesion. In this invention, put lowcarbon steel body on workbench horizontally with surface needed overlay welding upside; form one mould cavity by three composite mould plates, a fixed mould plate and part of steel body; the three composite mould plates links workbench to form mobile integer and translate with workbench synchronously; Use highcarbon blade steel as electrode that can cascade with multiple heads; dissolve the electro-slag power into liquid and decant cavity; the electrode fuses into metal liquid and is overlay welding evenly and continually on the steel body by adjust device; translate the workbench and expand the overlay welding layer to prepare two or multiple layers cutter billet with surface composite, then process to complex strip steel, flat material and plate material.

Owner:SHANGHAI JISI COMPOUND STEEL TECH DEV

Full-automatic excitation rotor winding machine

ActiveCN113315328ASatisfy productionHigh precision requirementsApplying solid insulationWinding machineProcess engineering

The invention discloses a full-automatic excitation rotor winding machine which comprises a tensioning unit, a winding unit and a mold unit which are arranged in a linear longitudinal sequence. The die unit comprises a die set, a cutting mechanism, a shaping mechanism, a paper feeding mechanism and a wire hook mechanism, wherein the cutting mechanism, the shaping mechanism, the paper feeding mechanism and the wire hook mechanism are arranged on the periphery of the die set in a circumferential array mode. According to the invention, automatic forming, feeding, winding and reversing of slot paper are achieved through cooperation of the tensioning unit, the winding unit, the mold unit, the PLC and other devices, so that manual winding is replaced, the production quality is guaranteed, the production working time is shortened, and the production efficiency is improved. The winding machine is compact in structure, cost-saving, high in working efficiency, low in production cost, good in product quality, high in yield and high in equipment utilization rate, and the labor cost and the labor intensity are reduced.

