Forced rolling mill feed device

A feeding device and rolling mill technology, applied in metal rolling, metal rolling, metal processing equipment and other directions, can solve the problems of late start of rare refractory metal sheet production, inability to meet the requirements of rolling mill bite, and high labor intensity of workers. , to achieve the effect of reducing labor intensity, simple structure and high degree of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

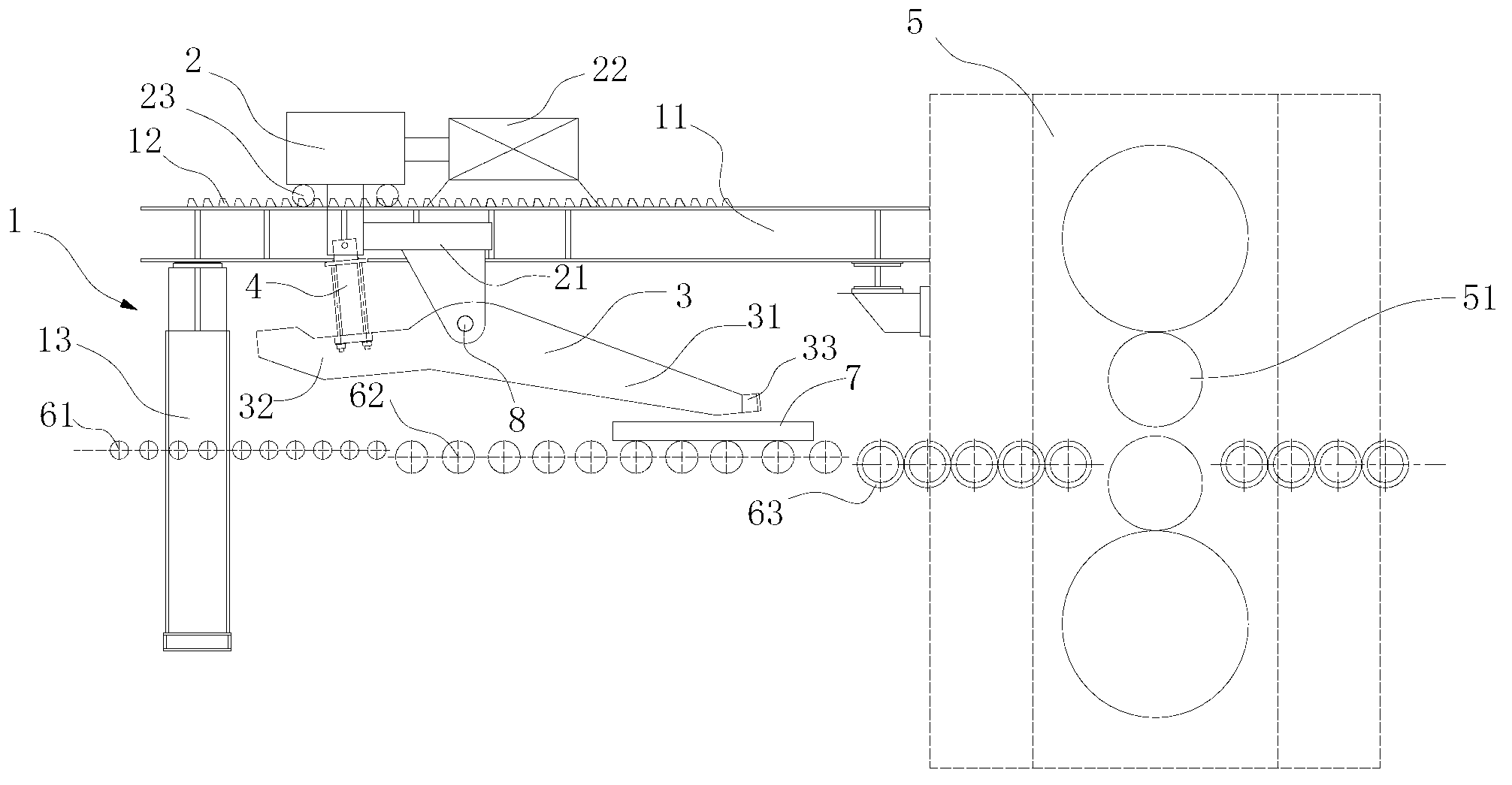

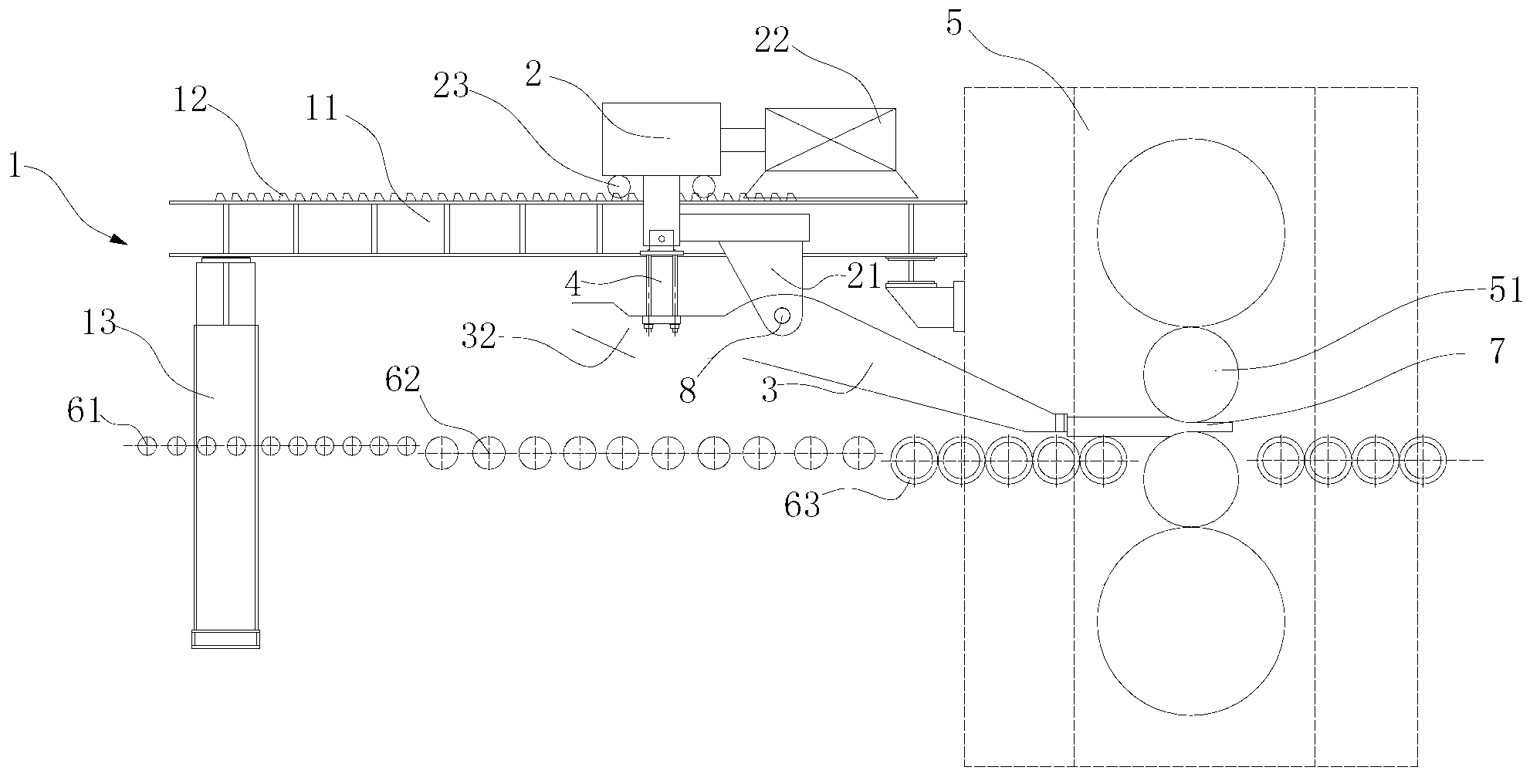

[0019] Such as figure 1 As shown, the rolling mill forced feeding device provided by the present invention includes a support stand 1, a translation trolley 2, and a lifting frame 3; the support stand 1 is provided with a suspension 11; the translation trolley 2 is arranged on the suspension 11; The elevating frame 3 is connected to the translation trolley 2 through the elevating device 4, and the elevating frame 3 is located below the suspension 11.

[0020] Such as figure 1 As shown, the lifting frame 3 of the forced feeding device of the rolling mill is in a raised state when the pusher section 31 is not working, and the lower end of the pusher section 31 forms a running channel for the rolled piece 7 . In the working state, the rolling piece 7 is transported to the corresponding position at the lower end of the lifting frame 3 by the transport dev...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com