Owner:厦门华工睿智智能设备有限公司

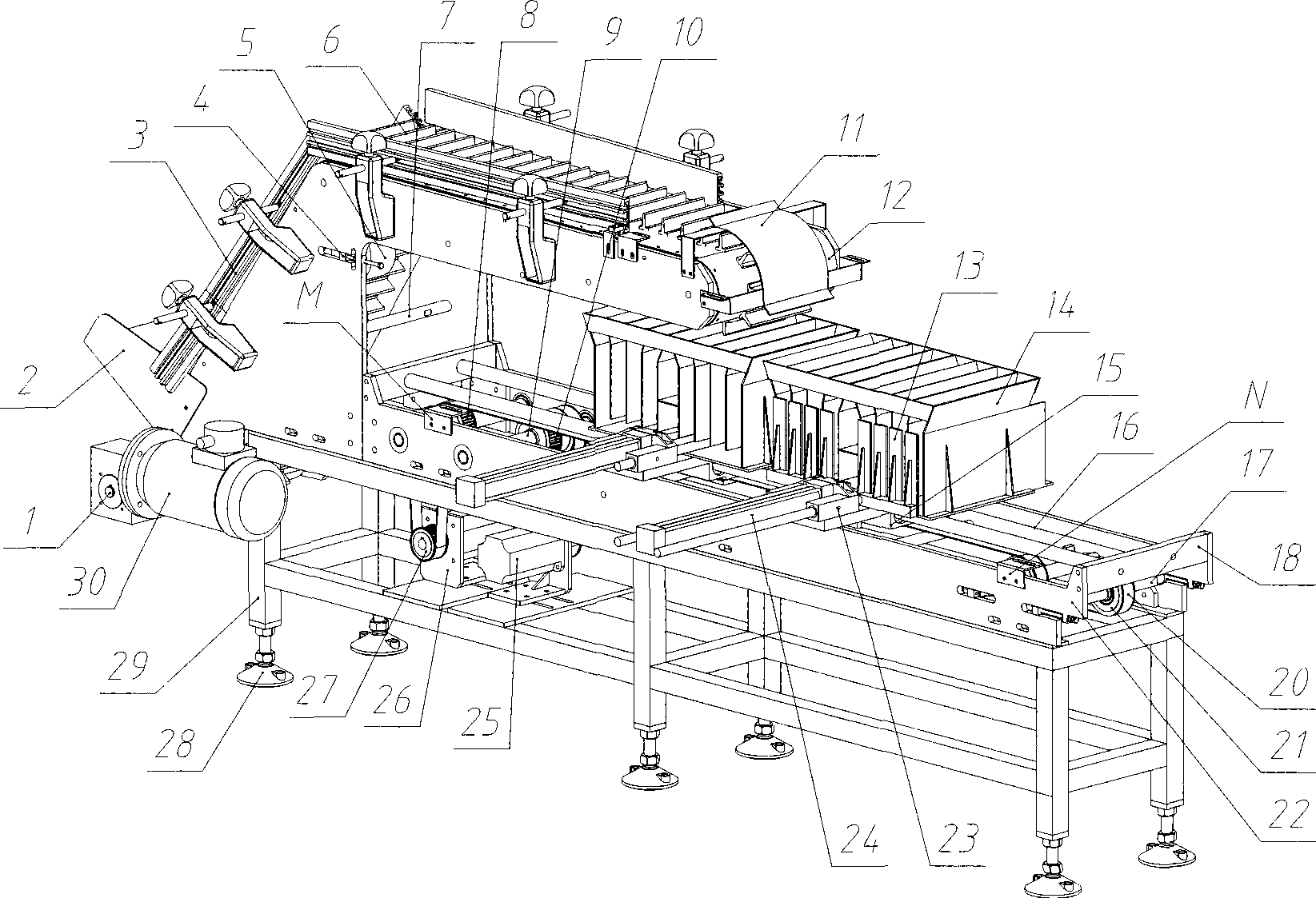

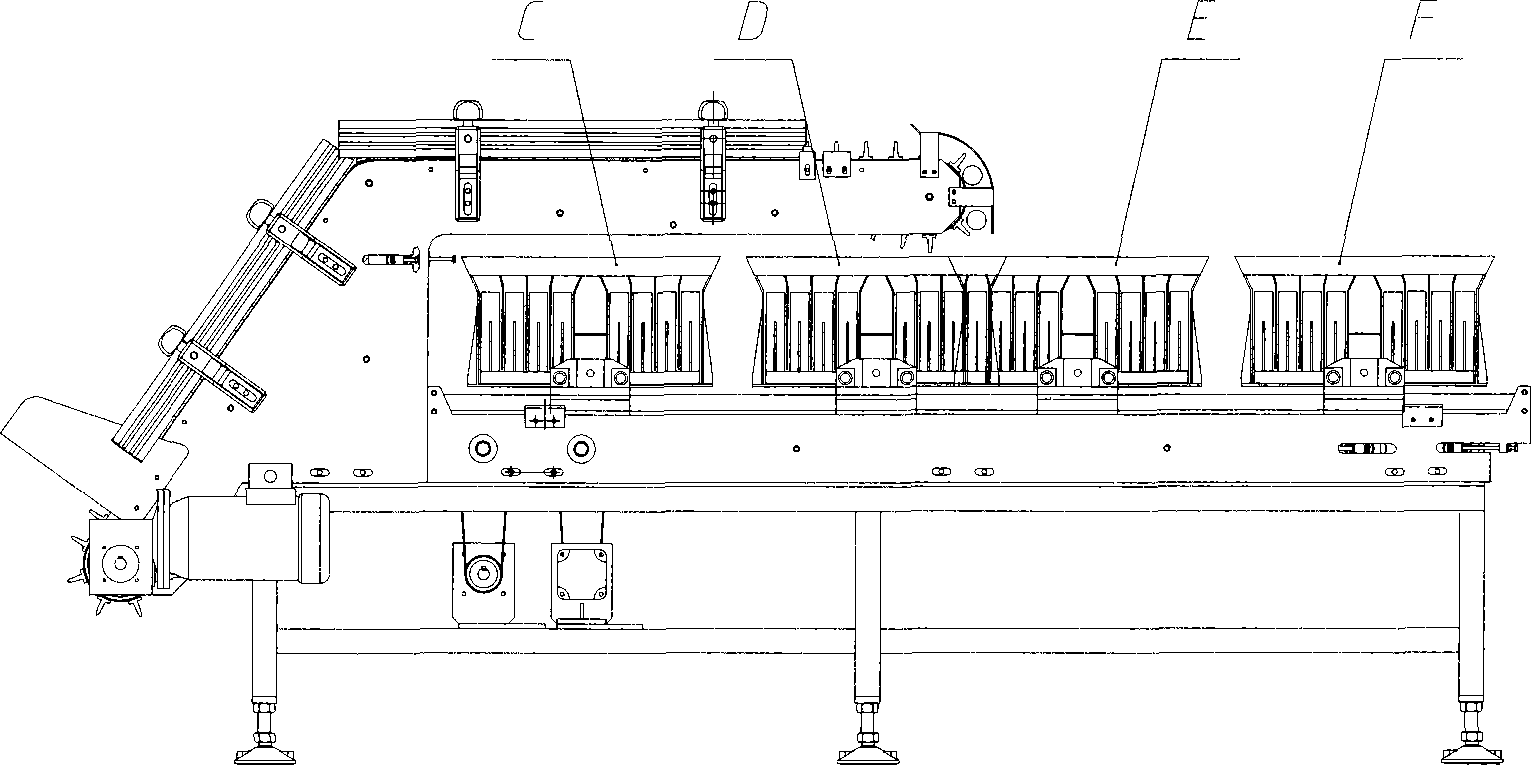

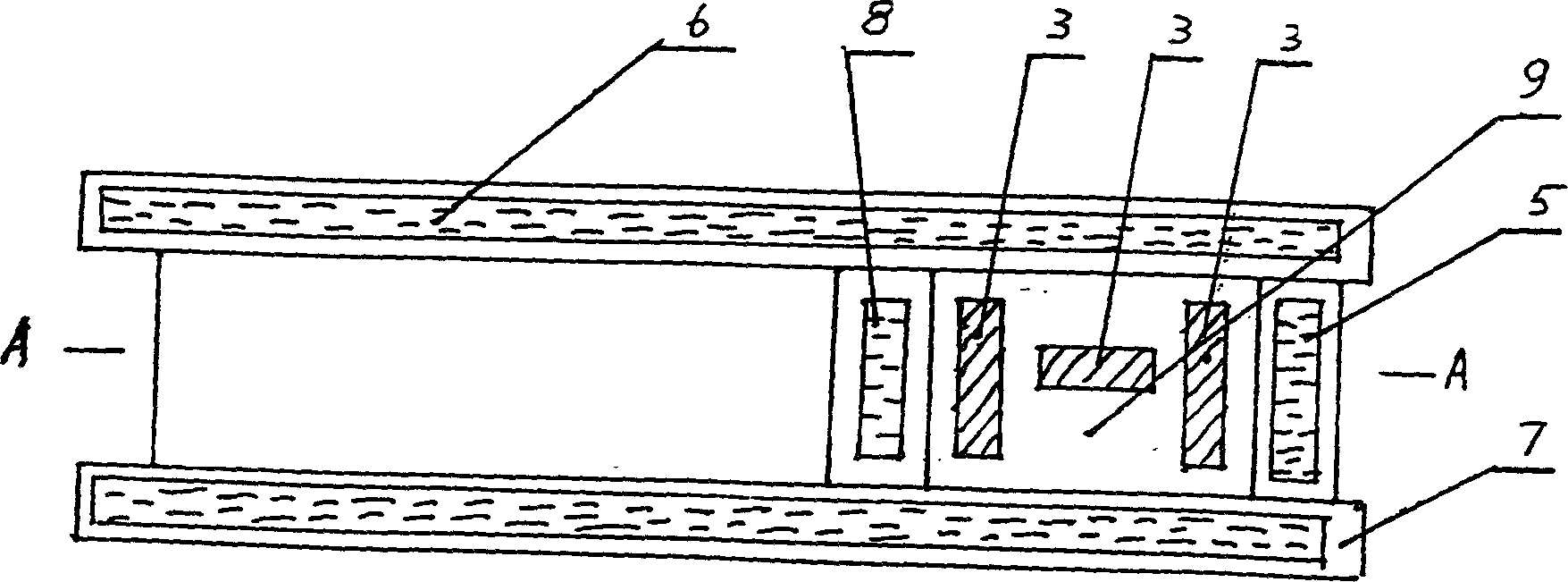

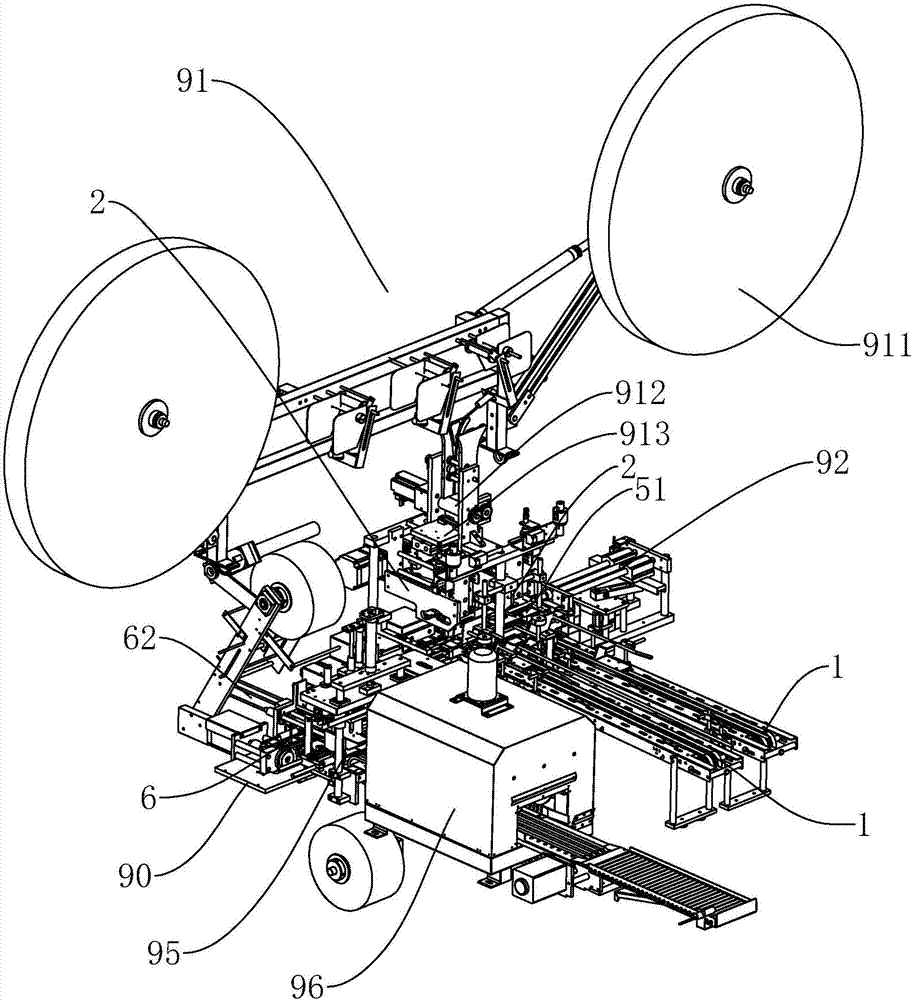

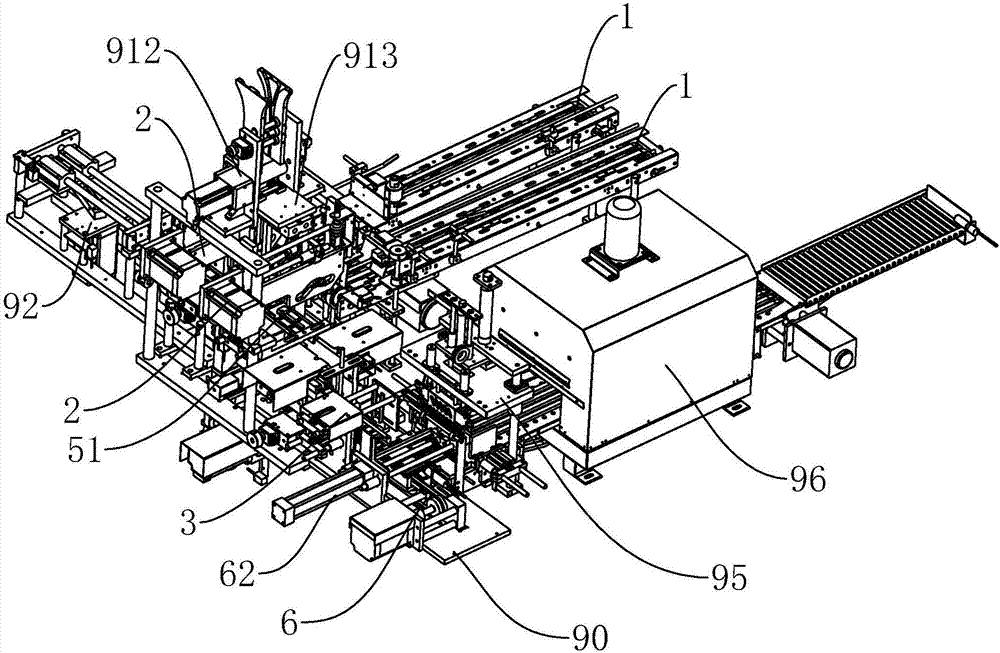

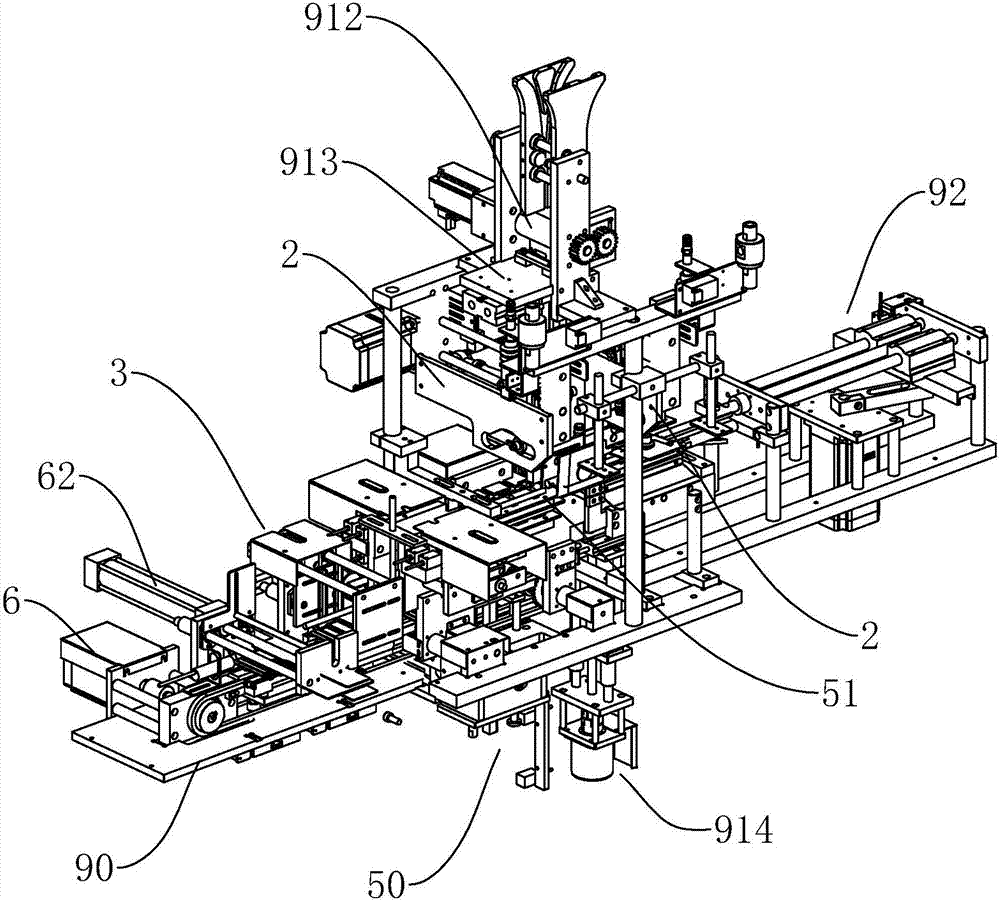

Storage battery electrode plate packaging machine

PendingCN107546406ASatisfy productionIncreased flexibility of useFinal product manufactureSecondary cells manufactureEngineeringBattery cell

The invention discloses a storage battery electrode plate packaging machine. The storage battery electrode plate packaging machine comprises a rack, a plate laminating mechanism, a plate conveying mechanism, a plate pushing mechanism and an output channel apparatus; the plate conveying mechanism can convey the electrode plate to the plate laminating mechanism; then the electrode plate is pushed bythe plate pushing mechanism to complete procedures of paper packaging and plate laminating; the laminated plate group after plate laminating is completed is sent out through the output channel apparatus; a laminated plate channel distance adjustment apparatus is arranged on a laminated plate channel of the plate laminating mechanism, so that the width of the laminated plate channel can be adjusted according to the specification of the electrode plate; and an electrode plate conveying apparatus of the plate conveying mechanism has a height adjustment apparatus, so that the height of the outletof the conveying channel can be adjusted according to the specification of the electrode plate. By adoption of the storage battery electrode plate packaging machine, conveying and plate laminating ofelectrode plates of different specifications can be satisfied, production of batteries of different specifications can be satisfied, and high use flexibility and wider application range can be realized.

Owner:ZHONGSHAN SHENGYI ELECTRIC MACHINERY CO LTD

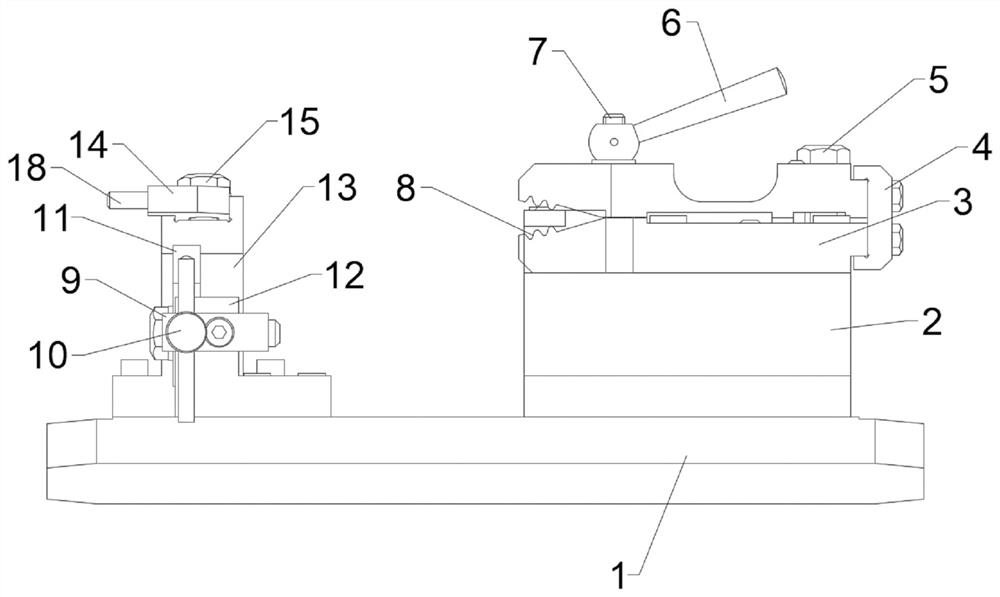

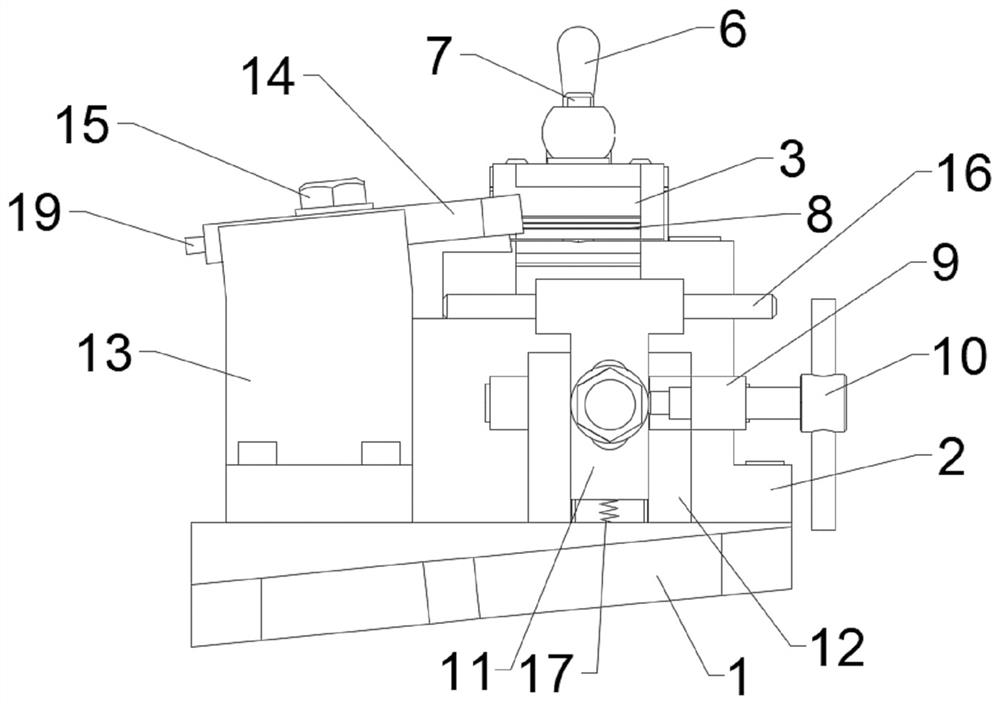

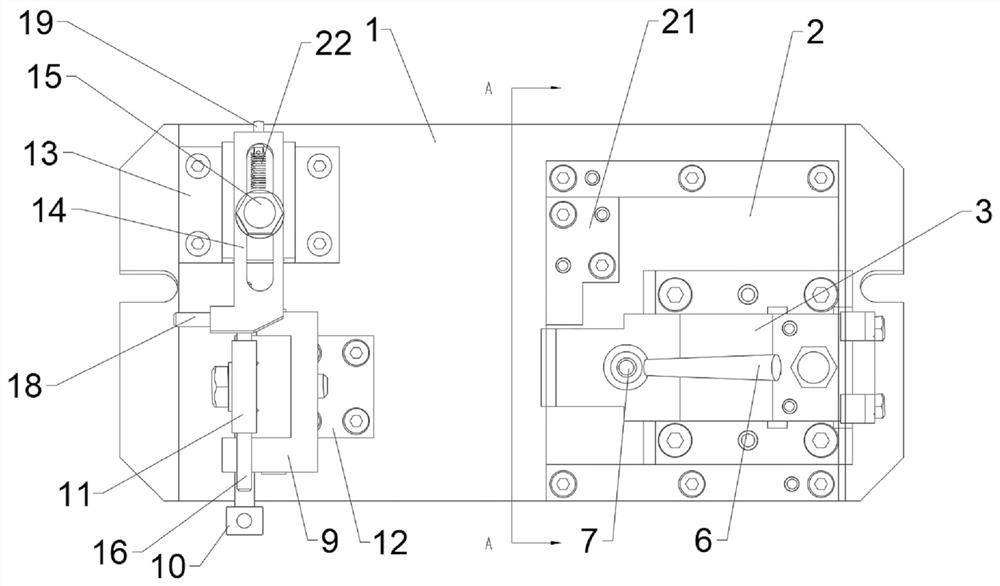

Fixing tool for turbine blade machining

The invention relates to a fixing tool for turbine blade machining, and belongs to the technical field of aero-engine manufacturing. The fixing tool comprises a bottom plate, a chuck, a transverse self-adaptive adjustment supporting assembly and a longitudinal self-adaptive adjustment supporting assembly; the chuck is used for clamping tenon teeth and is fixedly connected to one end of the bottomplate; the transverse self-adaptive adjustment supporting assembly is used for supporting the blade back of a blade, the transverse self-adaptive adjustment supporting assembly is fixedly connected toone side of the other end of the bottom plate, and the output end of the transverse self-adaptive adjustment supporting assembly abuts against the blade back; and the longitudinal self-adaptive adjustment supporting assembly is used for supporting the shroud of the blade, the longitudinal self-adaptive adjustment supporting assembly is fixedly connected to the other side of the other end of the bottom plate, and the output end of the longitudinal self-adaptive adjustment supporting assembly makes contact with the shroud. The fixing tool can well fix the turbine blade, the reliability of machining quality is improved, operation is convenient, and the labor intensity of an operator can be relieved.

Owner:GUIYANG AVIC POWER PRECISION CASTING

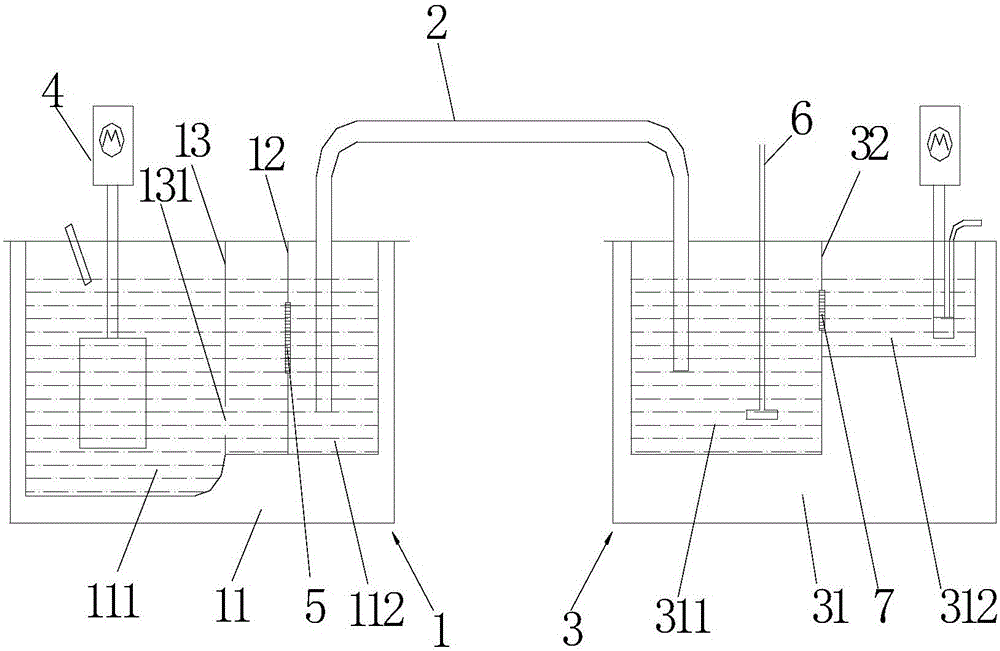

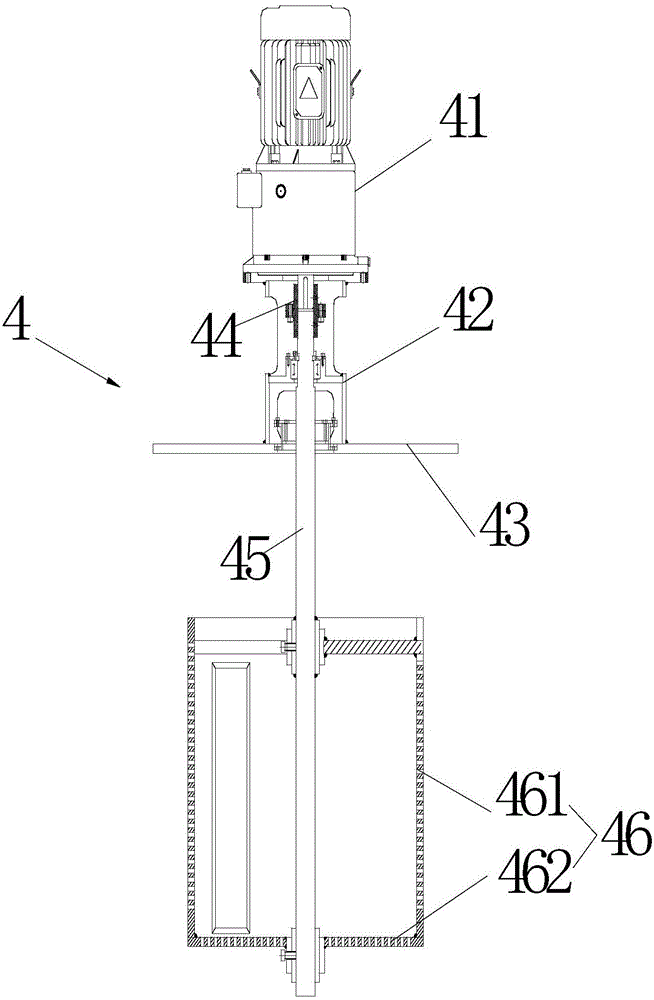

Magnesium alloy melt continuous liquid supply purifying device and technology

The invention discloses a magnesium alloy melt continuous liquid supply purifying device and technology. The magnesium alloy melt continuous liquid supply purifying device comprises a melting furnace, a heat insulation standing furnace and a melt transferring device. An inner cavity of a melting furnace body is divided into a melt melting cavity and a melt transferring cavity. A centrifugal filter is arranged in the melt melting cavity. An inner cavity of a heat insulation standing furnace body is divided into a separation cavity and a heat insulation standing cavity. An Ar gas input device is arranged in the separation cavity. A first filter is arranged in a first connecting port. A second filter is arranged in a second connecting port. According to the magnesium alloy melt continuous liquid supply purifying device and technology, melting treatment and purifying treatment are conducted in the wholly-sealed furnace, a solvent-free method is adopted, a corrosion source is prevented from entering melt, inclusions or films or particles and harmful gas in the magnesium alloy melt can be effectively removed, and purity of the magnesium alloy melt is improved. The magnesium alloy melt continuous liquid supply purifying device and technology have the beneficial effects of being short in process control and simple in operation; continuous liquid supply of the heat insulation standing furnace during casting and cast rolling is ensured; the melt purifying quality of casting and cast rolling is improved; the production efficiency is improved; and the production cost is reduced.

Owner:湖南金镁科新材料有限公司

High-aluminum egg-shell reinforced celadon and preparation method thereof

The invention discloses a high-aluminum egg-shell reinforced celadon and a preparation method thereof. The high-aluminum egg-shell reinforced celadon is prepared from a high-aluminum egg-shell reinforced celadon blank and high-aluminum egg-shell reinforced celadon green glaze. The high-aluminum egg-shell reinforced celadon blank is prepared from high-aluminum egg-shell reinforced celadon slurry. The high-aluminum egg-shell reinforced celadon slurry comprises, by weight, 25-35% of Baoxi porcelain clay, 13-23% of Zhuxiang porcelain clay, 25-35% of Yuandi porcelain clay, 20-35% of alpha-Al2O3 micro-powder, 2-4% of zirconia micro-powder and 0.5-2% of PVA. The celadon green glaze comprises, by weight, 30-45% of Huangshixuan glaze clay, 20-30% of Xiyuan glaze clay, 15-25% of limestone, 4-8% of quartz and 10-20% of potassium feldspar. Through use of a proper amount of alpha-Al2O3 micro-powder and zirconia micro-powder as toughening materials in blank materials and use of PVA as a plastic adjusting agent, blank strength is improved and the clay has a certain plasticity and daily use ceramic production requirements are satisfied.

Owner:LISHUI UNIV +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com